Atfer Hbot, go to CoreXY.

Posted by zelogik

|

Re: Atfer Hbot, go to CoreXY. March 04, 2014 12:03PM |

Registered: 12 years ago Posts: 199 |

@reinhold

You can use either 16 or 20 teeth pulleys. It does not matter for the design, both will fit.

16 teeth pulleys may easier skip a tooth. The belt touches the puley for almost the complete turn, so it will probably not make any difference. You will get a little more acuracy. But in my opinion you get a nicer stepsize with 20 teeth pulleys

On my mendel I use printed pulleys since day one. One of them is still Nophead original print. The other I printed myself. I needed to print the other two because the plastic around the setscrew is weak. I see no reason to replace it.

On my new printer I want to use metal pulleys. But I may even test with printed pulleys.

I am also a bit worried about all smooth idlers, but want to give it a try anyway. Time will tell.

Yes you have to tension both belts. You even want the same tension on both belts.

@zelogic

I know people have these artifacts, but I do not have it om my modified mendel, which uses 624 bearings and a T5 belt.

But the profile is different on GT2, rounded vs. Trapezial. So. .... ???

@all

The only reason I want to give 624 bearings a try is the costs of the pulleys. You stil need (smaller) bearings if you use modified pulleys.

If somebody has proven experience I like to know.

Edited 1 time(s). Last edit at 03/04/2014 12:06PM by jand.

You can use either 16 or 20 teeth pulleys. It does not matter for the design, both will fit.

16 teeth pulleys may easier skip a tooth. The belt touches the puley for almost the complete turn, so it will probably not make any difference. You will get a little more acuracy. But in my opinion you get a nicer stepsize with 20 teeth pulleys

On my mendel I use printed pulleys since day one. One of them is still Nophead original print. The other I printed myself. I needed to print the other two because the plastic around the setscrew is weak. I see no reason to replace it.

On my new printer I want to use metal pulleys. But I may even test with printed pulleys.

I am also a bit worried about all smooth idlers, but want to give it a try anyway. Time will tell.

Yes you have to tension both belts. You even want the same tension on both belts.

@zelogic

I know people have these artifacts, but I do not have it om my modified mendel, which uses 624 bearings and a T5 belt.

But the profile is different on GT2, rounded vs. Trapezial. So. .... ???

@all

The only reason I want to give 624 bearings a try is the costs of the pulleys. You stil need (smaller) bearings if you use modified pulleys.

If somebody has proven experience I like to know.

Edited 1 time(s). Last edit at 03/04/2014 12:06PM by jand.

|

Re: Atfer Hbot, go to CoreXY. March 04, 2014 12:36PM |

Registered: 11 years ago Posts: 225 |

@Reinhold:

The more important think for the idler pulley and "toothed pulley", the diameter:

-ALL idler pulley need to have the same size each.

-The fourth "toothed pulley" at each corner need to have the same size too

-And all last one the same size too.

After that:

-the diameters of ALL idler and toothed pulleys groups can have all a differents size and the size we want can be between 8mm and 12mm.

Don't use printed pulley for "force pulley", even if you have good printer. Metal or moulded plastic are cheap and better for me.

But i have said that only for the idler toothed pulley. I think printed one can be ok.

Finally I use 1/32 microstep driver. and not 1/16 driver.

Yes like Jand have said, you need the tension on both belt.

@Jand: Maybe if the tension of the belt is not too tightened, it's ok.

8x2$ + 20pcs/$10.85 = 26$+shipping of pulley .... if your solution don't work it's not a big mistake ;-)

But I see very small artifact with not completely rounded idler pulley (carbon rod), 10.98 to 11.05 ... so wait and see...

Quote

Need: -qt:28, 3x8x4 bearing (thanks to cheap china bearing :-D). -qt: 8, 20teeths gt2 pulley and 8mm bore from robodigg (and no 16teeth as say before), you need to dissassemble it and file it to have 8mm height pulley. -qt: 4, 8mm rod 320mm lenght for 220/230mm travel distance. -qt: 4, 11mm od, 8mm id, tube (ie: I have used a 8mm id and 10mm od aluminium tube inside a 11mm od 10mm id carbon tube.) with 8mm height -qt: 2 16/20 what you want teeth gt2 pulley with 5mm bore for motor.

The more important think for the idler pulley and "toothed pulley", the diameter:

-ALL idler pulley need to have the same size each.

-The fourth "toothed pulley" at each corner need to have the same size too

-And all last one the same size too.

After that:

-the diameters of ALL idler and toothed pulleys groups can have all a differents size and the size we want can be between 8mm and 12mm.

Don't use printed pulley for "force pulley", even if you have good printer. Metal or moulded plastic are cheap and better for me.

But i have said that only for the idler toothed pulley. I think printed one can be ok.

Finally I use 1/32 microstep driver. and not 1/16 driver.

Yes like Jand have said, you need the tension on both belt.

@Jand: Maybe if the tension of the belt is not too tightened, it's ok.

8x2$ + 20pcs/$10.85 = 26$+shipping of pulley .... if your solution don't work it's not a big mistake ;-)

But I see very small artifact with not completely rounded idler pulley (carbon rod), 10.98 to 11.05 ... so wait and see...

|

Re: Atfer Hbot, go to CoreXY. March 04, 2014 01:08PM |

Registered: 10 years ago Posts: 71 |

@jand

@zelogik

Thanks for your valuable comments ... the world needs even more pulleys

@zelogik

Sry - your quote hit it home ... this time I read the whole thread ...again but still have to ask

... this time I read the whole thread ...again but still have to ask

"Finally I use 1/32 microstep driver. and not 1/16 driver."

I can see "Arduino Mega 2560, Ramps 1.4(?) on it's back

Raspberry pi and some green board on the back of the pi (???)"

The "green board" then must be your 1/32 driver ???

...or are you using "DRV8825"

Which stepper motors are you using ?

@zelogik

Thanks for your valuable comments ... the world needs even more pulleys

@zelogik

Sry - your quote hit it home

... this time I read the whole thread ...again but still have to ask

... this time I read the whole thread ...again but still have to ask

"Finally I use 1/32 microstep driver. and not 1/16 driver."

I can see "Arduino Mega 2560, Ramps 1.4(?) on it's back

Raspberry pi and some green board on the back of the pi (???)"

The "green board" then must be your 1/32 driver ???

...or are you using "DRV8825"

Which stepper motors are you using ?

|

Re: Atfer Hbot, go to CoreXY. March 05, 2014 07:00AM |

Registered: 12 years ago Posts: 199 |

|

Re: Atfer Hbot, go to CoreXY. March 05, 2014 08:44AM |

Registered: 11 years ago Posts: 225 |

@Jand: Funny I have asked for that request today to robotdigg

Because the last time I have take many things on the same shop so the shipping cost was bigger.

So there:

Air mail 15-35 days arrival 5USD. for $2 x 10 x GT2 Pulley 20 Teeth 8mm Bore.

So $25 for 10 pulley (take spares because you need to make some modification on each )

)

But with some belt + pulley you can count on $10 for shipping cost to FR/UK/DE/NL ....

@Reinhold: 2x 20teeth for motor pulley with 5mm bore, 1/32 DRV8825 you're right and 1,8° motor step.

Maybe I don't have understand your first question

Because the last time I have take many things on the same shop so the shipping cost was bigger.

So there:

Air mail 15-35 days arrival 5USD. for $2 x 10 x GT2 Pulley 20 Teeth 8mm Bore.

So $25 for 10 pulley (take spares because you need to make some modification on each

)

)But with some belt + pulley you can count on $10 for shipping cost to FR/UK/DE/NL ....

@Reinhold: 2x 20teeth for motor pulley with 5mm bore, 1/32 DRV8825 you're right and 1,8° motor step.

Maybe I don't have understand your first question

|

Re: Atfer Hbot, go to CoreXY. March 05, 2014 10:11AM |

Registered: 10 years ago Posts: 71 |

@zelogik

What stepper motors are you using with your DRV8825 driver?

(Nema 17, 40mm?, 1.7A?, ??Ncm)

@all

Derek from robotdigg must have had a busy day...(his morning/middle of our night)

I asked him for 10+2 pulleys, a pack of mini bearings and a Nema23 Stepper...

...he quoted me 48usd for "express shipping" ... thats FOURTYEIGHT $$$

since express shipment here means "clearance fee" (~20€) (or another week wait)

then VAT (19%)+ (some tax) ...added on top of everything

... (for me) turns out as "not a real bargain"

I got nasty in the middle of the night then...

Since he has a little lecture on his webpage about "How to optimize shipping"

I decided to give him a little lecture" myself on how to avoid shipping cost and tax for europe

...all at night - so maybe he got reasonable again when YOU, zelogik, asked him

----------------- sry, still a little angry so here it si (use translate.google.com) -----------

...XIEXIE!, Dankeschön and Regards

Reinhold

只是FYI:上述€22歐盟關稅開始。

超過€22,我所付出的增值稅(+19%)+4-19%的關稅。

很多時候,它確實是有道理的使用廉價的中國郵政報文和發送2-3。

快遞經紀人通常有一個快遞,德國法蘭克福

他們收取20-30€的“清關”,這通常是緩慢...

因為在我的情況,我只是去了街道的盡頭(^_*)

---------------------------------------------------------------------------------------------------------------------------

... maybe with reasonable shipping we can organize a

pulley-groupbuy here???

(France and Netherlands are about 3-4€ (from Germany)...)

What stepper motors are you using with your DRV8825 driver?

(Nema 17, 40mm?, 1.7A?, ??Ncm)

@all

Derek from robotdigg must have had a busy day...(his morning/middle of our night)

I asked him for 10+2 pulleys, a pack of mini bearings and a Nema23 Stepper...

...he quoted me 48usd for "express shipping" ... thats FOURTYEIGHT $$$

since express shipment here means "clearance fee" (~20€) (or another week wait)

then VAT (19%)+ (some tax) ...added on top of everything

... (for me) turns out as "not a real bargain"

I got nasty in the middle of the night then...

Since he has a little lecture on his webpage about "How to optimize shipping"

I decided to give him a little lecture" myself on how to avoid shipping cost and tax for europe

...all at night - so maybe he got reasonable again when YOU, zelogik, asked him

----------------- sry, still a little angry so here it si (use translate.google.com) -----------

...XIEXIE!, Dankeschön and Regards

Reinhold

只是FYI:上述€22歐盟關稅開始。

超過€22,我所付出的增值稅(+19%)+4-19%的關稅。

很多時候,它確實是有道理的使用廉價的中國郵政報文和發送2-3。

快遞經紀人通常有一個快遞,德國法蘭克福

他們收取20-30€的“清關”,這通常是緩慢...

因為在我的情況,我只是去了街道的盡頭(^_*)

---------------------------------------------------------------------------------------------------------------------------

... maybe with reasonable shipping we can organize a

pulley-groupbuy here???

(France and Netherlands are about 3-4€ (from Germany)...)

|

Re: Atfer Hbot, go to CoreXY. March 08, 2014 02:00PM |

Registered: 12 years ago Posts: 199 |

I finally decided on the size of the exrusions It will be 360 mm horizontal and 400 mm vertical. This gives a nice 40 cm cube. I'll give the "add+20mm-Drill-Hole-and-connect-to-center-M6-opposite-profile" option a try. Although I will probably use 10mm.

I ordered the extrusions and two 12mm h6, ground and hardened shafts. Also the F624zz and LM12UU bearings are ordered.So hopefully I can build something next week.

In the meantime I will be working on the Z-axis and probably the endstops, which I more or less ignored.

I ordered the extrusions and two 12mm h6, ground and hardened shafts. Also the F624zz and LM12UU bearings are ordered.So hopefully I can build something next week.

In the meantime I will be working on the Z-axis and probably the endstops, which I more or less ignored.

|

Re: Atfer Hbot, go to CoreXY. March 08, 2014 02:28PM |

Registered: 11 years ago Posts: 225 |

@Jand: HUUUUUUUUUU 8-/... How can you put the LM12UU on the carriage ? You can put Igus bush or brass bush without problem with 12mm rod... but I have just take some time to seen quickly your drawing and the diameter is not 19mm but 15mm no?

Atfer with the "add +20mm-drill hole and connect to center m6 opposite profile" I see how to connect 2profiles each others ... but with 3profiles I need to see how it's work, it's a big mistake for me...

Have you looked for the Z-axis on my old printer (github -> HBot) ? almost all printed part and working really well.

For the endstop do you want more pictures from my printer? Or you can put endstop on each "XY-block-top-alt" instead or putting the 2 on the X-carriage.

Finally I impatient to see how you will clamp your belt and how you will tight the belt too.

@Reinhold: Too late .. i have already ordered some more pulley in case I build a second one for stacking it :-)

Atfer with the "add +20mm-drill hole and connect to center m6 opposite profile" I see how to connect 2profiles each others ... but with 3profiles I need to see how it's work, it's a big mistake for me...

Have you looked for the Z-axis on my old printer (github -> HBot) ? almost all printed part and working really well.

For the endstop do you want more pictures from my printer? Or you can put endstop on each "XY-block-top-alt" instead or putting the 2 on the X-carriage.

Finally I impatient to see how you will clamp your belt and how you will tight the belt too.

@Reinhold: Too late .. i have already ordered some more pulley in case I build a second one for stacking it :-)

|

Re: Atfer Hbot, go to CoreXY. March 08, 2014 03:09PM |

Registered: 12 years ago Posts: 199 |

@zelogic

Noooooo, the Lm12UU are for the Z-axis. The Z-axis will be 12 mm, All other axis will be 8 mm and LM8UU bearings. I have plenty of LM8UU, so I don't have to order them.

Hopefully this image will make things clear:

The green things are the screws. The hole is for the screwdriver, not for the screws.

Edited 1 time(s). Last edit at 03/08/2014 03:11PM by jand.

Noooooo, the Lm12UU are for the Z-axis. The Z-axis will be 12 mm, All other axis will be 8 mm and LM8UU bearings. I have plenty of LM8UU, so I don't have to order them.

Hopefully this image will make things clear:

The green things are the screws. The hole is for the screwdriver, not for the screws.

Edited 1 time(s). Last edit at 03/08/2014 03:11PM by jand.

|

Re: Atfer Hbot, go to CoreXY. March 08, 2014 03:14PM |

Registered: 11 years ago Posts: 225 |

|

Re: Atfer Hbot, go to CoreXY. March 16, 2014 10:37AM |

Registered: 10 years ago Posts: 71 |

|

Re: Atfer Hbot, go to CoreXY. March 16, 2014 12:02PM |

Registered: 12 years ago Posts: 199 |

Hi,

I am a little bit sad, I was hoping to get some alu extrusions and some more stuff this weekend. The only thing I got was the F624zz bearings.

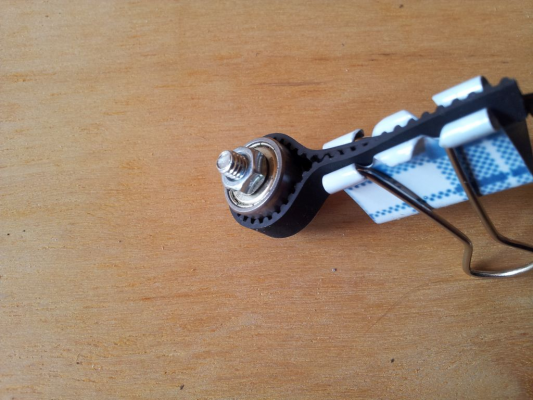

The bearing on the left is the flanged bearing, the one on the right is the normal 624 bearing. The flanged bearing will be at the bottom.

Here you can see how the belt wrap around the bearings.

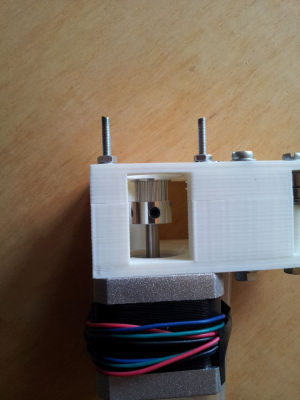

These two images show a potential problem. on the right motor mount part.The pulley is at the end of the motorshaft. The motorshaft is about half way in the pulley.

If it does not work the motor can be placed on the other side (top instead of bottom) But that does not look nice.

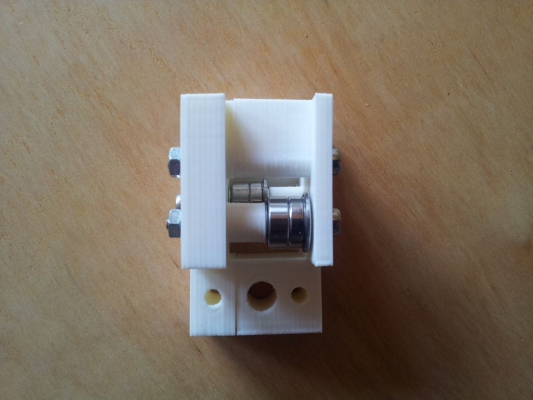

The front corner parts look like this

Edited 1 time(s). Last edit at 03/16/2014 12:04PM by jand.

I am a little bit sad, I was hoping to get some alu extrusions and some more stuff this weekend. The only thing I got was the F624zz bearings.

The bearing on the left is the flanged bearing, the one on the right is the normal 624 bearing. The flanged bearing will be at the bottom.

Here you can see how the belt wrap around the bearings.

These two images show a potential problem. on the right motor mount part.The pulley is at the end of the motorshaft. The motorshaft is about half way in the pulley.

If it does not work the motor can be placed on the other side (top instead of bottom) But that does not look nice.

The front corner parts look like this

Edited 1 time(s). Last edit at 03/16/2014 12:04PM by jand.

|

Re: Atfer Hbot, go to CoreXY. March 16, 2014 05:34PM |

Registered: 10 years ago Posts: 71 |

|

Re: Atfer Hbot, go to CoreXY. March 16, 2014 05:41PM |

Registered: 11 years ago Posts: 225 |

Very quick response:

@Jand: On the motor part, you have forgotten to add 10mm spacer, like you have done on the front corner part...

But you don't really need it, measure the distance, and normally the motor axle (22mm) is long enought (I have got the same false "problem" the first time

(I have got the same false "problem" the first time  )

)

@Reinhold, I make the enclosure and add some cable chain, for the noise of the DRV8825 ... not many improvement ...

@Jand: On the motor part, you have forgotten to add 10mm spacer, like you have done on the front corner part...

But you don't really need it, measure the distance, and normally the motor axle (22mm) is long enought

(I have got the same false "problem" the first time

(I have got the same false "problem" the first time  )

)@Reinhold, I make the enclosure and add some cable chain, for the noise of the DRV8825 ... not many improvement ...

|

Re: Atfer Hbot, go to CoreXY. March 16, 2014 06:45PM |

Registered: 12 years ago Posts: 199 |

|

Re: Atfer Hbot, go to CoreXY. March 27, 2014 03:38AM |

Registered: 12 years ago Posts: 199 |

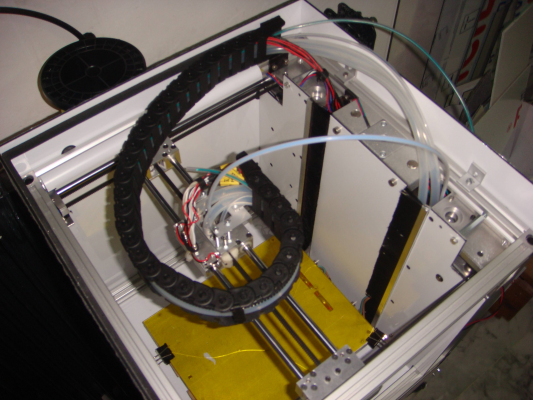

Finally I made some progress. I build the frame, it is 40 cm in all directions (outside). All plastic parts for the XY movements are printed and installed in the frame. 8mm smooth rods are placed. For now it’s just plain steel rods from a hardware store. I will replace then later with precision hardened steel rods later. The belts, motors and pulleys are installed.

I used an old RAMPS 1.2 I had laying around and installed repetier firmware on it. I do not have end stops yet, so that’s all in software for now.

Yesterday evening I fired up repetier-host and started some movement tests. After fixing direction problems I can move it around. It can move a lot faster than my mendel, but that’s not completely fair, because the extruder is not yet installed. I did some tests at 200 mm/s and 9000 mm/s^2.

The Z-axis is not yet build, because the LM12UU’s I ordered have not yet arrived. It appears they went back to Germany, because they could not be delivered. EBay Seller will send them again. The Z-axis does exist in CAD however.

I will try to make some pictures tonight.

@zelogic, can you post some pictures of your endstops and how they are mounted?

I used an old RAMPS 1.2 I had laying around and installed repetier firmware on it. I do not have end stops yet, so that’s all in software for now.

Yesterday evening I fired up repetier-host and started some movement tests. After fixing direction problems I can move it around. It can move a lot faster than my mendel, but that’s not completely fair, because the extruder is not yet installed. I did some tests at 200 mm/s and 9000 mm/s^2.

The Z-axis is not yet build, because the LM12UU’s I ordered have not yet arrived. It appears they went back to Germany, because they could not be delivered. EBay Seller will send them again. The Z-axis does exist in CAD however.

I will try to make some pictures tonight.

@zelogic, can you post some pictures of your endstops and how they are mounted?

|

Re: Atfer Hbot, go to CoreXY. March 27, 2014 10:37AM |

Registered: 10 years ago Posts: 71 |

Hi Jand

Good to see you making progress...

(I wouldn't mind more pictures (and a small video ;-) but ):

Correct me I believe that with a CoreX-Y and Repetier

just 1 single Endswitch is OK which

Zelogic shows on

[i.imgur.com]

(mechanical back left in my coordinate system )

BTW: Completely unexpected but I made good progress on

my long overdue StarLinearMotionGuideItemProfilePortal-Printer ...

(think Felix ... I dont want to hijack the thread)

How do you guys measure speed?

just what the printer (i.e. Marlin) tells Pronterface:

M201 - Set max acceleration in units/s^2 for print moves (M201 X1000 Y1000)

M203 - Set maximum feedrate that your machine can sustain (M203 X200 Y200 Z300 E10000) in mm/sec

M204 - Set default acceleration: S normal moves T filament only moves (M204 S3000 T7000) im mm/sec^2 also sets minimum segment time in ms (B20000) to prevent buffer underruns and M20 minimum feedrate

M205 - advanced settings: minimum travel speed S=while printing T=travel only, B=minimum segment time X= maximum xy jerk, Z=maximum Z jerk, E=maximum E jerk

?

...and what can we get with @zelogics setup ?

Good to see you making progress...

(I wouldn't mind more pictures (and a small video ;-) but ):

Correct me I believe that with a CoreX-Y and Repetier

just 1 single Endswitch is OK which

Zelogic shows on

[i.imgur.com]

(mechanical back left in my coordinate system )

BTW: Completely unexpected but I made good progress on

my long overdue StarLinearMotionGuideItemProfilePortal-Printer ...

(think Felix ... I dont want to hijack the thread)

How do you guys measure speed?

just what the printer (i.e. Marlin) tells Pronterface:

M201 - Set max acceleration in units/s^2 for print moves (M201 X1000 Y1000)

M203 - Set maximum feedrate that your machine can sustain (M203 X200 Y200 Z300 E10000) in mm/sec

M204 - Set default acceleration: S normal moves T filament only moves (M204 S3000 T7000) im mm/sec^2 also sets minimum segment time in ms (B20000) to prevent buffer underruns and M20 minimum feedrate

M205 - advanced settings: minimum travel speed S=while printing T=travel only, B=minimum segment time X= maximum xy jerk, Z=maximum Z jerk, E=maximum E jerk

?

...and what can we get with @zelogics setup ?

|

Re: Atfer Hbot, go to CoreXY. March 27, 2014 03:07PM |

Registered: 11 years ago Posts: 225 |

Hello!!

Sorry, to don't have put somes photos here, the project is not dead at all.

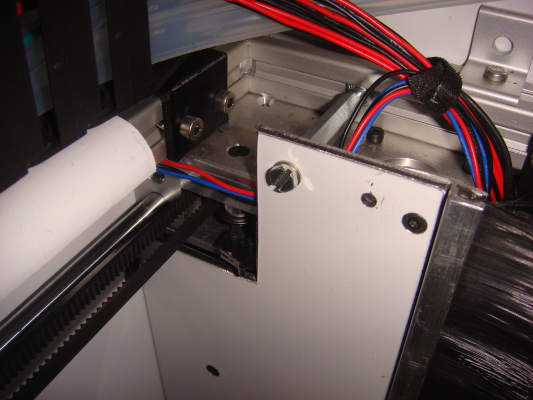

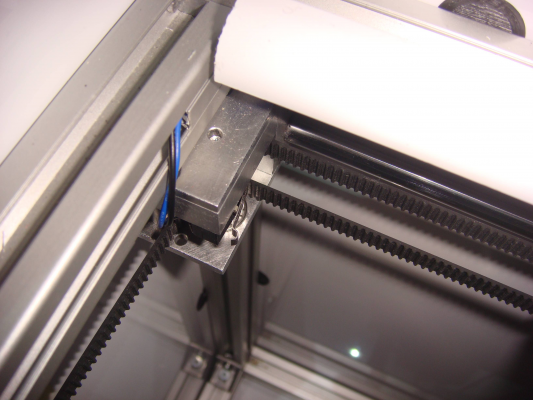

It's Y+ axis:

Y- Axis:

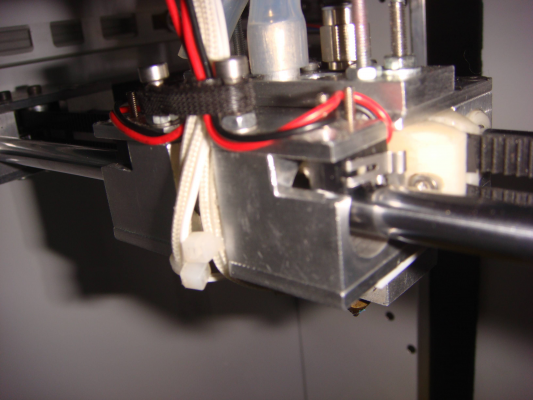

X- and X+ axis on the carriage head,

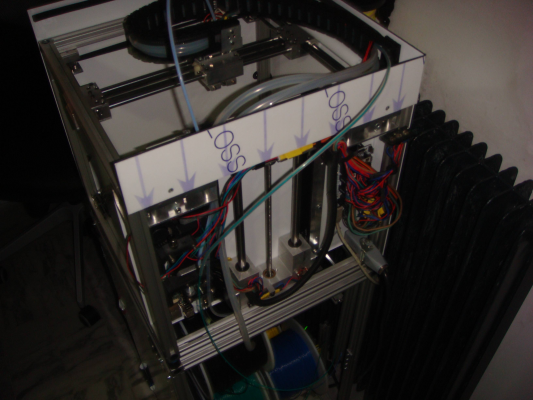

The back need some "cleaning" and rewiring

And that printer need some "finish" to be more professional, but the really cheap chinese chain cable are really nice.

And yes the dual nozzle is ready and alive and really easy to use/calibrate height. :-D

I have 2 sheet of 390x390 lexan/polycarbonate and 3D printed hinge for complete enclosure, byebye warping and fume.

I just waiting for PTFE tubing ... older are too short with the new cable chain holder, and what I have on my spare was a little less than ID:2mm diameter and not good...

ie:Yes I know, the glass with kapton is not beautiful and have crack...

Sorry, to don't have put somes photos here, the project is not dead at all.

It's Y+ axis:

Y- Axis:

X- and X+ axis on the carriage head,

The back need some "cleaning" and rewiring

And that printer need some "finish" to be more professional, but the really cheap chinese chain cable are really nice.

And yes the dual nozzle is ready and alive and really easy to use/calibrate height. :-D

I have 2 sheet of 390x390 lexan/polycarbonate and 3D printed hinge for complete enclosure, byebye warping and fume.

I just waiting for PTFE tubing ... older are too short with the new cable chain holder, and what I have on my spare was a little less than ID:2mm diameter and not good...

ie:Yes I know, the glass with kapton is not beautiful and have crack...

|

Re: Atfer Hbot, go to CoreXY. March 27, 2014 03:52PM |

Registered: 12 years ago Posts: 809 |

Very nice.

Inspired by your success I am working on finishing the model of a corexy variant based on openrail.

imgur

The horizontal extrusion lengths in the drawing are 600mm,and the pillars are a full meter tall. I'm planning on paring that down to 500mm horizontals and 750mm pillars. This should provide a build volume of about 300x300x~500.

I'm still playing with the X-axis and carriage, but inching toward completion.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

Inspired by your success I am working on finishing the model of a corexy variant based on openrail.

imgur

The horizontal extrusion lengths in the drawing are 600mm,and the pillars are a full meter tall. I'm planning on paring that down to 500mm horizontals and 750mm pillars. This should provide a build volume of about 300x300x~500.

I'm still playing with the X-axis and carriage, but inching toward completion.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Atfer Hbot, go to CoreXY. March 27, 2014 05:48PM |

Registered: 12 years ago Posts: 199 |

I made a few pictures pictures and put them on my google drive here

And a video of a first test.

[youtu.be]

See attachment for actual gcode used.

The pattern repeats at increasing speed: 6000, 12000, 18000, 24000, 30000 mm/min ( 100, 200, 300, 400 and 500 mm/s)

I limited the max feed rate at 300 mm/s in firmware.

It's time to build the Z-stage, unfortunately I have to wait for the LM12UU bearings, which hopefully next week will arrive.

And a video of a first test.

[youtu.be]

See attachment for actual gcode used.

The pattern repeats at increasing speed: 6000, 12000, 18000, 24000, 30000 mm/min ( 100, 200, 300, 400 and 500 mm/s)

I limited the max feed rate at 300 mm/s in firmware.

It's time to build the Z-stage, unfortunately I have to wait for the LM12UU bearings, which hopefully next week will arrive.

|

Re: Atfer Hbot, go to CoreXY. March 27, 2014 06:08PM |

Registered: 11 years ago Posts: 250 |

You guys rock!

Nice speeds! Can you go any faster?

- If firmware is limited to 300mm/s that was the fastest speed

Couple questions for yea:

What are the acceleration rates you have set?

Are your plastic parts the current ones in the GITHUB?

Do you have a BOM?

How long is each belt?

How many teeth on the pulleys?

I've started to order parts for my own build!

Edited 1 time(s). Last edit at 03/27/2014 06:08PM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Nice speeds! Can you go any faster?

- If firmware is limited to 300mm/s that was the fastest speed

Couple questions for yea:

What are the acceleration rates you have set?

Are your plastic parts the current ones in the GITHUB?

Do you have a BOM?

How long is each belt?

How many teeth on the pulleys?

I've started to order parts for my own build!

Edited 1 time(s). Last edit at 03/27/2014 06:08PM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Atfer Hbot, go to CoreXY. March 27, 2014 06:47PM |

Registered: 10 years ago Posts: 71 |

@zelogik:

If you add a video to all your pics, I'll "award" you a (german) beer

(over easter I'm vacationing in port grimaud for almost a decade now )

)

... but you have to tell us about "really cheap chinese chain cable" WHERE ???

Greeeeaaaat Jan !!!

...if you need help with the LM12UU's send me a PM

If you add a video to all your pics, I'll "award" you a (german) beer

(over easter I'm vacationing in port grimaud for almost a decade now

)

)... but you have to tell us about "really cheap chinese chain cable" WHERE ???

Quote

jand

I made a few pictures pictures and put them on my google drive....

Greeeeaaaat Jan !!!

...if you need help with the LM12UU's send me a PM

|

Re: Atfer Hbot, go to CoreXY. March 28, 2014 03:35AM |

Registered: 12 years ago Posts: 199 |

>> What are the acceleration rates you have set?

I used 9000 mm/s2

>> Are your plastic parts the current ones in the GITHUB?

No the plastic parts are not in the github. In the github are zelogic’s original metal parts. I did not release them yet. The XY part and the frame seems to be OK, but the Z-stage has not yet been verified in real hardware.

So I could release them now, but it’s not yet finished. If enough people are interested to have a look at the CAD files as they are now I might publish it this weekend. But I would not recommend to start your printer already.

>> Do you have a BOM?

I did not make a BOM yet, I think it only makes sense if you have a complete BOM.

>> How long is each belt?

Just under 2m each.

>> How many teeth on the pulleys?

I used 20 teeth pulleys.

I used 9000 mm/s2

>> Are your plastic parts the current ones in the GITHUB?

No the plastic parts are not in the github. In the github are zelogic’s original metal parts. I did not release them yet. The XY part and the frame seems to be OK, but the Z-stage has not yet been verified in real hardware.

So I could release them now, but it’s not yet finished. If enough people are interested to have a look at the CAD files as they are now I might publish it this weekend. But I would not recommend to start your printer already.

>> Do you have a BOM?

I did not make a BOM yet, I think it only makes sense if you have a complete BOM.

>> How long is each belt?

Just under 2m each.

>> How many teeth on the pulleys?

I used 20 teeth pulleys.

|

Re: Atfer Hbot, go to CoreXY. March 28, 2014 09:53AM |

Registered: 11 years ago Posts: 290 |

|

Re: Atfer Hbot, go to CoreXY. March 28, 2014 12:18PM |

Registered: 12 years ago Posts: 199 |

Maybe it is a good idea to publish it already now. All parts are desinged to use M4 screws to attach the plastic to the extrusions, so when you order T-nuts make sure they are M4. And make sure you get the ones that can be installed afterwards. This makes life a lot easier.

I will try to make the files publishable this weekend an make a preliminary BOM.

I will try to make the files publishable this weekend an make a preliminary BOM.

|

Re: Atfer Hbot, go to CoreXY. March 28, 2014 03:18PM |

Registered: 11 years ago Posts: 250 |

I have to use a cheaper solution for the framing... I can't afford the fancy extrusions.

I can however use the plastic parts you guys have and adapt it to an MDF frame.

My current Mendel90 is MDF and its 'good enough' and 'rigid enough' for the use.

I'll be using 12mm drill rod and LM12UU bearings.

I'm most curious to how you guys are going to work the Z axis.

I really don't like the cantilever design.

I do however prefer this kind of design used here:

[www.youtube.com]

Thoughts?

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

I can however use the plastic parts you guys have and adapt it to an MDF frame.

My current Mendel90 is MDF and its 'good enough' and 'rigid enough' for the use.

I'll be using 12mm drill rod and LM12UU bearings.

I'm most curious to how you guys are going to work the Z axis.

I really don't like the cantilever design.

I do however prefer this kind of design used here:

[www.youtube.com]

Thoughts?

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Atfer Hbot, go to CoreXY. March 28, 2014 03:31PM |

Registered: 12 years ago Posts: 809 |

Have you ordered from misumi before? If not they have a deal going on now - First $150 of your order is free. You pay shipping.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Atfer Hbot, go to CoreXY. March 28, 2014 03:36PM |

Registered: 11 years ago Posts: 250 |

You need a company for the deal.Quote

akhlut

Have you ordered from misumi before? If not they have a deal going on now - First $150 of your order is free. You pay shipping.

I'm just me

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Atfer Hbot, go to CoreXY. March 28, 2014 03:59PM |

Registered: 12 years ago Posts: 809 |

Nope. An individual can get in on the deal.

This thread has a ton of info:

[www.shapeoko.com]

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

This thread has a ton of info:

[www.shapeoko.com]

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Atfer Hbot, go to CoreXY. March 28, 2014 06:41PM |

Registered: 12 years ago Posts: 199 |

@mogal: I am not sure how you will be able to make a frame from MDF that is rigit enough and easy adaptable to the printed corner parts.

And I don't see why you want to use 12 mm rods, unless you want to scale it up really big. You will have a problem here, because the distance between the X-axis rods is 40mm. The size of an LM12UU is 21 mm, so this does not leave much space for the hotend in the carriage. With 8mm rod it's already a tight fit.

I don't know where you are from, but you can get aluminium extrusions for €3/m cut to size in Germany, that is 16x360mm = €17.25 for the complete frame. A bag of 100 T-slot nuts is €18.

And I don't see why you want to use 12 mm rods, unless you want to scale it up really big. You will have a problem here, because the distance between the X-axis rods is 40mm. The size of an LM12UU is 21 mm, so this does not leave much space for the hotend in the carriage. With 8mm rod it's already a tight fit.

I don't know where you are from, but you can get aluminium extrusions for €3/m cut to size in Germany, that is 16x360mm = €17.25 for the complete frame. A bag of 100 T-slot nuts is €18.

Sorry, only registered users may post in this forum.