Smooth rods dimensions for coreXY 300x300mm?

Posted by cristian

|

Smooth rods dimensions for coreXY 300x300mm? August 23, 2015 07:03PM |

Registered: 9 years ago Posts: 344 |

I am planning to build a machine based on coreXY that has a printable area of about 300x300mm with one extruder. I would like to be able to switch between direct feed and Bowden with one extruder, as well as to mount more than one extruder (up to four, with a Bowden setup of course) and still get at least 200x200mm as a printable area. I am still writing a tentative 3D model of the printer, but I guess the smooth rods of the X and Y axes will be about 500mm.

I don't know the weight of a typical direct feed extruder: given that 4 hotends should not weigh more than 400g, or alternatively a nema17 motor should not weigh more than 400g, I guess that the central carriage bearing the hotend(s) should weigh not more than 1kg including the nema motor with one extruder, or the 4 hotends.

So what would be the right diameter for the X smooth rods?

I tried to do some deflection calculations (for example here and here) to get some worst case numbers, although many variables cannot be taken into account (for example rods are fixed, but the frame is not perfectly rigid, etc). However, with a carriage weight of 1kg and 2 steel smooth rods with free ends, the deflection should be:

On the other hand, the Y axis (the outer one) should support a heavier load because of the X smooth rods and their respective supports. I don't know exactly how heavy they may be because I cannot find weight information for all the parts I am planning to use, but I guess it may reach 3 kg (the 2 X smooth rods would weigh 1 kg on their own, plus the central carriage that may reach 1 kg, plus the other supports). In this case the deflection should be:

What is your experience?

Edited 1 time(s). Last edit at 08/23/2015 07:12PM by cristian.

I don't know the weight of a typical direct feed extruder: given that 4 hotends should not weigh more than 400g, or alternatively a nema17 motor should not weigh more than 400g, I guess that the central carriage bearing the hotend(s) should weigh not more than 1kg including the nema motor with one extruder, or the 4 hotends.

So what would be the right diameter for the X smooth rods?

I tried to do some deflection calculations (for example here and here) to get some worst case numbers, although many variables cannot be taken into account (for example rods are fixed, but the frame is not perfectly rigid, etc). However, with a carriage weight of 1kg and 2 steel smooth rods with free ends, the deflection should be:

- 0.15mm for rods with diameter 10mm

- 0.07mm for rods with diameter 12mm

- 0.04mm for rods with diameter 14mm

On the other hand, the Y axis (the outer one) should support a heavier load because of the X smooth rods and their respective supports. I don't know exactly how heavy they may be because I cannot find weight information for all the parts I am planning to use, but I guess it may reach 3 kg (the 2 X smooth rods would weigh 1 kg on their own, plus the central carriage that may reach 1 kg, plus the other supports). In this case the deflection should be:

- 0.12mm for rods with diameter 14mm

- 0.07mm for rods with diameter 16mm

- 0.04mm for rods with diameter 18mm

What is your experience?

Edited 1 time(s). Last edit at 08/23/2015 07:12PM by cristian.

|

Re: Smooth rods dimensions for coreXY 300x300mm? August 24, 2015 09:43AM |

Registered: 9 years ago Posts: 722 |

Hi,

IMHO, smooth rods are not the good choice for large printers,

because the deflection is too important and that bearings have some play too.

A CoreXY is meant to run fast, especialy with a large build area.

So you will need the best possible accuracy to get perfect prints at high speed.

I think you'd rather fix a single linear rail on an aluminium profile for X,

and 2 linear rails on the overall structure for the Y axis.

Some Hiwin linear kits for Kossel mini printers can be great.

++JM

IMHO, smooth rods are not the good choice for large printers,

because the deflection is too important and that bearings have some play too.

A CoreXY is meant to run fast, especialy with a large build area.

So you will need the best possible accuracy to get perfect prints at high speed.

I think you'd rather fix a single linear rail on an aluminium profile for X,

and 2 linear rails on the overall structure for the Y axis.

Some Hiwin linear kits for Kossel mini printers can be great.

++JM

|

Re: Smooth rods dimensions for coreXY 300x300mm? August 24, 2015 12:19PM |

Registered: 9 years ago Posts: 344 |

I have searched a little and the problems with linear guides are that they are generally expensive and often I cannot find information about their accuracy, in particular for used ones. I also wonder what happens to their straightness when they are fixed to aluminium profiles that are not perfectly straight.

|

Re: Smooth rods dimensions for coreXY 300x300mm? August 24, 2015 03:22PM |

Registered: 9 years ago Posts: 346 |

I agree with J-max.

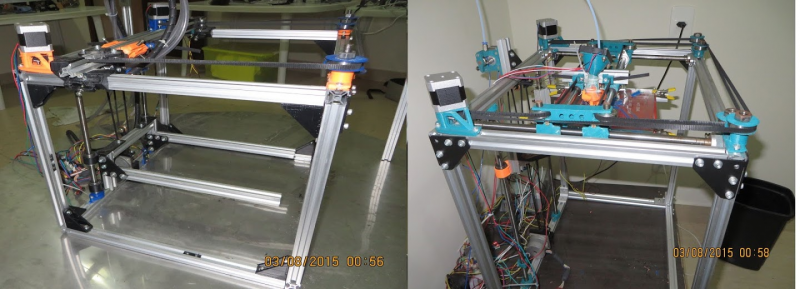

I have made two CoreXY. One with smooth rods and one with my own type of linear rails.

The way I see it, the problem with the linear rods is not deflection (I use 12mm) but rather the play in the linear bearings. The play in these is just so big that at high speed I have strong vibration and instability as a result. The internet says you can buy the more expensive bronze bushings instead of linear bearings and that will solve that - But then you are out of the "cheap" solutions anyway and then I think you should just go for the Hiwin or similar.

The Hiwin (or homemade) is just a simpler and neater solution in my opinion. Less parts and more flexible for the future.

As you can see I still use linear rods for my table because the load is constant and the motion slower.

Edited 1 time(s). Last edit at 08/24/2015 03:25PM by LarsK.

I have made two CoreXY. One with smooth rods and one with my own type of linear rails.

The way I see it, the problem with the linear rods is not deflection (I use 12mm) but rather the play in the linear bearings. The play in these is just so big that at high speed I have strong vibration and instability as a result. The internet says you can buy the more expensive bronze bushings instead of linear bearings and that will solve that - But then you are out of the "cheap" solutions anyway and then I think you should just go for the Hiwin or similar.

The Hiwin (or homemade) is just a simpler and neater solution in my opinion. Less parts and more flexible for the future.

As you can see I still use linear rods for my table because the load is constant and the motion slower.

Edited 1 time(s). Last edit at 08/24/2015 03:25PM by LarsK.

|

Re: Smooth rods dimensions for coreXY 300x300mm? August 24, 2015 04:44PM |

Registered: 9 years ago Posts: 344 |

It is difficult to compare the two coreXY builds in the picture because of many, many differences. Besides this, bearings are not all the same, and a linear guide may also have some play if it is low quality. In both cases (linear guide or shafts) I would like some indication about the precision rating of what I buy, that I find quite hard to obtain for all the parts. It is relatively easy for shafts to find hardness, straightness and dimensional information, less easy for bearings, and almost impossible for affordable linear guides (secondhand ones in particular). I must also admit that I am not yet able to interpret the technical specifications of brand new quality linear guides (although their price needs no interpretation).

Edit: here is some further basic explanation of shafts and bearings fits that I can understand as a newbie.

Edited 1 time(s). Last edit at 08/24/2015 04:57PM by cristian.

Edit: here is some further basic explanation of shafts and bearings fits that I can understand as a newbie.

Edited 1 time(s). Last edit at 08/24/2015 04:57PM by cristian.

|

Re: Smooth rods dimensions for coreXY 300x300mm? August 24, 2015 06:01PM |

Registered: 9 years ago Posts: 346 |

The links you just gave are for ball bearings (not linear bearings), for holes (not shafts) and the last one for hole and shaft fits - As in when you want to put a coupling on a shaft or a push fit into a roller bearing.

I personally cannot answer your question. I have a master degree in mechanical engineering and I have 4 years work experience.

That is because the information you are looking for is very much experience based and empirical and kept within the firms that has it. If you go buy a second hand NSK linear system you will get good quality. You might not be able to calculate what it will be, but it will work.

What I can say is this; The approach with calculating the deflection is way too simplistic when it comes to avoiding vibration when going high speed. Further, the deflections you calculated are on the conservative sides and more, in the range where, as you point out yourself, negligible. Yes, if you decide to print a full 300x300 part you might get a 0.1 difference from center to edge because of this, but that is completely negligible when considering all the other sources of error.

My suggestion for you is then this;

Instead of spending so much time on the theoretical side, try to see what options you actually have. What kind of parts can you actually get for the money you want to spend, what is the experience of other people.

My input to you is then: I tried the Chinese linear bearings and the play in them is holding me from going high speed. I found it harder to design with linear rods because using rails allowed me to easier put parts together and I found that going with linear rods needed more parts.

Other people here on the forum have said the same. Some people have said that going with bronze bushings (or linear plain bearings) instead of linear ball bearings gave good results. Many people are happy with the Hiwin slides (I have not tried those).

I am not saying I am 100% right. But I am sure you are better off googling for opinions like mine above then trying to google yourself to a depth of understanding that I can with much certainty say you will not find out there.

Edited 2 time(s). Last edit at 08/24/2015 06:04PM by LarsK.

I personally cannot answer your question. I have a master degree in mechanical engineering and I have 4 years work experience.

That is because the information you are looking for is very much experience based and empirical and kept within the firms that has it. If you go buy a second hand NSK linear system you will get good quality. You might not be able to calculate what it will be, but it will work.

What I can say is this; The approach with calculating the deflection is way too simplistic when it comes to avoiding vibration when going high speed. Further, the deflections you calculated are on the conservative sides and more, in the range where, as you point out yourself, negligible. Yes, if you decide to print a full 300x300 part you might get a 0.1 difference from center to edge because of this, but that is completely negligible when considering all the other sources of error.

My suggestion for you is then this;

Instead of spending so much time on the theoretical side, try to see what options you actually have. What kind of parts can you actually get for the money you want to spend, what is the experience of other people.

My input to you is then: I tried the Chinese linear bearings and the play in them is holding me from going high speed. I found it harder to design with linear rods because using rails allowed me to easier put parts together and I found that going with linear rods needed more parts.

Other people here on the forum have said the same. Some people have said that going with bronze bushings (or linear plain bearings) instead of linear ball bearings gave good results. Many people are happy with the Hiwin slides (I have not tried those).

I am not saying I am 100% right. But I am sure you are better off googling for opinions like mine above then trying to google yourself to a depth of understanding that I can with much certainty say you will not find out there.

Edited 2 time(s). Last edit at 08/24/2015 06:04PM by LarsK.

|

Re: Smooth rods dimensions for coreXY 300x300mm? August 24, 2015 07:43PM |

Registered: 9 years ago Posts: 344 |

The problem is that there are infinitely many options, as many as the sellers online times the experiences of other users. But the experience of other users may help me as well as lead me to bad choices. For example you have a lot of experience in mechanical engineering, that I guess helped you to build your own type of linear rail. If I try to build my own, maybe I will fail completely for some stupid mistake in the design or assembly of the part since I have no experience.

Moreover, there are thousands of users opinions online but many of them are newbie like me, and there is no guarantee that they understood all the mistakes they made nor that I would make their very same mistakes. Most people here buy cheap Chinese bearings (and low quality rods) without regard for their technical specifications (remarkably, some sellers specify information about fit tolerances and even vibration, although I don't know how reliable they are), so there is no surprise when they say that systems based on smooth rods perform poorly. However, if somebody tried supposedly good quality/well coupled rods+bearings and still found that they perform poorly, then this information would be very valuable.

Besides that, I do believe what you are saying about the fact that good linear guides are easier to install, more compact, silent and probably even more precise than most of the designs based on smooth rods (for sure better than the designs that I may realize with my poor DIY capabilities and experience), however I have no idea of what is a "good" linear guide for the printer I want to build. Hiwin website is not helping me in that respect (the descriptions of their products is a copy-and-paste everywhere, and I need more time to play and win "spot the differences"), most of Ebay stuff is affordable only in the US (I live in Europe) or has dead links to non existent technical specifications (that I would not be able to understand anyway), Aliexpress has a lot of products that may be as good as Hiwin stuff or as bad as cheap Chinese bearings. Even without understanding technical specifications, I should read hundreds of users posts to understand what I may buy at a reasonable quality/price ratio, since prices change unfortunately from country to country and "quality" has different meaning from user to user (quality for me may be crap for somebody else and vice versa).

One way or another, my head will blow before I build this printer. Even in that case, thank you all for reporting your experience!

Edited 1 time(s). Last edit at 08/24/2015 07:55PM by cristian.

Moreover, there are thousands of users opinions online but many of them are newbie like me, and there is no guarantee that they understood all the mistakes they made nor that I would make their very same mistakes. Most people here buy cheap Chinese bearings (and low quality rods) without regard for their technical specifications (remarkably, some sellers specify information about fit tolerances and even vibration, although I don't know how reliable they are), so there is no surprise when they say that systems based on smooth rods perform poorly. However, if somebody tried supposedly good quality/well coupled rods+bearings and still found that they perform poorly, then this information would be very valuable.

Besides that, I do believe what you are saying about the fact that good linear guides are easier to install, more compact, silent and probably even more precise than most of the designs based on smooth rods (for sure better than the designs that I may realize with my poor DIY capabilities and experience), however I have no idea of what is a "good" linear guide for the printer I want to build. Hiwin website is not helping me in that respect (the descriptions of their products is a copy-and-paste everywhere, and I need more time to play and win "spot the differences"), most of Ebay stuff is affordable only in the US (I live in Europe) or has dead links to non existent technical specifications (that I would not be able to understand anyway), Aliexpress has a lot of products that may be as good as Hiwin stuff or as bad as cheap Chinese bearings. Even without understanding technical specifications, I should read hundreds of users posts to understand what I may buy at a reasonable quality/price ratio, since prices change unfortunately from country to country and "quality" has different meaning from user to user (quality for me may be crap for somebody else and vice versa).

One way or another, my head will blow before I build this printer. Even in that case, thank you all for reporting your experience!

Edited 1 time(s). Last edit at 08/24/2015 07:55PM by cristian.

|

Re: Smooth rods dimensions for coreXY 300x300mm? August 25, 2015 07:02AM |

Registered: 9 years ago Posts: 722 |

Hi,

I mostly agree with LarsK.

You can dig deeply into technical specifications of each component.

If you do so, be aware engineering a new printer will probably takes you years.

Through, you will never be shure to get the best design and the best possible component.

It's just experimentation. That means, errors, adjustements, money...

My advices are :

Don't be cheap or prepare to spend more on necessary upgrades.

Don't dig to much into technique, because you won't reinvent the wheel anyways.

If you can stick to a working existing design, it's time and money savings.

About smooth rods/linear rails.

The diameter needs to be large to get enough stiffness, exponentialy for large print volume.

Quality bearings are around $15 each, polymers /bronze bushings are around 5€ each.

Larger means more weight. You need to be lightweight for a good acceleration.

Because you will need 2 smooth rods and at last 3 bearings,

the price will be not so far to a single good Hiwin rail and carriage.

Hiwin kit for kossel

Technical data @ hiwin.com

You can also choose any aluminium profile V-guide system

like Openbuilds or Makerslide. Which works properly too for a 3D printer.

It's a less expensive solution, still lightweight.

A Spanish supplier.

Aluminium profiles in europe.

++JM

Edited 1 time(s). Last edit at 08/25/2015 07:03AM by J-Max.

I mostly agree with LarsK.

You can dig deeply into technical specifications of each component.

If you do so, be aware engineering a new printer will probably takes you years.

Through, you will never be shure to get the best design and the best possible component.

It's just experimentation. That means, errors, adjustements, money...

My advices are :

Don't be cheap or prepare to spend more on necessary upgrades.

Don't dig to much into technique, because you won't reinvent the wheel anyways.

If you can stick to a working existing design, it's time and money savings.

About smooth rods/linear rails.

The diameter needs to be large to get enough stiffness, exponentialy for large print volume.

Quality bearings are around $15 each, polymers /bronze bushings are around 5€ each.

Larger means more weight. You need to be lightweight for a good acceleration.

Because you will need 2 smooth rods and at last 3 bearings,

the price will be not so far to a single good Hiwin rail and carriage.

Hiwin kit for kossel

Technical data @ hiwin.com

You can also choose any aluminium profile V-guide system

like Openbuilds or Makerslide. Which works properly too for a 3D printer.

It's a less expensive solution, still lightweight.

A Spanish supplier.

Aluminium profiles in europe.

++JM

Edited 1 time(s). Last edit at 08/25/2015 07:03AM by J-Max.

|

Re: Smooth rods dimensions for coreXY 300x300mm? August 25, 2015 11:16AM |

Registered: 9 years ago Posts: 344 |

|

Re: Smooth rods dimensions for coreXY 300x300mm? August 27, 2015 07:46AM |

Registered: 8 years ago Posts: 95 |

Quote

cristian

Yes, I guess I have no other choice than builiding by trial and error unfortunately...

If I ever manage to build the printer, I will post some reviews of the linear guides I buy.

Thanks for your advices.

I built the SmartCore Printer with a 300x300 bed .. with no problems .. do a search on it.. there is a OpenJcad that all you do is input the dimensions and it will give you the Box, belt and rod sizes..

|

Re: Smooth rods dimensions for coreXY 300x300mm? August 27, 2015 05:31PM |

Registered: 9 years ago Posts: 344 |

|

Re: Smooth rods dimensions for coreXY 300x300mm? August 31, 2015 04:16AM |

Registered: 9 years ago Posts: 722 |

Hi,

To me, a wooden box may be stiffer than a module20 aluminium structure,

and you already have an enclosure. But it's maybe a question of look.

Through, the SmartRapCore have 6mm rods, which is a too small diameter IMHO,

even for the 220x220 regular print area. Some users upgraded to 8mm.

I can't imagine a 300x300 print area may work well with 6mm rods.

Through, maybe the output expectations are low.

With the 10mm MDF frame, which is noisy, the last problem with the SmartRapCore

is the genuine Z axis which is not stiff enough.

Some users upgraded to the andreasL's improoved Z axis.

I've tested it and it works pretty well.

Just two things about it, the maximum Z resolution on a full step is 0.2mm,

so you need a 0.9° motor to hope reach precisely 0.1mm or 0.05mm layers.

Or, you can add a reduction, geared or belt.

I'm curently building another coreXY printer inside a 19mm wooden box chassis.

Seriously, it's not expensive, very stiff, and stands well vibrations.

It's ways quieter than genuine SmartRapCore,

and better than other cheap aluminium profile printers.

To give you any comparison, it's closer as a module40 structure, maybe better.

I believe it can easily stand a 300x300 print area.

Anyways, the most important part should be the guides.

Did you made any choices ? I will probably use Hiwin MGN or maybe Igus W guides.

++JM

To me, a wooden box may be stiffer than a module20 aluminium structure,

and you already have an enclosure. But it's maybe a question of look.

Through, the SmartRapCore have 6mm rods, which is a too small diameter IMHO,

even for the 220x220 regular print area. Some users upgraded to 8mm.

I can't imagine a 300x300 print area may work well with 6mm rods.

Through, maybe the output expectations are low.

With the 10mm MDF frame, which is noisy, the last problem with the SmartRapCore

is the genuine Z axis which is not stiff enough.

Some users upgraded to the andreasL's improoved Z axis.

I've tested it and it works pretty well.

Just two things about it, the maximum Z resolution on a full step is 0.2mm,

so you need a 0.9° motor to hope reach precisely 0.1mm or 0.05mm layers.

Or, you can add a reduction, geared or belt.

I'm curently building another coreXY printer inside a 19mm wooden box chassis.

Seriously, it's not expensive, very stiff, and stands well vibrations.

It's ways quieter than genuine SmartRapCore,

and better than other cheap aluminium profile printers.

To give you any comparison, it's closer as a module40 structure, maybe better.

I believe it can easily stand a 300x300 print area.

Anyways, the most important part should be the guides.

Did you made any choices ? I will probably use Hiwin MGN or maybe Igus W guides.

++JM

|

Re: Smooth rods dimensions for coreXY 300x300mm? August 31, 2015 05:31AM |

Registered: 9 years ago Posts: 344 |

I have been reading a little about linear guides ( a NSK tutorial for example, or a funny HIWIN video, any suggestion for further reading is very welcome) to understand better their pros and cons, the available types, etc. I am actually becoming a big fan of them (except for their price), thanks to the suggestions in this thread. I haven't made a choice yet, I am trying to understand if I would be able to mount them properly: they need a perfectly flat support, which is not that easy to get without proper machining (that I cannot do by myself or at the makerspace nearby).

However, given the cost and the difficulties of building a big printer, I am now considering a smaller printer but very precise (I will write more on this on the other thread I opened in this forum section).

About wood vs metal structure, I don't really know how well wood behaves at 1-0.1 mm scales, in particular over time (even if MDF should not undergo dramatic deformations), I feel more confident about metal.

However, given the cost and the difficulties of building a big printer, I am now considering a smaller printer but very precise (I will write more on this on the other thread I opened in this forum section).

About wood vs metal structure, I don't really know how well wood behaves at 1-0.1 mm scales, in particular over time (even if MDF should not undergo dramatic deformations), I feel more confident about metal.

|

Re: Smooth rods dimensions for coreXY 300x300mm? August 31, 2015 06:09AM |

Registered: 9 years ago Posts: 722 |

Hi again,

Well precision does not comes from your building material

but from your guides alignment and the lower play they allow.

If you're more confident with aluminium, and own the tools to work it properly, it's ok.

To get a flat support, you can buy full aluminum flat profile, but at last 10mm thick.

It's better than aluminium extrusions module20 alike, even if it's a bit heavyer.

Those you can use them for chassis only.

For the guides, the load will always be lower than what the rail's static rated moment allows.

Even the Hiwin MGN 7 allows 2.84 Nm.

So don't waste your time to try to make a difference between them.

The two things important are the weight and the play.

No matter with the play if you buy a genuine rail system for a serious brand.

It will be definitely ways better than chinese smooth rods ones, and will last longer.

Throught, keep in mind these are consumables.

The Hiwin MGN 12 looks like a good choice, because the carriages

are large enough to mount our stuff on it.

Otherhand, the Igus W series are larger and lighter,

the play can be adjusted, and they cost less to change.

Both will need a good support anyways.

Last, a rail selection depends of your budget too.

To me, it's more important to invest more into your rails,

than to spend 100€ or more for any expensive hotend.

++JM

Well precision does not comes from your building material

but from your guides alignment and the lower play they allow.

If you're more confident with aluminium, and own the tools to work it properly, it's ok.

To get a flat support, you can buy full aluminum flat profile, but at last 10mm thick.

It's better than aluminium extrusions module20 alike, even if it's a bit heavyer.

Those you can use them for chassis only.

For the guides, the load will always be lower than what the rail's static rated moment allows.

Even the Hiwin MGN 7 allows 2.84 Nm.

So don't waste your time to try to make a difference between them.

The two things important are the weight and the play.

No matter with the play if you buy a genuine rail system for a serious brand.

It will be definitely ways better than chinese smooth rods ones, and will last longer.

Throught, keep in mind these are consumables.

The Hiwin MGN 12 looks like a good choice, because the carriages

are large enough to mount our stuff on it.

Otherhand, the Igus W series are larger and lighter,

the play can be adjusted, and they cost less to change.

Both will need a good support anyways.

Last, a rail selection depends of your budget too.

To me, it's more important to invest more into your rails,

than to spend 100€ or more for any expensive hotend.

++JM

|

Re: Smooth rods dimensions for coreXY 300x300mm? August 31, 2015 09:19AM |

Registered: 8 years ago Posts: 95 |

Quote

J-Max

Hi,

To me, a wooden box may be stiffer than a module20 aluminium structure,

and you already have an enclosure. But it's maybe a question of look.

Through, the SmartRapCore have 6mm rods, which is a too small diameter IMHO,

even for the 220x220 regular print area. Some users upgraded to 8mm.

I can't imagine a 300x300 print area may work well with 6mm rods.

Through, maybe the output expectations are low.

With the 10mm MDF frame, which is noisy, the last problem with the SmartRapCore

is the genuine Z axis which is not stiff enough.

Some users upgraded to the andreasL's improoved Z axis.

I've tested it and it works pretty well.

Just two things about it, the maximum Z resolution on a full step is 0.2mm,

so you need a 0.9° motor to hope reach precisely 0.1mm or 0.05mm layers.

Or, you can add a reduction, geared or belt.

I'm curently building another coreXY printer inside a 19mm wooden box chassis.

Seriously, it's not expensive, very stiff, and stands well vibrations.

It's ways quieter than genuine SmartRapCore,

and better than other cheap aluminium profile printers.

To give you any comparison, it's closer as a module40 structure, maybe better.

I believe it can easily stand a 300x300 print area.

Anyways, the most important part should be the guides.

Did you made any choices ? I will probably use Hiwin MGN or maybe Igus W guides.

++JM

Built my Smartcore from 18mm cabinet grade plywood.. cut the centers out of the sides and back to reduce the noise .. very quite .. went with 8mm rods all around..300x300 print area .upgraded to the andreasL's improved Z axis.. all in in all the cost was around 165.00 usd .. after debugging and calibrating perfect prints every time..

Edited 1 time(s). Last edit at 08/31/2015 09:21AM by mike3.

|

Re: Smooth rods dimensions for coreXY 300x300mm? August 31, 2015 10:18AM |

Registered: 9 years ago Posts: 722 |

|

Re: Smooth rods dimensions for coreXY 300x300mm? August 31, 2015 12:49PM |

Registered: 9 years ago Posts: 344 |

Quote

J-Max

Well precision does not comes from your building material

but from your guides alignment and the lower play they allow.

The building material is very important to maintain precision over external stresses and time. Wood can warp over time because of prolonged deformations, humidity, ... MDF is less prone to that, but its stiffness is negligible with respect to metal, which is important in particular in the areas of contact of two surfaces. This does not mean of course that wood or MDF cannot be used to build a 3D printer (it has been done many times, I did it to reinforce my smartrap too) but one has to be aware of the possible drawbacks and design the printer to minimize these issues.

Quote

J-Max

To get a flat support, you can buy full aluminum flat profile, but at last 10mm thick.

It's better than aluminium extrusions module20 alike, even if it's a bit heavyer.

Those you can use them for chassis only.

Thanks for the link. Maybe because of automatic translation, I have been unable to find information about the precision of the pieces. Motedis makes them too although not big enough. They specify also the thickness tolerance (about 0.3 mm). I have no idea of the needed precision to mount linear guides, anyway.

Quote

J-Max

For the guides, the load will always be lower than what the rail's static rated moment allows.

Even the Hiwin MGN 7 allows 2.84 Nm.

So don't waste your time to try to make a difference between them.

The two things important are the weight and the play.

No matter with the play if you buy a genuine rail system for a serious brand.

It will be definitely ways better than chinese smooth rods ones, and will last longer.

Throught, keep in mind these are consumables.

I agree about the load, there are however things that are very important to know about play, for example if rails have to be used in pairs or not. The risk with good linear guides is that they don't slide if they are not properly mounted. Besides that, I agree that even the "worse" linear guide from a serius brand should be better than cheap linear bearing + smooth rods.

Quote

J-Max

The Hiwin MGN 12 looks like a good choice, because the carriages

are large enough to mount our stuff on it.

Otherhand, the Igus W series are larger and lighter,

the play can be adjusted, and they cost less to change.

Both will need a good support anyways.

I haven't read about igus products yet, it is on the TODO list.

Quote

J-Max

Last, a rail selection depends of your budget too.

To me, it's more important to invest more into your rails,

than to spend 100€ or more for any expensive hotend.

++JM

Well, I found the hotend that suits my needs for about 40€, I will stick to that.

The rest will go in the linear guides!

|

Re: Smooth rods dimensions for coreXY 300x300mm? August 31, 2015 06:26PM |

Registered: 9 years ago Posts: 344 |

|

Re: Smooth rods dimensions for coreXY 300x300mm? September 01, 2015 04:04AM |

Registered: 9 years ago Posts: 722 |

Hi,

Misumi is a serious brand too.

Actualy, it's more expensive than Hiwin for the same quality.

Look at Hiwin documentation on their website,

you'll get the same kind of informations.

Talking about the build material, don't think aluminium cannot expand too.

Pannelwood is not like solid wood. It may not change as much as you think.

If you apply some finishing, it will be sealed and won't move anymore.

Your arguments apply to solid wood versus heavy metal construction.

A 3D printer is a CNC, but it's closer to a laser CNC than to a CNC mill.

On a 3D printer external and internal stresses are no big deal.

If you use good guides, the more the structure will stand is light vibrations.

I don't want you to trust me blindly, but appreciate some material have its own properties,

and metal does not overwhelm other materials anytime.

We're talking here about 20x20 profiles.

Just by resting my hand on a 300mm piece, it will bend quickly about 0.3mm,

while a 19mm MDF pannel won't bend half of that.

If you own precise measuring tools, try this.

Through, MDF will bring other interesting properties,

like dumping vibrations on the structure and maintain heat better.

That's why I far prefer a 19mm structure than a 20x20mm profile structure.

If you plan to use 40x40mm or greater profiles, I will reconsider.

Otherhand, a 20x20mm aluminium structure looks better than any MDF one

++JM

Edited 4 time(s). Last edit at 09/01/2015 04:08AM by J-Max.

Misumi is a serious brand too.

Actualy, it's more expensive than Hiwin for the same quality.

Look at Hiwin documentation on their website,

you'll get the same kind of informations.

Talking about the build material, don't think aluminium cannot expand too.

Pannelwood is not like solid wood. It may not change as much as you think.

If you apply some finishing, it will be sealed and won't move anymore.

Your arguments apply to solid wood versus heavy metal construction.

A 3D printer is a CNC, but it's closer to a laser CNC than to a CNC mill.

On a 3D printer external and internal stresses are no big deal.

If you use good guides, the more the structure will stand is light vibrations.

I don't want you to trust me blindly, but appreciate some material have its own properties,

and metal does not overwhelm other materials anytime.

We're talking here about 20x20 profiles.

Just by resting my hand on a 300mm piece, it will bend quickly about 0.3mm,

while a 19mm MDF pannel won't bend half of that.

If you own precise measuring tools, try this.

Through, MDF will bring other interesting properties,

like dumping vibrations on the structure and maintain heat better.

That's why I far prefer a 19mm structure than a 20x20mm profile structure.

If you plan to use 40x40mm or greater profiles, I will reconsider.

Otherhand, a 20x20mm aluminium structure looks better than any MDF one

++JM

Edited 4 time(s). Last edit at 09/01/2015 04:08AM by J-Max.

|

Re: Smooth rods dimensions for coreXY 300x300mm? September 01, 2015 06:11AM |

Registered: 9 years ago Posts: 344 |

Quote

J-Max

Misumi is a serious brand too.

Actualy, it's more expensive than Hiwin for the same quality.

Look at Hiwin documentation on their website,

you'll get the same kind of informations.

Misumi website provides online configuration and direct sell, apparently. I am not aware of Hiwin resellers, I found products online here and there but it is difficult to find the exact product I want.

Quote

J-Max

We're talking here about 20x20 profiles.

Just by resting my hand on a 300mm piece, it will bend quickly about 0.3mm,

while a 19mm MDF pannel won't bend half of that.

I think you would be surprised. I don't have a 20x20 profile here nor a 19mm MDF panel, but I can do some rough calculations just for the example you made. The formula can be found online (for example here), and approximate Young's modulus for MDF and aluminium is here. The moment of inertia for 20x20 profile is for example here, while that of MDF can be easily calculated by the formulas here.

According to those approximate formulas, in order to bend by 0.3mm a 300mm long 20x20 profile you need to apply about 28kg. A 300x300x19mm MDF panel will bend a bit less under the same weight: 0.22mm. However 20x20 profiles should be used in pairs for the structure, so that two parallel 20x20 profiles will bend just 0.15mm. Metal wins!

Conversely, a 300x300x19mm panel can probably withstand shear stresses much better than a 20x20 profile square structure of the same size without diagonal supports. But it will also weigh much more.

Edit: I forgot to write that for MDF the weight should be evenly spread in the center along one direction, so the comparison cannot be really fair.

I would use 20x40 or 30x30 profiles for the structure, in any case.

Quote

J-Max

If you own precise measuring tools, try this.

I am waiting for the delivery of a dial test indicator with precision +-20µm, I will do some tests as soon as I get it.

Edited 1 time(s). Last edit at 09/01/2015 06:18AM by cristian.

|

Re: Smooth rods dimensions for coreXY 300x300mm? September 01, 2015 07:17AM |

Registered: 9 years ago Posts: 722 |

Hi again.

Forget theory a minute, get that small aluminium extrusion in hand, feel it, measure by yourself.

Theory is a perfect world where metal could win everything

especialy if you compares the wrong parts. Please read me again.

I did not compare that extrusion to a 20x20x300mm MDF piece, but to a 19mm pannel.

I mounted a square 300mm module20 extrusion structure by the past,

thinking this will be the ultimate structure I can get for my machine.

Just holding my hand on the top of that aluminium frame and the dial indicator jumps !

The type of jointing you will use can make things even worse, like universal blocks and little squares.

The interest of that kind of frame falls if you need to put 3 large aluminium triangles at each corner.

That profile's wall are just too thin i'm affraid, and that's too light too.

I replaced that expensive aluminium frame by a cheap 19mm MDF pannel structure

with better results at any points. Stiffer, heavyer, vibrations dump, and so on.

I just share my experience, I don't need to convince you.

Aluminium extrusion still have advantages, it's straight, it's easily cuttable, it have t-nut rails,

which makes structures easy to be mounted with costly hardware,

you can hide cables or belts inside, and it looks less DIY alike.

Use module20 aluminium frame if you like. It's not so bad.

It's surely better than any acrylic frame or any 6mm plywood one.

Choose what you like for your second machine, you need to enjoy it.

It will be probably functionnal and beautifull anyways.

++JM

Forget theory a minute, get that small aluminium extrusion in hand, feel it, measure by yourself.

Theory is a perfect world where metal could win everything

especialy if you compares the wrong parts. Please read me again.

I did not compare that extrusion to a 20x20x300mm MDF piece, but to a 19mm pannel.

I mounted a square 300mm module20 extrusion structure by the past,

thinking this will be the ultimate structure I can get for my machine.

Just holding my hand on the top of that aluminium frame and the dial indicator jumps !

The type of jointing you will use can make things even worse, like universal blocks and little squares.

The interest of that kind of frame falls if you need to put 3 large aluminium triangles at each corner.

That profile's wall are just too thin i'm affraid, and that's too light too.

I replaced that expensive aluminium frame by a cheap 19mm MDF pannel structure

with better results at any points. Stiffer, heavyer, vibrations dump, and so on.

I just share my experience, I don't need to convince you.

Aluminium extrusion still have advantages, it's straight, it's easily cuttable, it have t-nut rails,

which makes structures easy to be mounted with costly hardware,

you can hide cables or belts inside, and it looks less DIY alike.

Use module20 aluminium frame if you like. It's not so bad.

It's surely better than any acrylic frame or any 6mm plywood one.

Choose what you like for your second machine, you need to enjoy it.

It will be probably functionnal and beautifull anyways.

++JM

|

Re: Smooth rods dimensions for coreXY 300x300mm? September 01, 2015 08:50AM |

Registered: 9 years ago Posts: 344 |

Quote

J-Max

Forget theory a minute, get that small aluminium extrusion in hand, feel it, measure by yourself.

I don't own any 20x20 profile (or any other size, yet), nor a precise measuring device (yet) so I cannot do that now. I will measure deflections by myself as soon as I get everything I need, I am looking forward to that.

If you own a precise measuring device, it would be great if you may share some of your deflection measurements too. I will do the same as soon as I can. We are off topic however, it should be done in a new thread for readability.

Quote

J-Max

Theory is a perfect world where metal could win everything

I was joking about metal "winning"

, it simply has different properties from wood, as you already pointed out, stiffness being one of them.

, it simply has different properties from wood, as you already pointed out, stiffness being one of them.Quote

J-Max

especialy if you compares the wrong parts. Please read me again.

I did not compare that extrusion to a 20x20x300mm MDF piece, but to a 19mm pannel.

I compared a square MDF panel of width/length 300x300mm and thickness 19mm (I assumed 300mm for the dimension you had not previously specified) with a 20x20 aluminium profile of the length of 300mm, so please read me again.

Quote

J-Max

I just share my experience, I don't need to convince you.

I appreciate that you share your experience. On the other hand I share my thoughts as it is usually done in discussions, this is not supposed to be a challenge.

|

Re: Smooth rods dimensions for coreXY 300x300mm? September 01, 2015 06:48PM |

Registered: 9 years ago Posts: 344 |

After finding the formulas for the tolerances and those to calculate the order of magnitude of the life of linear guides (for example these), I feel no longer so "lost" and I think this is really the right way to go. I can't actually remember why I wanted to use smooth rods in the first place.

Many thanks J-Max and LarsK for your suggestions, they have been illuminating.

Many thanks J-Max and LarsK for your suggestions, they have been illuminating.

|

Re: Smooth rods dimensions for coreXY 300x300mm? November 16, 2016 04:02PM |

Registered: 7 years ago Posts: 1 |

Sorry, only registered users may post in this forum.