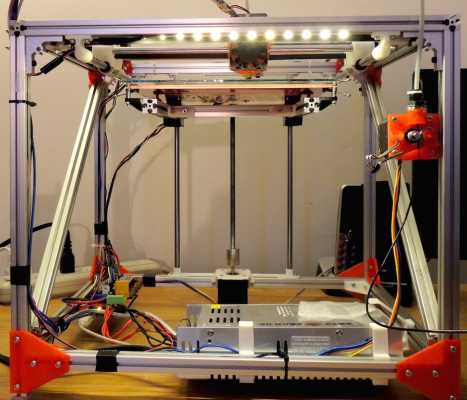

FuseBox ~$300 CoreXY Printer

Posted by AlexY

|

Re: FuseBox ~$300 CoreXY Printer February 19, 2016 10:46AM |

Registered: 8 years ago Posts: 6 |

|

Re: FuseBox ~$300 CoreXY Printer February 23, 2016 01:13AM |

Registered: 8 years ago Posts: 47 |

|

Re: FuseBox ~$300 CoreXY Printer February 23, 2016 05:20AM |

Registered: 9 years ago Posts: 21 |

|

Re: FuseBox ~$300 CoreXY Printer February 23, 2016 11:46AM |

Registered: 12 years ago Posts: 33 |

Does anybody have a listing of all the extrusion lengths and how they are calculated?

For example, for Alex's original Fusebox (1515) we have:

1515 Extrusion 380mm, 4

1515 Extrusion 330mm, 2

1515 Extrusion 345mm, 4

1515 Extrusion 300mm, 2

1515 Extrusion 250mm, 2

1515 Extrusion 152mm, 1

1515 Extrusion 386mm, 2

And in Culain's 2020 version it is:

4 x 345+ mm (Frame, vertical)

6 x 380 mm (Frame, X Axis + diagonal) (edit: 12-jan-2016 (+2 pc.))

2 x 340 mm (Frame, Y Axis top)

2 x 300 mm (Frame, Y Axis bottom)

2 x 250 mm (Bed, Z Axis)

1 x 147 mm (Bed, middle) (edit: 12-jan-2016 (+5mm))

I'd like to make a slightly bigger version (500mm cube frame size with 2020) and I need to know how to calculate the diagonal length and the bed supports.

For example:

4*500mm verticals

4*(500-20-20)= 4*460mm top square

4*(500-20-20)= 4*460mm bottom square

2*( sqrt(460^2+460^2)) = ~650mm diagonals minus some offset from the inside corner for the 3D printed diagonal supports so let's say around 610mm (650 - 20mm offset bottom - 20 mm offset top)

Bed z-axis: how to calculate? length of print bed? what are its limits?

Bed, middle: how to calculate? width of print bed? what are its limits?

thanks

Edited 1 time(s). Last edit at 02/23/2016 11:56AM by jonnycowboy.

For example, for Alex's original Fusebox (1515) we have:

1515 Extrusion 380mm, 4

1515 Extrusion 330mm, 2

1515 Extrusion 345mm, 4

1515 Extrusion 300mm, 2

1515 Extrusion 250mm, 2

1515 Extrusion 152mm, 1

1515 Extrusion 386mm, 2

And in Culain's 2020 version it is:

4 x 345+ mm (Frame, vertical)

6 x 380 mm (Frame, X Axis + diagonal) (edit: 12-jan-2016 (+2 pc.))

2 x 340 mm (Frame, Y Axis top)

2 x 300 mm (Frame, Y Axis bottom)

2 x 250 mm (Bed, Z Axis)

1 x 147 mm (Bed, middle) (edit: 12-jan-2016 (+5mm))

I'd like to make a slightly bigger version (500mm cube frame size with 2020) and I need to know how to calculate the diagonal length and the bed supports.

For example:

4*500mm verticals

4*(500-20-20)= 4*460mm top square

4*(500-20-20)= 4*460mm bottom square

2*( sqrt(460^2+460^2)) = ~650mm diagonals minus some offset from the inside corner for the 3D printed diagonal supports so let's say around 610mm (650 - 20mm offset bottom - 20 mm offset top)

Bed z-axis: how to calculate? length of print bed? what are its limits?

Bed, middle: how to calculate? width of print bed? what are its limits?

thanks

Edited 1 time(s). Last edit at 02/23/2016 11:56AM by jonnycowboy.

|

Re: FuseBox ~$300 CoreXY Printer February 23, 2016 01:25PM |

Registered: 9 years ago Posts: 21 |

|

Re: FuseBox ~$300 CoreXY Printer February 23, 2016 04:09PM |

Registered: 8 years ago Posts: 269 |

Quote

jonnycowboy

Ax, are your designs up on Thingiverse? I am modifying the design for 20x20 with a 500mm "box" square, so I wanted to start with a design that it is already built

thanks!

Yup.. [www.thingiverse.com] It's not complete yet, but I'm on the final hurdle I think.

Quote

dangasaur

Ax, do you have a github repo with your OpenSCAD and Sketchup files? I'd like to try to contribute some changes I have planned for my build (provisions for side panels, pcbless endstops, zmax vs. zmin endstop).

Not currently, I'll be moving it to github soon. Although there are files based off the Culain's base files, so it's imported STLS into OpenSCAD then modified from there.

|

Re: FuseBox ~$300 CoreXY Printer February 23, 2016 10:16PM |

Registered: 8 years ago Posts: 6 |

Quote

Ax

Quote

dangasaur

Ax, do you have a github repo with your OpenSCAD and Sketchup files? I'd like to try to contribute some changes I have planned for my build (provisions for side panels, pcbless endstops, zmax vs. zmin endstop).

Not currently, I'll be moving it to github soon. Although there are files based off the Culain's base files, so it's imported STLS into OpenSCAD then modified from there.

Looking forward to it. Trying to figure out how I'm going to print some of your pieces with no supports and minimal bridging (PETG).

|

Re: FuseBox ~$300 CoreXY Printer February 24, 2016 08:17PM |

Registered: 8 years ago Posts: 47 |

Quote

Culain

Well it's pretty simple constructed. I don't think you will need a guide to build it up.

Just maybe some tips here and there regarding details.

All in all I would start by mounting the frame and then add the smaller parts to it.

Maybe pre-mount the XY axis.

yea i was just hoping for some tips more then anything. i havent started to lay anything out yet. still need to buy a couple things to have all of the parts though i could scavange parts from the two-up.

|

Re: FuseBox ~$300 CoreXY Printer February 24, 2016 08:44PM |

Registered: 8 years ago Posts: 269 |

Quote

dangasaur

Quote

Ax

Quote

dangasaur

Ax, do you have a github repo with your OpenSCAD and Sketchup files? I'd like to try to contribute some changes I have planned for my build (provisions for side panels, pcbless endstops, zmax vs. zmin endstop).

Not currently, I'll be moving it to github soon. Although there are files based off the Culain's base files, so it's imported STLS into OpenSCAD then modified from there.

Looking forward to it. Trying to figure out how I'm going to print some of your pieces with no supports and minimal bridging (PETG).

Most of mine is printed in ColorFabb NGEN. There's the odd PLA part here and there due to running out of NGEN in Pink. Unfortunately, there's no real way to avoid not using supports with the pieces that need them tried to avoid it, but it was virtually impossible. Although the carriers should print without now, thinking about it as I've put inbuilt support in the clamp slots due to a couple of failed prints, the rest can be bridged. Files have just been fully refreshed, should all be manifold and correctly orientated.

|

Re: FuseBox ~$300 CoreXY Printer February 24, 2016 10:14PM |

Registered: 8 years ago Posts: 6 |

Ax, I just saw you update on thingiverse. I'll be printing everything out tonight and tomorrow. I'd still like to get my hands on source files for modifications but I think I'll print everything as is right now to get a feel for exactly what I'll need to modify.

What is your opinion on moving the X endstop to the X carriage so that there is only a single moving wire bundle instead of two?

What is your opinion on moving the X endstop to the X carriage so that there is only a single moving wire bundle instead of two?

|

Re: FuseBox ~$300 CoreXY Printer February 25, 2016 02:56AM |

Registered: 8 years ago Posts: 269 |

Quote

dangasaur

Ax, I just saw you update on thingiverse. I'll be printing everything out tonight and tomorrow. I'd still like to get my hands on source files for modifications but I think I'll print everything as is right now to get a feel for exactly what I'll need to modify.

What is your opinion on moving the X endstop to the X carriage so that there is only a single moving wire bundle instead of two?

That's one that's been niggling me over the past few days.. I may actually do that one. Just taking a look at the physical parts an Omron Microswitch would drop nicely beside the Belt clip, so all you'd need to do is just punch a couple of 2mm holes through and grab some M2 nuts and bolts. In fact, I'll add that option, it does mean printing the blasted Carriage for about the 7th time..

::Edit::

Now added, just grab a limit switch, it screws directly into the carriage with M2 bolts

Edited 1 time(s). Last edit at 02/25/2016 03:53AM by Ax.

|

Re: FuseBox ~$300 CoreXY Printer February 25, 2016 09:33AM |

Registered: 8 years ago Posts: 6 |

|

Re: FuseBox ~$300 CoreXY Printer February 25, 2016 10:55AM |

Registered: 8 years ago Posts: 269 |

Quote

dangasaur

Awesome, I'm a big fan of the plain jane omron switches vs. the pcb mounted switches anyway.

I discovered earlier that the switches I have to hand don't work, due to the SCAD model I used being way too large, gonna need to re-jig it.Should be a straight throigh hole and bolt in place

|

Re: FuseBox ~$300 CoreXY Printer February 25, 2016 02:26PM |

Registered: 8 years ago Posts: 6 |

Quote

Ax

Quote

dangasaur

Awesome, I'm a big fan of the plain jane omron switches vs. the pcb mounted switches anyway.

I discovered earlier that the switches I have to hand don't work, due to the SCAD model I used being way too large, gonna need to re-jig it.Should be a straight throigh hole and bolt in place

I find that #2 sheet metal screws work really well for fastening the omron micro switches.

|

Re: FuseBox ~$300 CoreXY Printer February 26, 2016 06:24PM |

Registered: 8 years ago Posts: 4 |

The design of the FuseBox is really nice there is a lot to like about it.

One thing that does not appeal to me so much about the design is having the stepper motors mounted on top crossbar of the frame. Anyone out there thought about mounting the motors to the underside of the crossbar?

It seems like it would make it easier to put a top cover on it when not in use and offer a barrier to the belts. The lines of the frame are so nice and clean, it seems a shame to have motors poking out of the top.

One thing that does not appeal to me so much about the design is having the stepper motors mounted on top crossbar of the frame. Anyone out there thought about mounting the motors to the underside of the crossbar?

It seems like it would make it easier to put a top cover on it when not in use and offer a barrier to the belts. The lines of the frame are so nice and clean, it seems a shame to have motors poking out of the top.

|

Re: FuseBox ~$300 CoreXY Printer February 26, 2016 06:30PM |

Registered: 8 years ago Posts: 269 |

Quote

3D_Printer_Guy

The design of the FuseBox is really nice there is a lot to like about it.

One thing that does not appeal to me so much about the design is having the stepper motors mounted on top crossbar of the frame. Anyone out there thought about mounting the motors to the underside of the crossbar?

It seems like it would make it easier to put a top cover on it when not in use and offer a barrier to the belts. The lines of the frame are so nice and clean, it seems a shame to have motors poking out of the top.

Just flip the motor mounts so the motor spindle is pointing upwards. Simples!

|

Re: FuseBox ~$300 CoreXY Printer February 26, 2016 10:43PM |

Registered: 8 years ago Posts: 6 |

Ax, if the carriage now has a provision for a limit switch is there still a need to differentiate the left and right carriers? Seems like the only two differences are a nub for the Y end limit switch and then a place to mount the old X limit switch. I'm going to experiment with removing the switch provision in scad but leaving the nub and printing the resulting model twice.

Also, I noticed that the Z bed supports have some internal structures that are maybe remnants of zip tie clamps? I didn't know if you left those in for a reason or it was just an oversight.

Also, I noticed that the Z bed supports have some internal structures that are maybe remnants of zip tie clamps? I didn't know if you left those in for a reason or it was just an oversight.

|

Re: FuseBox ~$300 CoreXY Printer February 27, 2016 04:07AM |

Registered: 8 years ago Posts: 269 |

Quote

dangasaur

Ax, if the carriage now has a provision for a limit switch is there still a need to differentiate the left and right carriers? Seems like the only two differences are a nub for the Y end limit switch and then a place to mount the old X limit switch. I'm going to experiment with removing the switch provision in scad but leaving the nub and printing the resulting model twice.

Also, I noticed that the Z bed supports have some internal structures that are maybe remnants of zip tie clamps? I didn't know if you left those in for a reason or it was just an oversight.

Technically, no, there's no real reason to differentiate apart from the switch bumper I've left it as it is to give people the option. I'm aware about the slots in the Z carriers, it's a remnant of the originals, those were just edited from the original STL, there's no real harm leaving the gaps in as it's still solid. I have noticed when test fitting the bed that the holes in the front bed carriers are out of alignment, so I'm going to redesign them, they'll probably be a bit more solid as I have a tendency to over-engineer.

::Edit::

I've just uploaded a left carrier without the slot for the endstop PCB.

Edited 1 time(s). Last edit at 02/27/2016 03:51PM by Ax.

|

Re: FuseBox ~$300 CoreXY Printer February 28, 2016 11:41AM |

Registered: 8 years ago Posts: 4 |

I have a question that is slightly off topic but still relevant to Fusebox.

With 150 M3 or M5 bolts to fasten, what tool do you like to use to make the build go quickly?

I'd like to use a cordless screw driver, but I can't find any metric hex drivers.

What do you like to use?

Edited 1 time(s). Last edit at 02/28/2016 11:43AM by 3D_Printer_Guy.

With 150 M3 or M5 bolts to fasten, what tool do you like to use to make the build go quickly?

I'd like to use a cordless screw driver, but I can't find any metric hex drivers.

What do you like to use?

Edited 1 time(s). Last edit at 02/28/2016 11:43AM by 3D_Printer_Guy.

|

Re: FuseBox ~$300 CoreXY Printer February 28, 2016 11:49AM |

Registered: 8 years ago Posts: 269 |

Quote

3D_Printer_Guy

I have a question that is slightly off topic but still relevant to Fusebox.

With 150 M3 or M5 bolts to fasten, what tool do you like to use to make the build go quickly?

I'd like to use a cordless screw driver, but I can't find any metric hex drivers.

What do you like to use?

Standard manual allen keys, it may be slower, but it also makes sure that stuff doesn't break from over-tightening.

|

Re: FuseBox ~$300 CoreXY Printer February 28, 2016 01:40PM |

Registered: 8 years ago Posts: 166 |

Quote

Ax

Quote

3D_Printer_Guy

The design of the FuseBox is really nice there is a lot to like about it.

One thing that does not appeal to me so much about the design is having the stepper motors mounted on top crossbar of the frame. Anyone out there thought about mounting the motors to the underside of the crossbar?

It seems like it would make it easier to put a top cover on it when not in use and offer a barrier to the belts. The lines of the frame are so nice and clean, it seems a shame to have motors poking out of the top.

Just flip the motor mounts so the motor spindle is pointing upwards. Simples!

I put the motors on top to increase the build area without having to use longer extrusions. Flipping them upside down means that the motor mounts will have to be extended a bit and the diagonal crossbars moved farther out to make room for the motor.

|

Re: FuseBox ~$300 CoreXY Printer February 28, 2016 03:08PM |

Registered: 8 years ago Posts: 269 |

Quote

AlexY

Quote

Ax

Quote

3D_Printer_Guy

The design of the FuseBox is really nice there is a lot to like about it.

One thing that does not appeal to me so much about the design is having the stepper motors mounted on top crossbar of the frame. Anyone out there thought about mounting the motors to the underside of the crossbar?

It seems like it would make it easier to put a top cover on it when not in use and offer a barrier to the belts. The lines of the frame are so nice and clean, it seems a shame to have motors poking out of the top.

Just flip the motor mounts so the motor spindle is pointing upwards. Simples!

I put the motors on top to increase the build area without having to use longer extrusions. Flipping them upside down means that the motor mounts will have to be extended a bit and the diagonal crossbars moved farther out to make room for the motor.

Hmm, I need to reassemble the frame, I'll double check with my 2020 version, I think there's actually enough space to flip the motors, hence me saying that, but until my belts and pulleys come in, I'm leaving it as it is.

|

Re: FuseBox ~$300 CoreXY Printer February 28, 2016 11:11PM |

Registered: 8 years ago Posts: 47 |

|

Re: FuseBox ~$300 CoreXY Printer February 29, 2016 03:59AM |

Registered: 8 years ago Posts: 47 |

|

Re: FuseBox ~$300 CoreXY Printer February 29, 2016 04:16PM |

Registered: 9 years ago Posts: 251 |

Quote

pen25

so got the frame together. but found out you have to mount the printed parts first. after i get it all worked out i will go through and write up some sort of guide or at least try too.

Awesome! I like the pdf also, got my extrusions a few days ago, and just started printing my parts! Looking forward to your guide.

|

Re: FuseBox ~$300 CoreXY Printer February 29, 2016 10:20PM |

Registered: 8 years ago Posts: 47 |

|

Re: FuseBox ~$300 CoreXY Printer March 03, 2016 10:14PM |

Registered: 8 years ago Posts: 4 |

|

Re: FuseBox ~$300 CoreXY Printer March 04, 2016 01:38AM |

Registered: 8 years ago Posts: 47 |

i think to stiffen the frame you really need the alum corner brackets. i used t plates and 45 plates where i could and it works allot better then the printed plates i have to order more plates though as i need 4 more i believe

[store.openbeamusa.com]

[store.openbeamusa.com]

they are sold out of the 45's and i will probably just end up picking up some flat stock and making some using these as a template. i will bring some in next week and scan them for anyone who wants a template

[store.openbeamusa.com]

[store.openbeamusa.com]

they are sold out of the 45's and i will probably just end up picking up some flat stock and making some using these as a template. i will bring some in next week and scan them for anyone who wants a template

|

Re: FuseBox ~$300 CoreXY Printer March 04, 2016 01:59AM |

Registered: 10 years ago Posts: 179 |

I think that adding atleast an extra set of extrusions in a horizontal plane would greatly increase the stiffness of the frame. Like on this printer except it has two sets of extra horizontal sets of extrusions: [3dprint.com] Just tapping and bolting should be sufficient.

It is really strange that more printers do not use this to increase the stiffness.

Edited 1 time(s). Last edit at 03/04/2016 01:59AM by Edvardas.

It is really strange that more printers do not use this to increase the stiffness.

Edited 1 time(s). Last edit at 03/04/2016 01:59AM by Edvardas.

|

Re: FuseBox ~$300 CoreXY Printer March 04, 2016 06:02PM |

Registered: 8 years ago Posts: 166 |

On my printer, I've used metal corner brackets from Misumi, part HBLTBS3; they're super strong and keep the frame very rigid, so I highly recommend replacing the printed brackets with them in at least 2 corners of the x-axis (the y-axis frame is already stiff because of the diagonal bars). I'm only using the brackets on the upper corners of the x axis, with normal printed brackets on the bottom, but using them in all 4 corners will make the frame even more stiff.

The diagonal bars and metal brackets are enough to keep the frame very rigid, so I decided not to add extra extrusions to lower the cost and reduce the number of bolts needed.

Edited 1 time(s). Last edit at 03/04/2016 06:05PM by AlexY.

Quote

Edvardas

I think that adding atleast an extra set of extrusions in a horizontal plane would greatly increase the stiffness of the frame. Like on this printer except it has two sets of extra horizontal sets of extrusions: [3dprint.com] Just tapping and bolting should be sufficient.

The diagonal bars and metal brackets are enough to keep the frame very rigid, so I decided not to add extra extrusions to lower the cost and reduce the number of bolts needed.

Edited 1 time(s). Last edit at 03/04/2016 06:05PM by AlexY.

Sorry, only registered users may post in this forum.