Core XY build - feedback appreciated

Posted by fisher

|

Core XY build - feedback appreciated January 23, 2020 09:59AM |

Registered: 9 years ago Posts: 14 |

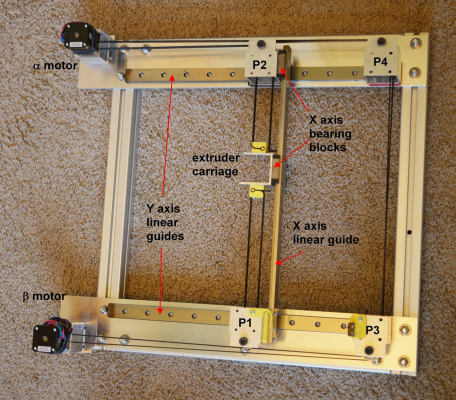

For the last couple of months i've been designing a Core XY 'dream machine' based roughly on the E3D tool changer. I'm now at the point of ordering alu plates to be waterjet cut. The idea is to create a super stable machine that can be easily modified in the future. to begin with it will just be running a single extruder but i think that will change in the near future.

Like the E3d machine all the xy movemnts are bolted to a single alu sheet with MGN rails, the x rail is genuine hiwin but the two y rails are knockoffs. im using 10mm gt2 belts to drive the motion, all idlers are mounted on shoulder bolts screwed directly into the alu sheet.

The Z axis is made up of components i managed to 'salvage' from work (I work as a design engineer) so there are 2 13mm THK rails mounted on a 4040 extrusion, these are being driven by a IGUS integrated leadscrew and stepper.

I would apriciate constructive feedback on the design, its taken a fair few itterations to get to this point.

If you would like the solidworks files i have uploaded them on openbuilds [openbuilds.com]

Cheers!

Like the E3d machine all the xy movemnts are bolted to a single alu sheet with MGN rails, the x rail is genuine hiwin but the two y rails are knockoffs. im using 10mm gt2 belts to drive the motion, all idlers are mounted on shoulder bolts screwed directly into the alu sheet.

The Z axis is made up of components i managed to 'salvage' from work (I work as a design engineer) so there are 2 13mm THK rails mounted on a 4040 extrusion, these are being driven by a IGUS integrated leadscrew and stepper.

I would apriciate constructive feedback on the design, its taken a fair few itterations to get to this point.

If you would like the solidworks files i have uploaded them on openbuilds [openbuilds.com]

Cheers!

Attachments:

open | download - Annotation 2020-01-23 142737.png (111.9 KB)

open | download - Annotation 2020-01-23 142850.png (258.8 KB)

open | download - Annotation 2020-01-23 142951.png (161.1 KB)

open | download - Annotation 2020-01-09 162730.png (93.6 KB)

open | download - Annotation 2020-01-09 162916.png (70 KB)

open | download - Annotation 2020-01-09 162942.png (61.9 KB)

open | download - tapping locations.pdf (102.1 KB)

open | download - Annotation 2020-01-23 142737.png (111.9 KB)

open | download - Annotation 2020-01-23 142850.png (258.8 KB)

open | download - Annotation 2020-01-23 142951.png (161.1 KB)

open | download - Annotation 2020-01-09 162730.png (93.6 KB)

open | download - Annotation 2020-01-09 162916.png (70 KB)

open | download - Annotation 2020-01-09 162942.png (61.9 KB)

open | download - tapping locations.pdf (102.1 KB)

|

Re: Core XY build - feedback appreciated January 23, 2020 12:57PM |

Registered: 11 years ago Posts: 5,780 |

I don't think that frame structure is going to be adequate.

You're relying on the stiffness of the top and bottom plates, but unless they are 15 mm thick (pulling a number out of thin air), they really won't be very rigid. The belts are on bottom side of the plate so the tension is going to be working to bow the plate upward. If the plate bows upward, the vertical frame members move closer together at the top of the printer. They act as levers to flex the bottom plate where they attach to it, and it will flex. The linear guides will help stiffen the top plate, and maybe the lower pulley axles will flex and relieve some of the force on the plate, but you really don't want the pulley axles to flex either. The type of construction you are proposing requires the vertical frame members to be exactly the same length (with ends milled square) or they will bend the top and or bottom plates when you bolt the plates to them.

I think you need to add some horizontal bracing to the top and bottom parts of the frame to ensure everything is rigid. The same goes for mounting the pulleys. If you don't prevent the free end of the axle from moving (not such a problem for your top belt, but a potentially big problem for the bottom belt with the longer axles) the pulleys will tilt inward and the belt(s) will start riding on the pulley flanges.

I don't know how fast you intend to print with this machine, but cantilevered beds usually require relatively low speed printing because the free end of the bed bounces when the machine shakes as the X axis and extruder carriage masses are thrown back and forth during printing. I can't see much detail of how you're building the Z axis but it doesn't look especially robust.

I prevented the pulley tilt problem in my printer by mounting the pulleys in rectangular aluminum tubes. I prevented the XY base plate flex problem by mounting the base plate(s) on a 4040 t-slot frame.

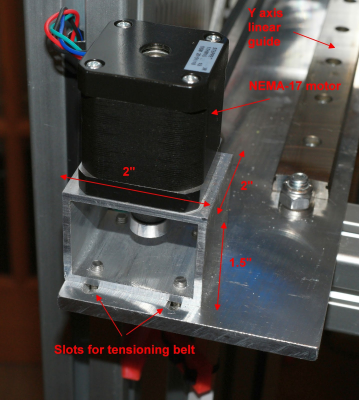

I used aluminum tubes to make the motor mounts as well- the aluminum is rigid and conducts heat, hopefully away from the motors.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You're relying on the stiffness of the top and bottom plates, but unless they are 15 mm thick (pulling a number out of thin air), they really won't be very rigid. The belts are on bottom side of the plate so the tension is going to be working to bow the plate upward. If the plate bows upward, the vertical frame members move closer together at the top of the printer. They act as levers to flex the bottom plate where they attach to it, and it will flex. The linear guides will help stiffen the top plate, and maybe the lower pulley axles will flex and relieve some of the force on the plate, but you really don't want the pulley axles to flex either. The type of construction you are proposing requires the vertical frame members to be exactly the same length (with ends milled square) or they will bend the top and or bottom plates when you bolt the plates to them.

I think you need to add some horizontal bracing to the top and bottom parts of the frame to ensure everything is rigid. The same goes for mounting the pulleys. If you don't prevent the free end of the axle from moving (not such a problem for your top belt, but a potentially big problem for the bottom belt with the longer axles) the pulleys will tilt inward and the belt(s) will start riding on the pulley flanges.

I don't know how fast you intend to print with this machine, but cantilevered beds usually require relatively low speed printing because the free end of the bed bounces when the machine shakes as the X axis and extruder carriage masses are thrown back and forth during printing. I can't see much detail of how you're building the Z axis but it doesn't look especially robust.

I prevented the pulley tilt problem in my printer by mounting the pulleys in rectangular aluminum tubes. I prevented the XY base plate flex problem by mounting the base plate(s) on a 4040 t-slot frame.

I used aluminum tubes to make the motor mounts as well- the aluminum is rigid and conducts heat, hopefully away from the motors.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Core XY build - feedback appreciated January 23, 2020 02:24PM |

Registered: 9 years ago Posts: 14 |

Thanks for the feedback. how much tension are you putting on your belts?! I cant belive a few Kg of belt tension is going to bow 8mm aluminium tooling plate. Three sides of the machine will be clad in polycarbonate sheet bolted to the uprights which will provide some bracing. Bed wobble was a concern when i was designing it, the bed is supported on 2 horizontal sections of the same 8mm tooling plate each riding on a THK 13mm rails rated to 457 Nm acording to the spec sheet, [docs.rs-online.com]. I managed to get these from the automation department of my previous job  . I like your idea of the box section for motor stand offs, my intention is to eventually machine the stand offs for this machine, but they will be printed at first. only the pulleys next to the motors are double height, these are supported half way up the shoulder bolt by the motor stand offs. So realy the moment will be similar to the single height ones, with the bottom pully being in double shear. But hey all theory, will have to see how the build goes

. I like your idea of the box section for motor stand offs, my intention is to eventually machine the stand offs for this machine, but they will be printed at first. only the pulleys next to the motors are double height, these are supported half way up the shoulder bolt by the motor stand offs. So realy the moment will be similar to the single height ones, with the bottom pully being in double shear. But hey all theory, will have to see how the build goes .

.

. I like your idea of the box section for motor stand offs, my intention is to eventually machine the stand offs for this machine, but they will be printed at first. only the pulleys next to the motors are double height, these are supported half way up the shoulder bolt by the motor stand offs. So realy the moment will be similar to the single height ones, with the bottom pully being in double shear. But hey all theory, will have to see how the build goes

. I like your idea of the box section for motor stand offs, my intention is to eventually machine the stand offs for this machine, but they will be printed at first. only the pulleys next to the motors are double height, these are supported half way up the shoulder bolt by the motor stand offs. So realy the moment will be similar to the single height ones, with the bottom pully being in double shear. But hey all theory, will have to see how the build goes .

.

|

Re: Core XY build - feedback appreciated January 23, 2020 02:48PM |

Registered: 11 years ago Posts: 5,780 |

Belt tension? Just enough, but not too much! My sand stable uses a 45mm square t-slot frame and the belts are located inside the frame. I recently realized I had a problem with the belts bowing the t-slot (almost 2m long) and had to brace the frame against it.

10mm wide belts are good, but don't use steel core belts.

8mm plate is probably going to hold up OK. Keep us posted on your progress.

Edited 1 time(s). Last edit at 01/23/2020 02:50PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

10mm wide belts are good, but don't use steel core belts.

8mm plate is probably going to hold up OK. Keep us posted on your progress.

Edited 1 time(s). Last edit at 01/23/2020 02:50PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Core XY build - feedback appreciated January 24, 2020 04:26AM |

Registered: 6 years ago Posts: 1,007 |

Why people keep asking opinion on computer renderings when it is obvious they didn't read all the other similar inquiries (most never materialize btw), making the same mistakes, calling for the same remarks, again and again ????

And of course read about the few working machines.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

And of course read about the few working machines.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Core XY build - feedback appreciated January 24, 2020 05:41AM |

Registered: 9 years ago Posts: 14 |

I started the thread because i thought you might have something constructive to say about it, clearly that was a mistake. I have read a lot of material on the forum that has informed my decision making along the way. I would be genuinely interested what the 'same mistakes' are that you think i have made, but it seems your more comfortable making vaguely personal negative comments than addressing whats actually under discussion.

I'm new to posting on the forums and based on stuff like this, i don't think i'll be coming back much.

I'm new to posting on the forums and based on stuff like this, i don't think i'll be coming back much.

|

Re: Core XY build - feedback appreciated January 24, 2020 06:02AM |

Registered: 6 years ago Posts: 1,007 |

Quote

fisher

I started the thread because i thought you might have something constructive to say about it, clearly that was a mistake. I have read a lot of material on the forum that has informed my decision making along the way. I would be genuinely interested what the 'same mistakes' are that you think i have made, but it seems your more comfortable making vaguely personal negative comments than addressing whats actually under discussion.

I'm new to posting on the forums and based on stuff like this, i don't think i'll be coming back much.

DD pointed some, read his blog, and other "projects" like yours here.

Edited 1 time(s). Last edit at 01/24/2020 06:04AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Core XY build - feedback appreciated January 24, 2020 06:10AM |

Registered: 9 years ago Posts: 14 |

Quote

MKSA

Quote

fisher

I started the thread because i thought you might have something constructive to say about it, clearly that was a mistake. I have read a lot of material on the forum that has informed my decision making along the way. I would be genuinely interested what the 'same mistakes' are that you think i have made, but it seems your more comfortable making vaguely personal negative comments than addressing whats actually under discussion.

I'm new to posting on the forums and based on stuff like this, i don't think i'll be coming back much.

DD pointed some, read his blog, and other "projects" like yours here.

There's no link there. DD made some helpful points that i addressed in my previous comment, you've added nothing apart from sarcastic quotation marks. Thanks for your help with my " "project" "

|

Re: Core XY build - feedback appreciated January 24, 2020 06:46AM |

Registered: 11 years ago Posts: 5,780 |

There's more than one way to do most things.

You can see my builds, many mistakes, and a few successes in the links in my sig, below.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You can see my builds, many mistakes, and a few successes in the links in my sig, below.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Core XY build - feedback appreciated January 24, 2020 11:14AM |

Registered: 7 years ago Posts: 619 |

Quote

fisher

I started the thread because i thought you might have something constructive to say about it, clearly that was a mistake. I have read a lot of material on the forum that has informed my decision making along the way. I would be genuinely interested what the 'same mistakes' are that you think i have made, but it seems your more comfortable making vaguely personal negative comments than addressing whats actually under discussion.

I'm new to posting on the forums and based on stuff like this, i don't think i'll be coming back much.

Don't worry about MKSA, he isn't really a troll, he's just perpetually grumpy. A kind comment from him is unusual in these forums, however, Digital Dentist qualifies as a guru and is one that is always worth reading.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Core XY build - feedback appreciated January 24, 2020 12:42PM |

Registered: 6 years ago Posts: 1,007 |

Quote

dlc60

Quote

fisher

I started the thread because i thought you might have something constructive to say about it, clearly that was a mistake. I have read a lot of material on the forum that has informed my decision making along the way. I would be genuinely interested what the 'same mistakes' are that you think i have made, but it seems your more comfortable making vaguely personal negative comments than addressing whats actually under discussion.

I'm new to posting on the forums and based on stuff like this, i don't think i'll be coming back much.

Don't worry about MKSA, he isn't really a troll, he's just perpetually grumpy. A kind comment from him is unusual in these forums, however, Digital Dentist qualifies as a guru and is one that is always worth reading.

DLC

Go ahead, feel free to give positive comments and let see.

Start with the bed as it has not yet been discussed and is an easy subject

Who is John Galt ?

Edited 1 time(s). Last edit at 01/24/2020 12:44PM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Core XY build - feedback appreciated January 25, 2020 04:37PM |

Registered: 8 years ago Posts: 1,671 |

The Father of all Children? Dont throw all the toys out at once

Yeah let's start with the bed & which side you got out of it this mornin

Edited 2 time(s). Last edit at 01/25/2020 04:39PM by MechaBits.

|

Re: Core XY build - feedback appreciated February 02, 2020 09:45AM |

Registered: 8 years ago Posts: 622 |

Quote

fisher

.................. a Core XY 'dream machine' based roughly on the E3D tool changer.

I would apriciate constructive feedback on the design, its taken a fair few itterations to get to this point.

Cheers!

You asked for constructive feedback so here is my opinion for what it's worth. IMO the phrases "dream machine" and "E3D tool changer" don't really belong in the same sentence because of the cantilevered bed arrangement. 3 screws arranged in an equilateral triangle, driving the Z axis via a single motor and continuous belt will be much more stable if "dream machine" really is your objective. (but that's just my twopence worth).

[somei3deas.wordpress.com]

[www.youtube.com]

|

Re: Core XY build - feedback appreciated February 02, 2020 12:16PM |

Registered: 9 years ago Posts: 14 |

Fair enough, I spent a long time debating the bed arrangement. I know that a cantilevered design is inherently not as robust as other methods. but I had a few really nice linear rails lying arround that are (at least in theory) way over spec for something like this. And given that when printing the dynamic loads on the bed will be small, as it's not going to move quickly. It might take another revision to get it right, but some basic FEA I've done suggests it should be ok. From a usability standpoint I prefer the cantilevered design, but that's just my opinion.

|

Re: Core XY build - feedback appreciated February 02, 2020 03:00PM |

Registered: 10 years ago Posts: 14,672 |

The cantilevered bed on the E3D tool changer is surprisingly (to me) stable. The bed is only 200mm across in the direction of the cantilever, which helps to explain it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Core XY build - feedback appreciated February 03, 2020 12:44AM |

Registered: 7 years ago Posts: 249 |

|

Re: Core XY build - feedback appreciated December 11, 2020 04:44PM |

Registered: 9 years ago Posts: 14 |

Finaly getting this thing put together after covid meant it was sat at my work for 8 months untouched.

Link to some images : [drive.google.com]

sorry picture quality isnt the best.

Just waiting on the bottom Alu plate to arrive then its on to wiring. Happy with everything so far, both the core xy gantry and the bed seem super rigid.

I'll share more pictures as it comes together.

Link to some images : [drive.google.com]

sorry picture quality isnt the best.

Just waiting on the bottom Alu plate to arrive then its on to wiring. Happy with everything so far, both the core xy gantry and the bed seem super rigid.

I'll share more pictures as it comes together.

|

Re: Core XY build - feedback appreciated December 11, 2020 06:05PM |

Registered: 11 years ago Posts: 5,780 |

It looks nicely built, except I agree with prototypical- standing the pulleys on posts is not a great way to go. We'll see how the cantilevered bed behaves when the X axis is flying back and forth on the Y axis rails. They have a tendency to bounce, but if the construction is solid enough, it may not be an issue.

Where will you be mounting the electronics?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Where will you be mounting the electronics?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Core XY build - feedback appreciated December 14, 2020 01:21PM |

Registered: 9 years ago Posts: 14 |

Quote

the_digital_dentist

It looks nicely built, except I agree with prototypical- standing the pulleys on posts is not a great way to go. We'll see how the cantilevered bed behaves when the X axis is flying back and forth on the Y axis rails. They have a tendency to bounce, but if the construction is solid enough, it may not be an issue.

Where will you be mounting the electronics?

The idlers are mounted on sholder bolts like this (https://www.accu.co.uk/en/socket-shoulder-screws/10389-SSH-M4-20-A2) threaded directly in to the ALU sheet, seem rock solid to me but will have to see how they fare with prolonged use.

Electronics will be mounted on the back while im debugging not decided where to put them long term.

Should be getting the final Alu pannels this week, hoping to get it printing over xmas, love it when a machine starts comming together.

|

Re: Core XY build - feedback appreciated December 14, 2020 02:06PM |

Registered: 11 years ago Posts: 5,780 |

With the XY stage built on a plate mounted on top of the verticals, and another plate on the bottom, the lengths of the verticals better be well matched or the XY stage is liable to twist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Core XY build - feedback appreciated December 14, 2020 03:12PM |

Registered: 9 years ago Posts: 14 |

Quote

the_digital_dentist

With the XY stage built on a plate mounted on top of the verticals, and another plate on the bottom, the lengths of the verticals better be well matched or the XY stage is liable to twist.

All milled to length by myself

one of the perks of working for a university and having access to the machine shop.

one of the perks of working for a university and having access to the machine shop.Edited 2 time(s). Last edit at 12/14/2020 03:14PM by fisher.

|

Re: Core XY build - feedback appreciated December 14, 2020 03:31PM |

Registered: 11 years ago Posts: 5,780 |

Should be fine, then! I use a Bridgeport mill at the Milwaukee Makerspace. I recently acquired a three flute, 1/2", tungsten carbide end mill with a 50mm cutting length, specifically for milling t-slot. It leaves an almost mirror finish on the ends of the t-slot!

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Core XY build - feedback appreciated January 24, 2021 10:02AM |

Registered: 9 years ago Posts: 14 |

exactly a year since my op and this project is nearing 'completion' if these things are ever really complete. been printing with it for a few weeks with some very nice results.

ive uploaded some more pictures here: [drive.google.com]

ive had to return my duet 2 due to a bad solder joint and am currently witing for a replacement which should be here in a few days. theres a whole list of things i'll be improving in the future, main thing at the moment is print cooling. Im going to completly redesign the toolhead with an all metal carriage spending more time to think about center of gravity, cable management, fan placement etc.

what im realy pleased about vs my previous printer is the work flow both in terms of how easy it is to make modifications to the printer and machine controll using duet which has been a revelation ( my previous machine was hacked together using ramps way back in 2014)

so far parts seem to have good dimentional accuracy, only noticed a tiny ammount of ringing when i run the machine over 80mm/s - i think this mainly comes down to the cheap belts wich i will replace at some point. its a little on the noisy side - mostly the fans.

one thing i want a solution to is finding a good surface to place the printer on, or finding some damping feet that i can level the machine with - id be interested to see others solutions to this. ive cuttently got it sat on some fairly rigid foam matting designed to got under wood flooring.

Edited 1 time(s). Last edit at 01/24/2021 10:06AM by fisher.

ive uploaded some more pictures here: [drive.google.com]

ive had to return my duet 2 due to a bad solder joint and am currently witing for a replacement which should be here in a few days. theres a whole list of things i'll be improving in the future, main thing at the moment is print cooling. Im going to completly redesign the toolhead with an all metal carriage spending more time to think about center of gravity, cable management, fan placement etc.

what im realy pleased about vs my previous printer is the work flow both in terms of how easy it is to make modifications to the printer and machine controll using duet which has been a revelation ( my previous machine was hacked together using ramps way back in 2014)

so far parts seem to have good dimentional accuracy, only noticed a tiny ammount of ringing when i run the machine over 80mm/s - i think this mainly comes down to the cheap belts wich i will replace at some point. its a little on the noisy side - mostly the fans.

one thing i want a solution to is finding a good surface to place the printer on, or finding some damping feet that i can level the machine with - id be interested to see others solutions to this. ive cuttently got it sat on some fairly rigid foam matting designed to got under wood flooring.

Edited 1 time(s). Last edit at 01/24/2021 10:06AM by fisher.

Sorry, only registered users may post in this forum.