FuseBox ~$300 CoreXY Printer

Posted by AlexY

|

Re: FuseBox ~$300 CoreXY Printer March 05, 2016 03:56AM |

Registered: 10 years ago Posts: 179 |

I think a whole community who is working on 2020 framed printers should admit that printing the corner brackets was a mistake from a start. Sorry but you are not helping with your excuses trying to defend it

You are not reducing the cost nor the number of bolts. I can clearly see that you have way more than one bolt connecting one 2020 profile to the other. Four 40cm long 2020 profiles costs 5 EUR from Motedis. You need 8 bolts to connect them to the existing frame- That is cheap. How much was one of those Mitsumi corner brackets?

I have 50 cast metal corner brackets together with 100 spring t-nuts and a bunch of bolts on my printer. I admit that it was a mistake and an overkill. All this hardware cost me around 40 EUR. Now I would just change them to the tapped holes and a bunch of button head bolts to connect profiles.

Edited 1 time(s). Last edit at 03/05/2016 03:57AM by Edvardas.

You are not reducing the cost nor the number of bolts. I can clearly see that you have way more than one bolt connecting one 2020 profile to the other. Four 40cm long 2020 profiles costs 5 EUR from Motedis. You need 8 bolts to connect them to the existing frame- That is cheap. How much was one of those Mitsumi corner brackets?

I have 50 cast metal corner brackets together with 100 spring t-nuts and a bunch of bolts on my printer. I admit that it was a mistake and an overkill. All this hardware cost me around 40 EUR. Now I would just change them to the tapped holes and a bunch of button head bolts to connect profiles.

Edited 1 time(s). Last edit at 03/05/2016 03:57AM by Edvardas.

|

Re: FuseBox ~$300 CoreXY Printer March 05, 2016 03:45PM |

Registered: 8 years ago Posts: 166 |

Didn't realize you were talking about tapping and drilling the extrusions; I thought you meant attaching the extra bars with more brackets, which looks like what the printer in your picture is doing

I went with brackets mostly for convenience; I don't have a tap or even a drill handy so I made the frame able to be assembled with a hex key only. The metal corner brackets are $0.75 each, so using a pair of them on top with printed brackets underneath is cheaper than adding another horizontal extrusion (I'm using 1515, not 2020, and another length would be around $2.50). I don't notice any flex when trying to manually bend the frame, and there isn't much inertia in the x direction anyways since it's just the carriage moving. The y-axis is also similarly rigid with no noticeable flex; the diagonal bars on each side also serve as convenient carrying handles and provide more mounting flexibility.

I went with brackets mostly for convenience; I don't have a tap or even a drill handy so I made the frame able to be assembled with a hex key only. The metal corner brackets are $0.75 each, so using a pair of them on top with printed brackets underneath is cheaper than adding another horizontal extrusion (I'm using 1515, not 2020, and another length would be around $2.50). I don't notice any flex when trying to manually bend the frame, and there isn't much inertia in the x direction anyways since it's just the carriage moving. The y-axis is also similarly rigid with no noticeable flex; the diagonal bars on each side also serve as convenient carrying handles and provide more mounting flexibility.

|

Re: FuseBox ~$300 CoreXY Printer March 05, 2016 04:39PM |

Registered: 9 years ago Posts: 722 |

Hi guys,

AlexY, you should try to flex your 1515 structure with a dial indicator. You'll see that the flex is not anecdotic

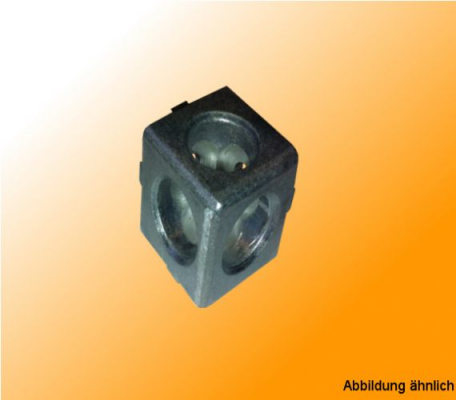

There's some realy usefull hardware for 2020 or 1515 profiles. For example the 3 ways corners.

Light and cheap version :

Heavy and clean version :

Both minimize the use of extra hardware.

Note, for both of it you can add plugin caps for a clean look.

++JM

^ Things I said. My thingiverse here. My website there (in french).

AlexY, you should try to flex your 1515 structure with a dial indicator. You'll see that the flex is not anecdotic

There's some realy usefull hardware for 2020 or 1515 profiles. For example the 3 ways corners.

Light and cheap version :

Heavy and clean version :

Both minimize the use of extra hardware.

Note, for both of it you can add plugin caps for a clean look.

++JM

^ Things I said. My thingiverse here. My website there (in french).

|

Re: FuseBox ~$300 CoreXY Printer March 05, 2016 06:15PM |

Registered: 8 years ago Posts: 166 |

|

Re: FuseBox ~$300 CoreXY Printer March 05, 2016 06:41PM |

Registered: 10 years ago Posts: 179 |

Quote

J-Max

Hi guys,

AlexY, you should try to flex your 1515 structure with a dial indicator. You'll see that the flex is not anecdotic

There's some realy usefull hardware for 2020 or 1515 profiles. For example the 3 ways corners.

Light and cheap version :

Heavy and clean version :

Both minimize the use of extra hardware.

Note, for both of it you can add plugin caps for a clean look.

++JM

None of these make a structure any stronger than just tapped hole with a bolt in it.

|

Re: FuseBox ~$300 CoreXY Printer March 06, 2016 01:08AM |

Registered: 8 years ago Posts: 47 |

i havent found the end blocks for 1515. openbeam says hey are going to make them but havent unless someone has a link. IMHO though those end blocks wont stiffen must more and might possibly strip the threading. the best way to stiffen is acrylic panels along the three sides. along with straps top and bottom on the front with probably 2 or 3 screws or a panel with a window cut

|

Re: FuseBox ~$300 CoreXY Printer March 06, 2016 06:54AM |

Registered: 9 years ago Posts: 722 |

Hi guys,

@Edvardas : that's not stronger, but it's pretty the same strenght, just you don't spend time to drill holes, and it realy unexpensive <$2/pc

@AlexyY : well, if you understand well what any aluminium extrusion system is, whatever the module (15, 20, etc) you don't want any brackets.

You just want the right joint at the right place. And sometimes the right connector. That means the simpler one, in method or number of parts.

Hardware providers or aluminium extrusion manufacturers like Mitsumi, Bosch, etc. Provides any kind of connectors for their profiles.

Dont' stick to a particular brand. Since the module and slot are the same, any corresponding hardware will fit.

Some people wants brackets because their structure is not stiff enough.

If brackets realy helps, the structure is probably poorly engineered.

But most of the time, the profiles are just too small for the use.

Plastic brackets is the worst idea ever, because plastic is not stiff enough, even for a bracket connector.

You could make a plastic bracket 5 times bigger than a metal one, it will still bend too much.

Acrylic pannel is plastic. And think about the amount of material, and the cost, to do what a simple connector and a screw do.

Think simple. That's what aluminium profiles structures are all about.

If you need pannes or brackets, you've got the wrong aluminium profile for the job. Do calculations to select the right one.

Last about brackets. Look at the screw positions that are small and perpendicular at the movement you want to halt.

If you use end corners, like I shown earlier, the screw is deeper in the material and in the optimal direction.

If the profile is choosen at purpose, you don't need anything but this screw.

@pen25 : A thread connection is meant to be good enough when the thread at last equals the diameter of the screw.

On end corners, if you need it, you can thread 2 or 3 times the diameter of the screw. It's the same process and closely the same cost.

This way, be sure the profile will be destroyed before the thread can be stripped.

++JM

Edited 1 time(s). Last edit at 03/06/2016 06:57AM by J-Max.

^ Things I said. My thingiverse here. My website there (in french).

@Edvardas : that's not stronger, but it's pretty the same strenght, just you don't spend time to drill holes, and it realy unexpensive <$2/pc

@AlexyY : well, if you understand well what any aluminium extrusion system is, whatever the module (15, 20, etc) you don't want any brackets.

You just want the right joint at the right place. And sometimes the right connector. That means the simpler one, in method or number of parts.

Hardware providers or aluminium extrusion manufacturers like Mitsumi, Bosch, etc. Provides any kind of connectors for their profiles.

Dont' stick to a particular brand. Since the module and slot are the same, any corresponding hardware will fit.

Some people wants brackets because their structure is not stiff enough.

If brackets realy helps, the structure is probably poorly engineered.

But most of the time, the profiles are just too small for the use.

Plastic brackets is the worst idea ever, because plastic is not stiff enough, even for a bracket connector.

You could make a plastic bracket 5 times bigger than a metal one, it will still bend too much.

Acrylic pannel is plastic. And think about the amount of material, and the cost, to do what a simple connector and a screw do.

Think simple. That's what aluminium profiles structures are all about.

If you need pannes or brackets, you've got the wrong aluminium profile for the job. Do calculations to select the right one.

Last about brackets. Look at the screw positions that are small and perpendicular at the movement you want to halt.

If you use end corners, like I shown earlier, the screw is deeper in the material and in the optimal direction.

If the profile is choosen at purpose, you don't need anything but this screw.

@pen25 : A thread connection is meant to be good enough when the thread at last equals the diameter of the screw.

On end corners, if you need it, you can thread 2 or 3 times the diameter of the screw. It's the same process and closely the same cost.

This way, be sure the profile will be destroyed before the thread can be stripped.

++JM

Edited 1 time(s). Last edit at 03/06/2016 06:57AM by J-Max.

^ Things I said. My thingiverse here. My website there (in french).

|

Re: FuseBox ~$300 CoreXY Printer March 06, 2016 02:45PM |

Registered: 10 years ago Posts: 179 |

Quote

J-Max

Hi guys,

@Edvardas : that's not stronger, but it's pretty the same strenght, just you don't spend time to drill holes, and it realy unexpensive <$2/pc

++JM

That is 16 dollars for just a simple cube (8 corners). Add a few for a bed or some extra beams and it is expensive. I made an order at Motedis a few weeks ago and these corner cubes came up almost as expensive as corner brackets. And without any benefit over just a bolt connecting two profiles

|

Re: FuseBox ~$300 CoreXY Printer March 06, 2016 03:07PM |

Registered: 9 years ago Posts: 722 |

Hi guys,

@Edvardas : to me that money is well spend with conenctors (speed building, comparable strenght, dismantlability, aesthetics and so on).

But I respect your point of view. If expenses is the main and single thing that matters, you're right.

++JM

^ Things I said. My thingiverse here. My website there (in french).

@Edvardas : to me that money is well spend with conenctors (speed building, comparable strenght, dismantlability, aesthetics and so on).

But I respect your point of view. If expenses is the main and single thing that matters, you're right.

++JM

^ Things I said. My thingiverse here. My website there (in french).

|

Re: FuseBox ~$300 CoreXY Printer March 07, 2016 02:41PM |

Registered: 9 years ago Posts: 251 |

|

Re: FuseBox ~$300 CoreXY Printer March 09, 2016 09:26PM |

Registered: 8 years ago Posts: 47 |

alex has said he uses 76oz. i just bought some 84oz steppers and have a set of cheap single stacks at home i got from sainsmart in a package deal with a megatronics setup for 60 bucks. i will try them first to see how it works out. you dont need a ton of torque because the extruder and carriage is light enough to not need allot of torque.

|

Re: FuseBox ~$300 CoreXY Printer March 09, 2016 10:06PM |

Registered: 9 years ago Posts: 251 |

|

Re: FuseBox ~$300 CoreXY Printer March 17, 2016 11:02AM |

Registered: 8 years ago Posts: 776 |

hi alex, i thought you might appreciate knowing that i'm creating a derivative of the fusebox, called the "foldable sandwich 200". as the name suggests, it's a foldable, portable 3d printer - there aren't very many of those out there. one thing i've done is raised the XY components up - the y-rod mounts are now on *top* for example - and the motors are on the outside edge not the inner edge. in this way there is a significant amount of extra clearance, so that the overall outer dimensions of the frame can be reduced. i have the width and height at 368 x 390, now.

the extra clearance was - is - essential for me, so as to be able to get the outer box (which is used for keeping the whole thing rigid during operation) into "carryon luggage" dimensions. anyway, all the top corexy parts you (or anyone else) should be able to obtain and use as drop-in replacements.

thank you for your work alex!

[forums.reprap.org]

the extra clearance was - is - essential for me, so as to be able to get the outer box (which is used for keeping the whole thing rigid during operation) into "carryon luggage" dimensions. anyway, all the top corexy parts you (or anyone else) should be able to obtain and use as drop-in replacements.

thank you for your work alex!

[forums.reprap.org]

|

Re: FuseBox ~$300 CoreXY Printer March 17, 2016 11:06AM |

Registered: 8 years ago Posts: 776 |

Quote

rmrf

Quote

Ax

Just a quick one, Misumi EU is based in Frankfurt. So you can actually order direct. I basically did that for 2020s.

Did you buy through company? Misumi EU seem only to work with companies.

i'm getting 1515 extrusion frame through makerbeam.com (openbeam) as well as the corner brackets and corner plates. i'll be hand-cutting the 1m lengths to the required size.

|

Re: FuseBox ~$300 CoreXY Printer March 17, 2016 02:49PM |

Registered: 8 years ago Posts: 269 |

Quote

lkcl

Quote

rmrf

Quote

Ax

Just a quick one, Misumi EU is based in Frankfurt. So you can actually order direct. I basically did that for 2020s.

Did you buy through company? Misumi EU seem only to work with companies.

i'm getting 1515 extrusion frame through makerbeam.com (openbeam) as well as the corner brackets and corner plates. i'll be hand-cutting the 1m lengths to the required size.

Yeah, did mention above that it was bought through my Company

|

Re: FuseBox ~$300 CoreXY Printer March 18, 2016 05:21PM |

Registered: 8 years ago Posts: 166 |

Quote

lkcl

hi alex, i thought you might appreciate knowing that i'm creating a derivative of the fusebox, called the "foldable sandwich 200". as the name suggests, it's a foldable, portable 3d printer - there aren't very many of those out there. one thing i've done is raised the XY components up - the y-rod mounts are now on *top* for example - and the motors are on the outside edge not the inner edge. in this way there is a significant amount of extra clearance, so that the overall outer dimensions of the frame can be reduced. i have the width and height at 368 x 390, now.

Cool!

Edited 1 time(s). Last edit at 03/18/2016 05:21PM by AlexY.

|

LM8LUU bearings March 18, 2016 08:57PM |

Registered: 8 years ago Posts: 776 |

|

Re: LM8LUU bearings March 19, 2016 04:59AM |

Registered: 9 years ago Posts: 722 |

[www.zappautomation.co.uk]

You should consider also Igus Polymer bearings, which are quieter with less play IMHO.

++JM

^ Things I said. My thingiverse here. My website there (in french).

You should consider also Igus Polymer bearings, which are quieter with less play IMHO.

++JM

^ Things I said. My thingiverse here. My website there (in french).

|

Re: LM8LUU bearings March 19, 2016 05:38AM |

Registered: 8 years ago Posts: 776 |

Quote

J-Max

[www.zappautomation.co.uk]

You should consider also Igus Polymer bearings, which are quieter with less play IMHO.

++JM

briiiliant, thanks. for the z-axis arrangement less play is important with this design, much appreciated. [update: ah! those igus polymer bearings aren't a drop-in replacement for LM8LUU so i would need a redesign, and i'm on a tight deadline so am keeping as much as i can to the original fusebox STL parts. for sandwich200 version 2 i'll take a closer look, max]

[2nd update - sorry j-max, clarity only comes sometimes by comparison: zappautomation only have LM08UU (aka LM8UU) bearings - i'm specifically after the longer LM08LUU (aka LM8LUU). these longer 45mm bearings are critically required for this particular design, especially on the z-axis, because the entire bed is supported solely on the 2 upright rods. turns out that using LM8LUU bearings for the x and y assembly instead of a pair of LM8UU bearings also reduces noise at higher speed, so the entire design of the fusebox uses LM8LUU bearings. not many 3d printer designs do that, hence the reason why LM8LUU bearings are harder to get hold of. i found some with wedo3dprinting so will try them].

Edited 2 time(s). Last edit at 03/19/2016 06:06AM by lkcl.

|

Re: LM8LUU bearings March 19, 2016 06:46AM |

Registered: 10 years ago Posts: 179 |

Quote

lkcl

btw does anyone know of a european supplier of the LM8LUU bearings? all the EU suppliers i've found so far only have the LM8UU smaller bearings.

[www.dold-mechatronik.de] This is close and probably even better than lm8luu but it comes at a price.

|

Re: LM8LUU bearings March 19, 2016 06:55AM |

Registered: 8 years ago Posts: 776 |

Quote

Edvardas

[www.dold-mechatronik.de] This is close and probably even better than lm8luu but it comes at a price.

wow those look great - look at the figures, 800N somethingsomething that's 80 times gravity. i note they even have something on the side, presumably so you can oil them in situ. it's a pity that they're not drop-in replacements for LM8LUU - they're also a bit longer (54mm) and i'm looking specifically to avoid any kind of redesigns of the sandwich200 (based on the fusebox). so again, another one to look at for a 2nd revision. thank you edvardas

|

Re: FuseBox ~$300 CoreXY Printer March 19, 2016 04:37PM |

Registered: 8 years ago Posts: 6 |

Inverting Z seemed to do the trick. I guess I was scared to mess with anything in the firmware until I had some feedback.

Edited 1 time(s). Last edit at 03/19/2016 05:05PM by Jellypowered.

Quote

So I've built one of these after having issues with my Delta printer's limited build size. I'm having Z homing issues.

With X and Y they are working as intended. I'm using the firmware alex included the only modifications are the Steps per MM due to using a Tr8*8 Leadscrew (8mm per rotation)

I can click home X and it moves X to the left toward the limit switch and stops when it hits it.

When I click Home Y it moves towards the back of the machine and stops on the limit switch as intended.

Before tinkering with anything clicking home z lowers the bed to where it sits almost halfway down the printer.

After tinkering it still wont head towards the limit switch for Z

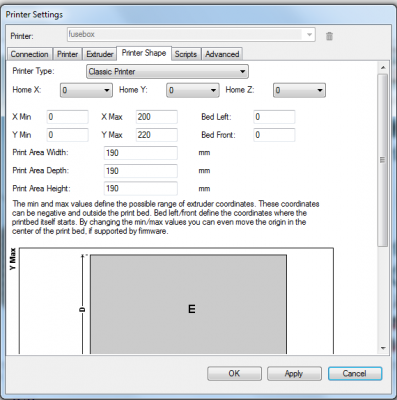

Can someone post their Repetier-host->printer settings->Printer Shape settings? Here's mine.

I'm really stumped by this. I have a Delta printer and it took me quite a bit of googling to figure it out, but it seems like nobody has this similar issue for this type of (corexy) machine. It's probably something insanely stupid and easy to fix, i'm just not seeing it.

Also just in case someone needs it, my configuration.h

Configuration.h

Edited 1 time(s). Last edit at 03/19/2016 05:05PM by Jellypowered.

|

Re: LM8LUU bearings March 22, 2016 12:24AM |

Registered: 8 years ago Posts: 47 |

Quote

J-Max

[www.zappautomation.co.uk]

You should consider also Igus Polymer bearings, which are quieter with less play IMHO.

++JM

they dont make an lm8luu version

|

Re: FuseBox ~$300 CoreXY Printer March 22, 2016 02:41AM |

Registered: 8 years ago Posts: 25 |

|

Re: FuseBox ~$300 CoreXY Printer March 22, 2016 10:46AM |

Registered: 8 years ago Posts: 4 |

|

Re: FuseBox ~$300 CoreXY Printer March 22, 2016 12:12PM |

Registered: 9 years ago Posts: 251 |

Quote

godefroi

I've gotten the itch to build a printer, and I'd kinda like to build a CoreXY variant instead of a Prusa-type (which seems to be the standard default). If I wanted to get a set of the necessary printed parts for the Fuse Box, would that be possible, and where might I look?

If you have a printer available you can just print them yourself, [www.thingiverse.com]

Otherwise you could try to find a local makerspace, or try searching www.3dhubs.com for a printer near you!

|

Re: FuseBox ~$300 CoreXY Printer March 22, 2016 12:18PM |

Registered: 9 years ago Posts: 251 |

|

Re: FuseBox ~$300 CoreXY Printer March 22, 2016 05:27PM |

Registered: 8 years ago Posts: 269 |

Been a little quiet, here's my Version of the Fusebox with 2020 extrusions, dubbed the FB2020. All cable-tied bearings have been replaced with push fit. Still needs a little work, but it's pretty much there.

Edited 1 time(s). Last edit at 03/22/2016 05:28PM by Ax.

Edited 1 time(s). Last edit at 03/22/2016 05:28PM by Ax.

|

Re: FuseBox ~$300 CoreXY Printer March 22, 2016 06:48PM |

Registered: 8 years ago Posts: 25 |

Quote

widespreaddeadhead

try searching www.3dhubs.com for a printer near you!

Ah, perfect, that's exactly the sort of thing I was looking for, thanks!

I also found a coworker who has a printer (XYZ da Vinci) who is eager to print the parts for cost, so I'm going to try that route for the first couple parts. I'm not sure he'll be able to do much troubleshooting if something's not perfect, though, but 3dhubs has quite a few "Hubs" very close to me, so I'm sure I'll get it worked out. Thank you!

|

Re: FuseBox ~$300 CoreXY Printer March 22, 2016 09:46PM |

Registered: 9 years ago Posts: 251 |

Quote

godefroi

Quote

widespreaddeadhead

try searching www.3dhubs.com for a printer near you!

Ah, perfect, that's exactly the sort of thing I was looking for, thanks!

I also found a coworker who has a printer (XYZ da Vinci) who is eager to print the parts for cost, so I'm going to try that route for the first couple parts. I'm not sure he'll be able to do much troubleshooting if something's not perfect, though, but 3dhubs has quite a few "Hubs" very close to me, so I'm sure I'll get it worked out. Thank you!

Just by chance, what state are you located in?

Edited 1 time(s). Last edit at 03/22/2016 09:47PM by widespreaddeadhead.

Sorry, only registered users may post in this forum.