Atfer Hbot, go to CoreXY.

Posted by zelogik

|

Re: Atfer Hbot, go to CoreXY. February 04, 2014 07:26AM |

Registered: 10 years ago Posts: 3 |

Hi,

Your printer looks really good.

I'm currently designing my own CoreXY printer. With printed parts, a slightly bigger build volume and a direct drive extruder. Now I need some help with the rod diameter.

My X-axis rods will be 440mm long and 8mm in diameter. The X-carriage with extruder will weigh about 600g. Do you think 8mm rods will do the job, or would it be better to change to 10mm.

I hope you can help me with this issue.

Edited 1 time(s). Last edit at 02/04/2014 07:27AM by mls.

Your printer looks really good.

I'm currently designing my own CoreXY printer. With printed parts, a slightly bigger build volume and a direct drive extruder. Now I need some help with the rod diameter.

My X-axis rods will be 440mm long and 8mm in diameter. The X-carriage with extruder will weigh about 600g. Do you think 8mm rods will do the job, or would it be better to change to 10mm.

I hope you can help me with this issue.

Edited 1 time(s). Last edit at 02/04/2014 07:27AM by mls.

|

Re: Atfer Hbot, go to CoreXY. February 04, 2014 09:38AM |

Registered: 11 years ago Posts: 225 |

@mls: Do you realize/make your printer with my drawing? or it's completely your own design?

I asking you that question only because, the drawing I have done, don't constraint the rod (the minimum possible), I have seen many concepts of corexy or hbot (maybe all I have seen so far) with overhang or cantilevered constrains on all axis or on Yaxis or Xaxis between belt and rod axis.

Maybe if you can, It's more smart to reduce the length of X-axis(moving axis) and keep 8mm rod, and lengthen the Y-axis (not moving axis) and put 10 or 12mm rod. If you don't care to have a square print area.

After that, I was able to drive my carriage at 9000mm/s² and 350mm speed with direct drive extruder without loosing any steps. I don't have printed with that configuration, but I thing this config have many damping problems (wave at corner after change of direction) at that speed. the X-axis carriage was 1kg with the extruder motor.

I asking you that question only because, the drawing I have done, don't constraint the rod (the minimum possible), I have seen many concepts of corexy or hbot (maybe all I have seen so far) with overhang or cantilevered constrains on all axis or on Yaxis or Xaxis between belt and rod axis.

Maybe if you can, It's more smart to reduce the length of X-axis(moving axis) and keep 8mm rod, and lengthen the Y-axis (not moving axis) and put 10 or 12mm rod. If you don't care to have a square print area.

After that, I was able to drive my carriage at 9000mm/s² and 350mm speed with direct drive extruder without loosing any steps. I don't have printed with that configuration, but I thing this config have many damping problems (wave at corner after change of direction) at that speed. the X-axis carriage was 1kg with the extruder motor.

|

Re: Atfer Hbot, go to CoreXY. February 04, 2014 03:14PM |

Registered: 10 years ago Posts: 38 |

Quote

zelogik

@Newkidontheblock: So have so much question, that only you can response with your experience and calculation etc...

The more easy to you is to draw your project/frame on inventor/solidworks/cao program and simulate deformations, moments, constraints.

For the shaking, it's because I have put too soft vibration dampener for the foot, and it's the complete "tower" that shake.

Thank you Zelogik for all your assistance and input.

Did the shaking of the complete tower affect the quality of your prints?

|

Re: Atfer Hbot, go to CoreXY. February 04, 2014 05:41PM |

Registered: 10 years ago Posts: 3 |

@zelogik

It's my own design. I'm working on it for some time now and hopefully I can start building the first prototype next month.

I think I'll try to shorten the X-axis. When I rotate my printbed and reduce size of the X-carriage I could save about 7-8cm. With this changes I would have a total length of 360mm, which is hopefully short enough for 8mm rods.

On the Y-axis I allready have 10mm rods.

Have you allready tested how fast you can go while printing?

It's my own design. I'm working on it for some time now and hopefully I can start building the first prototype next month.

I think I'll try to shorten the X-axis. When I rotate my printbed and reduce size of the X-carriage I could save about 7-8cm. With this changes I would have a total length of 360mm, which is hopefully short enough for 8mm rods.

On the Y-axis I allready have 10mm rods.

Have you allready tested how fast you can go while printing?

|

Re: Atfer Hbot, go to CoreXY. February 05, 2014 05:57PM |

Registered: 10 years ago Posts: 38 |

|

Re: Atfer Hbot, go to CoreXY. February 12, 2014 01:34AM |

Registered: 11 years ago Posts: 290 |

This is excellent printer. I like it. I have 12 40-cm pieces of T-Slot Alu Profile just laying around. So leaning toward to build similar printer using them. Same problem is no milling machine access. probably waiting for printed version. Been watching this thread. Any further update?

What short of connector/bracket do you use to connect the 3-way in the corners?

What short of connector/bracket do you use to connect the 3-way in the corners?

|

Re: Atfer Hbot, go to CoreXY. February 12, 2014 01:44AM |

Registered: 11 years ago Posts: 225 |

@mls: Can go until 150mm/s with 0.35mm nozzle and 0.12/0.14 layer height without problems.

@NewkidOntheBlock: Corexy -> simple cartesians system, Delta printer, nice to see moving, but waiting to see non-artistic print without artifact on straight line.

@Zungmann: I hope for you Jand is still on the printed part project. And for the connector I use: I'm Not affiliated with this site ;-) bad news for you because 1 year and half ago their was only at 2.8€/pcs ...

For updates: I have somes 'non' straight line on X axis (the moving one).. I think the problem it's because the Iglidur bush have too much clearance, H7 in plastic spacer is not good.. metal one will be made today.

@NewkidOntheBlock: Corexy -> simple cartesians system, Delta printer, nice to see moving, but waiting to see non-artistic print without artifact on straight line.

@Zungmann: I hope for you Jand is still on the printed part project. And for the connector I use: I'm Not affiliated with this site ;-) bad news for you because 1 year and half ago their was only at 2.8€/pcs ...

For updates: I have somes 'non' straight line on X axis (the moving one).. I think the problem it's because the Iglidur bush have too much clearance, H7 in plastic spacer is not good.. metal one will be made today.

|

Re: Atfer Hbot, go to CoreXY. February 12, 2014 10:33AM |

Registered: 10 years ago Posts: 45 |

Hi There,

here is a link for some fair priced alu profiles and connectors from Germany...

[stores.ebay.de]

I will order my parts from their shop, the cut is free !!!

here is a link for some fair priced alu profiles and connectors from Germany...

[stores.ebay.de]

I will order my parts from their shop, the cut is free !!!

|

Re: Atfer Hbot, go to CoreXY. February 12, 2014 02:42PM |

Registered: 11 years ago Posts: 53 |

hi

here is also a good shop for aluminum profiles from Germany

[www.smt-montagetechnik.de]

greeting

nothing11

here is also a good shop for aluminum profiles from Germany

[www.smt-montagetechnik.de]

greeting

nothing11

|

Re: Atfer Hbot, go to CoreXY. February 12, 2014 03:55PM |

Registered: 12 years ago Posts: 199 |

I am still working on printed parts for a core-XY based printer. I use zelogik parts as a base.

I already made the XY-part, the carriage and the corner motor parts.

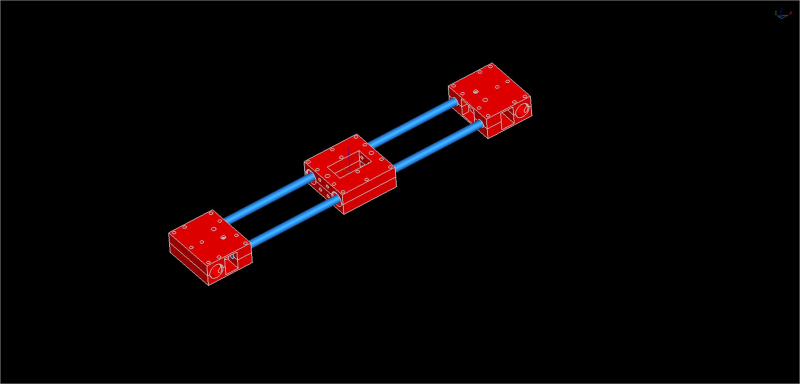

The X axis looks like this:

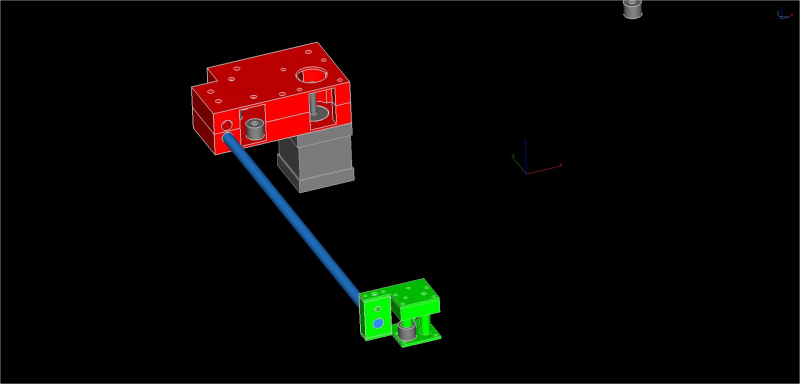

end the left Y-axis looks like this:

The green corner part is zelogiks original part.

This will be the next part I redisign. After that I wil start printing these parts to see if everything fits and is strong enough.

I my model everything seems to fit, so I am hopefull.

@zelogik: What size extrusions did you use? In the model I made I used 330mm for X and Y.

I already made the XY-part, the carriage and the corner motor parts.

The X axis looks like this:

end the left Y-axis looks like this:

The green corner part is zelogiks original part.

This will be the next part I redisign. After that I wil start printing these parts to see if everything fits and is strong enough.

I my model everything seems to fit, so I am hopefull.

@zelogik: What size extrusions did you use? In the model I made I used 330mm for X and Y.

|

Re: Atfer Hbot, go to CoreXY. February 12, 2014 04:50PM |

Registered: 11 years ago Posts: 225 |

X and Y aluminium extrusion are both 350mm long. But it's need 20mm for each corner on both side. So total size of my printer is 390mm in length and depth.

Really nice fork, for your information, the part in green you don't have been done yet was the more tricky one for my brain. ;-) you don't have so much space for put screws, belt and pulley.

Have you left some space and fixating hole for the belt tensioning on the y axis block?

Ie: its very important to adjust tension and tune perpendicularity for x and y axis.

Really nice fork, for your information, the part in green you don't have been done yet was the more tricky one for my brain. ;-) you don't have so much space for put screws, belt and pulley.

Have you left some space and fixating hole for the belt tensioning on the y axis block?

Ie: its very important to adjust tension and tune perpendicularity for x and y axis.

|

Re: Atfer Hbot, go to CoreXY. February 19, 2014 10:52AM |

Registered: 10 years ago Posts: 71 |

Just a short praise on zelogik's achievement..

foudroyante...

foudroyante...

As to the frame-connection:

i) Motedis Germany still have that connector for 2.52€ (3.02€ 1pc) "Würfelverbinder 40 I-Typ Nut 8"

ii) ...but you don't really need it (imho)

- at each corner just make a single (40x40) extrusion 40mm longer ("include" the Cornerconnect so to speak)

- tap a M8 thread into the "extrusion center hole" (of one of the 2 short extrusion pieces)

- drill a hole in the center of the 40mm longer piece connecting to the M8 thread

- fix with M8 screw

...repeat for 2nd direction

- drill a hole in the 'other face' center of the 40mm elongation

- tap a M8 thread into the "extrusion center hole" you "see through that just drilled hole"

Now for the price of +40mm extrusion, two selfmade taps and two M8 screws you have the same result!

...sorry I have not pictures available now but I am sure you'll understand

foudroyante...

foudroyante...

As to the frame-connection:

i) Motedis Germany still have that connector for 2.52€ (3.02€ 1pc) "Würfelverbinder 40 I-Typ Nut 8"

ii) ...but you don't really need it (imho)

- at each corner just make a single (40x40) extrusion 40mm longer ("include" the Cornerconnect so to speak)

- tap a M8 thread into the "extrusion center hole" (of one of the 2 short extrusion pieces)

- drill a hole in the center of the 40mm longer piece connecting to the M8 thread

- fix with M8 screw

...repeat for 2nd direction

- drill a hole in the 'other face' center of the 40mm elongation

- tap a M8 thread into the "extrusion center hole" you "see through that just drilled hole"

Now for the price of +40mm extrusion, two selfmade taps and two M8 screws you have the same result!

...sorry I have not pictures available now but I am sure you'll understand

|

Re: Atfer Hbot, go to CoreXY. February 27, 2014 05:36AM |

Registered: 11 years ago Posts: 225 |

Hello,

@Reinhold: Thanks for that nice french word

Be careful, the connector you show is for 40mm profile. And all my printer is tested with 20mm profile.

Some news from my city of Nice :-D (and my printer of course):

So that 3D printer have more or less 100 hours of movement now. I have replaced the igus bush with LM8UU (don't see many difference except a little more noise, I thinking to reput igus bush...), and reduce acceleration to remove damping/wave at corner (3500mm/s²,20mm jerk, between 50 and 150mm/s for print and 9000mm/s² and 350mm/s for travel).

The noise of the mecanical structure is very low, for informations, the noise the fans produce is louder ... (electronic fan, Nozzle fan, and object cooling fan).

I have took some 3mm Dibond and brush isolator for Zaxis to make a good enclosure today or this week.

And I looking for a better printing surface ... glass with kapton is not so bad but not really perfect... for ABS,Nylon,PLA...

@Jand: Some update?

@Reinhold: Thanks for that nice french word

Be careful, the connector you show is for 40mm profile. And all my printer is tested with 20mm profile.

Some news from my city of Nice :-D (and my printer of course):

So that 3D printer have more or less 100 hours of movement now. I have replaced the igus bush with LM8UU (don't see many difference except a little more noise, I thinking to reput igus bush...), and reduce acceleration to remove damping/wave at corner (3500mm/s²,20mm jerk, between 50 and 150mm/s for print and 9000mm/s² and 350mm/s for travel).

The noise of the mecanical structure is very low, for informations, the noise the fans produce is louder ... (electronic fan, Nozzle fan, and object cooling fan).

I have took some 3mm Dibond and brush isolator for Zaxis to make a good enclosure today or this week.

And I looking for a better printing surface ... glass with kapton is not so bad but not really perfect... for ABS,Nylon,PLA...

@Jand: Some update?

|

Re: Atfer Hbot, go to CoreXY. February 28, 2014 05:57AM |

Registered: 10 years ago Posts: 71 |

Quote

zelogik

...make a good enclosure today or this week.

You know what they say: "No pics ? ... it didn't happen !"

Can you (really) "see" (=prove) a speed difference with LM8EE vs IGUS ? ... WHAT do you see?

Printing Surface

Some (german) Developers are enthusiastic about what they call a PermanentPlate (Dauerdruckplatte)

a PEI "impregnated" (=coated) 3 mm Aluminium plate (mostly with a carbon heater on the back or MK Elements).

BTW: I was so overwhelmed that I didn't even notice your profile was 20mm instead of 40mm (which I think cheaper,better, fatter)

|

Re: Atfer Hbot, go to CoreXY. February 28, 2014 08:48AM |

Registered: 11 years ago Posts: 225 |

Igus bush: Less noise, more gap but with the corexy don't see any difference with the movement.

LM8UU: More noise, prone to accept more parallel problem of axis or bending tolerance problem.

(ie: I can't show to you all prints I have made for a friend where we don't see difference between lm8uu and igus bush)

20mm profile is normally always cheaper than 40mm profile ;-)

Have you some link or more information on your PEI plate ... I looking for it here in France.

LM8UU: More noise, prone to accept more parallel problem of axis or bending tolerance problem.

(ie: I can't show to you all prints I have made for a friend where we don't see difference between lm8uu and igus bush)

20mm profile is normally always cheaper than 40mm profile ;-)

Have you some link or more information on your PEI plate ... I looking for it here in France.

|

Re: Atfer Hbot, go to CoreXY. February 28, 2014 01:15PM |

Registered: 12 years ago Posts: 809 |

Look for ULTEM PEI sheets as well.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Atfer Hbot, go to CoreXY. March 01, 2014 04:30AM |

Registered: 11 years ago Posts: 225 |

Ultem® is no more than Polyetherimide (PEI) and I will look for that, maybe more easy to found with the real name of the molecule ;-)

Because it's impossible to found easily PEI plate there in France...

I have looked for polyimide (PI) plate (Kapton® or ultem® Brand name) but way to much expensive.

I desesperate to found a plate here ...

Because it's impossible to found easily PEI plate there in France...

I have looked for polyimide (PI) plate (Kapton® or ultem® Brand name) but way to much expensive.

I desesperate to found a plate here ...

|

Re: Atfer Hbot, go to CoreXY. March 01, 2014 06:38AM |

Registered: 10 years ago Posts: 71 |

Greetings to Nice la Belle

If you cannot find it in France ...

maybe you can make your own (seems you have workshop(s) available)...

[www.dr-henschke.de]

(german but translate.google.com gives a readable (sort of translation-else pm me))

(please don't hurt yourself using Dichlormethan !)

Available (sry) in RFA:

[reprap-fab.org]

(Active reprap developer: Wolfgang Vogel)

[youprintin3d.de]

(Active reprap developer: Axel Burger)

[www.3dprinterstore24.de]

...but it seems they cannot fulfill demand now

Video view(s):

[www.youtube.com]

[www.youtube.com]

Edited 1 time(s). Last edit at 03/01/2014 06:40AM by Reinhold.

If you cannot find it in France ...

maybe you can make your own (seems you have workshop(s) available)...

[www.dr-henschke.de]

(german but translate.google.com gives a readable (sort of translation-else pm me))

(please don't hurt yourself using Dichlormethan !)

Quote

dr.henschke

Coating procedure: The PEI (polyetherimide) is dissolved in dichloromethane (poisonous! and highly flammable)

and painted (brushed) onto the previously anodized but not compacted aluminum plate.

According to my theory, the PEI molecules assemble in the open pores of the anodic coating

and are therefore bond very firmly to the aluminum.

Available (sry) in RFA:

[reprap-fab.org]

(Active reprap developer: Wolfgang Vogel)

[youprintin3d.de]

(Active reprap developer: Axel Burger)

[www.3dprinterstore24.de]

...but it seems they cannot fulfill demand now

Video view(s):

[www.youtube.com]

[www.youtube.com]

Edited 1 time(s). Last edit at 03/01/2014 06:40AM by Reinhold.

|

Re: Atfer Hbot, go to CoreXY. March 01, 2014 02:02PM |

Registered: 11 years ago Posts: 225 |

reprap-fab: In den Warenkorb not displaying :-(

youprintin3D.de : Dieser Artikel steht derzeit nicht zur Verfügung!

@reinhold: Shame on you for showing me something like that but not available anymore ! :-p

I think I have both at work ( dichloromethane & polyetherimide)... I have maybe a very flat aluminium plate and all I need for anodize it, but not many information on quantity and time exposure etc...

But I'm ready to bought it at 50€ for magic plate.

Just curious... I don't have seen many print with ABS and that plate... only PLA on youtube.

youprintin3D.de : Dieser Artikel steht derzeit nicht zur Verfügung!

@reinhold: Shame on you for showing me something like that but not available anymore ! :-p

I think I have both at work ( dichloromethane & polyetherimide)... I have maybe a very flat aluminium plate and all I need for anodize it, but not many information on quantity and time exposure etc...

But I'm ready to bought it at 50€ for magic plate.

Just curious... I don't have seen many print with ABS and that plate... only PLA on youtube.

|

Re: Atfer Hbot, go to CoreXY. March 03, 2014 03:02PM |

Registered: 12 years ago Posts: 199 |

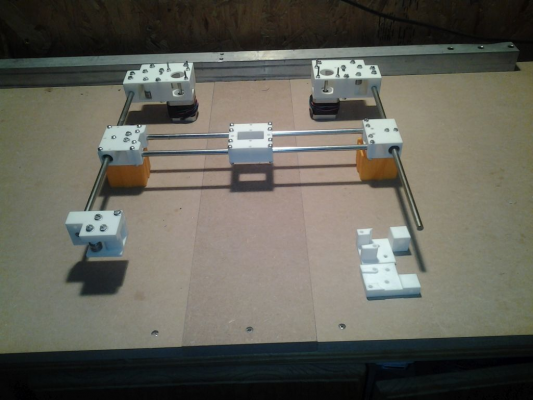

Just a little update on the printed parts. This weekend I printed the parts for the XY part. That is the two motor parts, the two Idler parts, two XY-ends and the carriage.

(The orange parts do not belong to the printer)

I screwed them together and seems a nice fit. I think the parts are strong enough. So it's time to spend some money, I have to order the alu profiles, belts, pulleys and idlers.

As idler I use two bearings, one flanged bearing (F625zz) and one normal bearing (625zz).

For the frame I want to use these profiles and These brackets

Does anyone have any experience with the corner brackets?

(The orange parts do not belong to the printer)

I screwed them together and seems a nice fit. I think the parts are strong enough. So it's time to spend some money, I have to order the alu profiles, belts, pulleys and idlers.

As idler I use two bearings, one flanged bearing (F625zz) and one normal bearing (625zz).

For the frame I want to use these profiles and These brackets

Does anyone have any experience with the corner brackets?

Attachments:

open | download - 20140303_200841.jpg (95.5 KB)

open | download - 20140303_200850.jpg (94.4 KB)

open | download - 20140303_200902.jpg (105.6 KB)

open | download - 20140303_200918.jpg (85.9 KB)

open | download - 20140303_201010.jpg (99.6 KB)

open | download - 20140303_201032.jpg (99.2 KB)

open | download - 20140303_200841.jpg (95.5 KB)

open | download - 20140303_200850.jpg (94.4 KB)

open | download - 20140303_200902.jpg (105.6 KB)

open | download - 20140303_200918.jpg (85.9 KB)

open | download - 20140303_201010.jpg (99.6 KB)

open | download - 20140303_201032.jpg (99.2 KB)

|

Re: Atfer Hbot, go to CoreXY. March 03, 2014 04:42PM |

Registered: 10 years ago Posts: 71 |

@jand

Nice work!

Try the "add+20mm-Drill-Hole-and-connect-to-center-M6-opposite-profile" and imho you don't need "Innenwinkel" for frame

(what do you do with the remaining 96pcs anyway ;-) )

;-) )

Depending on where you are and whether you can buy as a company these may come cheap(er):

[www.dold-mechatronik.de]

[www.alu-profil-technik.de]

(http://www.ebay.de/itm/150650616574)

I can absolutely recommend Dold as a reliable source.

Where are you going to buy belts and pulleys ?

Nice work!

Try the "add+20mm-Drill-Hole-and-connect-to-center-M6-opposite-profile" and imho you don't need "Innenwinkel" for frame

(what do you do with the remaining 96pcs anyway

;-) )

;-) )Depending on where you are and whether you can buy as a company these may come cheap(er):

[www.dold-mechatronik.de]

[www.alu-profil-technik.de]

(http://www.ebay.de/itm/150650616574)

I can absolutely recommend Dold as a reliable source.

Where are you going to buy belts and pulleys ?

|

Re: Atfer Hbot, go to CoreXY. March 03, 2014 06:05PM |

Registered: 12 years ago Posts: 199 |

@Reinhold

Thanks for the Thumb.I have been looking around at Dold, Profiles are cheaper there, but only standard length. Not really a problem just have to change my model.

I just wait to order, have to look around. Seems they ship to the netherlands, I registered and it looks like I do not have to be a company. Need to figure out shipping costs.

Nice they also have smooth-rod, trapezium-rods and linear bearings.

"add+20mm-Drill-Hole-and-connect-to-center-M6-opposite-profile": is this an option I missed on the webshop, or do I drill myself?

I do not realy like the drill myself part and you need more than 4 parts. 8 for the top, 8 for the bottom and 8 for the lower center part.(I have an extra set horizontal profiles. And you don't have to buy 100.

I have not yet decided where to buy the belts and pulleys, maybe reprapworld.nl. I want quality belts and pulleys. Someone have a good suggestion (in NL,DE or maybe UK)

Thanks for the Thumb.I have been looking around at Dold, Profiles are cheaper there, but only standard length. Not really a problem just have to change my model.

I just wait to order, have to look around. Seems they ship to the netherlands, I registered and it looks like I do not have to be a company. Need to figure out shipping costs.

Nice they also have smooth-rod, trapezium-rods and linear bearings.

"add+20mm-Drill-Hole-and-connect-to-center-M6-opposite-profile": is this an option I missed on the webshop, or do I drill myself?

I do not realy like the drill myself part and you need more than 4 parts. 8 for the top, 8 for the bottom and 8 for the lower center part.(I have an extra set horizontal profiles. And you don't have to buy 100.

I have not yet decided where to buy the belts and pulleys, maybe reprapworld.nl. I want quality belts and pulleys. Someone have a good suggestion (in NL,DE or maybe UK)

|

Re: Atfer Hbot, go to CoreXY. March 03, 2014 10:18PM |

Registered: 11 years ago Posts: 290 |

Glad to see your progress. Looks really good. I guess its time to print the parts…

@Jand, would you share the STL of the printed part?

I already have the 20x20 alu profile, but still looking for the 3-way bracket. Getting from Europe will cost me a fortune (am in, Indonesia, South East Asia). I will try this: HBLCR5-B from Misumi.

@Jand, would you share the STL of the printed part?

I already have the 20x20 alu profile, but still looking for the 3-way bracket. Getting from Europe will cost me a fortune (am in, Indonesia, South East Asia). I will try this: HBLCR5-B from Misumi.

|

Re: Atfer Hbot, go to CoreXY. March 04, 2014 04:39AM |

Registered: 11 years ago Posts: 225 |

@Jand: I have exactly the same profile 20x20mm from motedis and working well.

For the braquet I think Braquets are more square (it's molded) than the folded/bended braquets you have showed.(I never seen exactly 90° bended profile, it's always 90° +/- 4°)

For lowering a little bit the price you can put Cheaper braquet not everywhere but make a mix between two kind of braquet.

For the belt and pulley I'm really satisfied with robotdigg, really cheap and very good quality.$2/pc and you need 8pcs. (but come from China)(And I think the pulley you bought from DE,NL,UK come from China but with the reseller profit...).

FIY don't use carbon rod (for 10 to 11mm) for idler pulley as there are non completely round and put some very small artifact/wave on big print (impossible to took the problem on photo...). Finally a 10mm idler pulley (bearing like you) are enough and better..

@zungmann: or use the "add+20mm-Drill-Hole-and-connect-to-center-M6-opposite-profile" Reinhold have said, cheaper but time consuming :-D

@Reinhold: I'm not affiliated at all with Motedis but when I check for price it's less expensive.

at dolt -> 32cm 1.15€

at motedis -> 32cm 1.14€ (and with motedis you can have 32.5 or 33, and not with dolt)

For the braquet I think Braquets are more square (it's molded) than the folded/bended braquets you have showed.(I never seen exactly 90° bended profile, it's always 90° +/- 4°)

For lowering a little bit the price you can put Cheaper braquet not everywhere but make a mix between two kind of braquet.

For the belt and pulley I'm really satisfied with robotdigg, really cheap and very good quality.$2/pc and you need 8pcs. (but come from China)(And I think the pulley you bought from DE,NL,UK come from China but with the reseller profit...).

FIY don't use carbon rod (for 10 to 11mm) for idler pulley as there are non completely round and put some very small artifact/wave on big print (impossible to took the problem on photo...). Finally a 10mm idler pulley (bearing like you) are enough and better..

@zungmann: or use the "add+20mm-Drill-Hole-and-connect-to-center-M6-opposite-profile" Reinhold have said, cheaper but time consuming :-D

@Reinhold: I'm not affiliated at all with Motedis but when I check for price it's less expensive.

at dolt -> 32cm 1.15€

at motedis -> 32cm 1.14€ (and with motedis you can have 32.5 or 33, and not with dolt)

|

Re: Atfer Hbot, go to CoreXY. March 04, 2014 06:41AM |

Registered: 10 years ago Posts: 71 |

@jand

@zelogik

(I am also not affiliated to any of the 3(!) companies I cited)

As I said "it depends" ... from where it is cheaper/better to buy

(for me with a tiny order like this it's "all shipping cost" )

)

(BTW: Dold is a Motedis Partner and they actually offer any cut as service ($))

...but I drill myself ;-) ... and haven't asked them (I did see a bench drill on your pics )

)

Have you seen this (Motedis about us)( funny)

I also bought belt from China (Alibaba not recommended) but it most likely was made by "Continental"

(...who's customer support tells me "cannot sell in small numbers )

)

Does anybody object against pulleys as follows:

2x 16 teeth on steppers, rest all 20 teeth ?

@zelogik

Your belt-tensioners are fine engineering...

...but if you observe them closely now, do you think you could do without?

(just oblong hole for stepper motor ?)

(and please don't hit me )

)

@zelogik

(I am also not affiliated to any of the 3(!) companies I cited)

As I said "it depends" ... from where it is cheaper/better to buy

(for me with a tiny order like this it's "all shipping cost"

)

)(BTW: Dold is a Motedis Partner and they actually offer any cut as service ($))

...but I drill myself ;-) ... and haven't asked them (I did see a bench drill on your pics

)

)Have you seen this (Motedis about us)( funny)

I also bought belt from China (Alibaba not recommended) but it most likely was made by "Continental"

(...who's customer support tells me "cannot sell in small numbers

)

)Does anybody object against pulleys as follows:

2x 16 teeth on steppers, rest all 20 teeth ?

@zelogik

Your belt-tensioners are fine engineering...

...but if you observe them closely now, do you think you could do without?

(just oblong hole for stepper motor ?)

(and please don't hit me

)

)

|

Re: Atfer Hbot, go to CoreXY. March 04, 2014 07:12AM |

Registered: 12 years ago Posts: 199 |

@Reinhold

After a better look there is not much difference in price for me. (At first I compared a 50cm piece with a 1m piece) I will have to compare shipping costs

@Zelogic

For Idlers I only use bearings, so I only need two pulleys. I am not sure if this works, but wil give it a try.

@zungmann

I will release the files, but it is probably better to wait a little longer until I tested it before you start printing.

After a better look there is not much difference in price for me. (At first I compared a 50cm piece with a 1m piece) I will have to compare shipping costs

@Zelogic

For Idlers I only use bearings, so I only need two pulleys. I am not sure if this works, but wil give it a try.

@zungmann

I will release the files, but it is probably better to wait a little longer until I tested it before you start printing.

|

Re: Atfer Hbot, go to CoreXY. March 04, 2014 08:03AM |

Registered: 11 years ago Posts: 225 |

@Reinhold: Of course your idea of oblong hole is good (I even thinking about that at developpement. ;-) ) but:

+it's more easy to screw/unscrew ONE screw for tight the belt than screw/unscrew 4 screws + push the motor at the same time

+close a little bit the belt on the pulley so you take 1 or 2 teeth more for the traction (I don't know if somebody can understand me here ...)

+COMPLETELY static motor, you can't have sliding even if the screws are non really well tensionned.

-More easy and less expensive to make 5 oblong hole (yes 22mm oblog hole too), than make a connecting rod + 2bearings (even more easy with printed version)

So for me it's and 3 vs 1... so you have the respond why I have choose the belt-tensionner and not the oblong hole. But of course my files are all open-source and your idea is far from stupid (I don't hit you ).

).

For finish the best argument, is the "easyness" for tightening the belt... make a square X axis again Y axis is painless with my version (screw a little more one screw or the other side), with oblong hole i think it's an another story...

@Jand:

You have 16 pivots axis:

-2 motors (teeth profile)

-2 belt tensionners (smooth profile)

-4 idler (smooth profile) (where you put your flanged bearing no?)

-8 idler (teeth profile).

Sorry, I think we don't spoke about the same thing ... what to you mean by 'idler' ?

For the Z axis i don't know if I have posted my old printed version on github ... before the aluminium one... I will look for it for you

And before you will post the file, you have 2 solutions: You post all file now with update time to time AND write that your version is in developpement and not well tested...

Or waiting for release it, when you see that your version is ready to "production".

I prefere the second one, but with what I have already seen, your file look good

+it's more easy to screw/unscrew ONE screw for tight the belt than screw/unscrew 4 screws + push the motor at the same time

+close a little bit the belt on the pulley so you take 1 or 2 teeth more for the traction (I don't know if somebody can understand me here ...)

+COMPLETELY static motor, you can't have sliding even if the screws are non really well tensionned.

-More easy and less expensive to make 5 oblong hole (yes 22mm oblog hole too), than make a connecting rod + 2bearings (even more easy with printed version)

So for me it's and 3 vs 1... so you have the respond why I have choose the belt-tensionner and not the oblong hole. But of course my files are all open-source and your idea is far from stupid (I don't hit you

).

).For finish the best argument, is the "easyness" for tightening the belt... make a square X axis again Y axis is painless with my version (screw a little more one screw or the other side), with oblong hole i think it's an another story...

@Jand:

You have 16 pivots axis:

-2 motors (teeth profile)

-2 belt tensionners (smooth profile)

-4 idler (smooth profile) (where you put your flanged bearing no?)

-8 idler (teeth profile).

Sorry, I think we don't spoke about the same thing ... what to you mean by 'idler' ?

For the Z axis i don't know if I have posted my old printed version on github ... before the aluminium one... I will look for it for you

And before you will post the file, you have 2 solutions: You post all file now with update time to time AND write that your version is in developpement and not well tested...

Or waiting for release it, when you see that your version is ready to "production".

I prefere the second one, but with what I have already seen, your file look good

|

Re: Atfer Hbot, go to CoreXY. March 04, 2014 08:17AM |

Registered: 12 years ago Posts: 199 |

@zelogic

By idler I mean everything the belt is touching except the motor pulley. So everywhere the belt is turning I have two bearings, one with flange (bottom) and one without at the top. So also where the teeth are touching the bearings.

This is what happens when two non native english people are talking (writing) english. But we will figure it out I think. I think native english people with laugh at our conversation, but who cares.

I guess it best to wait just a little before posting the files. But I someone wants to help we can work things out.

Edited 1 time(s). Last edit at 03/04/2014 08:18AM by jand.

By idler I mean everything the belt is touching except the motor pulley. So everywhere the belt is turning I have two bearings, one with flange (bottom) and one without at the top. So also where the teeth are touching the bearings.

This is what happens when two non native english people are talking (writing) english. But we will figure it out I think. I think native english people with laugh at our conversation, but who cares.

I guess it best to wait just a little before posting the files. But I someone wants to help we can work things out.

Edited 1 time(s). Last edit at 03/04/2014 08:18AM by jand.

|

Re: Atfer Hbot, go to CoreXY. March 04, 2014 08:27AM |

Registered: 11 years ago Posts: 225 |

You will have some problems i'm scared.... artifact like that will occur:

.

from [forums.reprap.org]

Maybe you will need 8mm id bore to gt2 tooth profile ... I have seen many customizable printing thing on thingiverse GT2 8mm bore

But you can test without ...

Yes who care, almost everybody can understand which one with more or less difficulty ;-)

Edited 1 time(s). Last edit at 03/04/2014 08:28AM by zelogik.

.

from [forums.reprap.org]

Maybe you will need 8mm id bore to gt2 tooth profile ... I have seen many customizable printing thing on thingiverse GT2 8mm bore

But you can test without ...

Yes who care, almost everybody can understand which one with more or less difficulty ;-)

Edited 1 time(s). Last edit at 03/04/2014 08:28AM by zelogik.

|

Re: Atfer Hbot, go to CoreXY. March 04, 2014 10:03AM |

Registered: 10 years ago Posts: 71 |

I am no native english speaker either but "who cares"

Let's call it "idler pulley" vs "tooth pulley" for now (know?)

(which I know to be incorrect...)

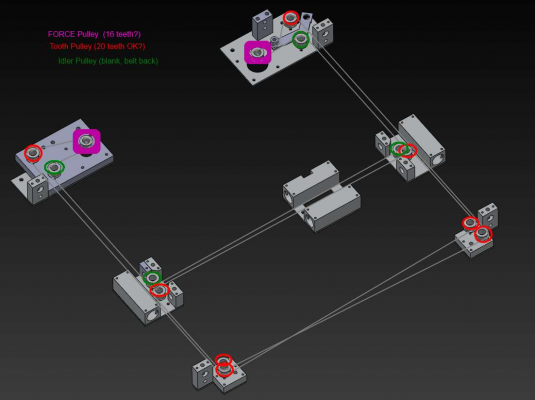

This is what zelogik designed:

- I have little experience using bearings on the tooth-side of a pulley ...

BUT what little I have says"BAD" ... so I wouldn't use a blank bearing on the tooth side of the belt but a toothed pulley.

- As said before/above I'd like to know your opinion:

...on using 16teeth belts for the drive (pulleys marked violet)

and 20teeth belts (red idler pulleys)

and bearing idlers (green) elsewhere..

Reason? ... For the sake of accuracy:

(Motor 1.8° and 16 teeth @ 2mm (GT2) -> 0.16mm/Step ___vs___ Motor 1.8° and 20 teeth @ 2mm (GT2) -> 0.2mm/Step

@zelogik: Somehow I cannot find what you are using...

Please comment!

@zelogik AL...I think there are many sources of 20tooth GT2 pulleys with 5mm bore (Nema17) but also a few 16tooth GT2 5mm bore...

All printed GT2 pulleys I've seen were not very good (actually rather bad) compared to the aluminium pulleys!

- One more (stupid?) question: Technically We would/should need to tension both belts - wouldn't we?

Edited 1 time(s). Last edit at 03/04/2014 10:04AM by Reinhold.

Let's call it "idler pulley" vs "tooth pulley" for now (know?)

(which I know to be incorrect...)

This is what zelogik designed:

- I have little experience using bearings on the tooth-side of a pulley ...

BUT what little I have says"BAD" ... so I wouldn't use a blank bearing on the tooth side of the belt but a toothed pulley.

- As said before/above I'd like to know your opinion:

...on using 16teeth belts for the drive (pulleys marked violet)

and 20teeth belts (red idler pulleys)

and bearing idlers (green) elsewhere..

Reason? ... For the sake of accuracy:

(Motor 1.8° and 16 teeth @ 2mm (GT2) -> 0.16mm/Step ___vs___ Motor 1.8° and 20 teeth @ 2mm (GT2) -> 0.2mm/Step

@zelogik: Somehow I cannot find what you are using...

Please comment!

@zelogik AL...I think there are many sources of 20tooth GT2 pulleys with 5mm bore (Nema17) but also a few 16tooth GT2 5mm bore...

All printed GT2 pulleys I've seen were not very good (actually rather bad) compared to the aluminium pulleys!

- One more (stupid?) question: Technically We would/should need to tension both belts - wouldn't we?

Edited 1 time(s). Last edit at 03/04/2014 10:04AM by Reinhold.

Sorry, only registered users may post in this forum.