Alternative to Bowden extruder

Posted by scubi

|

Alternative to Bowden extruder August 17, 2015 07:34AM |

Registered: 11 years ago Posts: 154 |

Hi Guys

I am the process of building the Smartrapcore printer with square Aluminum ( 19.07mm ) tube.

I was wonder if anyone is using a Greg's wade extruder with their Smartrapcore because I read that Flexible filament does not do well with the Bowden extruder ?

I would appreciate your advice and which extruder I can use.

Thanks

Vaughan

I am the process of building the Smartrapcore printer with square Aluminum ( 19.07mm ) tube.

I was wonder if anyone is using a Greg's wade extruder with their Smartrapcore because I read that Flexible filament does not do well with the Bowden extruder ?

I would appreciate your advice and which extruder I can use.

Thanks

Vaughan

|

Re: Alternative to Bowden extruder August 19, 2015 07:32AM |

Registered: 9 years ago Posts: 977 |

You can use a Greg's Wade's Geared Extruder with basically any 3D FDM printer, and there are Bowden versions of the Greg's Wade's too. Note that unless you run a PTFE tube from the nozzle right up to the hobbed bolt, a standard Greg's Wade's Geared Extruder won't work particularly well with flexible filament.

In the case of both Core XY and linear delta printers, you are better off with a Bowden arrangement in any case, so printing flexible filaments with these kinds of printers is not recommended, and most people rarely have a need to print with flexible filaments anyways.

If you really have a need to print various kg of flexible filament, you are advised to use a separate printer with an extruder on the print head (meaning probably a Cartesian design) and an extruder design with a proven history of good quality printing with flexible filaments.

In the case of both Core XY and linear delta printers, you are better off with a Bowden arrangement in any case, so printing flexible filaments with these kinds of printers is not recommended, and most people rarely have a need to print with flexible filaments anyways.

If you really have a need to print various kg of flexible filament, you are advised to use a separate printer with an extruder on the print head (meaning probably a Cartesian design) and an extruder design with a proven history of good quality printing with flexible filaments.

|

Re: Alternative to Bowden extruder August 19, 2015 08:02AM |

Registered: 9 years ago Posts: 1,159 |

Quote

AndrewBCN

You can use a Greg's Wade's Geared Extruder with basically any 3D FDM printer, and there are Bowden versions of the Greg's Wade's too. Note that unless you run a PTFE tube from the nozzle right up to the hobbed bolt, a standard Greg's Wade's Geared Extruder won't work particularly well with flexible filament.

In the case of both Core XY and linear delta printers, you are better off with a Bowden arrangement in any case, so printing flexible filaments with these kinds of printers is not recommended, and most people rarely have a need to print with flexible filaments anyways.

If you really have a need to print various kg of flexible filament, you are advised to use a separate printer with an extruder on the print head (meaning probably a Cartesian design) and an extruder design with a proven history of good quality printing with flexible filaments.

I'll second that

Doug

|

Re: Alternative to Bowden extruder August 19, 2015 02:41PM |

Registered: 8 years ago Posts: 49 |

Quote

AndrewBCN

In the case of both Core XY and linear delta printers, you are better off with a Bowden arrangement in any case, so printing flexible filaments with these kinds of printers is not recommended, and most people rarely have a need to print with flexible filaments anyways.

If you really have a need to print various kg of flexible filament, you are advised to use a separate printer with an extruder on the print head (meaning probably a Cartesian design) and an extruder design with a proven history of good quality printing with flexible filaments.

While I understand that CoreXY provides the ability to dramatically reduce the total inertial mass that is being moved around, is there some reason why having the extruder on the print head is undesireable in a CoreXY setup vs, say, a serially stacked cartesian? Is it somehow less cabable of handling the inertia of the extruder motor? I understand the reasoning in a delta, where you have the print head suspended from slender rods, but it would seem to me that a CoreXY is not any more subject to inertial effects than a cartesian.

What hotends and extruder designs have a good history with flexible filaments?

Edited 1 time(s). Last edit at 08/19/2015 02:43PM by wfcook.

|

Re: Alternative to Bowden extruder August 22, 2015 12:39AM |

Registered: 8 years ago Posts: 166 |

|

Re: Alternative to Bowden extruder September 09, 2015 06:49PM |

Registered: 8 years ago Posts: 346 |

|

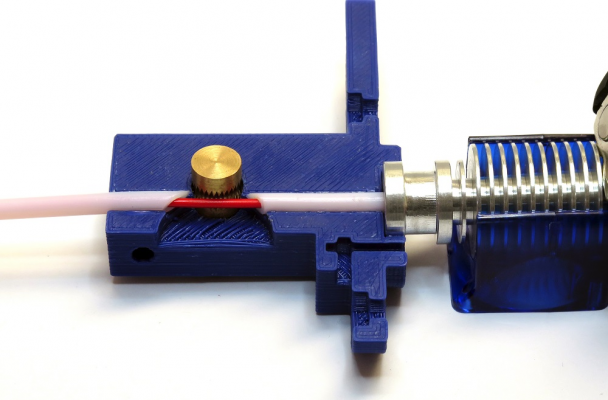

Re: Alternative to Bowden extruder September 10, 2015 09:01AM |

Registered: 9 years ago Posts: 722 |

Hi,

CoreXY can allow very fast moves.

And speed is the seccond thing you need since your printer is stiff and square.

If you add some weight on the printhead with a direct drive extruder,

you reduce the max acceleration, that means you slow your printer down.

I used both direct drive and bowdens. Actualy, I prefer bowdens.

I do not use often flexible filaments, but I used them on my bowdens configurations.

As it was said above, if the filament is well guided from start to end,

you don't have any issue with bowdens.

I upgraded E3D v6 for bowden purpose with a 3mm inside diameter heatsink,

a 3mm(2mm inside) PTFE tube from the nozzle to the pneufit connector,

then a 4mm(2mm inside) PTFE tube from the pneufit to the wade extruder.

That tube cross thru the wade, with just a half blind opening near the hobbed bolt.

I never experience any jam with this system.

Please note flexible filaments are not used very often (very rarely here).

Otherhand, flexibles needs a low printing speed to produce good results.

If you're going to print principaly flexible parts,

you don't care to add a direct drive even on a CoreXY.

BUT, keep in mind the smartrapcore uses 6mm rods,

and any extra weight may bend them or make them vibrate.

The smartrapcore design is very light.

My advice is to keep on with a bowden system.

++JM

CoreXY can allow very fast moves.

And speed is the seccond thing you need since your printer is stiff and square.

If you add some weight on the printhead with a direct drive extruder,

you reduce the max acceleration, that means you slow your printer down.

I used both direct drive and bowdens. Actualy, I prefer bowdens.

I do not use often flexible filaments, but I used them on my bowdens configurations.

As it was said above, if the filament is well guided from start to end,

you don't have any issue with bowdens.

I upgraded E3D v6 for bowden purpose with a 3mm inside diameter heatsink,

a 3mm(2mm inside) PTFE tube from the nozzle to the pneufit connector,

then a 4mm(2mm inside) PTFE tube from the pneufit to the wade extruder.

That tube cross thru the wade, with just a half blind opening near the hobbed bolt.

I never experience any jam with this system.

Please note flexible filaments are not used very often (very rarely here).

Otherhand, flexibles needs a low printing speed to produce good results.

If you're going to print principaly flexible parts,

you don't care to add a direct drive even on a CoreXY.

BUT, keep in mind the smartrapcore uses 6mm rods,

and any extra weight may bend them or make them vibrate.

The smartrapcore design is very light.

My advice is to keep on with a bowden system.

++JM

|

Re: Alternative to Bowden extruder October 11, 2015 10:32AM |

Registered: 9 years ago Posts: 210 |

There is also the idea of "flexible drive shaft extruder" like this one [mutley3d.com]

Sorry, only registered users may post in this forum.