G&C Printer

Posted by filipeCampos

|

Re: G&C Printer February 29, 2016 11:37AM |

Registered: 9 years ago Posts: 893 |

That looks good, Filipe.

I thought about building one of those CNC machines, but I just don't have anywhere to put it.

I can also add a late update: when I first built my G&C printer I decided that it was too much trouble to print the 4 panels that cover the base (my Prusa couldn't manage the full 200x200mm) so I made one out of acrylic sheet. After a while I decided that the acrylic sheet was too cumbersome, making it difficult to make minor changes to the stuff underneath. In the end I sorted out my Prusa so that it could use the whole bed and printed the panels - I used the Prusa because I wanted to use up some 3mm black PLA before converting that machine to 1.75mm. The preliminary printed loops that were laid down before the actual part was started actually printed at the very edge of the heated bed, and over the glass clips!

It's now much easier to get into the lower area...

I thought about building one of those CNC machines, but I just don't have anywhere to put it.

I can also add a late update: when I first built my G&C printer I decided that it was too much trouble to print the 4 panels that cover the base (my Prusa couldn't manage the full 200x200mm) so I made one out of acrylic sheet. After a while I decided that the acrylic sheet was too cumbersome, making it difficult to make minor changes to the stuff underneath. In the end I sorted out my Prusa so that it could use the whole bed and printed the panels - I used the Prusa because I wanted to use up some 3mm black PLA before converting that machine to 1.75mm. The preliminary printed loops that were laid down before the actual part was started actually printed at the very edge of the heated bed, and over the glass clips!

It's now much easier to get into the lower area...

|

Re: G&C Printer February 29, 2016 04:41PM |

Registered: 8 years ago Posts: 346 |

The cnc is pretty messy, is definitely not something you want in the house...

I have used to cnc only to cut some 2 e 3 mm acrylic, wood and mdf, and it works great. In the future i will try with aluminium, but i still not sure if the machine was enough power for the job...

About the center panel you are correct, one big 40cm x 40cm in not easy to remove in case you need to access to board.

In my case i do not see this to be an problem, after i configured everything like i want i never have the need to get access to the board.

I have used to cnc only to cut some 2 e 3 mm acrylic, wood and mdf, and it works great. In the future i will try with aluminium, but i still not sure if the machine was enough power for the job...

About the center panel you are correct, one big 40cm x 40cm in not easy to remove in case you need to access to board.

In my case i do not see this to be an problem, after i configured everything like i want i never have the need to get access to the board.

|

Re: G&C Printer February 29, 2016 04:49PM |

Registered: 9 years ago Posts: 893 |

The main reason I have for getting into that area is to get at the Duet's SD card - I don't have to do it very often, but sometimes there's no alternative. It was very difficult previously, but now I just loosen 3 screws and I'm in.

I'm also having problems with a noisy cooling fan in there, so I'll need to open up and get that replaced soon.

I'm also having problems with a noisy cooling fan in there, so I'll need to open up and get that replaced soon.

|

Re: G&C Printer March 05, 2016 05:04PM |

Registered: 8 years ago Posts: 346 |

Finished to cut and install all acrylic panels, made a little video to show the final result.

[youtube.com]

Edited 1 time(s). Last edit at 03/05/2016 05:13PM by filipeCampos.

[youtube.com]

Edited 1 time(s). Last edit at 03/05/2016 05:13PM by filipeCampos.

|

Re: G&C Printer March 06, 2016 04:35AM |

Registered: 9 years ago Posts: 893 |

|

Re: G&C Printer March 06, 2016 04:35PM |

Registered: 8 years ago Posts: 24 |

|

Re: G&C Printer March 08, 2016 11:25AM |

Registered: 9 years ago Posts: 29 |

I really like this design, so much that I am going to make my own copy of the G&C printer

All parts are ordered and my Prusa is already working overtime the print all the plastic pieces. I expect the first shipment to arrive tomorrow, but most of the stuff is ordered in China and this will take much longer to arrive.

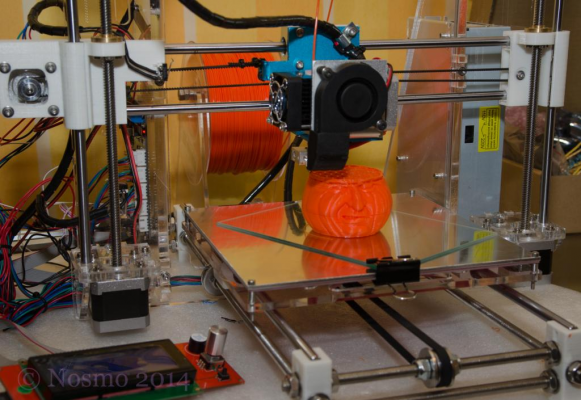

This is what I've got so far...

I will follow Filipe's design as much as possible but I will make modifications where necessary.

The specs will be;

- Original size according to Filipe's design

- Enclosed at 5 sides, the top will stay open

- MKS SBase 32bit contoller (Smoothieboard ripoff!)

- 3.2" color touchscreen

- Single Bowden hotend, maybe a second one in the future

- 200 x 200mm Mk3 heated bed, with a glass build surface

- IGUS bearings for the X and Y axis.

Edited 1 time(s). Last edit at 03/08/2016 11:28AM by Nosmo.

All parts are ordered and my Prusa is already working overtime the print all the plastic pieces. I expect the first shipment to arrive tomorrow, but most of the stuff is ordered in China and this will take much longer to arrive.

This is what I've got so far...

I will follow Filipe's design as much as possible but I will make modifications where necessary.

The specs will be;

- Original size according to Filipe's design

- Enclosed at 5 sides, the top will stay open

- MKS SBase 32bit contoller (Smoothieboard ripoff!)

- 3.2" color touchscreen

- Single Bowden hotend, maybe a second one in the future

- 200 x 200mm Mk3 heated bed, with a glass build surface

- IGUS bearings for the X and Y axis.

Edited 1 time(s). Last edit at 03/08/2016 11:28AM by Nosmo.

|

Re: G&C Printer March 08, 2016 02:48PM |

Registered: 8 years ago Posts: 346 |

I will fallow your build and hope you do not fallow too much my design and come with some new ideas i can use too

About the enclosure, i have used 7 panels. I have one panel at the bottom of the printer to protected the electronics and is not visible in the photos or video. I have uploaded all panels on the page on the printer (thingiverse), but i pretty sure you can not directly use the design of these panels because of the M4 holes. You need to change the positions of this M4 holes to adapt to your printer and change the cut of the radds lcd to the 3.2''.

My first extruder setup was an mk8 bowden. I never solved complety to retractions problems, i hope you have better Luke.

Igus bearings are great but all made of plastic.. you need to be careful and not screw too much the printed pieces.

By the way, what prusa is one the photo? can you upload a complete photo of the printer?

About the enclosure, i have used 7 panels. I have one panel at the bottom of the printer to protected the electronics and is not visible in the photos or video. I have uploaded all panels on the page on the printer (thingiverse), but i pretty sure you can not directly use the design of these panels because of the M4 holes. You need to change the positions of this M4 holes to adapt to your printer and change the cut of the radds lcd to the 3.2''.

My first extruder setup was an mk8 bowden. I never solved complety to retractions problems, i hope you have better Luke.

Igus bearings are great but all made of plastic.. you need to be careful and not screw too much the printed pieces.

By the way, what prusa is one the photo? can you upload a complete photo of the printer?

|

Re: G&C Printer March 08, 2016 03:23PM |

Registered: 9 years ago Posts: 29 |

My Prusa started it's life as a cheap plastic Chinese i3 kit. Since then almost everything is modified and upgraded the only original parts are the electronics and the stepper motors.

The frame is a Prusa steel frame from Spain, the aluminium X axis is a Chinese kit from AliExpress and is totally modified to make it fit.

I will take some pictures tomorrow during daylight.

The frame is a Prusa steel frame from Spain, the aluminium X axis is a Chinese kit from AliExpress and is totally modified to make it fit.

I will take some pictures tomorrow during daylight.

|

Re: G&C Printer March 09, 2016 07:41AM |

Registered: 9 years ago Posts: 29 |

Quote

filipeCampos

By the way, what prusa is one the photo? can you upload a complete photo of the printer?

The piece of cardboard at the back is an experiment to reduce draft from the power supply fan. I used to have lifting issues at only the right side of the print bed, the back was always worse than the front. After this cardboard deflector the lifting issues have disappeared.

My plan was to make some kind of enclosure for this printer to eliminate all draft issues and to change the extruder for a bowden setup, but that is not going to happen anytime soon now that I'm going to build a coreXY.

This is the printer when everything was still original;

Anyway, lets not pollute your topic with Prusa pics.

Edited 1 time(s). Last edit at 03/09/2016 07:48AM by Nosmo.

|

Re: G&C Printer March 09, 2016 08:01AM |

Registered: 8 years ago Posts: 346 |

My first printer was an prusa steel, buyed the kit online from spain (createc3d).

The printer was nice overall, but the print quality far to be the best and very noisy. Builded the next enclosure:[www.thingiverse.com]

The enclosure helped to reduse the noise, but was very big and almost impossible to move.

The printer was nice overall, but the print quality far to be the best and very noisy. Builded the next enclosure:[www.thingiverse.com]

The enclosure helped to reduse the noise, but was very big and almost impossible to move.

|

Re: G&C Printer March 10, 2016 03:32PM |

Registered: 9 years ago Posts: 29 |

Filipe, just a quick question;

In the BOM is a 608zz bearing listed. I can't find any place in the 123dx file where to put this bearing.

Am I right to assume that this bearing is a support for the Z-spindle, but that the bracket is missing from the 123dx file?

Edited 1 time(s). Last edit at 03/10/2016 03:34PM by Nosmo.

In the BOM is a 608zz bearing listed. I can't find any place in the 123dx file where to put this bearing.

Am I right to assume that this bearing is a support for the Z-spindle, but that the bracket is missing from the 123dx file?

Edited 1 time(s). Last edit at 03/10/2016 03:34PM by Nosmo.

|

Re: G&C Printer March 10, 2016 03:48PM |

Registered: 8 years ago Posts: 346 |

Yes, it was for the z spindle. In the first version the z motor was on the top, them i moved to the bottom. I actually using this spindle on my printer only because i already have printed before and helps a little to center the z screw, but is not something is necessary.

At this point i can update the bom file and remove the bearing or upload a new version of the project with the spindle. What option you prefer?

At this point i can update the bom file and remove the bearing or upload a new version of the project with the spindle. What option you prefer?

|

Re: G&C Printer March 10, 2016 05:43PM |

Registered: 9 years ago Posts: 29 |

|

Re: G&C Printer March 11, 2016 04:54AM |

Registered: 8 years ago Posts: 346 |

not having it installed will not affect the print quality, but it help the z thread rod to rotate a little more perfectly when the bed is on the bottom of the printer and reduce the vibrations when the bed move fast.

I have installed on my printer because to me is better to have it, i think David is not using this spindle on is printer.

I have added again the spindle to the 123dx project and moved the back 2020 bar more to the top to support it.

I have installed on my printer because to me is better to have it, i think David is not using this spindle on is printer.

I have added again the spindle to the 123dx project and moved the back 2020 bar more to the top to support it.

|

Re: G&C Printer March 11, 2016 05:05AM |

Registered: 9 years ago Posts: 893 |

|

Re: G&C Printer March 12, 2016 05:38PM |

Registered: 9 years ago Posts: 29 |

Making some slow progress, all plastic parts are printed and ready for assembly but most other parts are on the slow boat from China so I'm kind of dead in the water here.

Anyway, I managed to do some assembly;

More jigsaw pieces;

And the steppermotors from reprapworld have arrived (4 in total).

Anyway, I managed to do some assembly;

More jigsaw pieces;

And the steppermotors from reprapworld have arrived (4 in total).

|

Re: G&C Printer March 17, 2016 04:10PM |

Registered: 9 years ago Posts: 29 |

A small package from motedis.com arrived today;

A few hours later;

A few hours later;

|

Re: G&C Printer March 17, 2016 06:36PM |

Registered: 8 years ago Posts: 346 |

|

Re: G&C Printer March 18, 2016 12:06PM |

Registered: 9 years ago Posts: 893 |

|

Re: G&C Printer March 18, 2016 01:56PM |

Registered: 9 years ago Posts: 29 |

No complaints so far, the shipment was 100% complete.

Also the cuts are very precise, just as Felipe already mentioned. My initial idea was to cut the profiles myself but I couldn't have done a better job myself.

Parts are starting to arrive, but not in any predictable or logical order so progress is still very slow.

Also the cuts are very precise, just as Felipe already mentioned. My initial idea was to cut the profiles myself but I couldn't have done a better job myself.

Parts are starting to arrive, but not in any predictable or logical order so progress is still very slow.

|

Re: G&C Printer March 18, 2016 07:29PM |

Registered: 9 years ago Posts: 29 |

|

Re: G&C Printer March 20, 2016 01:44PM |

Registered: 9 years ago Posts: 29 |

Change of plan!

I've build the X and Y axis but I'm not happy with the stability, there is too much flex in the Igus bearings. If I tighten the screws more the flex gets less but the bearings don't glide smoothly over the rods anymore. And even with all screws tight there is still too much flex. I suppose that Igus bearings need a metal housing to work properly and the printed plastic bearing housings need steel bearings to get rigid enough to do the job.

So for now I will replace the Y axis bearings for LM8UU's and leave the Igus bearings in the X axis carriage.

I've build the X and Y axis but I'm not happy with the stability, there is too much flex in the Igus bearings. If I tighten the screws more the flex gets less but the bearings don't glide smoothly over the rods anymore. And even with all screws tight there is still too much flex. I suppose that Igus bearings need a metal housing to work properly and the printed plastic bearing housings need steel bearings to get rigid enough to do the job.

So for now I will replace the Y axis bearings for LM8UU's and leave the Igus bearings in the X axis carriage.

|

Re: G&C Printer March 21, 2016 04:32AM |

Registered: 9 years ago Posts: 893 |

|

Re: G&C Printer March 21, 2016 05:53AM |

Registered: 8 years ago Posts: 346 |

Hi,

The igus bearing are not easy to install because the casing is all plastic, in my printer i managed to install on both X and Y axis. On the Y axis i have zero play and in the carriage there is less of 1mm of play but is necessary to apply an good amount of force. I pretty sure there are not good for a CNC or something like this, but for 3d printing they do the job fine.

The main problem on installing these igus is to find the correct force apply on the screws, too much and the bearing will not move, less and you get flex. I have uploaded a video where i show the movements of both axis of my printer.

From the video you can see the movement on both axis is not smooth at all, but enough fluid to the motor move the carriage correctly. The height of the carriage is enough to move on the Y axis in case i lean the printer, but not in the X axis.

I think your problem is trying to get the same fluid movement you have with LM8UU, you need to tighten more the screws. The important is to the motor have enought power to move the carriage without losing steeps. My steppers are configured with [0.8, 0.9] volts.

The bronze bearings David suggest appears to be an excellent idea, for what i read there are silent and rigid. If someone try this solution, please tell the result. If there are good i think is the best to replace the info of the igus with this bronze one.

[www.youtube.com]

The igus bearing are not easy to install because the casing is all plastic, in my printer i managed to install on both X and Y axis. On the Y axis i have zero play and in the carriage there is less of 1mm of play but is necessary to apply an good amount of force. I pretty sure there are not good for a CNC or something like this, but for 3d printing they do the job fine.

The main problem on installing these igus is to find the correct force apply on the screws, too much and the bearing will not move, less and you get flex. I have uploaded a video where i show the movements of both axis of my printer.

From the video you can see the movement on both axis is not smooth at all, but enough fluid to the motor move the carriage correctly. The height of the carriage is enough to move on the Y axis in case i lean the printer, but not in the X axis.

I think your problem is trying to get the same fluid movement you have with LM8UU, you need to tighten more the screws. The important is to the motor have enought power to move the carriage without losing steeps. My steppers are configured with [0.8, 0.9] volts.

The bronze bearings David suggest appears to be an excellent idea, for what i read there are silent and rigid. If someone try this solution, please tell the result. If there are good i think is the best to replace the info of the igus with this bronze one.

[www.youtube.com]

|

Re: G&C Printer March 21, 2016 06:20AM |

Registered: 9 years ago Posts: 893 |

|

Re: G&C Printer March 26, 2016 07:13AM |

Registered: 8 years ago Posts: 9 |

My build is now pretty much complete and I'm in the midst of the painful process of calibration and configuration. My hardware list looks pretty much the same as yours @Nosmo - we're both using the MKS SBASE Smoothieware board I think. Could you please share your config with me?

Edited 2 time(s). Last edit at 03/26/2016 07:15AM by simon_smithson.

Edited 2 time(s). Last edit at 03/26/2016 07:15AM by simon_smithson.

|

Re: G&C Printer March 26, 2016 09:57AM |

Registered: 9 years ago Posts: 29 |

|

Re: G&C Printer March 26, 2016 11:06AM |

Registered: 8 years ago Posts: 9 |

In which case, If I do ever manage to get it printing well I'll share my config with you!

Biggest issue I'm currently having is with the extruder. I'm currently using a single direct drive. It seems to go wildly from under to over extruding. Not entirely convinced that having the print spool at the bottom of the machine and a length of PTFE tubing is the best approach for me, so I might shift the filament holder to the top of the machine.

Biggest issue I'm currently having is with the extruder. I'm currently using a single direct drive. It seems to go wildly from under to over extruding. Not entirely convinced that having the print spool at the bottom of the machine and a length of PTFE tubing is the best approach for me, so I might shift the filament holder to the top of the machine.

|

Re: G&C Printer March 26, 2016 12:00PM |

Registered: 8 years ago Posts: 11 |

Sorry, only registered users may post in this forum.