Core xy cable path

Posted by arcadeperfect

|

Core xy cable path March 19, 2021 08:00PM |

Registered: 5 years ago Posts: 3 |

Hi,

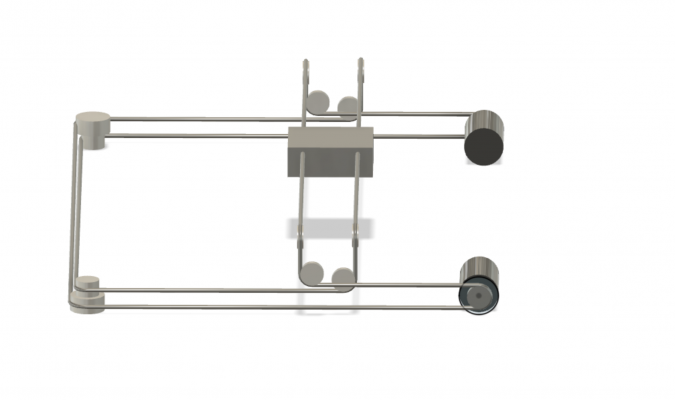

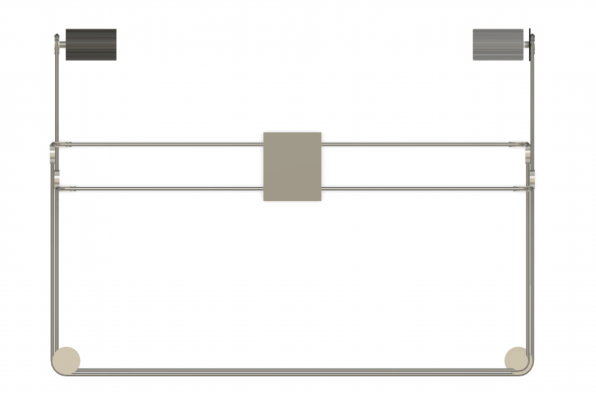

Any reason this twist (ahem) on the core xy layout won't work? It would be using cable or synchromesh instead of belts.

One of the cables has two slightly larger idlers at the front to prevent the cables interfering. Is that a problem? In my head, that would effect the speed the idlers rotate but not the resulting forces applied to the carriage, but things in my head are often wrong.

And before you ask BUT WHY, there are reasons for this geometry. It's for a pen plotter / laser, and the idea is to machine a frame whereby there's a perfectly fit cavity underneath for everything except the x axis gantry which would protrude above through slots.

This is because having frames and belts and motors around really gets annoying when you're working with paper and various media. Also because I like it to be hard, and I think it will look cool.

Thanks for any advice

Any reason this twist (ahem) on the core xy layout won't work? It would be using cable or synchromesh instead of belts.

One of the cables has two slightly larger idlers at the front to prevent the cables interfering. Is that a problem? In my head, that would effect the speed the idlers rotate but not the resulting forces applied to the carriage, but things in my head are often wrong.

And before you ask BUT WHY, there are reasons for this geometry. It's for a pen plotter / laser, and the idea is to machine a frame whereby there's a perfectly fit cavity underneath for everything except the x axis gantry which would protrude above through slots.

This is because having frames and belts and motors around really gets annoying when you're working with paper and various media. Also because I like it to be hard, and I think it will look cool.

Thanks for any advice

|

Re: Core xy cable path March 20, 2021 10:45AM |

Registered: 11 years ago Posts: 5,780 |

That's an interesting layout if you're committed to cable drive. I see three main problems with cable drive. Installing the cables, maintaining the mechanism, and dealing with the motors.

We tend to think of pulleys in ideal terms as being lossless, but the friction at each pulley (and force required to wrap the belts/cables around the pulleys) adds up fast. A corexy mechanism is a surprisingly difficult load for the motors - try pushing the carriage around in XY with motor power off. Your layout adds four more pulleys to a minimal pulley count corexy layout.

Cables are a friction drive system and it usually takes multiple wraps of cable around the drive pulleys to ensure sufficient friction that the mechanism won't slip. Look up the capstan equation. As soon as you use multiple wraps, the cable walks along the length (width?) of the drive pulley as it spins. That walking will change the angle that the cable makes with the pulley(s) on the ends of the X axis. That will in turn change cable tension depending on the pen carriage position in XY space. That will also change steps/mm depending on position, so drawings will be distorted. If the cable tension varies enough in the wrong direction, the mechanism may slip because the friction on the drive pulley will change with the tension change.

You can fix the drive pulley problem by using steering pulley(s) to ensure that the cable doesn't walk along the drive pulley, but that may require some modification of your pulley positions. You're using a single cable loop for the whole system which should be OK. You can close the loop at the pen carriage or maybe in one of the motor-to-corner pulley segments, depending on how large the drawing area is compared to the mechanism. Here's the maintenance problem- in order to do things like replace pulleys, bearings, etc., you have to release the tension on the cable(s). As soon as you do, the cable will jump off all the pulleys if there are no mechanical means to prevent it. The biggest problem occurs at the motors with steering pulleys and multiple loops around the drive pulley. Repositioning the cable at all the pulleys can be difficult.

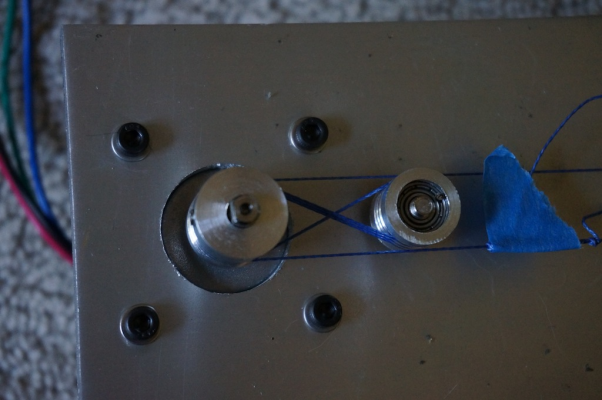

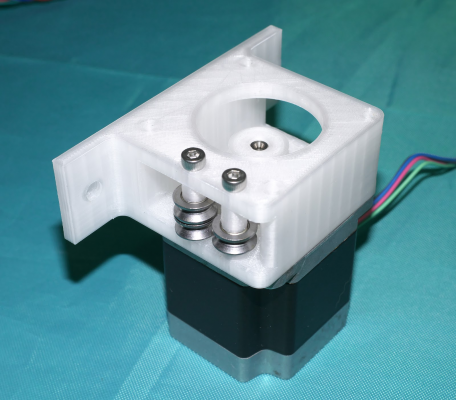

Here's one way to fix the angles of the cable going on and off the drive pulley:

Here's one I made when I made a cable driven corexy sand table:

I used very cheap pulleys for the steerers (and all the other pulleys), and the mechanism was very noisy. Those tiny pulleys had even tinier bearings that would not last. I recommend you use much bigger bearings for quieter and longer life operation.

You can hear the noise it made here: [vimeo.com]

If you consider these problems from the start you can probably design a mechanism that is quiet and reliable enough not to require a lot of service and is relatively easy to service when necessary- i.e. learn from my mistakes and try not to repeat them...

Edited 1 time(s). Last edit at 03/20/2021 10:48AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

We tend to think of pulleys in ideal terms as being lossless, but the friction at each pulley (and force required to wrap the belts/cables around the pulleys) adds up fast. A corexy mechanism is a surprisingly difficult load for the motors - try pushing the carriage around in XY with motor power off. Your layout adds four more pulleys to a minimal pulley count corexy layout.

Cables are a friction drive system and it usually takes multiple wraps of cable around the drive pulleys to ensure sufficient friction that the mechanism won't slip. Look up the capstan equation. As soon as you use multiple wraps, the cable walks along the length (width?) of the drive pulley as it spins. That walking will change the angle that the cable makes with the pulley(s) on the ends of the X axis. That will in turn change cable tension depending on the pen carriage position in XY space. That will also change steps/mm depending on position, so drawings will be distorted. If the cable tension varies enough in the wrong direction, the mechanism may slip because the friction on the drive pulley will change with the tension change.

You can fix the drive pulley problem by using steering pulley(s) to ensure that the cable doesn't walk along the drive pulley, but that may require some modification of your pulley positions. You're using a single cable loop for the whole system which should be OK. You can close the loop at the pen carriage or maybe in one of the motor-to-corner pulley segments, depending on how large the drawing area is compared to the mechanism. Here's the maintenance problem- in order to do things like replace pulleys, bearings, etc., you have to release the tension on the cable(s). As soon as you do, the cable will jump off all the pulleys if there are no mechanical means to prevent it. The biggest problem occurs at the motors with steering pulleys and multiple loops around the drive pulley. Repositioning the cable at all the pulleys can be difficult.

Here's one way to fix the angles of the cable going on and off the drive pulley:

Here's one I made when I made a cable driven corexy sand table:

I used very cheap pulleys for the steerers (and all the other pulleys), and the mechanism was very noisy. Those tiny pulleys had even tinier bearings that would not last. I recommend you use much bigger bearings for quieter and longer life operation.

You can hear the noise it made here: [vimeo.com]

If you consider these problems from the start you can probably design a mechanism that is quiet and reliable enough not to require a lot of service and is relatively easy to service when necessary- i.e. learn from my mistakes and try not to repeat them...

Edited 1 time(s). Last edit at 03/20/2021 10:48AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Core xy cable path March 20, 2021 03:43PM |

Registered: 5 years ago Posts: 3 |

That's some interesting info thanks! Hadn't considered most of that.

Have you any experience with synchromesh? Should help with the walking but someone said it isn't very accurate, with cumulative error over many pitches. And I should imagine the pulleys would be even louder if anything. So maybe regular cable is better.

I am actually considering using odrive for x and y, and one idea I had was to put the encoders in place of one of the final pulleys before the cable hits the pen carriage. It would add annoying wiring to the design, but in theory it would mitigate inaccuracies introduced by walking cables etc.

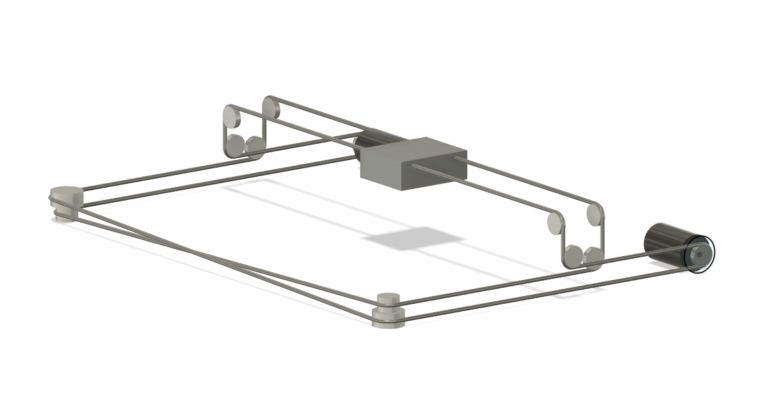

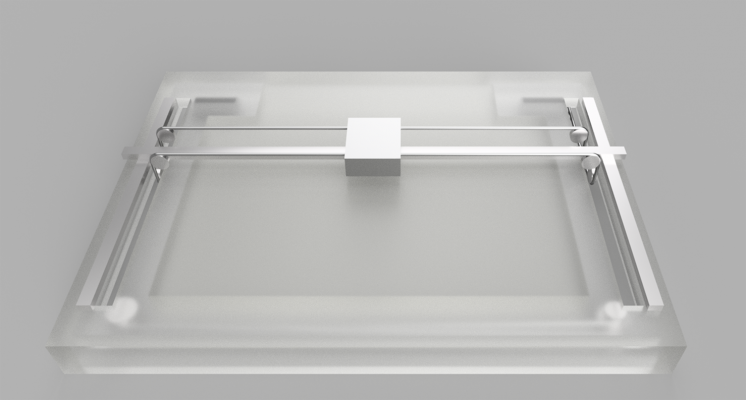

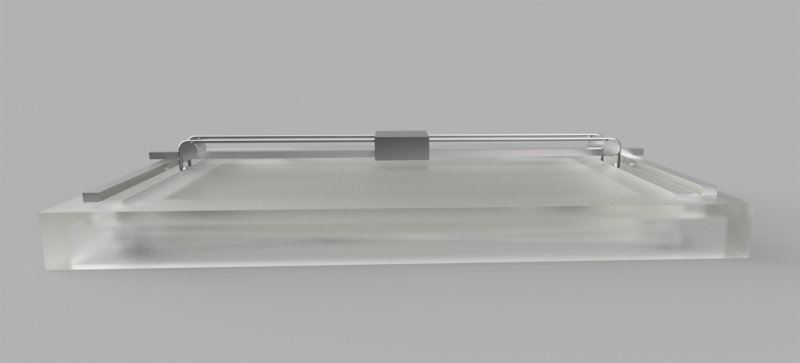

And just for fun here's some renders of the idea for the frame, if I had infinite money to machine it out of acrylic. I guess the maintenance is going to be a nightmare...

Have you any experience with synchromesh? Should help with the walking but someone said it isn't very accurate, with cumulative error over many pitches. And I should imagine the pulleys would be even louder if anything. So maybe regular cable is better.

I am actually considering using odrive for x and y, and one idea I had was to put the encoders in place of one of the final pulleys before the cable hits the pen carriage. It would add annoying wiring to the design, but in theory it would mitigate inaccuracies introduced by walking cables etc.

And just for fun here's some renders of the idea for the frame, if I had infinite money to machine it out of acrylic. I guess the maintenance is going to be a nightmare...

|

Re: Core xy cable path March 21, 2021 12:13AM |

Registered: 11 years ago Posts: 5,780 |

I haven't seen o-drive before- looks interesting.

Since you're planning on plotting and probably want to go fast, I don't think the synchromesh cable is going to work for you. Look at the video showing a 3D printer on the page you linked. Watch the cable going on and coming off the pulley- it bounces. It's going to be very noisy at high speed if it manages to stay on the pulleys. If you want fast and quiet operation I think the cable and pulleys are going to have to be pretty smooth.

Making things run quietly at high speed is not easy. I installed a couple integrated servomotors in my sand table and they drive the mechanism very fast- I have run it >2000 mm/sec and could go higher with a change in drive pulley diameter. See: [vimeo.com] In the sand table most of the noise is made by the belt teeth hitting the drive pulleys. The belts are twisted so that the smooth sides of the belts hit all the other pulleys. You have to be careful of the speed and acceleration settings- high acceleration requires a LOT of current and at high speeds the motors generate back EMF that can end up on the power bus and do all sorts of damage.

[drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Since you're planning on plotting and probably want to go fast, I don't think the synchromesh cable is going to work for you. Look at the video showing a 3D printer on the page you linked. Watch the cable going on and coming off the pulley- it bounces. It's going to be very noisy at high speed if it manages to stay on the pulleys. If you want fast and quiet operation I think the cable and pulleys are going to have to be pretty smooth.

Making things run quietly at high speed is not easy. I installed a couple integrated servomotors in my sand table and they drive the mechanism very fast- I have run it >2000 mm/sec and could go higher with a change in drive pulley diameter. See: [vimeo.com] In the sand table most of the noise is made by the belt teeth hitting the drive pulleys. The belts are twisted so that the smooth sides of the belts hit all the other pulleys. You have to be careful of the speed and acceleration settings- high acceleration requires a LOT of current and at high speeds the motors generate back EMF that can end up on the power bus and do all sorts of damage.

[drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Core xy cable path March 22, 2021 02:04AM |

Registered: 5 years ago Posts: 3 |

Sorry, only registered users may post in this forum.