CoreXY for bed instead of extruder(s), for small printer?

Posted by cristian

|

Re: CoreXY for bed instead of extruder(s), for small printer? October 13, 2015 07:40AM |

Registered: 9 years ago Posts: 344 |

Quote

dc42

I have no experience of CoreXY designs, but I am guessing that stretch in the long belts may be a limiting factor. If it isn't, or it can be overcome, then I think you should be able to achieve better than 50um resolution (but not accuracy) in the XY plane. You may need to use 0.9deg/step motors to get higher incremental torque, and small enough pulleys to get a high steps/mm factor.

Belts stretch is one of my main concerns indeed. My suspect is that in most of printers the precision of the positioning system is in general much worse than its typical resolution. This is what I see in my printer at least, where I have a micro-step resolution on the horizontal plane of about 13µ (if I remember correctly), while I can say by eye that the overall precision can't be better than something like 300µ (and I am not talking about the worst case...). Somehow such a high resolution is wasted: I could probably disable micro-steps and get equivalent results, besides a fancier surface look caused by small ridges on the external perimeters.

A more stable structure in my case would definitely help. But still it would be interesting to know what are the real limits of belts, given a reliable printer structure. I started making some measurement to be able to calculate at least an order of magnitude for that (excluding backlash given by teeth, if present), we'll see if I get somewhere.

|

Re: CoreXY for bed instead of extruder(s), for small printer? October 13, 2015 09:53AM |

Registered: 9 years ago Posts: 722 |

Hi,

A DLP printer (resin printer with video projector instead of SLA -laser)

can be achieved at reasonable price, because there's only one axis, one guide.

You just need to find one way to project any UV image.

There's a lot of inexpensive examples on the DIY community.

Definitely, for jewelry or precision figurines, you want a resin printer.

The values are estimated.

Some calculators are less optimist than me : [nathan7.eu]

Fluctuations are mostly stable, you can feel them by the touch but you can't eyeball it.

But it exists. IMHO, to have some very precise mecanics won't help over 100µ.

You won't notice any improvement because of the filament thing.

Some people believes in a heavy structures and precise guides for 3D printing.

For example the_digital_dentist's son of megamax..

His machine is very good and pretty interesting too.

Otherhand, some light machine can achieve close results with less precise/expensive components.

Please note, the son of megamax printer don't reach 50µ precision,

even if that eperienced repraper has come as far as possible with components/expenses.

++JM

A DLP printer (resin printer with video projector instead of SLA -laser)

can be achieved at reasonable price, because there's only one axis, one guide.

You just need to find one way to project any UV image.

There's a lot of inexpensive examples on the DIY community.

Definitely, for jewelry or precision figurines, you want a resin printer.

The values are estimated.

Some calculators are less optimist than me : [nathan7.eu]

Fluctuations are mostly stable, you can feel them by the touch but you can't eyeball it.

But it exists. IMHO, to have some very precise mecanics won't help over 100µ.

You won't notice any improvement because of the filament thing.

Some people believes in a heavy structures and precise guides for 3D printing.

For example the_digital_dentist's son of megamax..

His machine is very good and pretty interesting too.

Otherhand, some light machine can achieve close results with less precise/expensive components.

Please note, the son of megamax printer don't reach 50µ precision,

even if that eperienced repraper has come as far as possible with components/expenses.

++JM

|

Re: CoreXY for bed instead of extruder(s), for small printer? October 13, 2015 05:25PM |

Registered: 9 years ago Posts: 344 |

Quote

J-Max

A DLP printer (resin printer with video projector instead of SLA -laser)

can be achieved at reasonable price, because there's only one axis, one guide.

You just need to find one way to project any UV image.

There's a lot of inexpensive examples on the DIY community.

Definitely, for jewelry or precision figurines, you want a resin printer.

I think you are right. Thanks for the link, I didn't know SLA printers were so cheap to build (although resin is not so cheap). The problem is that nowadays there are very nice plastic filaments for FDM (wood, metal, all kinds of flexible filaments, etc.) but not so much for SLA (and many resins are quite expensive). Moreover, I have been told that some of them are very sensitive to light even after curing: the surface becomes quite ugly over time. Finally, I don't know how brittle resin objects are.

There is no mention of precision in that page. If you refer to the extrusion diameter or the smallest printable feature, this is definitely not a measure of precision (in itself).

Quote

J-Max

Fluctuations are mostly stable, you can feel them by the touch but you can't eyeball it.

But it exists. IMHO, to have some very precise mecanics won't help over 100µ.

You won't notice any improvement because of the filament thing.

Probably you are right, although 100µ would be way better than the precision of my current printer.

Quote

J-Max

Some people believes in a heavy structures and precise guides for 3D printing.

For example the_digital_dentist's son of megamax..

His machine is very good and pretty interesting too.

Otherhand, some light machine can achieve close results with less precise/expensive components.

Please note, the son of megamax printer don't reach 50µ precision,

even if that eperienced repraper has come as far as possible with components/expenses.

the_digital_dentist has influenced a lot my understanding of 3d printing.

His machine is quite big, I would not expect it to reach 50µ precision. On the other hand, a very small machine built with the same philosophy may have better chances.

|

Re: CoreXY for bed instead of extruder(s), for small printer? October 15, 2015 06:24AM |

Registered: 10 years ago Posts: 179 |

Cristian,

Have you considered a material to make a bed platform of? I tried to google hoping to find plenty of information on people using all kind of different materials on cartesian printers to lighten Y axis but came with nothing.

Aluminium-foam sandwich (dibond) came to my mind as it is light and stiff.

Have you considered a material to make a bed platform of? I tried to google hoping to find plenty of information on people using all kind of different materials on cartesian printers to lighten Y axis but came with nothing.

Aluminium-foam sandwich (dibond) came to my mind as it is light and stiff.

|

Re: CoreXY for bed instead of extruder(s), for small printer? October 15, 2015 07:47AM |

Registered: 9 years ago Posts: 722 |

|

Re: CoreXY for bed instead of extruder(s), for small printer? October 15, 2015 01:14PM |

Registered: 9 years ago Posts: 344 |

Quote

Edvardas

Have you considered a material to make a bed platform of? I tried to google hoping to find plenty of information on people using all kind of different materials on cartesian printers to lighten Y axis but came with nothing.

Aluminium-foam sandwich (dibond) came to my mind as it is light and stiff.

For a first prototype, I was thinking to stick to a classical cold glass bed. More ideas are welcome...

Quote

J-Max

The printing bed don't need to be light on a CoreXY printer.

better have a look at the subject of the thread then

|

Re: CoreXY for bed instead of extruder(s), for small printer? October 16, 2015 05:37PM |

Registered: 9 years ago Posts: 722 |

Hi,

Yep, I remember.

On a small printer, it realy does not matter.

I still don't think it's a good idea.

One of the more interesting thing about the CoreXY

is the still bed which moves only on the Z axis.

You want to move the lightest thing, because it's easyer and it can be fast.

Otherhand, moving beds always need some space to move.

If you want it small, you want the bed to move only on the Z axis.

Why not a XYbed ? It shoulld work anyways.

++JM

Yep, I remember.

On a small printer, it realy does not matter.

I still don't think it's a good idea.

One of the more interesting thing about the CoreXY

is the still bed which moves only on the Z axis.

You want to move the lightest thing, because it's easyer and it can be fast.

Otherhand, moving beds always need some space to move.

If you want it small, you want the bed to move only on the Z axis.

Why not a XYbed ? It shoulld work anyways.

++JM

|

Re: CoreXY for bed instead of extruder(s), for small printer? October 16, 2015 06:11PM |

Registered: 9 years ago Posts: 344 |

|

Re: CoreXY for bed instead of extruder(s), for small printer? November 06, 2015 11:46AM |

Registered: 11 years ago Posts: 5,780 |

I think that some of you guys are confusing precision, minimum feature size, minimum step size, resolution, and accuracy.

My printer has a 400 um nozzle, which limits the minimum feature size that is printable. That is easily modified by changing the extruder nozzle.

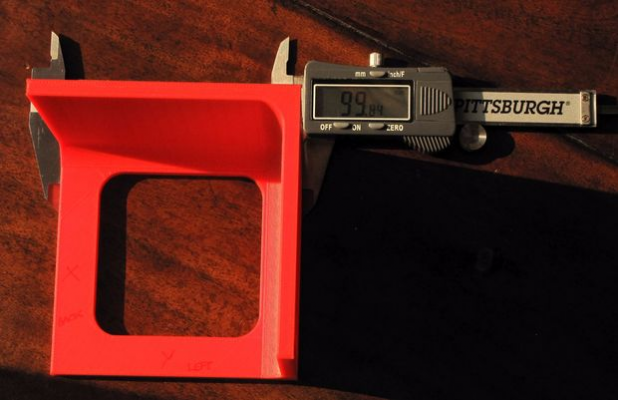

Accuracy is a measure of how close the print is to the design size. If you tell the printer to draw a 4mm long line, does it come out 4mm long? In the picture of the calibration cube from my machine a few posts up, the designed size was 100 mm and the printed size was 99.89 mm. That was printed before final calibration (that's what printing the cube is for).

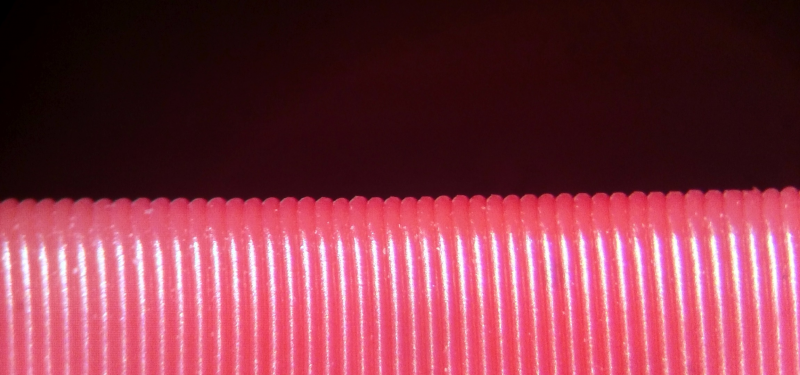

Precision is the ability to hit the same coordinates over and over (such as the corners of a cube) and has nothing to do with the accuracy or minimum step size of the printer. The effect of imprecision in the X and Y axes is for layers to be slightly misaligned which is ultimately a surface quality issue unless the machine is grossly imprecise. The effect of Z axis imprecision is variations in layer height that can likewise show up as a surface quality problem. Thinner layers will be squished wider and thicker layers will be narrower. Here is a photo of the edge of one corner of that same calibration cube (they all look like this one) which was printed in 250 um layers:

This picture was taken with my cell phone camera coupled to a microscope. The camera has some pincushion distortion that makes the center portion of the print appear to sag, but that is strictly an optical effect that does not exist in the actual print. If the precision were poor you would see the layers not stacking up so nearly perfectly, looking like a miniature version of Z axis wobble that we've all seen so many pictures of thanks to common use of bent threaded rods and flexible guide rails and printer frames. I don't have a measurement of the precision exhibited by the positioners in my machine, but you can see from the picture that the deviation from a straight line drawn along the bumps at each layer is a tiny fraction of the layer height. I believe that my printer's precision is limited not by the mechanism but by minor variations in filament diameter that cause slight over and underextrusion that is indistinguishable from mechanical positioning error.

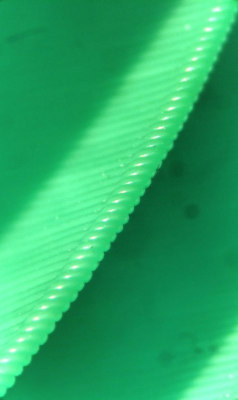

Here is a photo of the edge of the flutes on a vase (https://www.youmagine.com/designs/spiral-vase--2), a design which is a real printer precision torture test:

Minimum step size is what printer makers usually quote as "resolution" and is a function of the drive electronics and things like pulley diameters and screw pitches/leads. Resolution is actually the minimum distinguishable movement on the nozzle as seen in the print, and is limited by but not necessarily equal to minimum step size. If the minimum step size is 20 um in the X axis, can you see the difference in the print when plastic is put down on one layer at X=122.320 mm and the next layer is at X=122.340? Resolution could also be interpreted on a single layer- can you measure a difference between the lengths of a line that is supposed to be 100.000 mm long and one that is supposed to be 100.020 mm long?

The resolution can't be better than the minimum step size, but it isn't necessarily equal to the minimum step size either. Since we're talking about numbers in the 10s of microns range, everything has an effect including the basic precision and accuracy. If the machine can't put the nozzle at the target coordinate reliably, the resolution will be poorer than the minimum step size would indicate. Most printers with flexible frames, sloppy bearings, flexible guide rails probably have resolution that is much worse than their minimum step sizes. As rigid as my printer is, and as precise as its bearings are, I am pretty sure that my printer's resolution is likewise limited by the machine's overall precision which is in turn limited by the precision in the diameter of the filament. I have not tried to measure the resolution in my printer, but in case anyone is wondering, the steps per mm in the X, Y, and Z axes are 321.45, 1286.43, and 529.92 which by inversion translates to 3.11 um, 0.777um, and 1.89 um per microstep. I feel safe in saying that the overall resolution is worse than those step sizes would indicate, but I don't know how to accurately and precisely measure such small values, so we'll never know for sure.

Edited 7 time(s). Last edit at 11/06/2015 09:15PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

My printer has a 400 um nozzle, which limits the minimum feature size that is printable. That is easily modified by changing the extruder nozzle.

Accuracy is a measure of how close the print is to the design size. If you tell the printer to draw a 4mm long line, does it come out 4mm long? In the picture of the calibration cube from my machine a few posts up, the designed size was 100 mm and the printed size was 99.89 mm. That was printed before final calibration (that's what printing the cube is for).

Precision is the ability to hit the same coordinates over and over (such as the corners of a cube) and has nothing to do with the accuracy or minimum step size of the printer. The effect of imprecision in the X and Y axes is for layers to be slightly misaligned which is ultimately a surface quality issue unless the machine is grossly imprecise. The effect of Z axis imprecision is variations in layer height that can likewise show up as a surface quality problem. Thinner layers will be squished wider and thicker layers will be narrower. Here is a photo of the edge of one corner of that same calibration cube (they all look like this one) which was printed in 250 um layers:

This picture was taken with my cell phone camera coupled to a microscope. The camera has some pincushion distortion that makes the center portion of the print appear to sag, but that is strictly an optical effect that does not exist in the actual print. If the precision were poor you would see the layers not stacking up so nearly perfectly, looking like a miniature version of Z axis wobble that we've all seen so many pictures of thanks to common use of bent threaded rods and flexible guide rails and printer frames. I don't have a measurement of the precision exhibited by the positioners in my machine, but you can see from the picture that the deviation from a straight line drawn along the bumps at each layer is a tiny fraction of the layer height. I believe that my printer's precision is limited not by the mechanism but by minor variations in filament diameter that cause slight over and underextrusion that is indistinguishable from mechanical positioning error.

Here is a photo of the edge of the flutes on a vase (https://www.youmagine.com/designs/spiral-vase--2), a design which is a real printer precision torture test:

Minimum step size is what printer makers usually quote as "resolution" and is a function of the drive electronics and things like pulley diameters and screw pitches/leads. Resolution is actually the minimum distinguishable movement on the nozzle as seen in the print, and is limited by but not necessarily equal to minimum step size. If the minimum step size is 20 um in the X axis, can you see the difference in the print when plastic is put down on one layer at X=122.320 mm and the next layer is at X=122.340? Resolution could also be interpreted on a single layer- can you measure a difference between the lengths of a line that is supposed to be 100.000 mm long and one that is supposed to be 100.020 mm long?

The resolution can't be better than the minimum step size, but it isn't necessarily equal to the minimum step size either. Since we're talking about numbers in the 10s of microns range, everything has an effect including the basic precision and accuracy. If the machine can't put the nozzle at the target coordinate reliably, the resolution will be poorer than the minimum step size would indicate. Most printers with flexible frames, sloppy bearings, flexible guide rails probably have resolution that is much worse than their minimum step sizes. As rigid as my printer is, and as precise as its bearings are, I am pretty sure that my printer's resolution is likewise limited by the machine's overall precision which is in turn limited by the precision in the diameter of the filament. I have not tried to measure the resolution in my printer, but in case anyone is wondering, the steps per mm in the X, Y, and Z axes are 321.45, 1286.43, and 529.92 which by inversion translates to 3.11 um, 0.777um, and 1.89 um per microstep. I feel safe in saying that the overall resolution is worse than those step sizes would indicate, but I don't know how to accurately and precisely measure such small values, so we'll never know for sure.

Edited 7 time(s). Last edit at 11/06/2015 09:15PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY for bed instead of extruder(s), for small printer? November 11, 2015 01:00PM |

Registered: 10 years ago Posts: 73 |

Quote

cristian

For a printer with a small printing area (for example 100x100mm) and more than one extruder, in your opinion would it make sense to have a coreXY to move the small bed and have the (direct) extruders lifted only vertically?

Not a CoreXY, but a Delta:

[www.diyouware.com]

|

Re: CoreXY for bed instead of extruder(s), for small printer? November 11, 2015 10:41PM |

Registered: 10 years ago Posts: 15 |

Main problem of moving bed instead of moving extruder is space efficiency. When you design a printer with moving bed, you need at least 4X bed surface area for bed movement.

Let say you designing a printer with print size 100X100X100 by moving bed. Then your printer size will be at least 250X250X250 (bed movement plus bearing, motor, etc.).

In same case, if you design it in moving extruder mode. Then your printer size can be controlled in 200X200X200.

If the printer be enlarged to a bigger size, the different will be enlarged dramatically.

Edited 1 time(s). Last edit at 11/11/2015 10:42PM by bunbun.

Let say you designing a printer with print size 100X100X100 by moving bed. Then your printer size will be at least 250X250X250 (bed movement plus bearing, motor, etc.).

In same case, if you design it in moving extruder mode. Then your printer size can be controlled in 200X200X200.

If the printer be enlarged to a bigger size, the different will be enlarged dramatically.

Edited 1 time(s). Last edit at 11/11/2015 10:42PM by bunbun.

|

Re: CoreXY for bed instead of extruder(s), for small printer? November 12, 2015 06:22AM |

Registered: 10 years ago Posts: 179 |

Quote

bunbun

Main problem of moving bed instead of moving extruder is space efficiency. When you design a printer with moving bed, you need at least 4X bed surface area for bed movement.

Let say you designing a printer with print size 100X100X100 by moving bed. Then your printer size will be at least 250X250X250 (bed movement plus bearing, motor, etc.).

In same case, if you design it in moving extruder mode. Then your printer size can be controlled in 200X200X200.

If the printer be enlarged to a bigger size, the different will be enlarged dramatically.

How is it a MAIN problem? Getting longer aluminium extrusion and higher quality linear guiding system is not a problem.

You can mount a bed above the belts and motors to save space.

And it is not like a printer has to fit in a limited space next to the other components. So there is zero problem in this.

And if one wants a large bed then moving it is not a good decision and that is not what this thread is about. Red the subject of the thread where small bed is mentioned.

Edited 1 time(s). Last edit at 11/12/2015 06:24AM by Edvardas.

|

Re: CoreXY for bed instead of extruder(s), for small printer? November 12, 2015 10:45PM |

Registered: 10 years ago Posts: 15 |

|

Re: CoreXY for bed instead of extruder(s), for small printer? November 15, 2015 07:43AM |

Registered: 9 years ago Posts: 344 |

Quote

the_digital_dentist

I think that some of you guys are confusing precision, minimum feature size, minimum step size, resolution, and accuracy.

Thanks for the clarification. My objective is then getting the best resolution for a small bed printer.

Quote

VincentM

Quote

cristian

For a printer with a small printing area (for example 100x100mm) and more than one extruder, in your opinion would it make sense to have a coreXY to move the small bed and have the (direct) extruders lifted only vertically?

Not a CoreXY, but a Delta:

[www.diyouware.com]

Interesting. Does this give better resolution than a coreXY?

Quote

bunbun

As your title CoreXY for bed instead of extruder, for SMALL PRINTER. For me, it is talking about designing a small printer that in moving bed. Not a moving small bed printer.

My fault, what I meant was "small bed printer". It is indeed true that if the bed is moving, the printer itself will be much bigger than the printing volume.

|

Re: CoreXY for bed instead of extruder(s), for small printer? November 15, 2015 08:24AM |

Registered: 9 years ago Posts: 722 |

Hi,

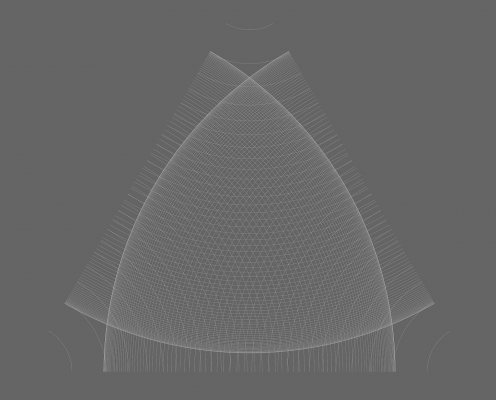

Delta have uncontinuous resolution, depending of distance of the effector from the pillar.

At the centre you have less resolution.

Anyways, whatever the architecture of the machine is, you can increase by any mecanical process

the number of steps per millimeter of your printer.

But, as I said above, you will be quickly limited by the FDM technology.

Even with a 0.1mm nozzle, 0.025 layers, and 0.001mm per step,

you will of course be able to print more details,

I can't remember if anybody pushed the resolution that far,

but I guess you will soon reach soon the limit of the technology.

I belive you will never be able to reach a 0.1mm precision on the part.

@the_digital_dentist, please appreciate english is not our first spoken language. (probably you could already guess)

Sorry if we look to don't understand the difference and we use a word instead of another sometimes.

Maybe you can trust us enough to understand that we make the difference in our mother language.

But feel free to tell us when we say something with the wrong word, it will help us to make ourselves more understandable.

++JM

Delta have uncontinuous resolution, depending of distance of the effector from the pillar.

At the centre you have less resolution.

Anyways, whatever the architecture of the machine is, you can increase by any mecanical process

the number of steps per millimeter of your printer.

But, as I said above, you will be quickly limited by the FDM technology.

Even with a 0.1mm nozzle, 0.025 layers, and 0.001mm per step,

you will of course be able to print more details,

I can't remember if anybody pushed the resolution that far,

but I guess you will soon reach soon the limit of the technology.

I belive you will never be able to reach a 0.1mm precision on the part.

@the_digital_dentist, please appreciate english is not our first spoken language. (probably you could already guess)

Sorry if we look to don't understand the difference and we use a word instead of another sometimes.

Maybe you can trust us enough to understand that we make the difference in our mother language.

But feel free to tell us when we say something with the wrong word, it will help us to make ourselves more understandable.

++JM

|

Re: CoreXY for bed instead of extruder(s), for small printer? November 15, 2015 09:38AM |

Registered: 11 years ago Posts: 5,780 |

Silly me. I thought English was your mother tongue. I would not have known from your posts that it wasn't.

Many people, including native English speakers, often misunderstand the meanings of and misuse the terms I was explaining. When you get down to tens of microns, they all get jumbled together and hard to separate.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Many people, including native English speakers, often misunderstand the meanings of and misuse the terms I was explaining. When you get down to tens of microns, they all get jumbled together and hard to separate.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY for bed instead of extruder(s), for small printer? November 15, 2015 11:27AM |

Registered: 9 years ago Posts: 722 |

|

Re: CoreXY for bed instead of extruder(s), for small printer? November 15, 2015 05:14PM |

Registered: 9 years ago Posts: 344 |

|

Re: CoreXY for bed instead of extruder(s), for small printer? January 08, 2016 01:05PM |

Registered: 11 years ago Posts: 490 |

You have to consider that the steppers only have a repeatability of +-5% or so, too. So 0.9° steppers not only increase resolution, but also precision. The positioning error is only applicable for full steps, though. Microsteps will have progressively higher errors (I think Nophead explained the science behind this on his blog). I only think in full steps when calculating resolution and precision because of that.

Next, fast movement and resolution are difficult to achieve at the same time (due to flex of parts, resonances etc.). You would need a very stable and sturdy printer. If you are willing to sacrifice speed, you can build a printer with very good resolution without shelling out obscene amounts of money.

The pulleys also have slop. You can order zero backlash ones to increase precision.

I have a pulley belt system on my printer, effectively doubling the resolution and precision. It is not compatible with CoreXY, as far as I know.

Because the belt moves half the distance per revolution of the motor as compared to a direct belt system, the positioning error gets cut in half.

You can theoretically increase the number of idlers to achieve even higher precision.

Another effect is that you only need a fraction of torque to move your printhead. The disadvantages of the pulley system are longer belts, slower maximum speeds and more parts / higher complexity (but the parts should still be cheaper than a preloaded ball screw).

With a 0.9° stepper, 20 teeth GT2 pulley and 2* mechanical advantage pulley system, I get 0.05mm / full step. Positioning error due to stepper repeatability alone would be (0.05mm * 0.05) / 2 = +-0.00125mm. Of course, you have to factor in tolerances of other parts, too.

The precision at the moment sucks, though, because I seriously really should retighten everything and recalibrate my printer, lol.

Next, fast movement and resolution are difficult to achieve at the same time (due to flex of parts, resonances etc.). You would need a very stable and sturdy printer. If you are willing to sacrifice speed, you can build a printer with very good resolution without shelling out obscene amounts of money.

The pulleys also have slop. You can order zero backlash ones to increase precision.

I have a pulley belt system on my printer, effectively doubling the resolution and precision. It is not compatible with CoreXY, as far as I know.

Because the belt moves half the distance per revolution of the motor as compared to a direct belt system, the positioning error gets cut in half.

You can theoretically increase the number of idlers to achieve even higher precision.

Another effect is that you only need a fraction of torque to move your printhead. The disadvantages of the pulley system are longer belts, slower maximum speeds and more parts / higher complexity (but the parts should still be cheaper than a preloaded ball screw).

With a 0.9° stepper, 20 teeth GT2 pulley and 2* mechanical advantage pulley system, I get 0.05mm / full step. Positioning error due to stepper repeatability alone would be (0.05mm * 0.05) / 2 = +-0.00125mm. Of course, you have to factor in tolerances of other parts, too.

The precision at the moment sucks, though, because I seriously really should retighten everything and recalibrate my printer, lol.

Sorry, only registered users may post in this forum.