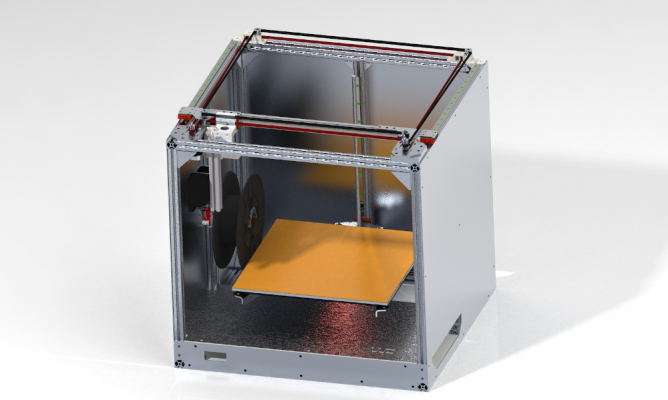

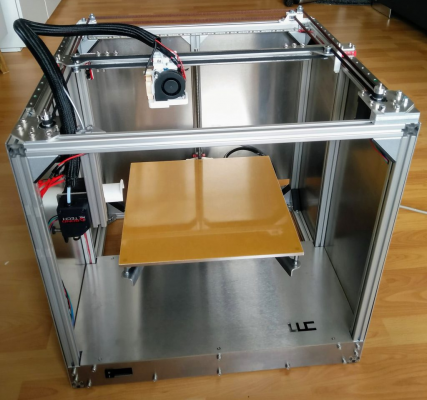

Linear Rail - CoreXY 326x326x320

Posted by seeul8er

|

Linear Rail - CoreXY 326x326x320 March 30, 2020 08:09AM |

Registered: 4 years ago Posts: 5 |

I set up a little project page. I'll update it from time to time when I got time and new stuff happened.

I always wanted a 3D printer of my own. Since no commercially available machine fulfilled all of my requirements I went designing my own.

Goals/Requirements

The requirements listed above manly originate from the fact that I need the printer to be big enough to produce highly integrated (high quality) parts for my drone(s). At the same time it needs to fit inside something like a kitchen cabinet since this is the only place where I can store the printer for now.

The design is heavily inspired by the HyperCube, RailCore II 300ZL and E3D Motion System (Toolchanger).

It is still not perfect, but it does produce great looking parts. The Z-axis wobble is fixed for the most part.

I am also developing a custom HMI for the printer. Sort of a DIY alternative for the PanelDue. It will be optimized for 3.5" displays and can be connected via WiFi or the PanelDue port. If you source the parts yourselfe it costs around 25€-30€.

I set up a forum post on the official Duet forum.

Edited 1 time(s). Last edit at 03/30/2020 08:13AM by seeul8er.

I always wanted a 3D printer of my own. Since no commercially available machine fulfilled all of my requirements I went designing my own.

Goals/Requirements

- Max. package: 550x490x500 mm

- Min. print volume: 300x300x300 mm

- Budged: 1500€ – 2000€

- Fast print speeds: >100 mm/s

- High quality prints: Equal of better than other printers in that price range (Ultimaker 3, RailCore II, Zortrax M200, etc.)

- Capable of printing engineering-grade materials (ABS, Nylon, etc.)

- Option to upgrade to multi-material printhead

- Easy to manufacture: No access to NC-Machines

The requirements listed above manly originate from the fact that I need the printer to be big enough to produce highly integrated (high quality) parts for my drone(s). At the same time it needs to fit inside something like a kitchen cabinet since this is the only place where I can store the printer for now.

The design is heavily inspired by the HyperCube, RailCore II 300ZL and E3D Motion System (Toolchanger).

It is still not perfect, but it does produce great looking parts. The Z-axis wobble is fixed for the most part.

I am also developing a custom HMI for the printer. Sort of a DIY alternative for the PanelDue. It will be optimized for 3.5" displays and can be connected via WiFi or the PanelDue port. If you source the parts yourselfe it costs around 25€-30€.

I set up a forum post on the official Duet forum.

Edited 1 time(s). Last edit at 03/30/2020 08:13AM by seeul8er.

|

Re: Linear Rail - CoreXY 326x326x320 April 14, 2020 07:58AM |

Registered: 5 years ago Posts: 10 |

Very nice build!

My first reaction was that your z-rail was far to small. And I can see that you have had issues with it too.

One possible reason for x-wobble of the bed, that you do not mention on your project page, is that the whole z-rail and the extrusion it is mounted to can twist. Those 2020's are very easy to twist, and so is a little 12mm rail. It might help if you use a 2040 or 2060 extrusion to mount the rail, they are a lot stiffer in torsion due to the box structure in the extrusion.

I have used Chinese MGW12s (RDBB brand sold by CNA) with great success in two smaller builds, just 220x220 beds and 300mm long rails. They are pretty expensive and not that common, but the simplicity and convenience when using them is very nice.

My first reaction was that your z-rail was far to small. And I can see that you have had issues with it too.

One possible reason for x-wobble of the bed, that you do not mention on your project page, is that the whole z-rail and the extrusion it is mounted to can twist. Those 2020's are very easy to twist, and so is a little 12mm rail. It might help if you use a 2040 or 2060 extrusion to mount the rail, they are a lot stiffer in torsion due to the box structure in the extrusion.

I have used Chinese MGW12s (RDBB brand sold by CNA) with great success in two smaller builds, just 220x220 beds and 300mm long rails. They are pretty expensive and not that common, but the simplicity and convenience when using them is very nice.

|

Re: Linear Rail - CoreXY 326x326x320 April 14, 2020 12:39PM |

Registered: 4 years ago Posts: 5 |

Thanks!

You are right! Torsion could contribute a lot. Maybe I should measure the X-Wobble-Amplitude at the very bottom and in the middle of the z-axis. At the top and bottom end it should be stiffer.

The current rail is a MGN15. A lot more rigid than those 12mm ones.

I'll start improving the design again once some prints have finished. At the moment I am pleased with the print quality. Then I might test a stiffer bed mount and z-axis support.

You are right! Torsion could contribute a lot. Maybe I should measure the X-Wobble-Amplitude at the very bottom and in the middle of the z-axis. At the top and bottom end it should be stiffer.

The current rail is a MGN15. A lot more rigid than those 12mm ones.

I'll start improving the design again once some prints have finished. At the moment I am pleased with the print quality. Then I might test a stiffer bed mount and z-axis support.

|

Re: Linear Rail - CoreXY 326x326x320 April 15, 2020 06:52PM |

Registered: 5 years ago Posts: 10 |

Sorry, only registered users may post in this forum.