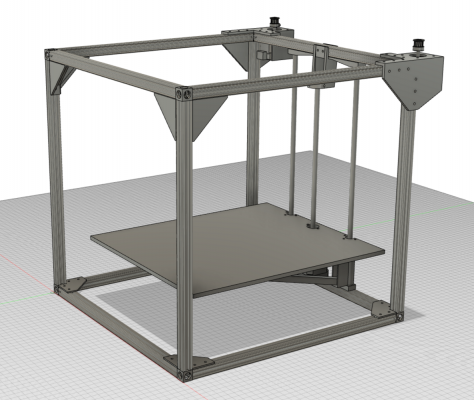

KEEVO V2.0

Posted by nuverian

|

KEEVO V2.0 August 03, 2020 11:56AM |

Registered: 5 years ago Posts: 13 |

Hello again,

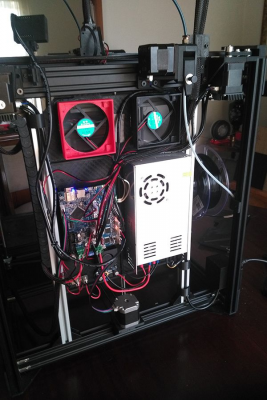

I finally was able to update the project and bring it to a state which I now consider finished (although no printer is really ever "finished" :- ) ) I am very happy with the end result and has proven to be a reliable machine.

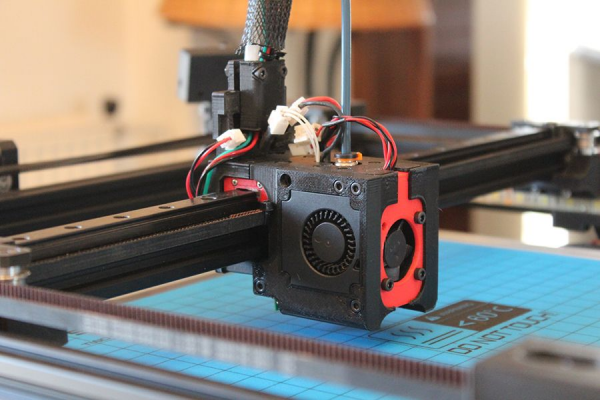

Some KEEVO printed parts:

I hope you like it. If you see any apparent improvements that can be made to the design, please let me know! The project can also be found on thingiverse: [www.thingiverse.com]

Cheers!

Edited 3 time(s). Last edit at 08/04/2020 10:22AM by nuverian.

I finally was able to update the project and bring it to a state which I now consider finished (although no printer is really ever "finished" :- ) ) I am very happy with the end result and has proven to be a reliable machine.

Some KEEVO printed parts:

I hope you like it. If you see any apparent improvements that can be made to the design, please let me know! The project can also be found on thingiverse: [www.thingiverse.com]

Cheers!

Edited 3 time(s). Last edit at 08/04/2020 10:22AM by nuverian.

|

Re: KEEVO V2.0 August 03, 2020 08:01PM |

Registered: 9 years ago Posts: 204 |

|

Re: KEEVO V2.0 August 03, 2020 08:15PM |

Registered: 11 years ago Posts: 5,780 |

|

Re: KEEVO V2.0 August 04, 2020 10:48AM |

Registered: 5 years ago Posts: 13 |

|

Re: KEEVO V2.0 August 05, 2020 06:39AM |

Registered: 7 years ago Posts: 143 |

Hi nuverian, it seams a very nice machine. My prototipe is simlar to yours and you solved some issues I have in a good way.

I've just a question: until yesterday there was some picture of the XY motors mount aligned on Y axis like your older Tribotron. In the current project you aded an idler and motors are been shifted. Is there a technical reason for that.

Luca

CoreXY custom (LF Mark1) 395x360x350 - Mega (clone per ora..) + RAMPS1.4 + 4xA4988 + 4 Nema17 17HS4401 - HotEnd V6 clone con ugello da 0.4mm - RepRapDiscount - Display LCD 2004 Smart Controller - Firmware MK4duo 4.2.9 - Repetier-Host 2.1.6

I've just a question: until yesterday there was some picture of the XY motors mount aligned on Y axis like your older Tribotron. In the current project you aded an idler and motors are been shifted. Is there a technical reason for that.

Luca

CoreXY custom (LF Mark1) 395x360x350 - Mega (clone per ora..) + RAMPS1.4 + 4xA4988 + 4 Nema17 17HS4401 - HotEnd V6 clone con ugello da 0.4mm - RepRapDiscount - Display LCD 2004 Smart Controller - Firmware MK4duo 4.2.9 - Repetier-Host 2.1.6

|

Re: KEEVO V2.0 August 05, 2020 11:40AM |

Registered: 5 years ago Posts: 13 |

Quote

truck64

Hi nuverian, it seams a very nice machine. My prototipe is simlar to yours and you solved some issues I have in a good way.

I've just a question: until yesterday there was some picture of the XY motors mount aligned on Y axis like your older Tribotron. In the current project you aded an idler and motors are been shifted. Is there a technical reason for that.

Hey, Thanks. I am glad you like it and it helped in your design

I accidentally uploaded the old version gif in my initial post (where the motors are mounted on the back), this is why I editing the post to re-upload the correct gif (which is the one shown now that has the motors shifted and placed in the backside inset).

The main reason for the new motor placement is so that they are placed within the back frame inset and thus not take more space on the back (sticking out). As such the whole printer has less depth (y) and can be placed closer against a wall. Thus it is a matter of making the machine a bit more compact. Additionally, the old motor brackets were ever so slightly bending over belt tension, whereas the new motor brackets do not.

Edited 2 time(s). Last edit at 08/05/2020 11:46AM by nuverian.

|

Re: KEEVO V2.0 August 05, 2020 05:03PM |

Admin Registered: 11 years ago Posts: 3,096 |

Wow, looking good. I might, in time, rebuild my CoreXY design when I have the funds and the time. It looks like you got it down. Do you have more examples of the prints it makes?

http://www.marinusdebeer.nl/

http://www.marinusdebeer.nl/

|

Re: KEEVO V2.0 August 10, 2020 03:00PM |

Registered: 5 years ago Posts: 13 |

Quote

Ohmarinus

Wow, looking good. I might, in time, rebuild my CoreXY design when I have the funds and the time. It looks like you got it down. Do you have more examples of the prints it makes?

Thanks!

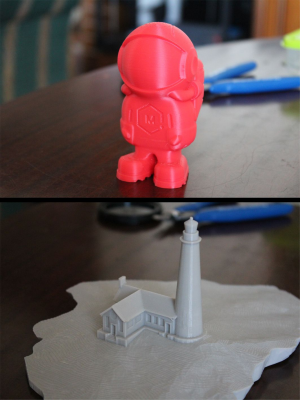

Here are some recent prints I did for 1/72 wargaming scenery (thus quite small).

These are printed rather fast, with 0.5 perimeter width (and nozzle) and 0.3 layer height. I am an impatient guy

|

Re: KEEVO V2.0 August 10, 2020 05:38PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

nuverian

Quote

Ohmarinus

Wow, looking good. I might, in time, rebuild my CoreXY design when I have the funds and the time. It looks like you got it down. Do you have more examples of the prints it makes?

Thanks!

Here are some recent prints I did for 1/72 wargaming scenery (thus quite small).

These are printed rather fast, with 0.5 perimeter width (and nozzle) and 0.3 layer height. I am an impatient guy

[attachment 116389 BattleTerrain.JPG]

Wow, looking very impressive. Now that's inspiring to me to rebuild this printer... I have a wonderful frame, but the insides are just not constructed well. I think the outside size is like 390x390x390mm so it won't be a super large build volume, however, I might be able to reuse the parts from my MendelMax to fit inside. Two linear slides for the Y-movement and two rods for the X-movement. For the Z-axis I have three acme screws laying around that I could use, and some leftover linear rods to guide the Z-stage.

Is there any reason why you didn't opt for a direct drive extruder?

http://www.marinusdebeer.nl/

|

Re: KEEVO V2.0 August 11, 2020 01:53AM |

Registered: 5 years ago Posts: 13 |

Thank you, I am glad you like those! If you end up building it or a derivative I would be glad to know how it turned out

Regarding direct drive, just because of the typical weight/space reasons, plus I don't really print flexibles which I see as the only good reason to use a direct drive.

Even so, if I ever am to convert keevo to a direct drive, I would first try out using a flex3drive though for sure.

Regarding direct drive, just because of the typical weight/space reasons, plus I don't really print flexibles which I see as the only good reason to use a direct drive.

Even so, if I ever am to convert keevo to a direct drive, I would first try out using a flex3drive though for sure.

|

Re: KEEVO V2.0 August 11, 2020 05:07AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

nuverian

Thank you, I am glad you like those! If you end up building it or a derivative I would be glad to know how it turned out

Regarding direct drive, just because of the typical weight/space reasons, plus I don't really print flexibles which I see as the only good reason to use a direct drive.

Even so, if I ever am to convert keevo to a direct drive, I would first try out using a flex3drive though for sure.

Yeah, I actually see the main benefit of the flex3drive being that you can use a full-sized stepper motor instead of a pancake one and your stepper motor doesn't suffer from the heat of the hotend and bed. I'm working on another closed printer and the direct-drive system I was using got so hot it melted the plastic extruder. So now I converted it to bowden with an all-metal extruder and it works. In time I might come back to making it direct drive again, but flex3drive looks interesting as well. If I can justify the cost some day I just might!

Found back the old drawings from 2014 or so so I have some basis to work with

Here's a video of the machine working as a laser cutter:

[www.youtube.com]

A shame I never really finished it up nicely.

Edited 1 time(s). Last edit at 08/11/2020 05:11AM by Ohmarinus.

http://www.marinusdebeer.nl/

Sorry, only registered users may post in this forum.