G&C Printer

Posted by filipeCampos

|

G&C Printer August 28, 2015 09:37AM |

Registered: 8 years ago Posts: 346 |

Hi,

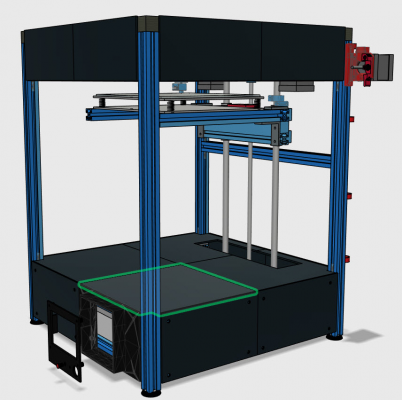

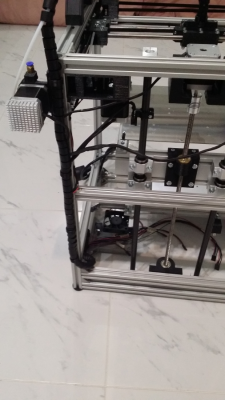

Created this post to present the corexy printer i actually building.

The printer is called G&C Printer, stand for Good and Cheap Printer.

My main goal is to build a fast and good quality printer under 500€. Is actual total cost is 490€.

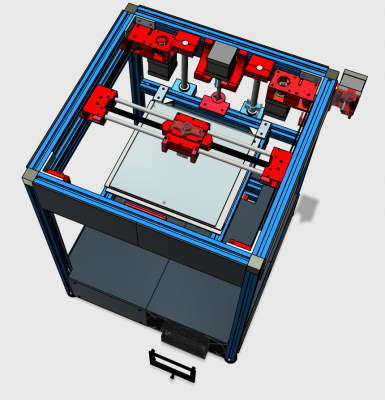

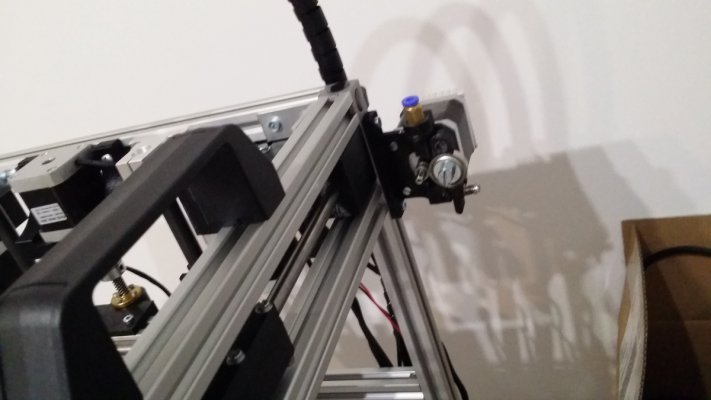

For the corexy mechanism i used the one created by zelogik (http://forums.reprap.org/read.php?397,297740,page=1), but with the pieces pla printed. used this x,y axis mechanism because in think is very good and well design.

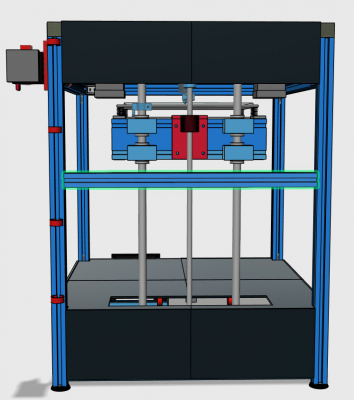

The Z axis and structure is of my design, the z is all aluminium and use one pla piece to connect the z screw to bed structure.

The printer size is 40x40x52cm and is print volume is 20x20x26cm. All the structure is made of aluminium and each side was 4 2020 extrusion bars to have a super rigid frame.

To reduce the cost of the printer i have a lot of hardware buy in ebay (made in china), but all the component that could affect the final printing quality are good quality (hotend E3d v6, linear movement components, main structure)

The printer has 6 endstops, each axis have an min and max endstop. I added the 3 extra max endstop because in the past i have several crash when i do some testing or when i forget homing. In theory only 3 endstop is enough, but shit Happens..

Video showing the first test movement of the printer:

[www.youtube.com]

3D project:

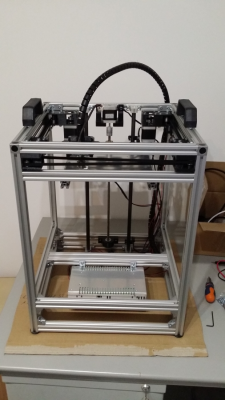

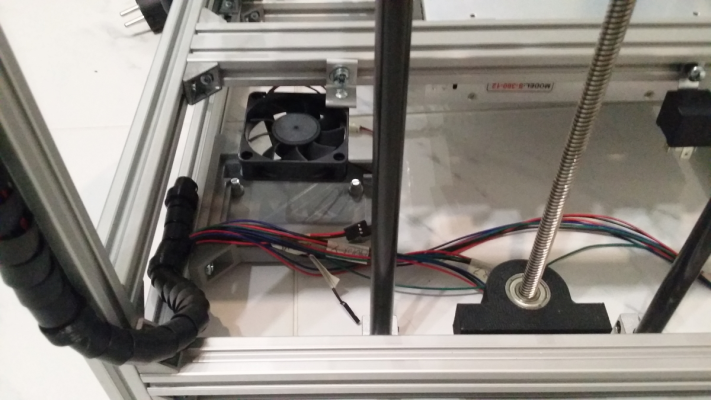

The building of the printer:

I hope you like my design, any suggestion of improvement is welcome...

Br,

Filipe Campos

Created this post to present the corexy printer i actually building.

The printer is called G&C Printer, stand for Good and Cheap Printer.

My main goal is to build a fast and good quality printer under 500€. Is actual total cost is 490€.

For the corexy mechanism i used the one created by zelogik (http://forums.reprap.org/read.php?397,297740,page=1), but with the pieces pla printed. used this x,y axis mechanism because in think is very good and well design.

The Z axis and structure is of my design, the z is all aluminium and use one pla piece to connect the z screw to bed structure.

The printer size is 40x40x52cm and is print volume is 20x20x26cm. All the structure is made of aluminium and each side was 4 2020 extrusion bars to have a super rigid frame.

To reduce the cost of the printer i have a lot of hardware buy in ebay (made in china), but all the component that could affect the final printing quality are good quality (hotend E3d v6, linear movement components, main structure)

The printer has 6 endstops, each axis have an min and max endstop. I added the 3 extra max endstop because in the past i have several crash when i do some testing or when i forget homing. In theory only 3 endstop is enough, but shit Happens..

Video showing the first test movement of the printer:

[www.youtube.com]

3D project:

The building of the printer:

I hope you like my design, any suggestion of improvement is welcome...

Br,

Filipe Campos

|

Re: G&C Printer August 28, 2015 10:40PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: G&C Printer August 29, 2015 06:55PM |

Registered: 8 years ago Posts: 346 |

I building this printer to be fast and this is the reason i need to try first an bowden extruder. In think your are correct and this extruder will give me only problems, but i need to try... the printer support bowden and direct, i have already an greg extruder printed and ready to be mounted...

Edited 5 time(s). Last edit at 08/30/2015 09:29AM by filipeCampos.

Edited 5 time(s). Last edit at 08/30/2015 09:29AM by filipeCampos.

|

Re: G&C Printer August 31, 2015 01:46AM |

Registered: 14 years ago Posts: 128 |

Great looking build,

How stable is the print bed being canti-levered?

I built a CoreXY using 15mm Aluminium extrusions very similar design. Have found the print bed does flex a little, still prints OK but would like it more stable.

I think the flex is from the 2 x 8mm shafts that I used as well as the arms that support the bed. Did use a 3mm thick heat treated piece of glass, couldn't get a thinner one which added weight.

I did try bigger shafts (12mm) with single linear bearing on each shaft but they were jamming at times. Don't think linear bearing like too much weight being off centred.

Currently adding 2 lead screws at the front (either side to the front of the print bed) to which they will being driven with one motor using drive belt. Just waiting for the pulleys to arrive before I try it out. Then will see how the alignment of these screws work.

Playing around with Marlin 1.1 Dev Now using 7 endstops- Xmin, Xmax, Ymin, Ymax, Zmax, Zmin and Z2Min endstop for the new motor. Have found Marlin has a set time to sync the two Z stepper motors no matter how far they take to home, unlike using just one motor.

Also added a filament run out sensor switch. Only good for when printing from SD cards.

I had to make a few changes to the Marlin firmware to get the sync operational with using the Z2Min endstop as well as getting the filament run out to work.

Also made some changes to get Gcode - M119 to show all 7 endstops as well as the filament switch status. Very handy when testing things..

Cheers Bruce

How stable is the print bed being canti-levered?

I built a CoreXY using 15mm Aluminium extrusions very similar design. Have found the print bed does flex a little, still prints OK but would like it more stable.

I think the flex is from the 2 x 8mm shafts that I used as well as the arms that support the bed. Did use a 3mm thick heat treated piece of glass, couldn't get a thinner one which added weight.

I did try bigger shafts (12mm) with single linear bearing on each shaft but they were jamming at times. Don't think linear bearing like too much weight being off centred.

Currently adding 2 lead screws at the front (either side to the front of the print bed) to which they will being driven with one motor using drive belt. Just waiting for the pulleys to arrive before I try it out. Then will see how the alignment of these screws work.

Playing around with Marlin 1.1 Dev Now using 7 endstops- Xmin, Xmax, Ymin, Ymax, Zmax, Zmin and Z2Min endstop for the new motor. Have found Marlin has a set time to sync the two Z stepper motors no matter how far they take to home, unlike using just one motor.

Also added a filament run out sensor switch. Only good for when printing from SD cards.

I had to make a few changes to the Marlin firmware to get the sync operational with using the Z2Min endstop as well as getting the filament run out to work.

Also made some changes to get Gcode - M119 to show all 7 endstops as well as the filament switch status. Very handy when testing things..

Cheers Bruce

|

Re: G&C Printer September 02, 2015 07:37PM |

Registered: 8 years ago Posts: 346 |

The bed is very stable, used 2020 aluminium to make the arms and 12mm shafts with 4 bearings with aluminium case. I only have one pla pieces to connect the z screw to the bed struture.

Using more that one lead screw i think will solve your problem.

Bruse, very nice printer.

Already made saveral prints and the quality is very good.

But, i have somes problems to solve. i have lots of noises and vibrations with the core movement at some speeds. Not sure if because i using ramps with 1/16 stepers or belt are not corretly tensioned.

Check the youtube video of one the first prints, you can see the noise problem i having.

[youtu.be]

Im usin merlin 1.1.0 dev, there is a bug that make the motor stop before reaching the end of the path with high speeds.

check my youtube channel, there are 2 videos with the bug. To solve this you can use the last stable version or correcting the bug in the dev version.

Using more that one lead screw i think will solve your problem.

Bruse, very nice printer.

Already made saveral prints and the quality is very good.

But, i have somes problems to solve. i have lots of noises and vibrations with the core movement at some speeds. Not sure if because i using ramps with 1/16 stepers or belt are not corretly tensioned.

Check the youtube video of one the first prints, you can see the noise problem i having.

[youtu.be]

Im usin merlin 1.1.0 dev, there is a bug that make the motor stop before reaching the end of the path with high speeds.

check my youtube channel, there are 2 videos with the bug. To solve this you can use the last stable version or correcting the bug in the dev version.

|

Re: G&C Printer September 03, 2015 04:40AM |

Registered: 14 years ago Posts: 128 |

First thing I found was to place your printer on some good blocks of soft foam, I found this reduced a lot of vibration that was being heard. Amazing how vibration travels about.

The next thing is to play around with the stepper current settings and also the acceleration settings. I think this is your real problem. Went down the same route myself.

I think you can have issues with setting the acceleration too high and then to overcome missing steps is to set the stepper driver current too high.

Just got my two new drive screws in place and now working, will upload a pic in due course..

Cheers

The next thing is to play around with the stepper current settings and also the acceleration settings. I think this is your real problem. Went down the same route myself.

I think you can have issues with setting the acceleration too high and then to overcome missing steps is to set the stepper driver current too high.

Just got my two new drive screws in place and now working, will upload a pic in due course..

Cheers

|

Re: G&C Printer September 03, 2015 09:32AM |

Registered: 10 years ago Posts: 553 |

Make sure your belts are correctly tensioned, your Vrefs are set correctly, and your idlers are moving smoothly. I had problems with really loud movement about a month ago when I was starting to move my printer. Once I fixed those things, it started running smoothly.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: G&C Printer September 08, 2015 05:55AM |

Registered: 8 years ago Posts: 346 |

The printer is finished, I have upload the complete 3d project, bom file and firmware (marlin and repetier) where:

[www.thingiverse.com]

My overall opinion of the printer:

The good:

Very good printer for is cost.

The precision is top notch, the print quality can be easy compare to the print result of an ultimaker with no problem.

The print can print up to 100mm/s without losing quality.

The sweet print speed of this printer is 80mm/s, very silent and no vibration at all.

Only printed with pla, but so far never have any jam.

The bad:

Printing at very low speed or superior to 80mm/s there are vibrations that comes from the carriage. i will try upgrade the linear bearing to solve this.

I using an bowden setup and the retraction is not working 100%.

Only printed with pla, not sure if work correctly with abs or soft filaments.

Lots of printed parts that can breaks in the future, need to start make backups pieces...

[www.thingiverse.com]

My overall opinion of the printer:

The good:

Very good printer for is cost.

The precision is top notch, the print quality can be easy compare to the print result of an ultimaker with no problem.

The print can print up to 100mm/s without losing quality.

The sweet print speed of this printer is 80mm/s, very silent and no vibration at all.

Only printed with pla, but so far never have any jam.

The bad:

Printing at very low speed or superior to 80mm/s there are vibrations that comes from the carriage. i will try upgrade the linear bearing to solve this.

I using an bowden setup and the retraction is not working 100%.

Only printed with pla, not sure if work correctly with abs or soft filaments.

Lots of printed parts that can breaks in the future, need to start make backups pieces...

|

Re: G&C Printer September 08, 2015 04:26PM |

Registered: 9 years ago Posts: 346 |

Hello Filipe,

First of all, thank you for posting your build. I think the CoreXY is in need of more reference builds and yours are sure a nice edition.

I would like to give some comments for your printer, while your are reading my comments, do keep in mind that I am no 3d printer expert / guru or anything and what I say is just as much an invitation for discussion.

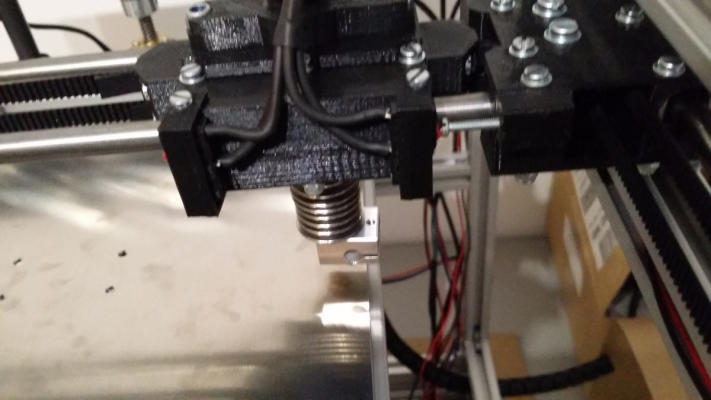

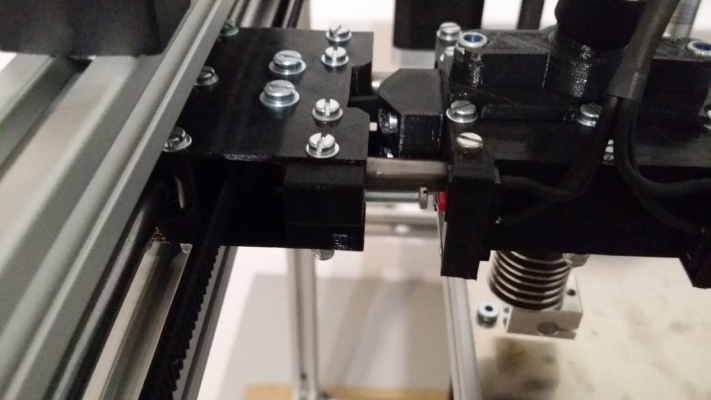

1) The carriage looks nice and is compact. I am a little worried for maintenance. It seems pretty difficult to get the hotend out and clean a jam? As you say your self, the linear bearings are vibration prone. If you go for an upgrade I think you should consider bushings instead of ball bearings ( [www.astbearings.com] ). I say that without having tried them my self (I just tried the Chinese linear ball bearings and found the same speed limits as what you are seeing).

2) I like how you put the two rods inside the structure with one 2020 on top and one below. It looks really neat and makes effective use of the space. Also your printer could without a ton of work be enclosed to make a heated build space.

3) I am a little worried about structural stiffness. Your printer is very tall without cross supports or even big angles. Did you consider some more reinforcements? Either cross reinforcement or you could put an entire steel plate on the back of the printer - Because your Z-axis is inside the printer it should be easy.

4) The way you have made your Z- axis is without a bearing to align the top. You have motor -> Coupling -> trapezoidal screw -> Bearing. A better practice is Motor -> Coupling -> Bearing -> Trapezoidal screw -> Bearing. We discuss this in this thread: [forums.reprap.org] . Obviously if your works it works. But how does it print something very tall? Try to print something that is supposed to be like 200 mm tall and see how straight and perfect it is in the lay shifts. Also even a small misalignment now might slowly develop over many hours of print.

5) I like how you made the bed support. Using simple extruded profile is just so simple and neat for us without the access to CNC and metal-laser cutters.

6) Speed - The video you posted - I am not entirely sure that is 100 mm/s. Remember that your RAMPS can slow down the print speed if it needs to make the calculation - So you can't always go by the set speeds. 100 mm/s would mean it covers half the heated bed distance in 1s. This video is more like 100 mm/s

[www.youtube.com] . It could just be the video that is tricking me, but my guess is that you are running at ~50 mm/s. This is not a criticism. I just tell you to give you the idea, that getting rid of your vibrations and maybe with other electronics (32 bit - I personally haven't tried) you should be able to get it moving much faster. I am however - As mentioned - seeing much the same speeds as you so I am in no way an expert on the super fast printers.

How "movable" if your printer? Is it really just to lift it in those two handles and ready?

First of all, thank you for posting your build. I think the CoreXY is in need of more reference builds and yours are sure a nice edition.

I would like to give some comments for your printer, while your are reading my comments, do keep in mind that I am no 3d printer expert / guru or anything and what I say is just as much an invitation for discussion.

1) The carriage looks nice and is compact. I am a little worried for maintenance. It seems pretty difficult to get the hotend out and clean a jam? As you say your self, the linear bearings are vibration prone. If you go for an upgrade I think you should consider bushings instead of ball bearings ( [www.astbearings.com] ). I say that without having tried them my self (I just tried the Chinese linear ball bearings and found the same speed limits as what you are seeing).

2) I like how you put the two rods inside the structure with one 2020 on top and one below. It looks really neat and makes effective use of the space. Also your printer could without a ton of work be enclosed to make a heated build space.

3) I am a little worried about structural stiffness. Your printer is very tall without cross supports or even big angles. Did you consider some more reinforcements? Either cross reinforcement or you could put an entire steel plate on the back of the printer - Because your Z-axis is inside the printer it should be easy.

4) The way you have made your Z- axis is without a bearing to align the top. You have motor -> Coupling -> trapezoidal screw -> Bearing. A better practice is Motor -> Coupling -> Bearing -> Trapezoidal screw -> Bearing. We discuss this in this thread: [forums.reprap.org] . Obviously if your works it works. But how does it print something very tall? Try to print something that is supposed to be like 200 mm tall and see how straight and perfect it is in the lay shifts. Also even a small misalignment now might slowly develop over many hours of print.

5) I like how you made the bed support. Using simple extruded profile is just so simple and neat for us without the access to CNC and metal-laser cutters.

6) Speed - The video you posted - I am not entirely sure that is 100 mm/s. Remember that your RAMPS can slow down the print speed if it needs to make the calculation - So you can't always go by the set speeds. 100 mm/s would mean it covers half the heated bed distance in 1s. This video is more like 100 mm/s

[www.youtube.com] . It could just be the video that is tricking me, but my guess is that you are running at ~50 mm/s. This is not a criticism. I just tell you to give you the idea, that getting rid of your vibrations and maybe with other electronics (32 bit - I personally haven't tried) you should be able to get it moving much faster. I am however - As mentioned - seeing much the same speeds as you so I am in no way an expert on the super fast printers.

How "movable" if your printer? Is it really just to lift it in those two handles and ready?

|

Re: G&C Printer September 09, 2015 05:04AM |

Registered: 8 years ago Posts: 346 |

Hi,

You have lots questions and very good ones

1) In case of jam is very easy to unmount the hotend, is only 2 screws, the ptfe tube goes from the extruder directly to the end of the hotend. So far i do not have any jam, but i still have to make more prints... I already investigate the vibration problem and the cause is the bearings, they have a little gap. I think you suggestion of using the bushings is a great one, i will try.

2) about the enclosed to make a heated build space.. not sure if is easy because of the top of the printer.

3) I do not have any problem of rigidity, the structure have 4 aluminium bar in each side. The only place where there are some movement is the carriage because of the bearing and the pla printed carriage. I think the structure is overkill for the dimension of the printer. Only 3 bars in each side will be ok.

4) Still need to print something big to check if i have z axis problems. If i found an misalignment problem is very easy to add an second bearing after the coupling, the are space and an 2020 bar to support the bearing.

5) the bed structure so far is appears to be perfect, I do not have see any z problems in my prints. Added a nice touch, the cut in the 2020 profile are making an lock of the nuts to be easy to level the mk2b bed. I have only level once end never touched again, the first layer is always perfect.

6) I never say the video it was printing at 100mm/s, i m think is was printing at 70 mm/s. I have made prints at 100mm/s, but there are vibrations and noises because of the carriage problem. I using ramps 1.4 and octoprint at the same time, not sure if it was in the reality printing at 100mm/s.

From my test i found the sweet speed print of the printer is between 60 and 80mm/s. low speed and superior at 80 make the vibration appears and lot of noise.

The printer is very easy to move, is only necessary to disconnect the power cord and use the 2 handles, but heavy 13kg... everything is well secure, you can transport with the filament mounted.

For now the printer have 2 main problem i trying to solve, the vibration of the carriage and lot of little filaments and some blob because of the incorrect configuration of the retractions values.

I have several print with lots of blob in the outside wall, i found the problem caused by the raspberry. The raspberry i using is the first model with 256mb, and the prints have micro stops when printing. I have try to print the same object directly from the lcd with sd card and no more blobs. I will try to use an raspberry 2, if this not solve then a will remove the raspberry and octoprint.

Edited 6 time(s). Last edit at 09/09/2015 02:10PM by filipeCampos.

You have lots questions and very good ones

1) In case of jam is very easy to unmount the hotend, is only 2 screws, the ptfe tube goes from the extruder directly to the end of the hotend. So far i do not have any jam, but i still have to make more prints... I already investigate the vibration problem and the cause is the bearings, they have a little gap. I think you suggestion of using the bushings is a great one, i will try.

2) about the enclosed to make a heated build space.. not sure if is easy because of the top of the printer.

3) I do not have any problem of rigidity, the structure have 4 aluminium bar in each side. The only place where there are some movement is the carriage because of the bearing and the pla printed carriage. I think the structure is overkill for the dimension of the printer. Only 3 bars in each side will be ok.

4) Still need to print something big to check if i have z axis problems. If i found an misalignment problem is very easy to add an second bearing after the coupling, the are space and an 2020 bar to support the bearing.

5) the bed structure so far is appears to be perfect, I do not have see any z problems in my prints. Added a nice touch, the cut in the 2020 profile are making an lock of the nuts to be easy to level the mk2b bed. I have only level once end never touched again, the first layer is always perfect.

6) I never say the video it was printing at 100mm/s, i m think is was printing at 70 mm/s. I have made prints at 100mm/s, but there are vibrations and noises because of the carriage problem. I using ramps 1.4 and octoprint at the same time, not sure if it was in the reality printing at 100mm/s.

From my test i found the sweet speed print of the printer is between 60 and 80mm/s. low speed and superior at 80 make the vibration appears and lot of noise.

The printer is very easy to move, is only necessary to disconnect the power cord and use the 2 handles, but heavy 13kg... everything is well secure, you can transport with the filament mounted.

For now the printer have 2 main problem i trying to solve, the vibration of the carriage and lot of little filaments and some blob because of the incorrect configuration of the retractions values.

I have several print with lots of blob in the outside wall, i found the problem caused by the raspberry. The raspberry i using is the first model with 256mb, and the prints have micro stops when printing. I have try to print the same object directly from the lcd with sd card and no more blobs. I will try to use an raspberry 2, if this not solve then a will remove the raspberry and octoprint.

Edited 6 time(s). Last edit at 09/09/2015 02:10PM by filipeCampos.

|

Re: G&C Printer September 11, 2015 07:54AM |

Registered: 8 years ago Posts: 346 |

|

Re: G&C Printer September 25, 2015 09:54AM |

Registered: 9 years ago Posts: 893 |

Hello Filipe,

I've been looking at the BOM and the images of the complete printer - could you please confirm where the 20x40 and 20x60 extrusions go? I have a suspicion, but I'm not sure!

I was also wondering why you used 12mm aluminium rod for the Z slides - won't this be vulnerable to wear? Or is it simply that the Z-axis doesn't move very fast, and very often (unlike the X and Y)?

Also - does the change to igus bushings mean a change to the pieces that hold them?

Thanks,

David

Update - I worked out where those extrusions go! If I'm correct, the 20x40 goes across the upper part of the base as a divider, and the 20x60 holds the bed. Is that right?

Edited 2 time(s). Last edit at 09/25/2015 11:40AM by David J.

I've been looking at the BOM and the images of the complete printer - could you please confirm where the 20x40 and 20x60 extrusions go? I have a suspicion, but I'm not sure!

I was also wondering why you used 12mm aluminium rod for the Z slides - won't this be vulnerable to wear? Or is it simply that the Z-axis doesn't move very fast, and very often (unlike the X and Y)?

Also - does the change to igus bushings mean a change to the pieces that hold them?

Thanks,

David

Update - I worked out where those extrusions go! If I'm correct, the 20x40 goes across the upper part of the base as a divider, and the 20x60 holds the bed. Is that right?

Edited 2 time(s). Last edit at 09/25/2015 11:40AM by David J.

|

Re: G&C Printer September 25, 2015 12:50PM |

Registered: 8 years ago Posts: 346 |

Hi David,

Was the bars 20x60 and 20x40 you are correct.

I have used 12mm aluminium because is cheap and is was an hardening treatment. So far there is no wear and they are very precise.

The igus bushings was the same dimension of the lm8uu, so there is no need for any type of changes in the pieces. I have replaced the 8 lm8uu for 8 igus, and the result is very good. the price igus is twice the lm8uu, but i think they are an must buy.

With the lm8uu i have lots of vibration and noise. With igus there not vibration at all, was the noise it was reduced a lot, now the fan make almost all the noise when the printer is printing.

some link:

igus: [www.ebay.com]

other good upgrade to reduce vibration is to add 3 dampers for the x, y and z. i have buy this one:

[www.ebay.com]

Other good change and is the same price, is to change the Z coupler for and rigid one. I have buy the flexible one, when to printer finish the bed loweres very fast and i have some vibration. Using an rigid coupler solve the problem.

[www.ebay.com]

The motors i have buy are overkill, there are 2.5A, using motors of 1.7A is better and cheaper.

Now i having problems because of the lack of computation power of the ramps 1.4 i using, to print at good speed is was necessary to disconnect the full graphic lcd. I have ordered an arduino due and radds 1.5 to place my ramps.

Edited 4 time(s). Last edit at 09/25/2015 12:55PM by filipeCampos.

Was the bars 20x60 and 20x40 you are correct.

I have used 12mm aluminium because is cheap and is was an hardening treatment. So far there is no wear and they are very precise.

The igus bushings was the same dimension of the lm8uu, so there is no need for any type of changes in the pieces. I have replaced the 8 lm8uu for 8 igus, and the result is very good. the price igus is twice the lm8uu, but i think they are an must buy.

With the lm8uu i have lots of vibration and noise. With igus there not vibration at all, was the noise it was reduced a lot, now the fan make almost all the noise when the printer is printing.

some link:

igus: [www.ebay.com]

other good upgrade to reduce vibration is to add 3 dampers for the x, y and z. i have buy this one:

[www.ebay.com]

Other good change and is the same price, is to change the Z coupler for and rigid one. I have buy the flexible one, when to printer finish the bed loweres very fast and i have some vibration. Using an rigid coupler solve the problem.

[www.ebay.com]

The motors i have buy are overkill, there are 2.5A, using motors of 1.7A is better and cheaper.

Now i having problems because of the lack of computation power of the ramps 1.4 i using, to print at good speed is was necessary to disconnect the full graphic lcd. I have ordered an arduino due and radds 1.5 to place my ramps.

Edited 4 time(s). Last edit at 09/25/2015 12:55PM by filipeCampos.

|

Re: G&C Printer September 25, 2015 01:30PM |

Registered: 9 years ago Posts: 893 |

Thanks, Filipe.

When you mentioned igus bearings I was thinking of something totally different - I had only seen the ones that look like a top hat; a cylinder with a flange. I can see how yours are a direct replacement for the lm8uu.

I plan to use my Duet board when I build a CoreXY printer... which may well be this one!

When you mentioned igus bearings I was thinking of something totally different - I had only seen the ones that look like a top hat; a cylinder with a flange. I can see how yours are a direct replacement for the lm8uu.

I plan to use my Duet board when I build a CoreXY printer... which may well be this one!

|

Re: G&C Printer September 25, 2015 01:49PM |

Registered: 8 years ago Posts: 346 |

Duet board is a good option, good and complete board, the version 0.6 is cheap. But if you live in Europe like me the duet it expensive because of the vat.

I order radds because is sells from germany (no vat), it support repetier (good firmware with a lot of support), i can reuse hardware i already have like 1/32 steppers, raspberry (with camera and wifi), is cheap in Europe, can support 1/128 steppers and is modular. the main problem of radds is the lack of information and support.

was smoothiboard: is the most expensive, but is a very good board, lots of support and was very good and stable firmware.

If you decide to build the same printer i can help you to build a better one. I have some suggestions/ideas to improve the g&c printer.

My next improvement is to add to the design an direct extruder and replace my bowden.

Now i have an bowden extruder, is very reliable for pla and abs (never have any jam) but give me lots of problems with bobs and tiny filaments.

Bowden entruder and 1.75 filament is a very bad mix... If your are thinking about using an bowden extruder in your corexy them is better to build an printer that use 3mm filament.

Edited 1 time(s). Last edit at 09/25/2015 01:59PM by filipeCampos.

I order radds because is sells from germany (no vat), it support repetier (good firmware with a lot of support), i can reuse hardware i already have like 1/32 steppers, raspberry (with camera and wifi), is cheap in Europe, can support 1/128 steppers and is modular. the main problem of radds is the lack of information and support.

was smoothiboard: is the most expensive, but is a very good board, lots of support and was very good and stable firmware.

If you decide to build the same printer i can help you to build a better one. I have some suggestions/ideas to improve the g&c printer.

My next improvement is to add to the design an direct extruder and replace my bowden.

Now i have an bowden extruder, is very reliable for pla and abs (never have any jam) but give me lots of problems with bobs and tiny filaments.

Bowden entruder and 1.75 filament is a very bad mix... If your are thinking about using an bowden extruder in your corexy them is better to build an printer that use 3mm filament.

Edited 1 time(s). Last edit at 09/25/2015 01:59PM by filipeCampos.

|

Re: G&C Printer September 25, 2015 03:43PM |

Registered: 10 years ago Posts: 14,672 |

Quote

filipeCampos

Duet board is a good option, good and complete board, the version 0.6 is cheap. But if you live in Europe like me the duet it expensive because of the vat.

I order radds because is sells from germany (no vat),

If you live in the EU then you are liable to pay VAT on electronics no matter where the board comes from, unless you are VAT-registered.

The price of RADDS does appear to have dropped recently, but unless you already have them you also need to factor in the cost of an Arduino Due, stepper drivers, and an RPi if you want a web interface. While it's nice to know you can exchange individual stepper drivers, drivers on plug in boards are more prone to overheating because the board area is too small to cool the driver chips properly - and you still have to use those awful pots to adjust the stepper motor driver currents.

btw there is now a port of RepRapFirmware for RADDS (without the web interface, obviously).

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: G&C Printer September 25, 2015 04:36PM |

Registered: 9 years ago Posts: 893 |

Quote

filipeCampos

If you decide to build the same printer i can help you to build a better one. I have some suggestions/ideas to improve the g&c printer.

Interesting... I'd like to know before I commit to spending money!

Quote

filipeCampos

My next improvement is to add to the design an direct extruder and replace my bowden.

Now i have an bowden extruder, is very reliable for pla and abs (never have any jam) but give me lots of problems with bobs and tiny filaments.

Bowden entruder and 1.75 filament is a very bad mix... If your are thinking about using an bowden extruder in your corexy them is better to build an printer that use 3mm filament.

I'm also in the EU - UK, to be exact.

I've found that retraction plays a large part in sorting out blobs and threads when printing - there's a fine line between blobbing and leaving filaments. I've just about got it right with my 1.75mm E3Dv6 on a delta printer, although I still prefer direct extruders. I have used a bowden feed for my 3mm Prusa i3 in the past, and found the standard direct extruder far easier to manage. I also prefer 3mm filament - partly because I already have a few rolls of it for my Prusa i3, and also I find that I have fewer problems with it when compared to 1.75mm.

I know a bowden feed is lighter, but speed isn't my objective - I just want something to replace the Prusa, as don't like all the mechanical compromises on that thing. Unfortunately I've put a lot of effort into getting the Prusa to produce good results, so whatever I build has to be able to produce results that are at least equal, and preferably better! Something a lot quieter would also be a bonus - to keep my wife happy.

Edited 1 time(s). Last edit at 09/25/2015 04:42PM by David J.

|

Re: G&C Printer September 25, 2015 05:04PM |

Registered: 8 years ago Posts: 346 |

I have considered the duet 0.6, but the cost of shipping to Portugal with all the tax will be something like 80 to 90 euro, and from my experience i will receive the board only in 2 months or more. Any buy that is not EUR country and more of 20 and something euros is subject of tax and an long waiting time in Portugal.

The arduino due clone + radds 1.5 + 5 clones steppers 1/32 is 72 euros. Both arduino and steppers are less 20 euro, the shipping is "only" 2 or 3 weeks.

At the end both have similar prices and both are good boards. I do not see the duet to be a better board that the radds or vise versa.

For me 1/16 steppers plug in the board is a big no no. The only go things i can see is the overheating issue and set the voltage by firmware.

Most of the board are moving to 1/32 steppers, is an question of time to be the default of the 32 bit boards. Overheating only happens if the voltage of the steppers are not corretly setup. The price of the steppers is really low and easy to replace, you can do future upgrades like 1/128. In case one of the stepper goes bad?? most people do not have the hardware or skills to replace and pluged steppers.

The arduino due clone + radds 1.5 + 5 clones steppers 1/32 is 72 euros. Both arduino and steppers are less 20 euro, the shipping is "only" 2 or 3 weeks.

At the end both have similar prices and both are good boards. I do not see the duet to be a better board that the radds or vise versa.

For me 1/16 steppers plug in the board is a big no no. The only go things i can see is the overheating issue and set the voltage by firmware.

Most of the board are moving to 1/32 steppers, is an question of time to be the default of the 32 bit boards. Overheating only happens if the voltage of the steppers are not corretly setup. The price of the steppers is really low and easy to replace, you can do future upgrades like 1/128. In case one of the stepper goes bad?? most people do not have the hardware or skills to replace and pluged steppers.

|

Re: G&C Printer September 25, 2015 05:33PM |

Registered: 10 years ago Posts: 14,672 |

I have only ever used 1.75mm Bowden extruders and I generally find them OK. I agree that getting the right amount of retraction is critical. I have not tried to print flexible filament.

A non Bowden extruder light enough for a delta printer would be nice. I have it in mind to build one around a small BLDC motor with reduction gearbox, encoder, and microcontroller.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

A non Bowden extruder light enough for a delta printer would be nice. I have it in mind to build one around a small BLDC motor with reduction gearbox, encoder, and microcontroller.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: G&C Printer September 25, 2015 05:48PM |

Registered: 8 years ago Posts: 346 |

Quote

David J

Quote

filipeCampos

If you decide to build the same printer i can help you to build a better one. I have some suggestions/ideas to improve the g&c printer.

Interesting... I'd like to know before I commit to spending money!

the main objectify of the printer is to be cheap, the ideas/suggestions i have is to replace some components and add upgrades. I think at the end the cost will be less or at most the same..

Some ideas, some already added to my printer but there are not reflected in the 3d design.

for example:

-add an simple led switch on/off that cut the power. (already done)

-add an led light that allow me to see the printing, very useful to check the 1 layer. The light can be controlled by the firmware if you connect to the 12v of the second hotend not used. (done)

-min Z endstop can be micro adjusted with an screw (done)

-the lcd can be placed more inside the printer.

-one of the printed panel can have an box to put some tools.

-one of the printed panel can have nozzle holder, exemple: [www.thingiverse.com] this nozzle holder can be "inside" of one of the panel.

-replace 30A power supply for 20 or 25A

-buy the t-nuts from ebay, reduce 8€ total cost..

-design an carriage that allow dual hotend, it can be necessary to replace the y axis with 10mm

min Z endstop can be micro adjusted:

led switch:

Edited 1 time(s). Last edit at 09/25/2015 05:56PM by filipeCampos.

|

Re: G&C Printer September 25, 2015 05:54PM |

Registered: 8 years ago Posts: 346 |

|

Re: G&C Printer September 26, 2015 05:19AM |

Registered: 9 years ago Posts: 893 |

Quote

filipeCampos

the main objectify of the printer is to be cheap, the ideas/suggestions i have is to replace some components and add upgrades. I think at the end the cost will be less or at most the same..

Some ideas, some already added to my printer but there are not reflected in the 3d design.

for example:

-add an simple led switch on/off that cut the power. (already done)

-add an led light that allow me to see the printing, very useful to check the 1 layer. The light can be controlled by the firmware if you connect to the 12v of the second hotend not used. (done)

-min Z endstop can be micro adjusted with an screw (done)

-the lcd can be placed more inside the printer.

-one of the printed panel can have an box to put some tools.

-one of the printed panel can have nozzle holder, exemple: [www.thingiverse.com] this nozzle holder can be "inside" of one of the panel.

-replace 30A power supply for 20 or 25A

-buy the t-nuts from ebay, reduce 8€ total cost..

-design an carriage that allow dual hotend, it can be necessary to replace the y axis with 10mm

I will be using an external 30A power supply (used for various tasks) so that eliminates a few of your upgrades!

I'm not bothered about the LCD as I'll be using my Duet board - it doesn't have a screen at the moment, and I don't feel a great need for one just now.

Printed panel changes - nice, but not urgent for me.

Dual hot-end - not a need at the moment, but it would be nice to know it's available for a future upgrade.

LED light is worth doing.

The other thing I'd want to do is set up auto-levelling using an IR probe (from dc42). I can't imagine that it would be too hard to add some lugs near the hot-end, although I have a design for a mount that screws to the E3Dv6 fan shroud.

All I need to do now is see how the costs add up, and whether my budget will allow it...

Thanks,

David

Edited 2 time(s). Last edit at 09/26/2015 04:41PM by David J.

|

Re: G&C Printer September 26, 2015 06:02AM |

Registered: 8 years ago Posts: 346 |

I have an prusa i3 steel and auto level is a must have for the printer. But for this corexy there is no need of the autoleveling, in my case i setup the level using the m3 screw and it is only necessary to do this one time. After changing nozzle normally is necessary to make an little ajustement using the screw, but it takes 5 min top. The bed was 4 screw in each side of the heated bed to level the bed. The bed struture is very ridig and precise.

|

Re: G&C Printer September 27, 2015 10:30AM |

Registered: 9 years ago Posts: 893 |

|

Re: G&C Printer September 27, 2015 01:13PM |

Registered: 9 years ago Posts: 83 |

Quote

dc42

I have only ever used 1.75mm Bowden extruders and I generally find them OK. I agree that getting the right amount of retraction is critical. I have not tried to print flexible filament.

A non Bowden extruder light enough for a delta printer would be nice. I have it in mind to build one around a small BLDC motor with reduction gearbox, encoder, and microcontroller.

Ultibots has one on their v-slot kossel printer, using a PG35L motor.

|

Re: G&C Printer September 27, 2015 02:26PM |

Registered: 9 years ago Posts: 893 |

Filipe,

What diameter and length screws did you use to hold the 2 parts of the motor mounts together? I guess that the front bearing holders will be the same?

Also, what size screws hold the X carriage together?

This info isn't in the BOM...

(only joking - few published designs have such a detailed BOM!)

Thanks,

David

What diameter and length screws did you use to hold the 2 parts of the motor mounts together? I guess that the front bearing holders will be the same?

Also, what size screws hold the X carriage together?

This info isn't in the BOM...

(only joking - few published designs have such a detailed BOM!)

Thanks,

David

|

Re: G&C Printer September 27, 2015 06:37PM |

Registered: 8 years ago Posts: 346 |

You need m3 and m4 screws, i need to count and check the size of each. I can only do this tomorrow after work. Tomorrow at the end of the day i will update the bom file with the list of the m3 and m4 screws necessary and there dimensions.

Have you decided the extruder you will use?

I have printed this today with the g&c printer

[www.thingiverse.com]

You can check in the last photo the vase, the precision is really good. Is a precision you do not get with an pruse i3. But i having some problems with the fan not cooling the pla fast. The top part of the print is not good because is was printing to fast 70mm/s and not time to cool the pla.

Edited 2 time(s). Last edit at 09/27/2015 06:47PM by filipeCampos.

Have you decided the extruder you will use?

I have printed this today with the g&c printer

[www.thingiverse.com]

You can check in the last photo the vase, the precision is really good. Is a precision you do not get with an pruse i3. But i having some problems with the fan not cooling the pla fast. The top part of the print is not good because is was printing to fast 70mm/s and not time to cool the pla.

Edited 2 time(s). Last edit at 09/27/2015 06:47PM by filipeCampos.

|

Re: G&C Printer September 28, 2015 03:41AM |

Registered: 9 years ago Posts: 893 |

Thanks for updating the BOM - I won't need to get any screws yet as I'm waiting for parts & materials to arrive!

I have a 1.75mm bowden E3Dv6 that will be going into this printer. This is one reason why I picked your design, as I know you are using an E3Dv6 Lite so mine will fit easily.

Regarding the cooling - I have read in several places that the ring nozzles (like yours) don't give a positive air flow as each side is blowing against itself, leaving no room for the hot air to escape. The suggested solution was to have a nozzle on each side, with lots of room for the heated air to exit. I must emphasise that I have no experience of this, as I've always used a snail blower feeding air from one side. This isn't an ideal solution either!

I see that the cat likes Groot...

Edited 1 time(s). Last edit at 09/28/2015 03:47AM by David J.

I have a 1.75mm bowden E3Dv6 that will be going into this printer. This is one reason why I picked your design, as I know you are using an E3Dv6 Lite so mine will fit easily.

Regarding the cooling - I have read in several places that the ring nozzles (like yours) don't give a positive air flow as each side is blowing against itself, leaving no room for the hot air to escape. The suggested solution was to have a nozzle on each side, with lots of room for the heated air to exit. I must emphasise that I have no experience of this, as I've always used a snail blower feeding air from one side. This isn't an ideal solution either!

I see that the cat likes Groot...

Edited 1 time(s). Last edit at 09/28/2015 03:47AM by David J.

|

Re: G&C Printer September 28, 2015 05:02AM |

Registered: 8 years ago Posts: 346 |

E3d v6 and the little version i think they can use the same support.

The ring cooling fan is not working very well, I need to find a better solution. Use 2 blower in each side can be a good solution, i think i will try this one...

I was asking about the extruder because i using an mk8 bowden and the result are not great, is very difficult to setup correctly and give me inconsistent results. I decided i will print and try an direct extruder. My problem is the time before it made an retraction is too long, was result i have always little bob and tiny filaments all over the print. The retraction take to much time, not sure if is because of the ramps board of the size or the tube that goes from the extruder to the hotend. Using slic3r there is an option that solve most part of the blob problem but still not a perfect solution. With the greg direct extruder of my prusa i never have this type of problems.

Edited 4 time(s). Last edit at 09/28/2015 05:08AM by filipeCampos.

The ring cooling fan is not working very well, I need to find a better solution. Use 2 blower in each side can be a good solution, i think i will try this one...

I was asking about the extruder because i using an mk8 bowden and the result are not great, is very difficult to setup correctly and give me inconsistent results. I decided i will print and try an direct extruder. My problem is the time before it made an retraction is too long, was result i have always little bob and tiny filaments all over the print. The retraction take to much time, not sure if is because of the ramps board of the size or the tube that goes from the extruder to the hotend. Using slic3r there is an option that solve most part of the blob problem but still not a perfect solution. With the greg direct extruder of my prusa i never have this type of problems.

Edited 4 time(s). Last edit at 09/28/2015 05:08AM by filipeCampos.

|

Re: G&C Printer September 28, 2015 05:18AM |

Registered: 9 years ago Posts: 893 |

I may be using a different method for mounting the E3Dv6, but I'm not sure yet. The setup on my delta works very well, so I will probably try to take the whole thing over to this printer. Your design gives a lot of flexibility, which helps a lot.

I will be transplanting a Gregs Wade geared bowden extruder into this printer - it was working well on my delta, so I hope it will work just as well here. I have tried a direct drive extruder on the delta, but it wasn't very successful - I had a lot of hot-end blockages.

I will be transplanting a Gregs Wade geared bowden extruder into this printer - it was working well on my delta, so I hope it will work just as well here. I have tried a direct drive extruder on the delta, but it wasn't very successful - I had a lot of hot-end blockages.

Sorry, only registered users may post in this forum.