My CoreXY printer iteration!

Posted by vinvin

|

My CoreXY printer iteration! December 21, 2014 10:38AM |

Registered: 9 years ago Posts: 2 |

Hi guys

I wanted to make my own printer. This is it!

[www.thingiverse.com]

[grabcad.com]

I went for a CoreXY (http://corexy.com) configuration with a bowden setup.

I decided to use SFU1204 ballscrew for the Z axis, synchromesh cables and guitar tensioning mechanisms. 10mm rod for the X axis, and 12mm for the Y axis.

I will be more than happy to read your opinions/critics/thougths about it!

ALSO : I haven't choose my electronic board yet, and doesn't know with one to choose. I wanted to go with 1/32 microstepping drivers since as i understood, Marlin implementation of corexy system divide the resolution by factor 2, and also for quietness of operation. Should I choose a 32bit capable board like the Azteeg X5 mini or a regular atmel 2560 will do?

I wanted to make my own printer. This is it!

[www.thingiverse.com]

[grabcad.com]

I went for a CoreXY (http://corexy.com) configuration with a bowden setup.

I decided to use SFU1204 ballscrew for the Z axis, synchromesh cables and guitar tensioning mechanisms. 10mm rod for the X axis, and 12mm for the Y axis.

I will be more than happy to read your opinions/critics/thougths about it!

ALSO : I haven't choose my electronic board yet, and doesn't know with one to choose. I wanted to go with 1/32 microstepping drivers since as i understood, Marlin implementation of corexy system divide the resolution by factor 2, and also for quietness of operation. Should I choose a 32bit capable board like the Azteeg X5 mini or a regular atmel 2560 will do?

|

Re: My CoreXY printer iteration! December 21, 2014 12:23PM |

Registered: 10 years ago Posts: 102 |

|

Re: My CoreXY printer iteration! December 21, 2014 11:00PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: My CoreXY printer iteration! December 22, 2014 11:38AM |

Registered: 9 years ago Posts: 44 |

I'm guessing that belt is shorter than the COREXY belts...or nearly the same length. Why would it be an accuracy issue and not the X and Y axis ones? If anything, the accuracy of belts in general CORE XY concept kind of prove there should not be an issue with using GT2s for this type of configuration.Quote

cozmicray

Neat Z Axis drive

but

a lot of belt stretching and moving -- less accuracy?

How about shaft drive

Shaft linkage from one stepper motor to three lift screws?

Ball screws expensive?

|

Re: My CoreXY printer iteration! December 22, 2014 11:45AM |

Registered: 9 years ago Posts: 2 |

Yes.... this is the best offer i came by:

ballscrews:

[www.aliexpress.com]

end support:

[www.aliexpress.com]

You mean 3 belts on the motor shaft? I don't have a motor shaft long enough for 3 pulleys, and it would take a lot of space

ballscrews:

[www.aliexpress.com]

end support:

[www.aliexpress.com]

You mean 3 belts on the motor shaft? I don't have a motor shaft long enough for 3 pulleys, and it would take a lot of space

|

Re: My CoreXY printer iteration! December 22, 2014 04:32PM |

Registered: 11 years ago Posts: 1,049 |

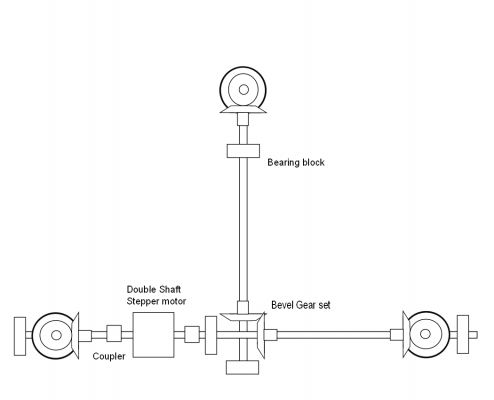

Tri Axis shaft drive

depending on gear sets should be very positive and accurate??

4 bevel gear sets (perhaps printed)

Double shaft stepper motor

couplers

5mm shafts

bearings

Fast sketch to get my idea

depending on gear sets should be very positive and accurate??

4 bevel gear sets (perhaps printed)

Double shaft stepper motor

couplers

5mm shafts

bearings

Fast sketch to get my idea

|

Re: My CoreXY printer iteration! December 22, 2014 06:26PM |

Registered: 10 years ago Posts: 553 |

Why do you need 3 lifting screws?

I'm making a large format printer that has build area ~2x as big and am only using 2. Plus the connecting set of bevel gears on the shaft for the 3rd motor will add backlash that the other two motors wont have, thus making it not level. I'd say, if you want to use 3 lift screws, use 3 motors.

Edited 1 time(s). Last edit at 12/22/2014 06:28PM by gmh39.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

I'm making a large format printer that has build area ~2x as big and am only using 2. Plus the connecting set of bevel gears on the shaft for the 3rd motor will add backlash that the other two motors wont have, thus making it not level. I'd say, if you want to use 3 lift screws, use 3 motors.

Edited 1 time(s). Last edit at 12/22/2014 06:28PM by gmh39.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: My CoreXY printer iteration! December 22, 2014 09:51PM |

Registered: 11 years ago Posts: 1,049 |

backlash

I think most prints would NOT be moving up/down,

just down --- Backlash not a problem.

and backlash (that can be dealt with in SW)

is greater than belt stretch and jiggle????

The Digital_Dentist proclaimed using multi motors bad

motors out of sync -- and driving more than one motor on a drive is not good

[forums.reprap.org]

One z-axis drive leaves big cantalever to jiggle around out there?

What makes an Ultimaker 3 much more accurate than a DaVinci other than $2000

I think most prints would NOT be moving up/down,

just down --- Backlash not a problem.

and backlash (that can be dealt with in SW)

is greater than belt stretch and jiggle????

The Digital_Dentist proclaimed using multi motors bad

motors out of sync -- and driving more than one motor on a drive is not good

[forums.reprap.org]

One z-axis drive leaves big cantalever to jiggle around out there?

What makes an Ultimaker 3 much more accurate than a DaVinci other than $2000

|

Re: My CoreXY printer iteration! January 05, 2015 06:43PM |

Admin Registered: 11 years ago Posts: 3,096 |

Hey vinvin, I think RobotDIGG might be worth to check out for you. They sure are cheap, offer nice ballscrews and are reliable. I'm Dutch and I received the parts in a week. However, I ordered the stepper-motor with a ballscrew on it (+2 spare nuts with a tensioner inside). Will be keeping a cantilever for my own design, but maybe RobotDIGG can help you with the parts you need.

Right now I'm in the process of finishing my CoreXY machine that will be a dedicated lasercutter for the first part of it's life Very curious how it al works!

Very curious how it al works!

http://www.marinusdebeer.nl/

Right now I'm in the process of finishing my CoreXY machine that will be a dedicated lasercutter for the first part of it's life

Very curious how it al works!

Very curious how it al works!http://www.marinusdebeer.nl/

Sorry, only registered users may post in this forum.