Building Core XY Printer: need help deciding on what built

Posted by J.A.C.

|

Building Core XY Printer: need help deciding on what built March 19, 2015 09:11PM |

Registered: 9 years ago Posts: 23 |

Hello everyone!

Ok, so, after much thinking, looking, asking, changing ideas... over and over... and over again, I have decided to go a head and make me a CoreXY.

I like the concept in general, and to me, platform working down makes more sense then arms swinging up with a model shaken right and left.

But, for my first 3D built, I do not wish to try to re-invent the wheel (it hurts saying that as i have so many ideas I want to try! but that will be for when I have more experience and want to evolve it)

but that will be for when I have more experience and want to evolve it)

I been looking around, but haven't fond a complete, clear one with full plans on how to built it. I am hopping that you guy's, that know the options out there, can give a few choices. (I want to follow instructions to a T, from bearings to the electronics)

What I am looking from a 3D printer:

- 8x8x8 Minimum,

- Simple is better, I am looking to learn.

- I am not in a hurry to the printer to print, it can take the time it wants, I have 2 baby's and a work load 2 miles long (yes, I know, adding the 3D printer, but the printer, hopefully, long term, will save me LOT of time and add a quality of life... I hope!)

- clear info on how to built it and configure it.

- I like to build it next month.

- Want to print ABS, PETg ( this: eSUN PETG ) and ninjaflex stuff, maybe even that bronze/metal filament!

- I plan on printing armor parts, masks and costumes accessory's, so big parts.

Now, I already own some 4 grove aluminum bars (tubes?) , this is what they look like, was wondering if I could use that for my structure

I have a lot, thinking of making something with storage cabinet for tools and material and such.

I was also considering, for my platform, using foam instead of heated bed.

Anyhow, hit me with recommendations! I can not wait to get started (I will keep y'll up to date)

Thank you,

Jonathan A. Connolly

Ok, so, after much thinking, looking, asking, changing ideas... over and over... and over again, I have decided to go a head and make me a CoreXY.

I like the concept in general, and to me, platform working down makes more sense then arms swinging up with a model shaken right and left.

But, for my first 3D built, I do not wish to try to re-invent the wheel (it hurts saying that as i have so many ideas I want to try!

but that will be for when I have more experience and want to evolve it)

but that will be for when I have more experience and want to evolve it)I been looking around, but haven't fond a complete, clear one with full plans on how to built it. I am hopping that you guy's, that know the options out there, can give a few choices. (I want to follow instructions to a T, from bearings to the electronics)

What I am looking from a 3D printer:

- 8x8x8 Minimum,

- Simple is better, I am looking to learn.

- I am not in a hurry to the printer to print, it can take the time it wants, I have 2 baby's and a work load 2 miles long (yes, I know, adding the 3D printer, but the printer, hopefully, long term, will save me LOT of time and add a quality of life... I hope!)

- clear info on how to built it and configure it.

- I like to build it next month.

- Want to print ABS, PETg ( this: eSUN PETG ) and ninjaflex stuff, maybe even that bronze/metal filament!

- I plan on printing armor parts, masks and costumes accessory's, so big parts.

Now, I already own some 4 grove aluminum bars (tubes?) , this is what they look like, was wondering if I could use that for my structure

I have a lot, thinking of making something with storage cabinet for tools and material and such.

I was also considering, for my platform, using foam instead of heated bed.

Anyhow, hit me with recommendations! I can not wait to get started (I will keep y'll up to date)

Thank you,

Jonathan A. Connolly

|

Re: Building Core XY Printer: need help deciding on what built March 19, 2015 11:49PM |

Registered: 10 years ago Posts: 102 |

First, you should look on Thingiverse for examples of the CoreXY setup. Here are a number of good links: Link 1, Link 2, Link 3, Link 4, Link 5.

Most of these links are fairly similar. Some don't have parts lists but maybe they will expose you to more options so you can get a good feel of what you are looking for. I recently finished a build that I designed that was based mostly on the belt path of Link 4. I found it to be the easiest way to run the belts. It may not be the best way but it seems to work well for me.

All of that T-Slot is great start for this type of printer, though. I don't know much about heated/foam beds, sorry.

Good luck!

Most of these links are fairly similar. Some don't have parts lists but maybe they will expose you to more options so you can get a good feel of what you are looking for. I recently finished a build that I designed that was based mostly on the belt path of Link 4. I found it to be the easiest way to run the belts. It may not be the best way but it seems to work well for me.

All of that T-Slot is great start for this type of printer, though. I don't know much about heated/foam beds, sorry.

Good luck!

|

Re: Building Core XY Printer: need help deciding on what built March 20, 2015 03:46PM |

Registered: 9 years ago Posts: 23 |

hmmm, ok, thank you.

After looking at many build plans, I have a idea what I want to do.

I will start making plans in Sketch-up. I am thinking of making as much as I can machined.

I have a local store near me that dose bearings only, I will go and see if they have something I can use with my X rods.

I will try to go simple. As I am looking at all this, Good chances It will be 12 inch +

Question: Should I do pulley cable or rod for the bed? I can see my self make a pulley system that dose two side, making it one motor instead of two motor and rods.

I am going to us rails, and not shafts.

After looking at many build plans, I have a idea what I want to do.

I will start making plans in Sketch-up. I am thinking of making as much as I can machined.

I have a local store near me that dose bearings only, I will go and see if they have something I can use with my X rods.

I will try to go simple. As I am looking at all this, Good chances It will be 12 inch +

Question: Should I do pulley cable or rod for the bed? I can see my self make a pulley system that dose two side, making it one motor instead of two motor and rods.

I am going to us rails, and not shafts.

|

Re: Building Core XY Printer: need help deciding on what built March 21, 2015 01:19AM |

Registered: 9 years ago Posts: 346 |

Hello J.A.C

I am currently also finishing up my first design for a CoreXY. It is 99% sketched and currently printing parts and waiting for some last things to arrive. I already have a Delta style.

I would like to offer you and anyone else reading the following inputs/opinions:

1) First thing you need to decide is if the support structure and linear movement parts will be together (the same) or apart.

CoreT is an example of a printer where the structure is both load carrying and functional:

The original CoreXY is an example of independent structure. There is both a supporting structure and rods for the linear movement.

I understand you have already pretty much settled on the combined style. Where the structure is carrying and functional.

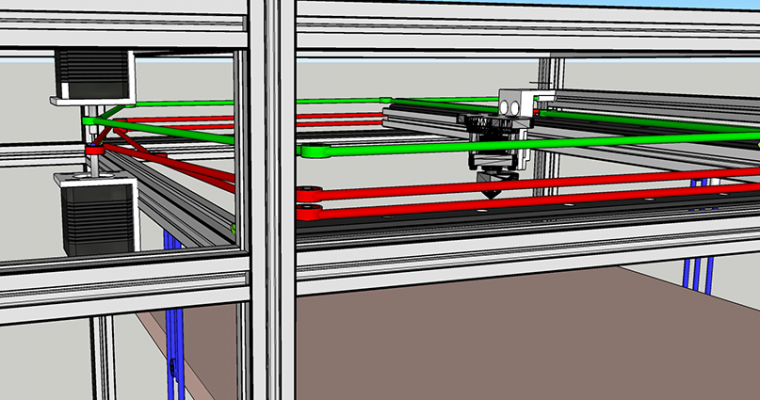

Then you need to decide if you will just use the extruded profiles plain or attach a rail to them. Attaching a rail is for example what Rectangle is doing:

Such is expensive but are more precise - But the limitations in extruder and electronics are so significant that I doubt you get much from the extra cost - Simply put, it does not help to improve something a bit if other issues are magnitudes bigger. One thing - If you go with bare alu profiles you cannot have any torque and twist in you carriages. That brings us to:

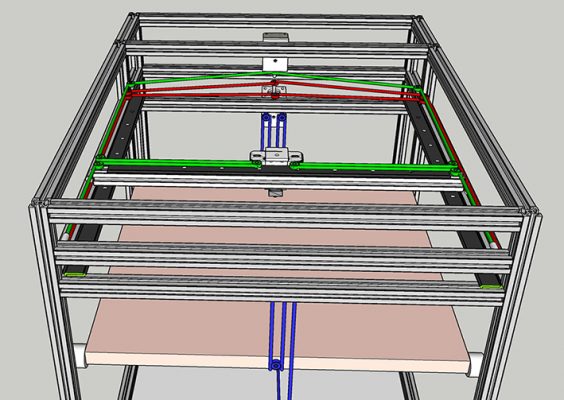

The carriage design - You can either do mono-rail or put two beams. Two rods shown here:

The advantage is the better load balancing. The disadvantage is added complexity.

A monorail with bare alu will be held in place by gravity so your extruder design becomes limited. You will not be able to later upgrade to a 4x extruder with water cooling setup if you just put a small monorail.

Going back to the two rails, some designs are these days puting them above each other. The advantage is that this plays very nicely with belts that are in different height plane and it takes up less space in the X direction.

Next stop is the drive and belts- You should use GT2 belts. There are a couple of things to consider:

- Belt tension system.

- Belts in plane with cross or different plane

- Motor mounting positioning

All 3 points are closely connected.

Some designs are tensioning the belts by positioning the motors. This can be seen on Sdavi's design:

The cost is another set of bearings to rotate the direction or to extend the printer backwards. Either way it requires that the design of the motor brackets can hand the force exerted while only being connected to one profile. That is not so hard I think.

Some designs have the tensioning where the belts terminate, again from Sdavi - I don't agree with him here. You should only need one tensioning point for each belt.

Some just don't tension the belts other then when clamping them.

The motors can be positioned inside or outside the frame, below or above. Most people who are using the alu profiles as functional seems to opt for positioning the motors and idlers inside the printer frame and having the belts in different heights (utilizing the height of the profiles). This is pretty much your only option because you wont print your parts. It will be so much easier to make when doing like this:

(Rectangled)

For the z you just need to move at one point. I think it is easier to reinforce that single point of lift to a point where it becomes stable, then to establishing a motor that drives two belt simultaneously. Having two points of lift will also reduce your access to the printing area because belt and rods will be in the way (only allowing access from two sides).

That is pretty much what considerations I have been making.

Finally - Make something that is easy. The materials for making these printers are cheap. Better to make one fast now that works, and then make the next awesome. Next time you will have a printer that can help by printing parts.

I am currently also finishing up my first design for a CoreXY. It is 99% sketched and currently printing parts and waiting for some last things to arrive. I already have a Delta style.

I would like to offer you and anyone else reading the following inputs/opinions:

1) First thing you need to decide is if the support structure and linear movement parts will be together (the same) or apart.

CoreT is an example of a printer where the structure is both load carrying and functional:

The original CoreXY is an example of independent structure. There is both a supporting structure and rods for the linear movement.

I understand you have already pretty much settled on the combined style. Where the structure is carrying and functional.

Then you need to decide if you will just use the extruded profiles plain or attach a rail to them. Attaching a rail is for example what Rectangle is doing:

Such is expensive but are more precise - But the limitations in extruder and electronics are so significant that I doubt you get much from the extra cost - Simply put, it does not help to improve something a bit if other issues are magnitudes bigger. One thing - If you go with bare alu profiles you cannot have any torque and twist in you carriages. That brings us to:

The carriage design - You can either do mono-rail or put two beams. Two rods shown here:

The advantage is the better load balancing. The disadvantage is added complexity.

A monorail with bare alu will be held in place by gravity so your extruder design becomes limited. You will not be able to later upgrade to a 4x extruder with water cooling setup if you just put a small monorail.

Going back to the two rails, some designs are these days puting them above each other. The advantage is that this plays very nicely with belts that are in different height plane and it takes up less space in the X direction.

Next stop is the drive and belts- You should use GT2 belts. There are a couple of things to consider:

- Belt tension system.

- Belts in plane with cross or different plane

- Motor mounting positioning

All 3 points are closely connected.

Some designs are tensioning the belts by positioning the motors. This can be seen on Sdavi's design:

The cost is another set of bearings to rotate the direction or to extend the printer backwards. Either way it requires that the design of the motor brackets can hand the force exerted while only being connected to one profile. That is not so hard I think.

Some designs have the tensioning where the belts terminate, again from Sdavi - I don't agree with him here. You should only need one tensioning point for each belt.

Some just don't tension the belts other then when clamping them.

The motors can be positioned inside or outside the frame, below or above. Most people who are using the alu profiles as functional seems to opt for positioning the motors and idlers inside the printer frame and having the belts in different heights (utilizing the height of the profiles). This is pretty much your only option because you wont print your parts. It will be so much easier to make when doing like this:

(Rectangled)

For the z you just need to move at one point. I think it is easier to reinforce that single point of lift to a point where it becomes stable, then to establishing a motor that drives two belt simultaneously. Having two points of lift will also reduce your access to the printing area because belt and rods will be in the way (only allowing access from two sides).

That is pretty much what considerations I have been making.

Finally - Make something that is easy. The materials for making these printers are cheap. Better to make one fast now that works, and then make the next awesome. Next time you will have a printer that can help by printing parts.

|

Re: Building Core XY Printer: need help deciding on what built March 21, 2015 02:11AM |

Registered: 9 years ago Posts: 977 |

@ LarsK: Thank you, that was a very interesting post about design choices for the structure / frame / mechanism for a CoreXY printer.

Just to complement your post, here are (in disorder) a few more things a developer has to be concerned with when developing a new printer design:

Any new, functional 3D printer design is the result of choices and decisions made pertaining to not only the printer mechanism which is already a complex issue in and of itself, but all these other points and probably many more which I have forgotten or do not even know about.

Edited 3 time(s). Last edit at 03/21/2015 07:19AM by AndrewBCN.

Just to complement your post, here are (in disorder) a few more things a developer has to be concerned with when developing a new printer design:

- Electronics: which controller to use? Does it support all the features I need or plan to use? Where do I put it, how do I hold it to the frame?

- Steppers: how much torque do I need? How do I mount my steppers?

- Wiring: how much wiring do I need? how do I route it? strain reliefs? Colors? connectors?

- Heated bed: what size and material? how much power? Can I use the standard MK2 PCB heatbed? How do I level it?

- Availability of standard parts: Do I have to custom machine any parts or have them machined for me on a CNC? How many standard parts can I use?

- Power supply: see Choosing a Power Supply

- Firmware: what are the firmwares supported by the controller I have chosen above, that support all the features I need? Which one to choose? How to configure it?

- Costs: this thing is going to end up costing me over $1000, how do I keep costs down?

- Extruder mechanism: choices, choices, choices...

- Hotend: and more choices...

- Cooling: my printer now sure prints fast, but the quality of the prints s...ks and it can't do bridges! Oh, wait, you said "cooling"?

- CAD software: Do I really have to learn OpenSCAD? (yes you do) Bah, no, Google Sketchup is good enough! (no it isn't)

- Last but not least, documentation. What 's that? BOM? Plans / Cad drawings / assembly manual / recommended settings? Who needs documentation, I have everything in my mind, anyways...

Any new, functional 3D printer design is the result of choices and decisions made pertaining to not only the printer mechanism which is already a complex issue in and of itself, but all these other points and probably many more which I have forgotten or do not even know about.

Edited 3 time(s). Last edit at 03/21/2015 07:19AM by AndrewBCN.

|

Re: Building Core XY Printer: need help deciding on what built March 21, 2015 07:39AM |

Registered: 10 years ago Posts: 341 |

Quote

LarsK

Some designs have the tensioning where the belts terminate, again from Sdavi - I don't agree with him here. You should only need one tensioning point for each belt.

Actually, I only use one tensioning point for each belt, the motors are both now fixed. A previous iteration I did tension only by sliding the motor mounts, but found this to be a less accurate way to apply tension, especially when both belts ideally should have equal tension. I find it much easier to pluck both belts and tighten a screw for the tension until they sound the same.

|

Re: Building Core XY Printer: need help deciding on what built March 21, 2015 11:00AM |

Registered: 9 years ago Posts: 346 |

Quote

sdavi

Quote

LarsK

Some designs have the tensioning where the belts terminate, again from Sdavi - I don't agree with him here. You should only need one tensioning point for each belt.

Actually, I only use one tensioning point for each belt, the motors are both now fixed. A previous iteration I did tension only by sliding the motor mounts, but found this to be a less accurate way to apply tension, especially when both belts ideally should have equal tension. I find it much easier to pluck both belts and tighten a screw for the tension until they sound the same.

Good morning Sdavi,

I stand corrected concerning your choice. It is interesting that sliding the motors did not work out so well. I do appreciate the simplicity in your carriage tensioning design.

@ AndrewBCN - I would like to give just my quick comment to your list because I think it is really good.

Electronics: The RAMPS board with Repetier or Marlin is what most is using and best chances of finding help on the internet.

Steppers: Nema 17 - Torque is in my opinion only a problem for z axis. But any of the many mid-markets should be able to do it.

Wiring: This makes the difference between a nice looking and a messy printer. I would say put it off and fix wires temporarily (but organized) with wire-strips. Once printer is up an running a first thing to print could be:

( by tosjduenfs)

Heated bed: Any heated bed works on the CoreXY. If using the software right (such as Repetier autolevel) then any linear leveling problems is easily absorbed.

Firmware: Repetier. Use what most are using.

Costs: This one is important. I think it is very important to think about what time is worth to you as a builder. For example the stepper motors - It may cost ~30 $ more to go for some of the biggest Nema 17 instead of the midrange/small. But then you know you will not have problems with power - Later you can change and re-use for other projects if overpowered. Or another example, if you buy off-she-shelve rails to mount on the alu profiles you know it is going to slide perfect.

Extruder mechanism: I think that on the CoreXY it really does not matter that much. If you position the motor on the carriage or use Bowden. But use direct extruder for simplicity. Again - Much easier just to buy that bigger Nema...

Hotend: Well, for just one extruder then it is pretty simple - Use what everybody is using: E3D or one of the variants

Cooling: As long as the hotend is cooled then cooling the print is for later when he can print the parts to cool. But probably good to think in now how to connect it.

Availability of standard parts: I understand from J.A.C that he has access to a mill.

|

Re: Building Core XY Printer: need help deciding on what built March 23, 2015 12:17AM |

Registered: 9 years ago Posts: 23 |

Ok, thank you for the comments, it guided me some decision making.

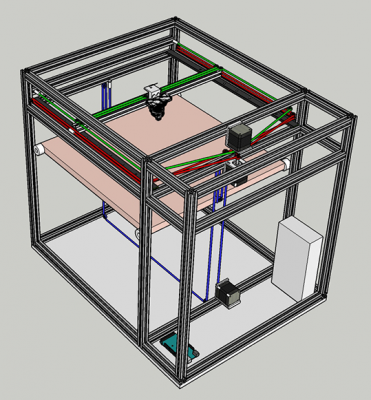

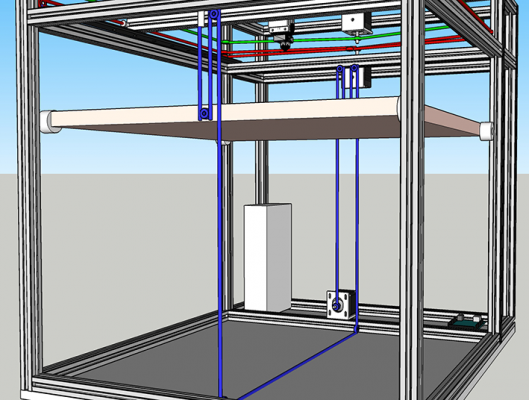

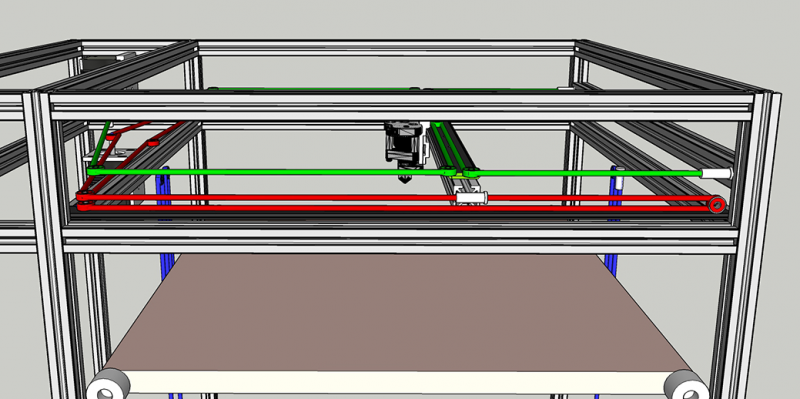

Now this my first "Idea" on my CoreXY. I did a quick sketchup to put my ideas on "paper".

I'd like any comments, I am willing to change and make it better as I go.

Now keep in mind that I was considering making it a Pulley Cable/wire Printer.

So here is a over look of the printer. I am putting all the electronics, motors and such on the side. I want to "Box" that, separated from the printer with a wall, and mount in some fan for extra cooling chamber (Like a computer tower). It also leaves me a easy access to everything.

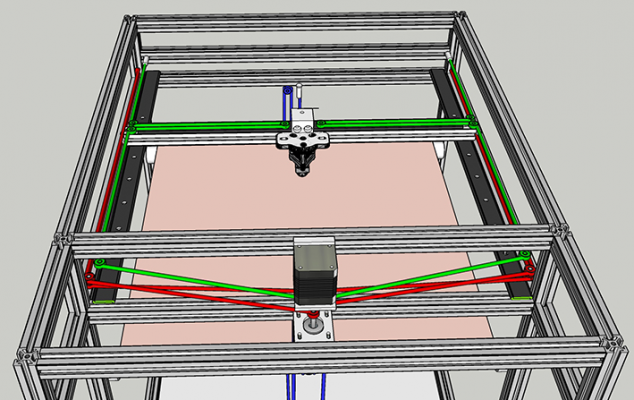

Now, the bed what drove me nuts at first, the concept is actually based from platform elevator system.

Now all this is really sketchy, but I wanted comments before I start making a real solid plan. I decided to center the motors for event stress on the cables and the pulley system.

The fun part about cable, is that do not have to stay "flat", Also, for the tension I am planning to have my hooks on nuts for putting the right tension on the cables.

Depending on what rail system I take, the print bed will be in the 14x16x18, but I will be happy with 12x14x16 , I left a lot of space so I have room to go in without worrying to much.

The bed will hold by 4 rail for a even and solid, I am not planning on putting a heated bed for now, and if I do, good chances it will be home made.

I am considering putting the extruder on the frame, keep everything as light as I can.

But as I said, I want to consider all the comments of ya guy's.

I started a BOM list, because I making/have most everything that is frame related, the price is keep low. I want to go with popularize systems/motors, and good quality, this should cost me in the 400$

Now this my first "Idea" on my CoreXY. I did a quick sketchup to put my ideas on "paper".

I'd like any comments, I am willing to change and make it better as I go.

Now keep in mind that I was considering making it a Pulley Cable/wire Printer.

So here is a over look of the printer. I am putting all the electronics, motors and such on the side. I want to "Box" that, separated from the printer with a wall, and mount in some fan for extra cooling chamber (Like a computer tower). It also leaves me a easy access to everything.

Now, the bed what drove me nuts at first, the concept is actually based from platform elevator system.

Now all this is really sketchy, but I wanted comments before I start making a real solid plan. I decided to center the motors for event stress on the cables and the pulley system.

The fun part about cable, is that do not have to stay "flat", Also, for the tension I am planning to have my hooks on nuts for putting the right tension on the cables.

Depending on what rail system I take, the print bed will be in the 14x16x18, but I will be happy with 12x14x16 , I left a lot of space so I have room to go in without worrying to much.

The bed will hold by 4 rail for a even and solid, I am not planning on putting a heated bed for now, and if I do, good chances it will be home made.

I am considering putting the extruder on the frame, keep everything as light as I can.

But as I said, I want to consider all the comments of ya guy's.

I started a BOM list, because I making/have most everything that is frame related, the price is keep low. I want to go with popularize systems/motors, and good quality, this should cost me in the 400$

|

Re: Building Core XY Printer: need help deciding on what built March 23, 2015 05:11AM |

Registered: 9 years ago Posts: 1,011 |

Hi, I'm not realy confident with your belt system. I would stick to the existing CoreXY belt system, why would I change it ? I'm sure you can improove your structure easily, and minimize cuts and hardware. You want a huge build plate. IMHO you can't multiply the build area of a prusa i3 by 10 while staying in a comparable build cost. Is it your first build ? Are the wheels at the corner of your bed carriage meant to guide it ?

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Building Core XY Printer: need help deciding on what built March 23, 2015 05:27AM |

Registered: 9 years ago Posts: 1,159 |

Quote

J.A.C.

Ok, thank you for the comments, it guided me some decision making.

Now this my first "Idea" on my CoreXY. I did a quick sketchup to put my ideas on "paper".

I'd like any comments, I am willing to change and make it better as I go.

Now keep in mind that I was considering making it a Pulley Cable/wire Printer.

So here is a over look of the printer. I am putting all the electronics, motors and such on the side. I want to "Box" that, separated from the printer with a wall, and mount in some fan for extra cooling chamber (Like a computer tower). It also leaves me a easy access to everything.

[attachment 51576 My_corexy-test-01-01.jpg]

Now, the bed what drove me nuts at first, the concept is actually based from platform elevator system.

[attachment 51577 My_corexy-test-01-02.jpg][attachment 51578 My_corexy-test-01-03.jpg]

Now all this is really sketchy, but I wanted comments before I start making a real solid plan. I decided to center the motors for event stress on the cables and the pulley system.

[attachment 51582 My_corexy-test-01-04.jpg]

The fun part about cable, is that do not have to stay "flat", Also, for the tension I am planning to have my hooks on nuts for putting the right tension on the cables.

[attachment 51581 My_corexy-test-01-05.jpg][attachment 51580 My_corexy-test-01-06.jpg][attachment 51579 My_corexy-test-01-07.jpg]

Depending on what rail system I take, the print bed will be in the 14x16x18, but I will be happy with 12x14x16 , I left a lot of space so I have room to go in without worrying to much.

The bed will hold by 4 rail for a even and solid, I am not planning on putting a heated bed for now, and if I do, good chances it will be home made.

I am considering putting the extruder on the frame, keep everything as light as I can.

But as I said, I want to consider all the comments of ya guy's.

I started a BOM list, because I making/have most everything that is frame related, the price is keep low. I want to go with popularize systems/motors, and good quality, this should cost me in the 400$

Looking at your belt path this looks more like a std Cartesian to me ie separate motions for the X and the Y where CoreXY uses both motors for both axis

Edited 1 time(s). Last edit at 03/23/2015 05:29AM by dougal1957.

|

Re: Building Core XY Printer: need help deciding on what built March 23, 2015 06:14AM |

Registered: 9 years ago Posts: 977 |

Well, it matters, because you want to minimize the mass of the moving head, to achieve the maximum potential speed of the CoreXY mechanism. That's why most CoreXY printers use a Bowden system. Unfortunately, using a Bowden system also brings its share of problems and further design decisions and compromises... So it's not that simple. Decisions, decisions...

|

Re: Building Core XY Printer: need help deciding on what built March 23, 2015 06:30AM |

Registered: 9 years ago Posts: 977 |

|

Re: Building Core XY Printer: need help deciding on what built March 23, 2015 07:29AM |

Registered: 9 years ago Posts: 23 |

(ps: yes this is my first printer)

-Cartesian, ahha, did not know that. Am I still in the the right Forum sector? ^_^ I was thinking of going with a cable system (Cartesian), but if that system is flawed, I would like to know (and why).

-Bowden system? what is the best way to minimize the problems that follow with it? Should I start with the extrude'r on top and evolve to a bowden later?

-The wheels on the bed plate are symbols. I haven't decided on what to use yet. I was maybe thinking putting "skates" on the 4 sides for a even, solid slide. I want to keep the bed as light and slick as possible, so that the pulley/cable dose not struggle. but since i am going with the gravity and not against it, I am not that worried.

- I am already rethinking the way I will cut and make the structure.

-Cartesian, ahha, did not know that. Am I still in the the right Forum sector? ^_^ I was thinking of going with a cable system (Cartesian), but if that system is flawed, I would like to know (and why).

-Bowden system? what is the best way to minimize the problems that follow with it? Should I start with the extrude'r on top and evolve to a bowden later?

-The wheels on the bed plate are symbols. I haven't decided on what to use yet. I was maybe thinking putting "skates" on the 4 sides for a even, solid slide. I want to keep the bed as light and slick as possible, so that the pulley/cable dose not struggle. but since i am going with the gravity and not against it, I am not that worried.

- I am already rethinking the way I will cut and make the structure.

|

Re: Building Core XY Printer: need help deciding on what built March 23, 2015 07:53AM |

Registered: 9 years ago Posts: 1,159 |

Quote

J.A.C.

(ps: yes this is my first printer)

-Cartesian, ahha, did not know that. Am I still in the the right Forum sector? ^_^ I was thinking of going with a cable system (Cartesian), but if that system is flawed, I would like to know (and why).

-Bowden system? what is the best way to minimize the problems that follow with it? Should I start with the extrude'r on top and evolve to a bowden later?

-The wheels on the bed plate are symbols. I haven't decided on what to use yet. I was maybe thinking putting "skates" on the 4 sides for a even, solid slide. I want to keep the bed as light and slick as possible, so that the pulley/cable dose not struggle. but since i am going with the gravity and not against it, I am not that worried.

- I am already rethinking the way I will cut and make the structure.

To better understand the CoreXY System have a read of Zeologic After H-Bot go CoreXY Thread it has lots of usefull and helpful stuff in there.

Doug

|

Re: Building Core XY Printer: need help deciding on what built March 24, 2015 09:36AM |

Registered: 9 years ago Posts: 346 |

Quote

AndrewBCN

Quote

LarsK

...

Extruder mechanism: I think that on the CoreXY it really does not matter that much. If you position the motor on the carriage or use Bowden. But use direct extruder for simplicity. Again - Much easier just to buy that bigger Nema...

...

Well, it matters, because you want to minimize the mass of the moving head, to achieve the maximum potential speed of the CoreXY mechanism. That's why most CoreXY printers use a Bowden system. Unfortunately, using a Bowden system also brings its share of problems and further design decisions and compromises... So it's not that simple. Decisions, decisions...

Do you know that because you experimented with it or do you say it because you read it elsewhere? Obviously mass matters in some way. But is it in anyway significant when talking about speeds that the Arduino environment and extruder systems can handle?

Maybe you could try to do two prints, one normal at max speed and then the same but with 0.5 kg bootstrapped to carriage and see how much it matters?

Personally I think the far biggest advantage of the CoreXY system to the cartesian system (like the one JAC presented) is that you have two motors working together to do a motion. If we assume there is a small error in motor one and it stops 1 later then motor two then the error the extruder will see is the average of the two. Thus 0.5. That fact, that errors and misalignment in the two systems of motion averages out is why it is good.

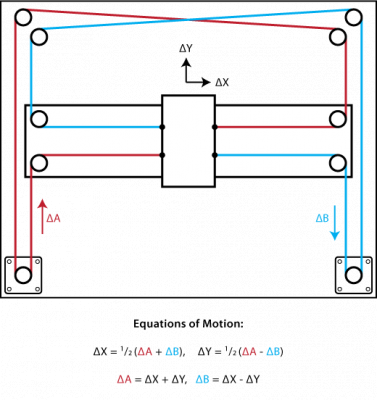

Also review the equations of motions as originally written by Moyer:

|

Re: Building Core XY Printer: need help deciding on what built March 24, 2015 10:07AM |

Registered: 9 years ago Posts: 346 |

Quote

J.A.C.

...

Now, the bed what drove me nuts at first, the concept is actually based from platform elevator system.

[attachment 51577 My_corexy-test-01-02.jpg][attachment 51578 My_corexy-test-01-03.jpg]

....

Hello J.A.C

That z level is very alternative. Try to consider how that will make it's movement in negative z direction (down) - You will be relying on gravity to position your bed when going down. 3d printers needs to be very exact and with nothing forcing it you can easily have a situation where one corner falls a little more then another. I urge you to reconsider making a single point of lift because that is the simplest. If you want two points of lift then please look at this design:

( Aalekh khetmali )

Not so much the rest of the printer. Just look at how simple the z axis drive is. One shaft driving two belts. Done.

Also you are overestimating how stiff your printer needs to be while your mounting of the motors may actually be too weak. Look at other designs and how many profiles they use. You should be able to do make it with the same numbers.

Finally, as others have said, your belts layout are wrong. Look at the picture I posted above of the basic CoreXY theory.

|

Re: Building Core XY Printer: need help deciding on what built March 24, 2015 01:13PM |

Registered: 9 years ago Posts: 977 |

Quote

LarsK

Quote

AndrewBCN

Quote

LarsK

...

Extruder mechanism: I think that on the CoreXY it really does not matter that much. If you position the motor on the carriage or use Bowden. But use direct extruder for simplicity. Again - Much easier just to buy that bigger Nema...

...

Well, it matters, because you want to minimize the mass of the moving head, to achieve the maximum potential speed of the CoreXY mechanism. That's why most CoreXY printers use a Bowden system. Unfortunately, using a Bowden system also brings its share of problems and further design decisions and compromises... So it's not that simple. Decisions, decisions...

Do you know that because you experimented with it or do you say it because you read it elsewhere? Obviously mass matters in some way. But is it in anyway significant when talking about speeds that the Arduino environment and extruder systems can handle?

Do you need to put your hand in the fire to know that you'll get burned? Obviously not. The same idea applies here, we can think about it in Newtonian mechanics terms: the kinetic energy of a moving extruder head is directly proportional to its mass and the square of its speed. If you want to double the speed you have to decrease the mass by a factor of four. This is the reason why most linear delta printers use a Bowden system and the same reason a CoreXY will reach its maximum printing speed with a low mass head using a Bowden system.

Quote

LarsK

Maybe you could try to do two prints, one normal at max speed and then the same but with 0.5 kg bootstrapped to carriage and see how much it matters?

I have used three different extruders (with slightly different weights) on my P3Steels and I could directly observe the relationship between the mass of the X and Y carriages and the maximum speed I could reach for a given print quality. So yes, I can tell that it matters a lot.

Quote

LarsK

Personally I think the far biggest advantage of the CoreXY system to the cartesian system (like the one JAC presented) is that you have two motors working together to do a motion. If we assume there is a small error in motor one and it stops 1 later then motor two then the error the extruder will see is the average of the two. Thus 0.5. That fact, that errors and misalignment in the two systems of motion averages out is why it is good.

Unfortunately your math is wrong... think about it for a moment...

Include an error factor in these equations and you'll notice that any error in A or B will cause an error of half magnitude in both X and Y i.e. the total error remains exactly the same, it is not halved as you incorrectly concluded above. Also, you should be aware that random errors in any system do not cancel out, they add up, just like noise.

Edited 2 time(s). Last edit at 03/24/2015 01:19PM by AndrewBCN.

|

Re: Building Core XY Printer: need help deciding on what built March 24, 2015 02:57PM |

Registered: 9 years ago Posts: 346 |

Quote

AndrewBCN

Unfortunately your math is wrong... think about it for a moment...

Include an error factor in these equations and you'll notice that any error in A or B will cause an error of half magnitude in both X and Y i.e. the total error remains exactly the same, it is not halved as you incorrectly concluded above. Also, you should be aware that random errors in any system do not cancel out, they add up, just like noise.

Ok - Does it half out if you have an error in one movement?

You are right. It does not. But you are also wrong.

In a normal cartesian printer your hotend will have moved a distance 1 if you have an error 1 on given motor. As you said, it will on the CoreXY have moved 0.5 in x and 0.5 in y.

Then the norm distance is: (0.5^2 + 0.5^2)^(1/2) = 0.707 distance from where you thought you were, to where you really are.

This is not 0.5 as I claimed. But it is better that when one motor is off by 1 then your hotend is just 0.7 from where you wanted to be.

Agreed?

As to your experiments different extruders on the P3Steels - Well that printer is moving the Z axis and then the weight will without doubt have a much bigger effect. I certainly think it is something to investigate further.

|

Re: Building Core XY Printer: need help deciding on what built March 25, 2015 12:15AM |

Registered: 9 years ago Posts: 158 |

Forget CoreXY go with cartesian, or maybe even something of the prusa style.

I say this from the perspective of having successfully built a coreXY.

I think I too was 'seduced' by the idea of having a high speed, low mass printhead churning out super fast prints.

I don't think moving mass is the limit to speed; It is partly the ability to extrude plastic quick enough and mainly the desire by most people to have a half decent looking print at the end of it and turning the speed down.

They are a pain to set up. You have to have 10 pulleys (including the motors) bang on square in 3 planes. If they're not parallel there are issues of belts riding off idlers or binding on pulley edges, If they are not perfectly square to the moving elements then the equations of motion above are not correct.

Compared to 4 pulleys in cartesian where each pair (or axis) of which can be considered and assembled as separate entities, then you need only get the 2 sub assemblies at 90 degrees.

I reckon they are also more prone to generate noise and resonance with so many points of contact between belt idlers/ motors and framework. Maybe that's just my cheap bearings. You can't skimp on components. The moving axis needs to be fairly substantial to cope with the torsion of setting up belt tensions (tho' it is equal when they are set up)

I used v-slot to build mine, I know using that for a cartesian build would have been a doddle in comparison, with so many easy ways to drive it (check out 'fixed belt in the slot like rack and pinion' - You can't get it wrong and nothing needs alignment)

CoreXY isn't fully and correctly implemented in Marlin (and probably others) firmware. I think there are bugs. Some features are not available - babystepping for one.

If using Ramps and Marlin, there is a problem with driving them at 1/32 step - there is an absolute limit of 125mm/s or 7500mm/min. feedrate on X or Y axis.

Set it to 7501mm/min and it does some horrible things to the sync of the motors. Print with it at real world sub 100mm/s type speed with 1/32 and there are occasional noises that don't inspire confidence.

Diagnosing motor issues is awkward even if you set it to cartesian to move only one motor, you're still dragging the other belt about and its hard to measure diagonal moves.

I mention Prusa's - Beauty is in the eye of the beholder they say, but I think that the one thing that Core XY and cartesians do have in common is they end up looking ugly big cubes that must contain the entire print volume, whether they're printing or not.

At least with a Mendel or Prusa style the print volume is out in fresh air that can be shared by other domestic appliances when they're not printing. And they can be prettied up a bit. And there's a lot of know how behind them.

Sure, the pro's make boxed in printers of the Core/ Cart variety -the motion control is better but would a home made effort be any better at printing than a well established reprap mendel style design?

There's a reason Stratasys spends millions of $ and thousands of man hours developing a printer - 'cos that's what it takes.

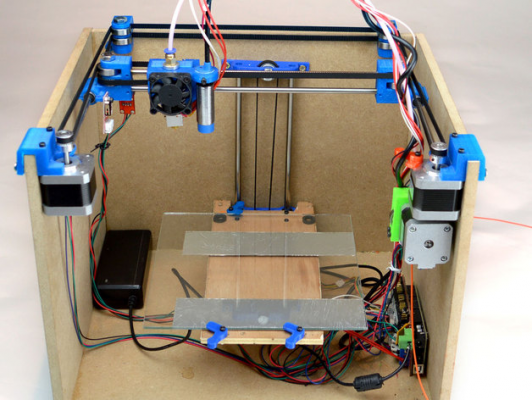

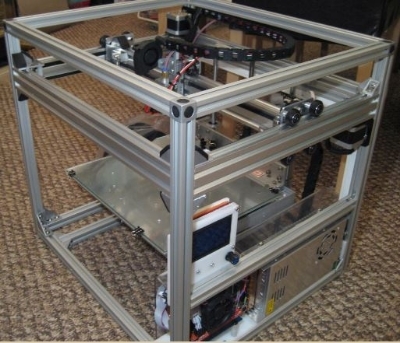

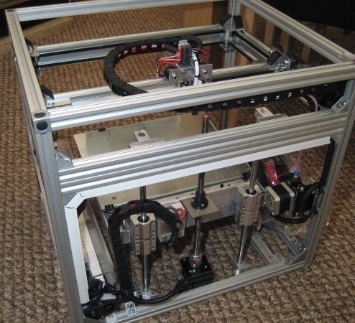

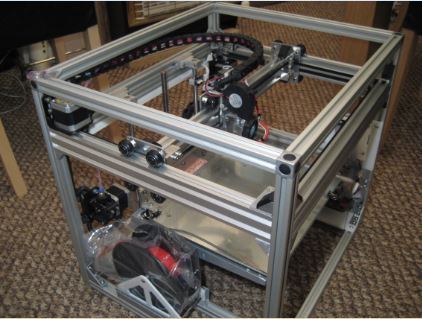

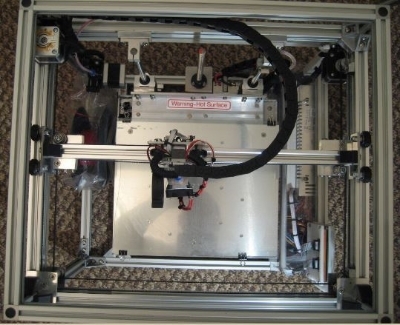

Anyway, enough moaning, here's mine if you want to see it. Just don't bother making one.

Love it really. Prints great. 304x214x220 print area in a box 420x480x450. Just waiting for the covers to arrive and its done.

-a

I say this from the perspective of having successfully built a coreXY.

I think I too was 'seduced' by the idea of having a high speed, low mass printhead churning out super fast prints.

I don't think moving mass is the limit to speed; It is partly the ability to extrude plastic quick enough and mainly the desire by most people to have a half decent looking print at the end of it and turning the speed down.

They are a pain to set up. You have to have 10 pulleys (including the motors) bang on square in 3 planes. If they're not parallel there are issues of belts riding off idlers or binding on pulley edges, If they are not perfectly square to the moving elements then the equations of motion above are not correct.

Compared to 4 pulleys in cartesian where each pair (or axis) of which can be considered and assembled as separate entities, then you need only get the 2 sub assemblies at 90 degrees.

I reckon they are also more prone to generate noise and resonance with so many points of contact between belt idlers/ motors and framework. Maybe that's just my cheap bearings. You can't skimp on components. The moving axis needs to be fairly substantial to cope with the torsion of setting up belt tensions (tho' it is equal when they are set up)

I used v-slot to build mine, I know using that for a cartesian build would have been a doddle in comparison, with so many easy ways to drive it (check out 'fixed belt in the slot like rack and pinion' - You can't get it wrong and nothing needs alignment)

CoreXY isn't fully and correctly implemented in Marlin (and probably others) firmware. I think there are bugs. Some features are not available - babystepping for one.

If using Ramps and Marlin, there is a problem with driving them at 1/32 step - there is an absolute limit of 125mm/s or 7500mm/min. feedrate on X or Y axis.

Set it to 7501mm/min and it does some horrible things to the sync of the motors. Print with it at real world sub 100mm/s type speed with 1/32 and there are occasional noises that don't inspire confidence.

Diagnosing motor issues is awkward even if you set it to cartesian to move only one motor, you're still dragging the other belt about and its hard to measure diagonal moves.

I mention Prusa's - Beauty is in the eye of the beholder they say, but I think that the one thing that Core XY and cartesians do have in common is they end up looking ugly big cubes that must contain the entire print volume, whether they're printing or not.

At least with a Mendel or Prusa style the print volume is out in fresh air that can be shared by other domestic appliances when they're not printing. And they can be prettied up a bit. And there's a lot of know how behind them.

Sure, the pro's make boxed in printers of the Core/ Cart variety -the motion control is better but would a home made effort be any better at printing than a well established reprap mendel style design?

There's a reason Stratasys spends millions of $ and thousands of man hours developing a printer - 'cos that's what it takes.

Anyway, enough moaning, here's mine if you want to see it. Just don't bother making one.

Love it really. Prints great. 304x214x220 print area in a box 420x480x450. Just waiting for the covers to arrive and its done.

-a

|

Re: Building Core XY Printer: need help deciding on what built March 26, 2015 03:14AM |

Registered: 9 years ago Posts: 977 |

@alan richard

First, quite a nice printer you have built there.

I can see two sharp bends in the filament path between the extruder and the print head, and although it makes for a neat layout, this will negatively affect both the quality and maximum achievable speed for your prints.

I guess it's one more item I should have added to the list of things one has to worry about in a new printer design!

First, quite a nice printer you have built there.

I can see two sharp bends in the filament path between the extruder and the print head, and although it makes for a neat layout, this will negatively affect both the quality and maximum achievable speed for your prints.

I guess it's one more item I should have added to the list of things one has to worry about in a new printer design!

|

Re: Building Core XY Printer: need help deciding on what built March 26, 2015 08:17AM |

Registered: 9 years ago Posts: 158 |

Hi Andrew. You are quite right, its not optimal.

It does print ok so far with PLA up to 80mm/s but something rougher like Timberfill wouldn't go up there.

I expect the friction on the filament will vary depending where the print head is which may show itself on bigger prints.

I don't usually do; 'form over function' but that was one case on this build to try and keep it all within the box.

I'll probably get some more ptfe tube tube to loop up and over in a conventional way.

(I could have taken 60 or 70mm off that cantilevered Z axis too - another sop to aesthetics to have the hotend visible from the 'front window' of the machine.)

@J.A.C. - 'Scuse me having an anti-CoreXY rant on your thread, especially here on the CoreXY forum! I was a bit tired and cross at the time.

CoreXY is a lovely quirky mechanism, set up right it works fine. Its a nice engineering challenge.

I just feel that in the 3D printing subculture there is unfair bias towards it being the answer to every problem without much focus on some if its negatives.

My own conclusion from doing this is that it is better suited to either mass production, fast non 3D printing applications, or a printer that has a huge span where every spare gram needs trimming off.

I am a printing newbie but familiar with machines. As a one-off 'build it in your shed' reprap, I think you could make a printer that's just as capable but a lot easier to put together using other methods and you did say 'simple is better' in your first post.

That's a handy looking stack of extrusion in your first picture. I used 20x20 standard extrusion and bought a couple of metres of Openbuilds V slot 40x20 for linear motion. I already had the round bar and SC10UU bearings (It started out as a Mendelmax 2 lookie like and evolved!)

With hindsight, a cartesian using this method

would have gone together easier, saved a lot of workshop time, cost less, run quieter and I'd feel more comfortable about firmware.

I can't really think of any downsides now I understand the printing side better.

Good luck whatever you build.

Alan

It does print ok so far with PLA up to 80mm/s but something rougher like Timberfill wouldn't go up there.

I expect the friction on the filament will vary depending where the print head is which may show itself on bigger prints.

I don't usually do; 'form over function' but that was one case on this build to try and keep it all within the box.

I'll probably get some more ptfe tube tube to loop up and over in a conventional way.

(I could have taken 60 or 70mm off that cantilevered Z axis too - another sop to aesthetics to have the hotend visible from the 'front window' of the machine.)

@J.A.C. - 'Scuse me having an anti-CoreXY rant on your thread, especially here on the CoreXY forum! I was a bit tired and cross at the time.

CoreXY is a lovely quirky mechanism, set up right it works fine. Its a nice engineering challenge.

I just feel that in the 3D printing subculture there is unfair bias towards it being the answer to every problem without much focus on some if its negatives.

My own conclusion from doing this is that it is better suited to either mass production, fast non 3D printing applications, or a printer that has a huge span where every spare gram needs trimming off.

I am a printing newbie but familiar with machines. As a one-off 'build it in your shed' reprap, I think you could make a printer that's just as capable but a lot easier to put together using other methods and you did say 'simple is better' in your first post.

That's a handy looking stack of extrusion in your first picture. I used 20x20 standard extrusion and bought a couple of metres of Openbuilds V slot 40x20 for linear motion. I already had the round bar and SC10UU bearings (It started out as a Mendelmax 2 lookie like and evolved!)

With hindsight, a cartesian using this method

would have gone together easier, saved a lot of workshop time, cost less, run quieter and I'd feel more comfortable about firmware.

I can't really think of any downsides now I understand the printing side better.

Good luck whatever you build.

Alan

|

Re: Building Core XY Printer: need help deciding on what built March 26, 2015 04:12PM |

Registered: 14 years ago Posts: 128 |

I agree with Alan in regards to not getting carried away thinking that CoreXY will give you faster print times with having a low mass head assembly. You can only push though filament at a maximum rate with a hot end. However with less head assembly mass you can have more acceleration and de-acceleration to reach maximum speed. Its may not be a lot but good direction to head for. Also less moving wires to at least one stepper motor which can keep the look better.

One needs to be careful that with CoreXY that you don't add a lot of mass with lots of moving parts and this includes any belts, pulleys, shafts that turn. If you do then you have wasted your energy with going CoreXY.

I think a lot depends on the total printer CoreXY design that is being built to whether its a good way to go or not.

I have found my Openbeam CoreXY design to be good at adjusting the alignment of pulleys and belts. just a case of aligning the bearings along the Openbeam extrusions and tightening the screws. Pulleys can be moved up and down the shafts to adjust belt heights.

Noise is low with using 8mm linear bearings and carbon steel shafts (you can't cut the carbon steel shafts with a hacksaw, too hard- have to use a electric grinder with a cutting wheel).

I like the fact that I was able to have whole printer including electronics, power supply, one roll of filament in one box area.

Good to see everyone is pushing the designs to see what we end up with...

Some good hard work has gone into your design Alan.

Cheers Bruce.

One needs to be careful that with CoreXY that you don't add a lot of mass with lots of moving parts and this includes any belts, pulleys, shafts that turn. If you do then you have wasted your energy with going CoreXY.

I think a lot depends on the total printer CoreXY design that is being built to whether its a good way to go or not.

I have found my Openbeam CoreXY design to be good at adjusting the alignment of pulleys and belts. just a case of aligning the bearings along the Openbeam extrusions and tightening the screws. Pulleys can be moved up and down the shafts to adjust belt heights.

Noise is low with using 8mm linear bearings and carbon steel shafts (you can't cut the carbon steel shafts with a hacksaw, too hard- have to use a electric grinder with a cutting wheel).

I like the fact that I was able to have whole printer including electronics, power supply, one roll of filament in one box area.

Good to see everyone is pushing the designs to see what we end up with...

Some good hard work has gone into your design Alan.

Cheers Bruce.

|

Re: Building Core XY Printer: need help deciding on what built March 26, 2015 04:50PM |

Registered: 10 years ago Posts: 14,672 |

My delta printer can print the same test piece at about twice the speed of my Cartesian printer for the same print quality. I ascribe this to having a low mass print head and a bed that does not move in the XY plane. I guess that a CoreXY design with Bowden extruder ought to be as fast as a delta for the same reasons.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Building Core XY Printer: need help deciding on what built March 26, 2015 05:43PM |

Registered: 9 years ago Posts: 31 |

|

Re: Building Core XY Printer: need help deciding on what built March 26, 2015 09:06PM |

Registered: 14 years ago Posts: 128 |

As per the attached picture, used polycarbonate for the block but you properly can use other materials even 3D print them.

Shaft is a 6mm dia which has been turned down in a mini lathe to fit the 5mm bearings. Used toy helicopter bearings from Ebay 10mm (outside dia) x 5mm (inside dia) x 4mm (wide).

The 2 blocks simply squeeze the bearings into the hold position. Loosen the screws and you can slide the whole thing when using Openbeam.

Cheers

Edited 1 time(s). Last edit at 03/26/2015 09:11PM by RepRot.

Shaft is a 6mm dia which has been turned down in a mini lathe to fit the 5mm bearings. Used toy helicopter bearings from Ebay 10mm (outside dia) x 5mm (inside dia) x 4mm (wide).

The 2 blocks simply squeeze the bearings into the hold position. Loosen the screws and you can slide the whole thing when using Openbeam.

Cheers

Edited 1 time(s). Last edit at 03/26/2015 09:11PM by RepRot.

|

Re: Building Core XY Printer: need help deciding on what built March 26, 2015 09:14PM |

Registered: 9 years ago Posts: 158 |

@Reprot - Thanks Bruce. Also I appreciate your assistance with a couple of issues I had. I have to say I drew inspiration from your 'everything inside the box' school of design.

@dc42 & @Reprot - I'm quite happy to stand corrected on these things, especially if I turns out I did the right thing after all. I've not been printing long enough to start pushing the speed and acceleration envelope.

Sorry it looks like I went off on a (semi drunken) moan about it all, when I come to re-read it.

@J.A.C - Excuse me hijacking your thread. I'll post my own build thread somewhere. I have quite a few components and assembly iterations modeled on CAD if they're of use.

Regards

a

@dc42 & @Reprot - I'm quite happy to stand corrected on these things, especially if I turns out I did the right thing after all. I've not been printing long enough to start pushing the speed and acceleration envelope.

Sorry it looks like I went off on a (semi drunken) moan about it all, when I come to re-read it.

@J.A.C - Excuse me hijacking your thread. I'll post my own build thread somewhere. I have quite a few components and assembly iterations modeled on CAD if they're of use.

Regards

a

Sorry, only registered users may post in this forum.