Atfer Hbot, go to CoreXY.

Posted by zelogik

|

Re: Atfer Hbot, go to CoreXY. June 09, 2014 09:39PM |

Registered: 11 years ago Posts: 47 |

Thanks cnc dick. I'm thinking of changing to 1.75 mm filament anyway...

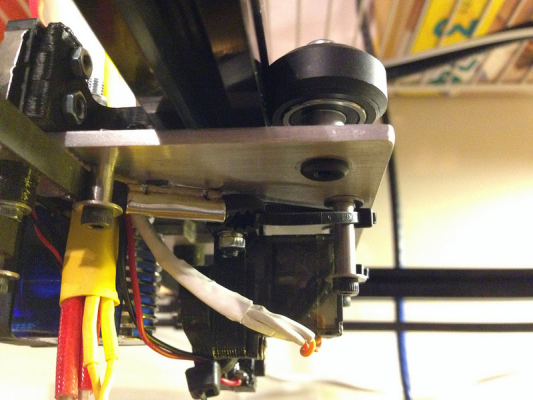

Dejay, my extrusions are 500 mm long so I'm not sure how something 1m or longer will behave. As for a tensioner, here is mine. A very sophisticated cable tie.

Dejay, my extrusions are 500 mm long so I'm not sure how something 1m or longer will behave. As for a tensioner, here is mine. A very sophisticated cable tie.

|

Re: Atfer Hbot, go to CoreXY. June 10, 2014 03:05PM |

Registered: 11 years ago Posts: 225 |

|

Re: Atfer Hbot, go to CoreXY. June 10, 2014 03:36PM |

Registered: 12 years ago Posts: 199 |

|

Re: Atfer Hbot, go to CoreXY. June 10, 2014 05:08PM |

Registered: 10 years ago Posts: 71 |

Quote

zelogik

I have put a droplet of oil on the rod and MAGIC !!! no more backlash

_ _ _ _

__ ___ _ _ __ _ _ _ __ _| |_ _ _| |__ _| |_(_)___ _ _ ___

/ _/ _ \ ' \/ _` | '_/ _` | _| || | / _` | _| / _ \ ' \(_-<

\__\___/_||_\__, |_| \__,_|\__|\_,_|_\__,_|\__|_\___/_||_/__/

|___/

Fairy-oil-recipesRegards

Reinhold

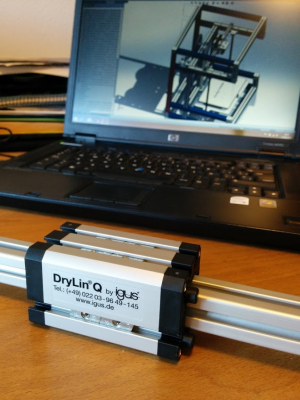

... "iglidur® polymer bearings - No lubrication required - igus.de - Reduce cost. Increase life."

|

Re: Atfer Hbot, go to CoreXY. June 10, 2014 06:30PM |

Registered: 9 years ago Posts: 210 |

Quote

zelogik

I have put a droplet of oil on the rod and MAGIC !!! no more backlashIt's was a stick-slip problem.

You think the igus bushing was squished too tight or regularly by the printed enclosure?

Would it be better to always use the aluminium encased igus bushings?

Thanks and sorry for derailing your thread a bit

|

Re: Atfer Hbot, go to CoreXY. June 11, 2014 06:55AM |

Registered: 9 years ago Posts: 24 |

I have a Prusa i3 and I also had put some PFTE oil on X carriage Igus RJMP-08 and it slide much better than oil-less. You're right about its too tight.

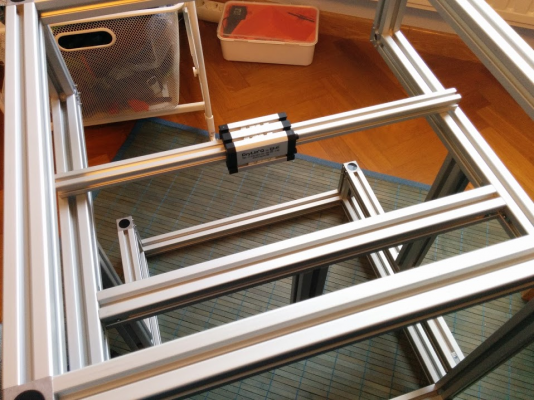

I'm designing a CoreXY motion 3DPrinter, learning from all of your post reading (so much info!). I will put Igus miniature linear motion slides on X and Y axis. This week i'll begin with the extrusion aluminium chassis.

I will upload some photos when it be done.

(I know, my english suck... Sorry).

I'm designing a CoreXY motion 3DPrinter, learning from all of your post reading (so much info!). I will put Igus miniature linear motion slides on X and Y axis. This week i'll begin with the extrusion aluminium chassis.

I will upload some photos when it be done.

(I know, my english suck... Sorry).

|

Re: Atfer Hbot, go to CoreXY. June 11, 2014 03:35PM |

Registered: 10 years ago Posts: 71 |

Quote

marcossf

(corexy) I will upload some photos when it be done..

YES Marcos please do ...if you have enough material open a new thread ... and let us know where we find it.

.

Don't worry! - We are here to reprap, not to give "grades for english (american)?"Quote

(I know, my english suck... Sorry).

...but if you need your grade: "you sound perfectly understandable to me - I want to read more of that!!!"

Regards

Reinhold

Edited 1 time(s). Last edit at 06/11/2014 03:36PM by Reinhold.

|

Re: Atfer Hbot, go to CoreXY. June 11, 2014 04:11PM |

Registered: 12 years ago Posts: 809 |

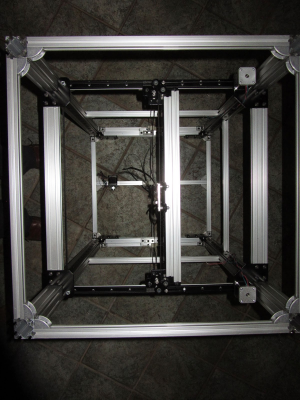

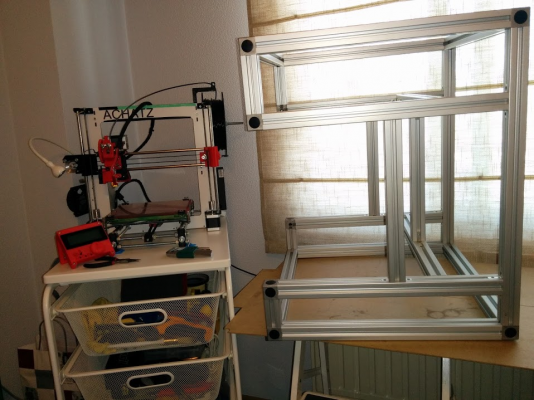

Waiting on parts is torture.

XY stage is done.

Need parts to finalize Z.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

XY stage is done.

Need parts to finalize Z.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Atfer Hbot, go to CoreXY. June 11, 2014 04:52PM |

Registered: 9 years ago Posts: 210 |

Hey, looks cool!

What did you use for the linear motion rail for the wheel? Where do I get it?

What is the size of the frame? Looks like 50cm

What extrusions did you use?

I was thinking of using 30x30 of 40x40 T-Slot extrusions from motendis for a large frame and make the CoreXY carriage from V-Slot. But using a linear rail is probably better and cheaper.

BTW, is there a subforum for CoreXY / HBot / XY printers? Or printers that move the print bed in Z and the print head in XY?

What did you use for the linear motion rail for the wheel? Where do I get it?

What is the size of the frame? Looks like 50cm

What extrusions did you use?

I was thinking of using 30x30 of 40x40 T-Slot extrusions from motendis for a large frame and make the CoreXY carriage from V-Slot. But using a linear rail is probably better and cheaper.

BTW, is there a subforum for CoreXY / HBot / XY printers? Or printers that move the print bed in Z and the print head in XY?

|

Re: Atfer Hbot, go to CoreXY. June 11, 2014 06:47PM |

Registered: 12 years ago Posts: 809 |

Everything is from either:

misumi (extrusions)

openbuilds (wheels, openrail)

inventables (aluminum spacers)

mcmaster (hardware)

robotdigg (timing pulleys, idlers, gt2 belt, bearings)

sparkfun (stepper motors)

sdp-si (100T timing pulley, timing belt)

Only the bearing blocks are printed. Everything else is milled out of aluminum.

Not a reprap in any way, shape or form.

Before you buy anything model it. This is iteration 23 of the cad model, and those individual components are not the original geometries either.

The frame risers are HFS5-4040-1000 and the members are HFS5-2020-500. Build envelope (estimate) is 350x350x500.

openbuilds v-slot is very nice, and is a lot easier to design around that the openrail I used.

try these links for corexy:

[groups.google.com]

[plus.google.com]

And search 'core xy' on Google+

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

misumi (extrusions)

openbuilds (wheels, openrail)

inventables (aluminum spacers)

mcmaster (hardware)

robotdigg (timing pulleys, idlers, gt2 belt, bearings)

sparkfun (stepper motors)

sdp-si (100T timing pulley, timing belt)

Only the bearing blocks are printed. Everything else is milled out of aluminum.

Not a reprap in any way, shape or form.

Before you buy anything model it. This is iteration 23 of the cad model, and those individual components are not the original geometries either.

The frame risers are HFS5-4040-1000 and the members are HFS5-2020-500. Build envelope (estimate) is 350x350x500.

openbuilds v-slot is very nice, and is a lot easier to design around that the openrail I used.

try these links for corexy:

[groups.google.com]

[plus.google.com]

And search 'core xy' on Google+

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Atfer Hbot, go to CoreXY. June 13, 2014 02:20PM |

Registered: 9 years ago Posts: 24 |

Quote

Reinhold

YES Marcos please do ...if you have enough material open a new thread ... and let us know where we find it.

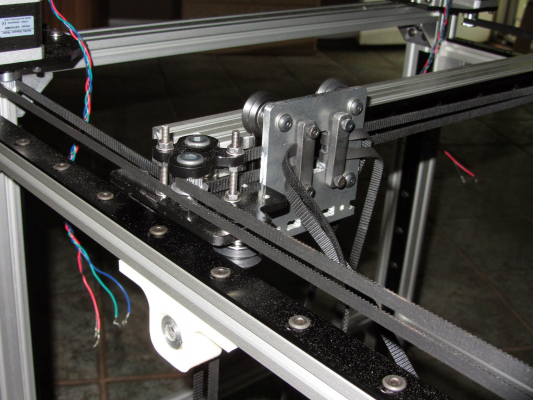

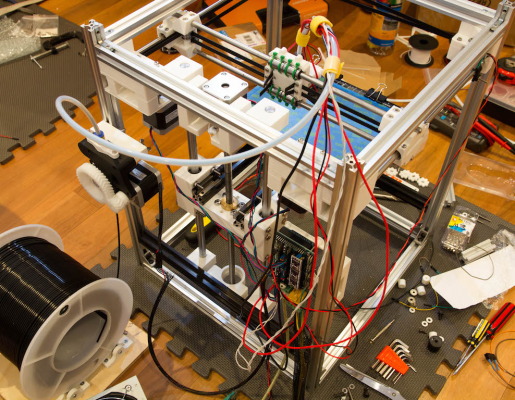

My design are on early stage, I just begin to build the chasis.

Next will be the Igus linear motion rails for Y and Z that I'm waiting for. And it's so much to do then (probably redesign/adapt the parts accuratelly to movements and gaps).

Here are some photos:

Sorry Jand and Zelogik for the off topic invasion

I will open a new topic when my corexy be more visible.

I will open a new topic when my corexy be more visible.Thank you all

|

Re: Atfer Hbot, go to CoreXY. June 20, 2014 11:15AM |

Registered: 9 years ago Posts: 3 |

Hi, Im going to build one of this brilliant printer.

I come from clone wars in Spain. I built a prusa i3 and now I want to improve and I decided to build this awesome printer.

I wanna ask you jang if I must increase the Z axis threated rod of your design 8mm to 10mm.

And if i do that, could you modifiqued the pieces please? I'm not familiar with CAD model and second, what bearing I must use in that case. I supposed 6010, no?

Thank's for all I love your design and I bought profile (98€ all with nuts and squares) and electronic.

I come from clone wars in Spain. I built a prusa i3 and now I want to improve and I decided to build this awesome printer.

I wanna ask you jang if I must increase the Z axis threated rod of your design 8mm to 10mm.

And if i do that, could you modifiqued the pieces please? I'm not familiar with CAD model and second, what bearing I must use in that case. I supposed 6010, no?

Thank's for all I love your design and I bought profile (98€ all with nuts and squares) and electronic.

|

Re: Atfer Hbot, go to CoreXY. June 20, 2014 11:59AM |

Registered: 9 years ago Posts: 210 |

Hey Marcossf, that frame looks pretty cool. How is that drylin Q carriage working out? It's pretty expensive on motedis.com, is there cheaper sources for something like that?

I'm been thinking about making a modified version of Johann's linear motion carriage with recirculating delrin / acetal spheres, so that it encapsulates a standard extrusion. The spheres would cost about 3$ for 100 and you would need 80 for four recirculating paths. That would even be cheaper than 4 or 6 wheels per extrusion. It should be reasonably precise as long as the main path where the spheres roll along is precise.

I'm been thinking about making a modified version of Johann's linear motion carriage with recirculating delrin / acetal spheres, so that it encapsulates a standard extrusion. The spheres would cost about 3$ for 100 and you would need 80 for four recirculating paths. That would even be cheaper than 4 or 6 wheels per extrusion. It should be reasonably precise as long as the main path where the spheres roll along is precise.

|

Re: Atfer Hbot, go to CoreXY. June 20, 2014 01:34PM |

Registered: 9 years ago Posts: 24 |

Quote

Dejay

Hey Marcossf, that frame looks pretty cool. How is that drylin Q carriage working out? It's pretty expensive on motedis.com, is there cheaper sources for something like that?

I'm been thinking about making a modified version of Johann's linear motion carriage with recirculating delrin / acetal spheres, so that it encapsulates a standard extrusion. The spheres would cost about 3$ for 100 and you would need 80 for four recirculating paths. That would even be cheaper than 4 or 6 wheels per extrusion. It should be reasonably precise as long as the main path where the spheres roll along is precise.

The drylin Q act as X-Carriage. It support 2 hotends E3D v6 in front face (upgradeable to direct extruder), on top face the bowden tubes, chain guide and cable quick connectors. On back, the CoreXY belt retainers, layer fan duct support and the autolevel system. Down it is a led light.

On Y-axis will be 2 Drylin NK27, and Drylin W + 2 leads screw on Z-Axis. All bought directly to Igus.

It isn't cheap at all, but it will be robust and reliable. All printed parts will be done on aluminium CNC, I think that not be called reprap anymore.

Pando855: Yo tambien soy de España

|

Re: Atfer Hbot, go to CoreXY. June 20, 2014 04:28PM |

Registered: 10 years ago Posts: 71 |

Why would you want to use an M10 threaded rod ? (instead of M8)Quote

pando855

M8 to M10

M10 would make z-resolution a lot worse and even an M6 rod (1mm/turn) can carry the load we expect here (no will, I'm using one)

(M6 1mm/turn M8 1.25mm/turn M10 1.5mm/turn)

The bearing Jand specifies is 608 ZZ (2Z) with (8x22x7 mm), it can carry 960N static and 2.4kN dynamic !

If you want something "better" use M6 or an Acme screw (tornillo Acme, Trapezgewindespindel) or a ball screw (tornillo de la bola, Kugelumlaufspindel)

... if I remember correctly jand was even proposing something like that somewhere.

In all cases you would need CAD redesign of around 5-6 parts of his z-stage...

Edited 2 time(s). Last edit at 06/20/2014 04:48PM by Reinhold.

|

Re: Atfer Hbot, go to CoreXY. June 20, 2014 05:54PM |

Registered: 12 years ago Posts: 199 |

I think you are right Reinhold, it does not make sense to increase the size of the threaded rod. A lot of work to redesign the z-axis parts and for what reson? Redesigning for M6 whould easier.

Why do you want to change the size of the threaded rod pando855?

Edited 2 time(s). Last edit at 06/20/2014 05:57PM by jand.

Why do you want to change the size of the threaded rod pando855?

Edited 2 time(s). Last edit at 06/20/2014 05:57PM by jand.

|

Re: Atfer Hbot, go to CoreXY. June 20, 2014 07:20PM |

Registered: 9 years ago Posts: 3 |

|

Re: Atfer Hbot, go to CoreXY. June 21, 2014 04:37AM |

Registered: 12 years ago Posts: 199 |

|

Re: Atfer Hbot, go to CoreXY. June 28, 2014 09:28PM |

Registered: 9 years ago Posts: 210 |

Quote

Reinhold

- tap a M8 thread into the "extrusion center hole" (of one of the 2 short extrusion pieces)

Just a quick note on this, probably everyone already knows this but I just found this and it looks mighty practical:

There are drills with included tap that seems to work very fast and you can use it with any kind of handheld drill. I linked the video just to show what I mean, I don't mean to recommend them. In german it's called "kombi gewindebohrer" and an M8 drill tap can be had for under 10€.

|

Re: Atfer Hbot, go to CoreXY. June 30, 2014 07:28AM |

Registered: 9 years ago Posts: 24 |

Quote

nhathaitrieu6

Hi zelogik and jand, is there any reason why the motor mount cannot be direct? What I mean is, remove the 2 idler pulleys in the motor block, and the 90degree bend from motor block to XY block. I have attached a picture to make it clearer.

It is that way because it need to have a tensioner idler on each belt (must to be the same tension on each one).

|

Re: Atfer Hbot, go to CoreXY. July 02, 2014 04:38PM |

Registered: 11 years ago Posts: 112 |

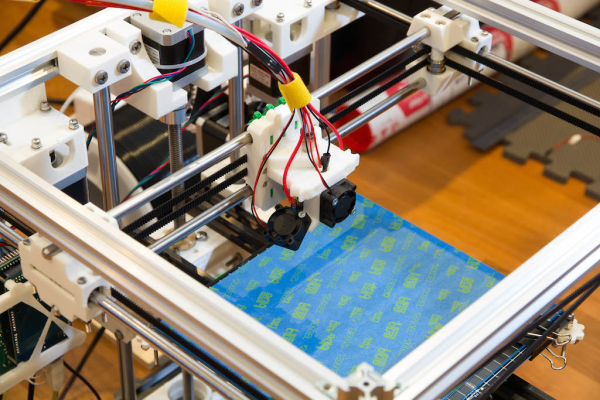

Thanks to the very nice parts design Zelogic and jand did share on this topic.

I am at the completion stage on my machine.

What I can say allready is the bed système is very stiff, the CoreXY part doest take lot of space, and I am going to be abble to print full size object I scan.

The conception is high level.

Edited 1 time(s). Last edit at 07/04/2014 02:53PM by ybm.

I am at the completion stage on my machine.

What I can say allready is the bed système is very stiff, the CoreXY part doest take lot of space, and I am going to be abble to print full size object I scan.

The conception is high level.

Edited 1 time(s). Last edit at 07/04/2014 02:53PM by ybm.

|

Re: Atfer Hbot, go to CoreXY. July 05, 2014 04:41AM |

Registered: 10 years ago Posts: 341 |

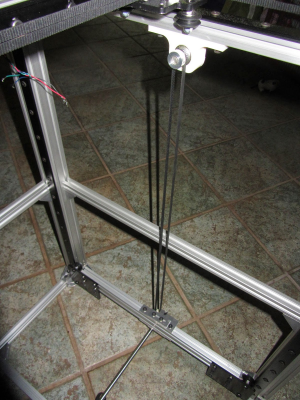

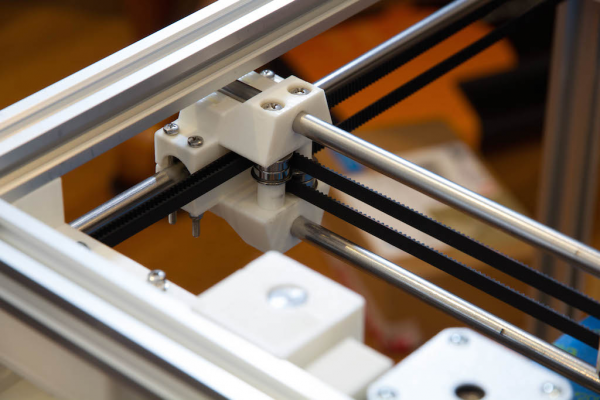

Another zelogik/jand based printer. Almost complete, still waiting for a few bits and pieces to turn up, but initial prints are looking very good.

Using a vertical x-axis, and also a tr10x2 leadscrew

Using a vertical x-axis, and also a tr10x2 leadscrew

|

Re: Atfer Hbot, go to CoreXY. July 11, 2014 01:16PM |

Registered: 9 years ago Posts: 24 |

One question to all of you

Where to buy shoulder screws (4mm and 5mm shoulder diameter and 25 mm shoulder long)?? I was unable to find everywhere and also its hard to find on internet.

Where to buy shoulder screws (4mm and 5mm shoulder diameter and 25 mm shoulder long)?? I was unable to find everywhere and also its hard to find on internet.

|

Re: Atfer Hbot, go to CoreXY. July 12, 2014 05:54PM |

Registered: 12 years ago Posts: 809 |

Quote

marcossf

One question to all of you

Where to buy shoulder screws (4mm and 5mm shoulder diameter and 25 mm shoulder long)?? I was unable to find everywhere and also its hard to find on internet.

Misumi or mcmaster

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Atfer Hbot, go to CoreXY. July 14, 2014 11:32AM |

Registered: 11 years ago Posts: 112 |

I live in Europe, in France more exactly and I found some in this shop Vis à épaulement

|

Re: Atfer Hbot, go to CoreXY. July 17, 2014 08:03AM |

Registered: 9 years ago Posts: 24 |

akhlut: Misumi europe only sell to bussines not individuals and their UPS charge its mindblowing. Mcmaster its at USA, and here in Spain it will be charged for importing fee (so much!).

ybm: The french page doesn't have on 4 and 5mm shoulder diameter. The lesser its 6 mm.

I'll keep going searching.

Thank you two.

ybm: The french page doesn't have on 4 and 5mm shoulder diameter. The lesser its 6 mm.

I'll keep going searching.

Thank you two.

|

Re: Atfer Hbot, go to CoreXY. July 22, 2014 06:08PM |

Registered: 10 years ago Posts: 14 |

Hi there,

Thought I would add to the list of people building one of these.

I'm reusing 300mm extrusion I had left over from a failed build, and have printed some corner brackets instead of using expensive mounting hardware.

I'm still waiting for my F624 bearings to arrive from China. Because of my shortened aluminium lengths I am going to have to redesign the z-stage, and was thinking of going down the belt route. Has anyone used a pulley system to increase the resolution of a belted z-stage?

Best Wishes

Conoral11

Thought I would add to the list of people building one of these.

I'm reusing 300mm extrusion I had left over from a failed build, and have printed some corner brackets instead of using expensive mounting hardware.

I'm still waiting for my F624 bearings to arrive from China. Because of my shortened aluminium lengths I am going to have to redesign the z-stage, and was thinking of going down the belt route. Has anyone used a pulley system to increase the resolution of a belted z-stage?

Best Wishes

Conoral11

|

Re: Atfer Hbot, go to CoreXY. July 23, 2014 07:15AM |

Registered: 12 years ago Posts: 199 |

This is great , I come back from hollidays and see a few people building printers. Keep up the good work

@Conoral11: Maybe look around in the Ingentis and Eustathios Builders Community. (Google+ group) You may get some Ideas for a Z-Axis there. I think Ingentis has belt Z-axis.

@sdavi Nice Vertical X-axis you made , What X and Y ranges do you get with it? I guess X will be more or less the same.

, What X and Y ranges do you get with it? I guess X will be more or less the same.

This reminds me I should make the Z-motor mounts a little smaller. That would give us a few extra milliliters in Y direction.

@ybm: you mention the stiffness of the Z-system. I had some doubts at the beginning about the cantilever system, but I can also confirm the stiffness of the Z-axis. I am very pleased with it.

I can't see it in your picture, but did you use my parts for the Z-axis or did you modify them?

@Conoral11: Maybe look around in the Ingentis and Eustathios Builders Community. (Google+ group) You may get some Ideas for a Z-Axis there. I think Ingentis has belt Z-axis.

@sdavi Nice Vertical X-axis you made

, What X and Y ranges do you get with it? I guess X will be more or less the same.

, What X and Y ranges do you get with it? I guess X will be more or less the same.This reminds me I should make the Z-motor mounts a little smaller. That would give us a few extra milliliters in Y direction.

@ybm: you mention the stiffness of the Z-system. I had some doubts at the beginning about the cantilever system, but I can also confirm the stiffness of the Z-axis. I am very pleased with it.

I can't see it in your picture, but did you use my parts for the Z-axis or did you modify them?

|

Re: Atfer Hbot, go to CoreXY. July 23, 2014 09:10AM |

Registered: 10 years ago Posts: 341 |

@jand - yeah X and Y are about the same, i get the full 200x200, with about 50mm spare X. I'm currently making a dual hotend mount so that extra space should hopefully be just about right. I did loose a little height on the Z, but its 196mm which was about the same as i had with my prusa i3 anyway.

I was also initially hesitant building a cantilever Z axis but i am happy with it. It doesn't bounce or anything during a print and I'm getting some great prints off it.

I've also uploaded all my files onto Github in case anyone is interested.

I was also initially hesitant building a cantilever Z axis but i am happy with it. It doesn't bounce or anything during a print and I'm getting some great prints off it.

I've also uploaded all my files onto Github in case anyone is interested.

|

Re: Atfer Hbot, go to CoreXY. July 23, 2014 05:12PM |

Registered: 11 years ago Posts: 112 |

Sorry, only registered users may post in this forum.