G&C Printer

Posted by filipeCampos

|

Re: G&C Printer November 30, 2015 08:26AM |

Registered: 8 years ago Posts: 346 |

|

Re: G&C Printer November 30, 2015 08:54AM |

Registered: 9 years ago Posts: 893 |

|

Re: G&C Printer December 06, 2015 05:22AM |

Registered: 9 years ago Posts: 893 |

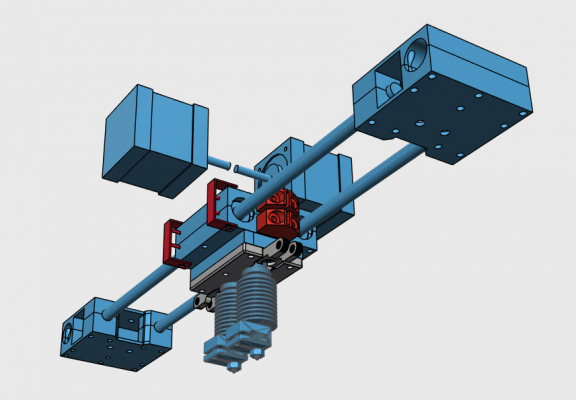

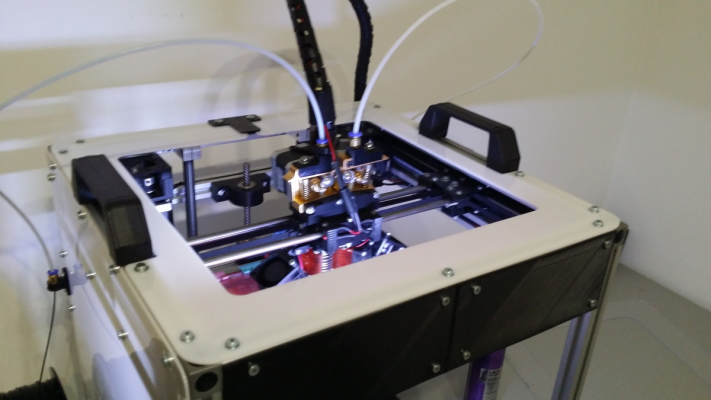

Well - I re-designed the layout for my print cooling fans! I tried to get both fans vertical, but there simply wasn't enough clearance between the fan casings and the frames on each side - I could barely get a piece of paper between the two. Now I have rotated the fans so that they are horizontal in the Y plane, and 45 degrees in the X plane (I think I've got that the right way around!).

I tried to keep everything as simple as possible - a bracket is screwed to the fan, and a small pivot fastened to the X carriage using the hot-end mounting screws on each side.

I've glued a simple nozzle into each fan's outlet, printed using ABS as they are so close to the hot-end. Each nozzle has a slight offset as the fans don't point exactly at the hot-end tip (not that it's a problem anyway).

This setup gives a respectable amount of clearance all around (but see note below) and a lot of adjustment. Note that each fan has identical mounts and nozzles - there are no 'left-' or 'right-handed' parts.

The only down-side is that I now have to move my Z-axis cable chain, as the right-hand fan collides with it at anything above X190 Y190! Hopefully this won't be too difficult, as it's only a case of moving it about 15mm. Time will tell...

Note that I've only attached the SCAD files this time - the STL file for the fan mount was way over the forum's file size limit. I will see if I can get these pieces onto Thingiverse shortly, so that I can upload the STLs as well.

Edited 1 time(s). Last edit at 12/06/2015 05:29AM by David J.

I tried to keep everything as simple as possible - a bracket is screwed to the fan, and a small pivot fastened to the X carriage using the hot-end mounting screws on each side.

I've glued a simple nozzle into each fan's outlet, printed using ABS as they are so close to the hot-end. Each nozzle has a slight offset as the fans don't point exactly at the hot-end tip (not that it's a problem anyway).

This setup gives a respectable amount of clearance all around (but see note below) and a lot of adjustment. Note that each fan has identical mounts and nozzles - there are no 'left-' or 'right-handed' parts.

The only down-side is that I now have to move my Z-axis cable chain, as the right-hand fan collides with it at anything above X190 Y190! Hopefully this won't be too difficult, as it's only a case of moving it about 15mm. Time will tell...

Note that I've only attached the SCAD files this time - the STL file for the fan mount was way over the forum's file size limit. I will see if I can get these pieces onto Thingiverse shortly, so that I can upload the STLs as well.

Edited 1 time(s). Last edit at 12/06/2015 05:29AM by David J.

|

Re: G&C Printer December 06, 2015 02:57PM |

Registered: 8 years ago Posts: 346 |

|

Re: G&C Printer December 06, 2015 04:37PM |

Registered: 9 years ago Posts: 893 |

|

Re: G&C Printer December 07, 2015 03:32PM |

Registered: 8 years ago Posts: 346 |

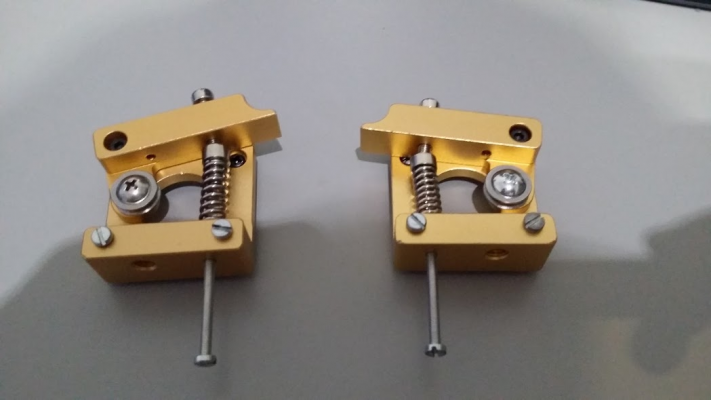

I put the same on my printer, is really a good design.

Order on ebay an second 50mm radial fan to put one the other side.

[www.thingiverse.com]

Order on ebay an second 50mm radial fan to put one the other side.

[www.thingiverse.com]

|

Re: G&C Printer December 07, 2015 04:32PM |

Registered: 9 years ago Posts: 893 |

|

Re: G&C Printer December 09, 2015 06:51AM |

Registered: 8 years ago Posts: 346 |

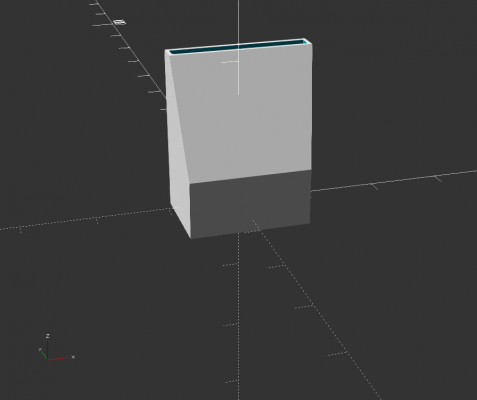

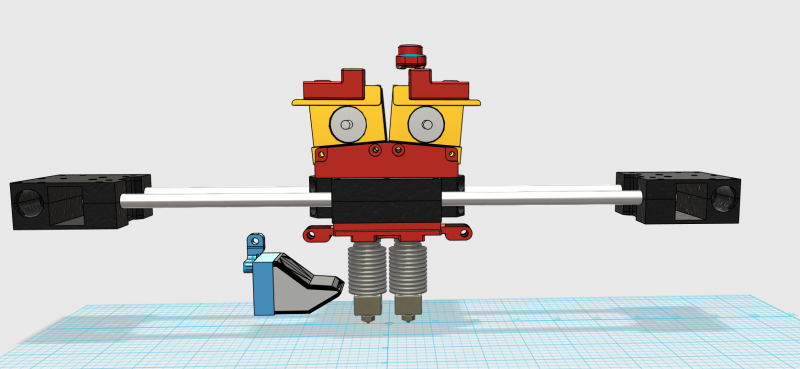

Hi David,

I making an new design to add an second E3D v6. I´m trying to design the new pieces without the need to change the carriage, so far i have the first version of the 2 piece that will secure the two E3D V6. I still need to design an piece that will secure two mk8 extruder on the top of the carriage, I will use two china aluminium mk8. The two E3D will have an bowden setup, there will be an ptfe tube of 6 to 10 cm that will go from the hotend directly to the mk8.

Already put two piece to secure the radial fan on each side, i think i will be necessary to make some adjustment to the fan support because of the fan of the E3D.

I still have lot of work to do and i sharing the design in this early stage because i need some help/ideas to put the two mk8 on the top... I already put a lot of thinking on this and is not a easy task.

MK8:

I making an new design to add an second E3D v6. I´m trying to design the new pieces without the need to change the carriage, so far i have the first version of the 2 piece that will secure the two E3D V6. I still need to design an piece that will secure two mk8 extruder on the top of the carriage, I will use two china aluminium mk8. The two E3D will have an bowden setup, there will be an ptfe tube of 6 to 10 cm that will go from the hotend directly to the mk8.

Already put two piece to secure the radial fan on each side, i think i will be necessary to make some adjustment to the fan support because of the fan of the E3D.

I still have lot of work to do and i sharing the design in this early stage because i need some help/ideas to put the two mk8 on the top... I already put a lot of thinking on this and is not a easy task.

MK8:

|

Re: G&C Printer December 09, 2015 05:05PM |

Registered: 9 years ago Posts: 893 |

That's a tough challenge! I wonder whether the weight of 2 direct extruders might be too much - you risk losing all the benefits of CoreXY. In the layout you propose you will have to mount the motors high to clear the motors and the top of the frame, which is going to introduce all sorts of momentum problems (I think).

I know you had a tough time with bowden, but I think it's the answer in this case. But I will be happy if you prove me wrong!

I know you had a tough time with bowden, but I think it's the answer in this case. But I will be happy if you prove me wrong!

|

Re: G&C Printer December 10, 2015 05:18AM |

Registered: 8 years ago Posts: 346 |

At the moment i have an big motor in the carriage and already printed as 120mm/s without any problem.

I will add a new small motor (285gr), mk8, e3d and one more radial fan, adding more an total 350 to 400gr

My goal is to have an good print quality with speeds between 60mm to 80mm/s, i think there are good chance to achieve this.

In case i have artifact in the print, then i planning to change the design to have the little motor on the carriage and put the heavy one was bowdem setup. With this setup i almost 100% sure there will be no problems.

Edited 1 time(s). Last edit at 12/10/2015 05:23AM by filipeCampos.

I will add a new small motor (285gr), mk8, e3d and one more radial fan, adding more an total 350 to 400gr

My goal is to have an good print quality with speeds between 60mm to 80mm/s, i think there are good chance to achieve this.

In case i have artifact in the print, then i planning to change the design to have the little motor on the carriage and put the heavy one was bowdem setup. With this setup i almost 100% sure there will be no problems.

Edited 1 time(s). Last edit at 12/10/2015 05:23AM by filipeCampos.

|

Re: G&C Printer December 31, 2015 08:27AM |

Registered: 8 years ago Posts: 346 |

Hi,

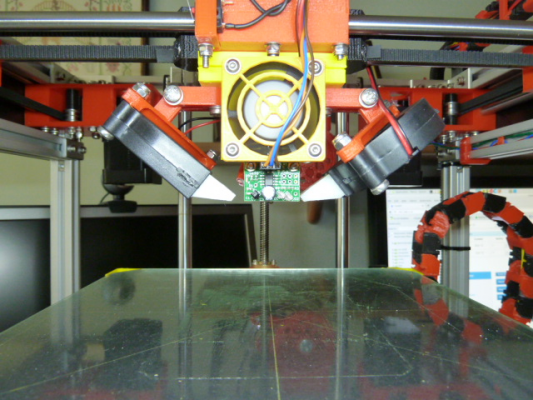

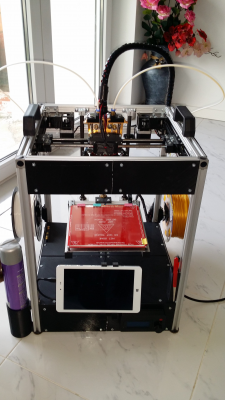

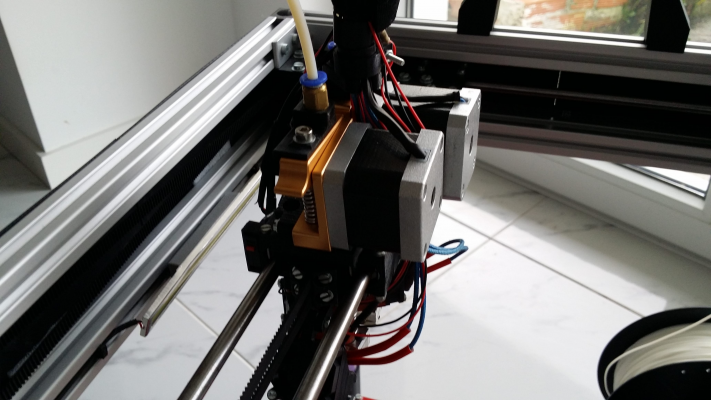

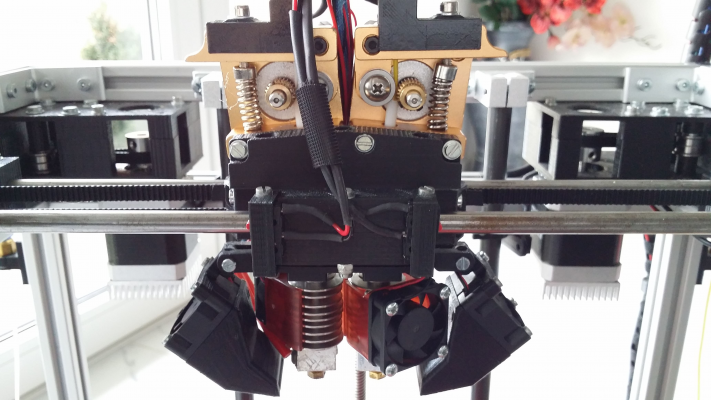

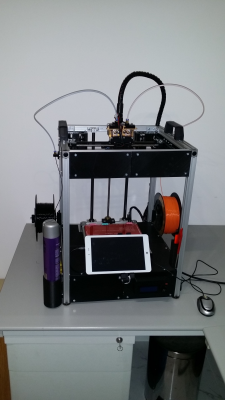

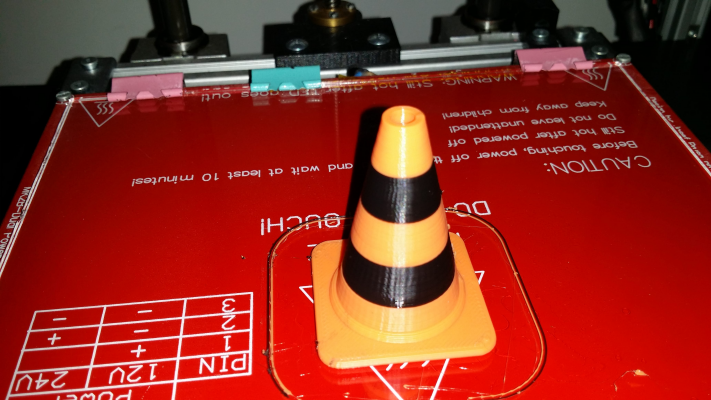

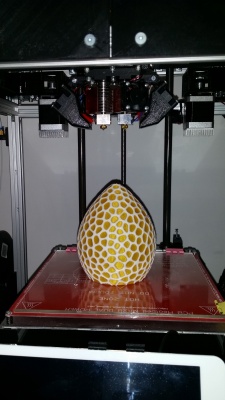

Finished the conversion of the printer to an dual hotend. It use 2 E3D v6 or E3D v6 little version. The carriage is was not modify, this allow to easy modify or change again to only one hotend.

Where are some picture of the final result.

I still need to make some final adjustment to the 3d files, after theses adjustment i will upload the project.

I have made some prints to tests and overall the quality is good, but the carriage is heavy and i printed at an max of 80mm/s for infill and 60mm/s walls. When printing is necessary to use some Technics to control the oozing of the nozzle not used, like lower the temperature of the hotend not printing, outside walls and increase the retractions.

Edited 1 time(s). Last edit at 12/31/2015 08:34AM by filipeCampos.

Finished the conversion of the printer to an dual hotend. It use 2 E3D v6 or E3D v6 little version. The carriage is was not modify, this allow to easy modify or change again to only one hotend.

Where are some picture of the final result.

I still need to make some final adjustment to the 3d files, after theses adjustment i will upload the project.

I have made some prints to tests and overall the quality is good, but the carriage is heavy and i printed at an max of 80mm/s for infill and 60mm/s walls. When printing is necessary to use some Technics to control the oozing of the nozzle not used, like lower the temperature of the hotend not printing, outside walls and increase the retractions.

Edited 1 time(s). Last edit at 12/31/2015 08:34AM by filipeCampos.

|

Re: G&C Printer December 31, 2015 11:07AM |

Registered: 9 years ago Posts: 893 |

|

Re: G&C Printer January 01, 2016 06:22AM |

Registered: 9 years ago Posts: 95 |

|

Re: G&C Printer January 01, 2016 03:35PM |

Registered: 8 years ago Posts: 346 |

|

Re: G&C Printer January 01, 2016 03:38PM |

Registered: 8 years ago Posts: 11 |

Hi! I've been doing some looking around and I plan to make this my next build. I'll probably get started sooner, but it may take a month or more before I really get ramped up on this.

I did have two questions:

1) If I wanted to increase the build plate size, is there any issue with the cantilevered bed if I widen the Z axis rails? Also, what are your thoughts on adding a crossbeam between the two cantilever arms if I do so? I want a 250^3 or even 300^3 build volume.

2) I have access to a laser cutter and would rather laser cut the cover plates than print them - Are those in the 123d file?

3) I don't have any 20x40 or 20x60 - but I have shedloads of 20x20 - are there any issues to watch out for by clamping two or three pieces of 20x20 together to make the other sizes?

Danny

Edited 1 time(s). Last edit at 01/01/2016 03:39PM by critter42.

I did have two questions:

1) If I wanted to increase the build plate size, is there any issue with the cantilevered bed if I widen the Z axis rails? Also, what are your thoughts on adding a crossbeam between the two cantilever arms if I do so? I want a 250^3 or even 300^3 build volume.

2) I have access to a laser cutter and would rather laser cut the cover plates than print them - Are those in the 123d file?

3) I don't have any 20x40 or 20x60 - but I have shedloads of 20x20 - are there any issues to watch out for by clamping two or three pieces of 20x20 together to make the other sizes?

Danny

Edited 1 time(s). Last edit at 01/01/2016 03:39PM by critter42.

|

Re: G&C Printer January 01, 2016 05:05PM |

Registered: 8 years ago Posts: 346 |

Quote

critter42

Hi! I've been doing some looking around and I plan to make this my next build. I'll probably get started sooner, but it may take a month or more before I really get ramped up on this.

I did have two questions:

1) If I wanted to increase the build plate size, is there any issue with the cantilevered bed if I widen the Z axis rails? Also, what are your thoughts on adding a crossbeam between the two cantilever arms if I do so? I want a 250^3 or even 300^3 build volume.

2) I have access to a laser cutter and would rather laser cut the cover plates than print them - Are those in the 123d file?

3) I don't have any 20x40 or 20x60 - but I have shedloads of 20x20 - are there any issues to watch out for by clamping two or three pieces of 20x20 together to make the other sizes?

Danny

1) cantilevered bed can be an problem with big size beds, i think it will work fine on bed up to 30cm x 30cm. For bigger sizes you can simply use bigger rodds (14mm or 16mm) or an second Z screw.

I using an 3mm aluminium plate secured on both arms and do the same job of the crossbeam. For bigger beg the crossbeam is an good solution.Quote

critter42

what are your thoughts on adding a crossbeam between the two cantilever arms if I do so?

2) the cover plates are in the 123d file. laser cuted plates are far better than printed ones, i have printed my plates because i do not have access to an laser cutter. You can joins all the plates and obtain the plates to cut with the laser from the 123d project.

3) i do not think it will work for the 20x60 used for the bed. For the 20x40, it was used to secure the 4 printed plates, in your case you will have only one big plate, so you can simply replace with an 20x20 or not use at all.

The build volume is 250^3 to 300^3, but this not say the size x and y of the bed.. What will be the size of the bed?

|

Re: G&C Printer January 02, 2016 03:16AM |

Registered: 8 years ago Posts: 11 |

I've got access to 12"x12" (300x300mm) heated bed assembly that I'd like to use, so that's really what I have in mind. Z-height isn't as critical. My current plans are to finish a couple of upgrades on the i3 I currently have (hopefully by the end of next week), then start printing the printed parts, getting a few of the fastening pieces I need and start assembling the frame. After that, it's just a matter if I can order my new hotend before the middle of February (E3D V6).

|

Re: G&C Printer January 03, 2016 02:56PM |

Registered: 9 years ago Posts: 104 |

|

Re: G&C Printer January 03, 2016 03:45PM |

Registered: 8 years ago Posts: 346 |

|

Re: G&C Printer January 04, 2016 11:09AM |

Registered: 9 years ago Posts: 104 |

could i use this [www.3dprintingstore.co.za] instead of the SCV12UU as they are not available in my country

|

Re: G&C Printer January 04, 2016 12:49PM |

Registered: 8 years ago Posts: 346 |

Quote

eviltoy

could i use this [www.3dprintingstore.co.za] instead of the SCV12UU as they are not available in my country

No, you can not secure correctly the sc12uu bearings to the 20x60 aluminium bar.

The sc12uu and scv12uu are almost the same, but the sc12uu use 4 screws to be secured on the aluminum profile and the scv12uu only 2 screws.

On the original design, the 4 linear bearings will be secured on the 20x60 aluminium bar and not allow to secure 4 x sc12uu.

The sc12luu will not work too, the 20x60 profile was 40mm of spacing and the sc12luu is 50mm.

If it was me, i will use 2 x sc12luu instead of the 4 x scv12u and secure each sc12luu to the 20x60 using an new pla printed pieces. It will be necessary too to make some little modifications to the printed object that secure the Z screw.

someone have a better idea?

|

Re: G&C Printer January 11, 2016 12:10AM |

Registered: 8 years ago Posts: 11 |

Quote

filipeCampos

3) i do not think it will work for the 20x60 used for the bed. For the 20x40, it was used to secure the 4 printed plates, in your case you will have only one big plate, so you can simply replace with an 20x20 or not use at all.

OK, I see what you're saying about the 2060 now that I've looked at it closer. Now it's just a matter if I can get my parts orders started and on their way across the pond before the Chinese New Year shutdown...

Edited 1 time(s). Last edit at 01/11/2016 12:10AM by critter42.

|

Re: G&C Printer January 20, 2016 06:49AM |

Registered: 9 years ago Posts: 104 |

|

Re: G&C Printer January 20, 2016 07:24AM |

Registered: 8 years ago Posts: 346 |

I do not know for sure, but i think is not an good choise.

The cube was 20x20mm, you can add 20mm more to the 4 horizontal 2020 bars and use other type of metallic connector, like this one:

[www.ebay.com]

or better, an bracket to put on the top:

[www.ebay.com]

You have lots of possible option, avoid at the maximum to use printed parts on the main structure.

Edited 3 time(s). Last edit at 01/20/2016 07:55AM by filipeCampos.

The cube was 20x20mm, you can add 20mm more to the 4 horizontal 2020 bars and use other type of metallic connector, like this one:

[www.ebay.com]

or better, an bracket to put on the top:

[www.ebay.com]

You have lots of possible option, avoid at the maximum to use printed parts on the main structure.

Edited 3 time(s). Last edit at 01/20/2016 07:55AM by filipeCampos.

|

Re: G&C Printer January 20, 2016 12:32PM |

Registered: 9 years ago Posts: 104 |

|

Re: G&C Printer January 20, 2016 12:48PM |

Registered: 9 years ago Posts: 104 |

|

Re: G&C Printer January 20, 2016 12:48PM |

Registered: 8 years ago Posts: 346 |

extend the 4 verticle posts by 20mm to compensate the missing cubes. in the bom file there have 500mm, you need to buy with 520mm. You need 8 joints, before buying check if the dimensions are the correct one for your 2020 profile. The link i have put was only an example and i do not have confirmed if the dimension are ok.

If you have already buy the 4 x 2020 posts, you can still use is... but the printer will have less 2cm of print volume in the Z axis

Edited 2 time(s). Last edit at 01/20/2016 12:52PM by filipeCampos.

If you have already buy the 4 x 2020 posts, you can still use is... but the printer will have less 2cm of print volume in the Z axis

Edited 2 time(s). Last edit at 01/20/2016 12:52PM by filipeCampos.

|

Re: G&C Printer February 03, 2016 04:22AM |

Registered: 8 years ago Posts: 11 |

Finally starting to order the parts (missed the CNY window, so the actual build won't start until the end of March now :p ), had a couple of more questions.

1) If I'm going to use the 30cmx30cm heated bed, what do I need to change the various frame lengths to? Or better asked, which rails/extrusions need to be adjusted and by how much? I'm having a little trouble with the calculations.

2) the BOM on the Thingiverse thing has the parts list for the bowden format, rather than the direct drive, correct?

That's it for now, I'm sure they'll be more the rest of the week, but thanks for the help you've provided so far, and in the future!

1) If I'm going to use the 30cmx30cm heated bed, what do I need to change the various frame lengths to? Or better asked, which rails/extrusions need to be adjusted and by how much? I'm having a little trouble with the calculations.

2) the BOM on the Thingiverse thing has the parts list for the bowden format, rather than the direct drive, correct?

That's it for now, I'm sure they'll be more the rest of the week, but thanks for the help you've provided so far, and in the future!

|

Re: G&C Printer February 03, 2016 04:56AM |

Registered: 8 years ago Posts: 346 |

1) First i need to say i not 100% sure what are all the necessary changes to put an 30x30 bed, but i will try to not forget anything.

-The obvious changes: buy all lateral 20x20 extrusion with more 10cm, The 20x60 extrusion add too more 10cm and more 10 to the 2 20x20 bed arms

- instead of two 12mm rods use 14mm rods and buy the receptive 14mm linear bearings for this rods. I not sure if the 12mm rods will give problems, so.. i think is better to upgrade to the 14mm. It will be necessary to check if the dimension are the same, in case not is necessary to redesign the printed pieces that secure the Z thread rod. If you have difficulty with this task i can help you and make the changes.

-Add 10cm for the 4 x 8mm rods. If you planning to go with dual direct extruder i think it will be better to use 10mm rods. If you planning only one direct or bowden extruder, then the 8mm will be fine.

-There are some hardware in the boom file that are only valid for the 20x20 bed, you need to get something else to replace this ones. like the aluminium plate that secure the heated bed.

2) no, the hardware for the bowden and printed direct mk8 are the same. The bom file only do not have for the dual direct extruder.

Edited 2 time(s). Last edit at 02/03/2016 05:46AM by filipeCampos.

-The obvious changes: buy all lateral 20x20 extrusion with more 10cm, The 20x60 extrusion add too more 10cm and more 10 to the 2 20x20 bed arms

- instead of two 12mm rods use 14mm rods and buy the receptive 14mm linear bearings for this rods. I not sure if the 12mm rods will give problems, so.. i think is better to upgrade to the 14mm. It will be necessary to check if the dimension are the same, in case not is necessary to redesign the printed pieces that secure the Z thread rod. If you have difficulty with this task i can help you and make the changes.

-Add 10cm for the 4 x 8mm rods. If you planning to go with dual direct extruder i think it will be better to use 10mm rods. If you planning only one direct or bowden extruder, then the 8mm will be fine.

-There are some hardware in the boom file that are only valid for the 20x20 bed, you need to get something else to replace this ones. like the aluminium plate that secure the heated bed.

2) no, the hardware for the bowden and printed direct mk8 are the same. The bom file only do not have for the dual direct extruder.

Edited 2 time(s). Last edit at 02/03/2016 05:46AM by filipeCampos.

|

Re: G&C Printer February 29, 2016 11:14AM |

Registered: 8 years ago Posts: 346 |

Hi,

Some updates on the printer...

I have build an printed CNC, the CNC is called Mostly Printed CNC. where is the link: [www.thingiverse.com]

There are two version: the original and the internacial. I have build the internacional.

The cnc is finished and allows me to add some new upgrades to the G&C printer.

the CNC:

First upgrade i working on is some nice acrylic panels. I designing panels to cover all side of the printer, so far i have cut and installed the top and left panels.

some photos:

next, i will cut and install the back, front, right and center panels.

And was future upgrades i will start to replace some printed pieces with aluminium.

Some updates on the printer...

I have build an printed CNC, the CNC is called Mostly Printed CNC. where is the link: [www.thingiverse.com]

There are two version: the original and the internacial. I have build the internacional.

The cnc is finished and allows me to add some new upgrades to the G&C printer.

the CNC:

First upgrade i working on is some nice acrylic panels. I designing panels to cover all side of the printer, so far i have cut and installed the top and left panels.

some photos:

next, i will cut and install the back, front, right and center panels.

And was future upgrades i will start to replace some printed pieces with aluminium.

Sorry, only registered users may post in this forum.