FuseBox ~$300 CoreXY Printer

Posted by AlexY

|

Re: FuseBox ~$300 CoreXY Printer April 08, 2016 10:56AM |

Registered: 8 years ago Posts: 776 |

|

Re: FuseBox ~$300 CoreXY Printer April 09, 2016 09:20AM |

Registered: 8 years ago Posts: 776 |

Quote

lkcl

Quote

phord

I was hoping your redesign would include a useful extruder for 3mm

ok i've _had_ to replace the metal arm with a printed one so that's now in the repository. testing it now.

still didn't fix the problem i was having difficulties with skipping at a very specific angle - at least now it's a PLA part. what _has_ solved the skipping is splitting the extruder gear into two pars: one that holds the drive gear, and then the main 46-tooth gear. i was *really* getting fed up of waiting 45 minutes to print out 1m of PLA only to have it destroyed and useless due to the drive gear going in at the wrong angle. so now if that goes wrong it's 10mins and 0.2m of PLA. plus, you can create any adapter you like, for any drive gear, with simple geometric shapes: a cube and 5 cylinders.

anyway, i'm running at 350mm/sec, and a flow rate of 28mm3/sec with a 0.4mm nozzle, 3mm PLA, and 1/4 micro-steps. phord (or anyone else for that matter) you should be able to achieve the same sort of rates with a Fusebox, with this geared extruder: the Fusebox and the Sandwich200 are effectively the same design.

|

Re: FuseBox ~$300 CoreXY Printer April 10, 2016 03:12PM |

Registered: 8 years ago Posts: 776 |

hiya phord,

okaaay, latest revision to the geared extruder, i upped the ratio to 53:13 (4.07:1) because i was still getting skipping at 3.54:1 (grr) - i also thinned down the height by almost 10mm, and i split out the gear from the drive-attachment as well as split out the filament exit guide. the general idea is, if you want to change or develop something different, it saves plastic. i was getting *really* fed up of wasting 1m of PLA every time i pushed the MK8 incorrectly into the hub. also i've backed down to 250mm/s and i'm getting much smoother prints.

okaaay, latest revision to the geared extruder, i upped the ratio to 53:13 (4.07:1) because i was still getting skipping at 3.54:1 (grr) - i also thinned down the height by almost 10mm, and i split out the gear from the drive-attachment as well as split out the filament exit guide. the general idea is, if you want to change or develop something different, it saves plastic. i was getting *really* fed up of wasting 1m of PLA every time i pushed the MK8 incorrectly into the hub. also i've backed down to 250mm/s and i'm getting much smoother prints.

|

Re: FuseBox ~$300 CoreXY Printer April 12, 2016 11:27AM |

Registered: 8 years ago Posts: 776 |

Quote

phord

I was hoping your redesign would include a useful extruder for 3mm

ok phord, i've created a set of build instructions for the 53:13 geared extruder, here: [hands.com] - it includes photos and a commissioning video, i got 120mm/min (12.75mm3/sec) at 210C cleany. at 150mm/min it started skipping. the usual maximum for standard E3Dv6 extruders is around 10mm3/sec. that's with a 0.4mm nozzle, 1/4 microstepping and a 1.1A current limit.

Edited 1 time(s). Last edit at 04/12/2016 11:27AM by lkcl.

|

Re: FuseBox ~$300 CoreXY Printer April 12, 2016 06:43PM |

Registered: 12 years ago Posts: 44 |

Quote

lkcl

ok phord, i've created a set of build instructions for the 53:13 geared extruder, here: [hands.com] - it includes photos and a commissioning video, i got 120mm/min (12.75mm3/sec) at 210C cleany. at 150mm/min it started skipping. the usual maximum for standard E3Dv6 extruders is around 10mm3/sec. that's with a 0.4mm nozzle, 1/4 microstepping and a 1.1A current limit.

Nice!

You've clearly put a lot of design work into this and I'm excited to try it out. I have an extra MK8 gear here and about half the other needed parts. I'll start sourcing the assortment of screws, nuts and bearings next week.

In the meantime I reworked the schnozzle for 3mm but it is still direct drive. I haven't got as far as trying it out yet, and I have a catalog of about 19 things that can cause an extruder to fail, so I believe you when you say it will skip. :-)

It does make me wonder why I'm still using 3mm filament. Maybe it's because I have a half-dozen e3d's and J-Heads in my spares kit.

I assume you mean 120mm/sec instead of 120mm/min above. But I'm not clear on how you calculated the volume rate. nozzle=0.4mm, radius=0.2mm, area = PI *r^2; 120mm * pi * (0.2mm)^2 = 15mm^3. That's not taking into account the layer height, but in your video you were only extruding into empty space, so I assume the normal "layer*nozzle*length" doesn't really apply.

|

Re: FuseBox ~$300 CoreXY Printer April 12, 2016 08:28PM |

Registered: 8 years ago Posts: 776 |

Quote

phord

Quote

lkcl

ok phord, i've created a set of build instructions for the 53:13 geared extruder, here: [hands.com] - it includes photos and a commissioning video, i got 120mm/min (12.75mm3/sec) at 210C cleany. at 150mm/min it started skipping. the usual maximum for standard E3Dv6 extruders is around 10mm3/sec. that's with a 0.4mm nozzle, 1/4 microstepping and a 1.1A current limit.

Nice!

You've clearly put a lot of design work into this and I'm excited to try it out. I have an extra MK8 gear here and about half the other needed parts. I'll start sourcing the assortment of screws, nuts and bearings next week.

cool. let me know if you run into any issues. btw i just... i originally bought one of those "all aluminum" direct drive extruder kits - it came with everything i needed. got it from alfa-tech i think, and they were very quick (don't know where you're based, they're in denmark).

Quote

In the meantime I reworked the schnozzle for 3mm but it is still direct drive. I haven't got as far as trying it out yet, and I have a catalog of about 19 things that can cause an extruder to fail, so I believe you when you say it will skip. :-)

weeelll... if you're happy to run at ooo... a printing speed of 40mm/sec, then you might be fiiine...

Quote

It does make me wonder why I'm still using 3mm filament. Maybe it's because I have a half-dozen e3d's and J-Heads in my spares kit.

i've seen people converting them to 1.75 with the addition of a short piece of PTFE tube. i'd like to try that, and the other reason for doing so is because i want to keep the OD 6mm tubing, and put a *second* tube inside it (3mm-to-1.8mm) to see what happens. soooo aaaactually, i really *want* 3mm hotends, in order to get the right bowden inlet diameter when converting them to 1.75. i really don't trust the thinness of those 1.75mm bowden tubes. maybe that's just me... but i've just ordered a "volcano" set for the E3Dv6 and i want to see how far i can push it.

Quote

I assume you mean 120mm/sec instead of 120mm/min above.

no really it's 120mm/min feed rate.

Quote

But I'm not clear on how you calculated the volume rate. nozzle=0.4mm, radius=0.2mm, area = PI *r^2; 120mm * pi * (0.2mm)^2 = 15mm^3. That's not taking into account the layer height, but in your video you were only extruding into empty space, so I assume the normal "layer*nozzle*length" doesn't really apply.

forget the nozzle size - it's the volume that stays constant, regardless of "in" or "out", it's going to be exactly the same volume of plastic that goes out as goes in.

sooo, you take 2.85, divide by 2 to get the radius, then you want pi-r-squared, that gives you the area of the filament being fed in. theeen, you convert the feed rate120mm/min into seconds (divide by 60), and multiply it by the area, that gives you volume per second.

sooo.... (2.85/2)^2 * 3.14159265358979323 * (120/60) = eerr.... something

Edited 1 time(s). Last edit at 04/12/2016 08:28PM by lkcl.

|

Re: FuseBox ~$300 CoreXY Printer April 15, 2016 03:37PM |

Registered: 8 years ago Posts: 12 |

I will start to order parts for FB2020 by Ax printer in a few days, and since that is my first printer i have few questions.

Ax is planning to upgrade Z axis smooth rods from 8 to 10mm and i will do the same, but idk if i should also upgrade leadscrew to 10mm or stay with 8mm?

Is motedis.com&www.dold-mechatronik.de leadscrew/nut worth the price (leadscrew is 5€ & brass nut is 14€) or should i order cheap $7 chinese leadscrew/nut?

Edited 1 time(s). Last edit at 04/15/2016 04:08PM by ivo95.

Ax is planning to upgrade Z axis smooth rods from 8 to 10mm and i will do the same, but idk if i should also upgrade leadscrew to 10mm or stay with 8mm?

Is motedis.com&www.dold-mechatronik.de leadscrew/nut worth the price (leadscrew is 5€ & brass nut is 14€) or should i order cheap $7 chinese leadscrew/nut?

Edited 1 time(s). Last edit at 04/15/2016 04:08PM by ivo95.

|

Re: FuseBox ~$300 CoreXY Printer April 15, 2016 04:09PM |

Registered: 8 years ago Posts: 776 |

Quote

ivo95

I will start to order parts for FB2020 by Ax printer in a few days, and since that is my first printer i have few questions.

Ax is planning to upgrade Z axis smooth rods from 8 to 10mm and i will do the same, but idk if i should also upgrade leadscrew to 10mm or stay with 8mm?

Is motedis.com&www.dold-mechatronik.de leadscrew/nut worth the price (leadscrew is 5€ & brass nut is 14€) or should i order cheap $7 chinese leadscrew/nut?

Is mk8 full metal extruder kit good or waste of money?

for 3.0mm filament: waste of money as-is but the parts in the kit are actually really useful, if you find it a pain to source qty strong spring qty1 604 bearing blah blah it's worth it.

leadscrews, there's some discussion about those, it's up to you. some people consider the lack of precision (less steps) to be an acceptable trade-off vs M8x1 threaded bar. personally i'm happy with the accuracy, although you do really need to get reputable bar and nuts. don't for goodness sake go with cheap. just... don't. variations in the screw-thread will screw _you_ over

z-rods to 10mm? mmm.... mehh. i wouldn't say that's a high priority. what completely overshadows that is a design flaw in the FuseBox, which i've documented here: [reprap.org]

|

Re: FuseBox ~$300 CoreXY Printer April 15, 2016 06:29PM |

Registered: 8 years ago Posts: 12 |

Quote

lkcl

z-rods to 10mm? mmm.... mehh. i wouldn't say that's a high priority. what completely overshadows that is a design flaw in the FuseBox, which i've documented here: [reprap.org]

I think that ax (http://www.thingiverse.com/thing:1313587) already fixed that problem in his design: [thingiverse-production-new.s3.amazonaws.com]

|

Re: FuseBox ~$300 CoreXY Printer April 15, 2016 06:54PM |

Registered: 8 years ago Posts: 776 |

Quote

ivo95

Quote

lkcl

z-rods to 10mm? mmm.... mehh. i wouldn't say that's a high priority. what completely overshadows that is a design flaw in the FuseBox, which i've documented here: [reprap.org]

I think that ax (http://www.thingiverse.com/thing:1313587) already fixed that problem in his design: [thingiverse-production-new.s3.amazonaws.com]

he's made an attempt to do so, but that's not diagonal bracing, is it? yes he's moved the bar back, yes it's 20mm extrusion, but... let me think.... if the crossbar was soundly attached using the trick that Edvardas recommended, which is to machine the ends of the crossbar to ABSOLUTELY dead-flat, then drill holes in the side-bars and put allen-key bolts through, it's described here:

[forums.reprap.org]

*if* he did that, *and* the forward-facing bars were somehow rigidly attached to the plastic in several places, *then* any push on one side would turn into a rotation of the linear bearings, which would be resisted by the z-rods and you've solved the problem.

but otherwise, ax's design is critically-dependent on the shear-strength of the plastic connecting the cross-bar, and i don't believe it's in any way sufficient.

diagonal cross-bracing from the very top *and* bottom of the linear z-rail parts, all the way to the middle z-nut on both left *AND* right sides is about the only way to stop see-sawing. and even then, with the Fusebox only having a single 45mm bearing spanning 140mm it's still pretty touch-and-go.

with the Sandwich200 i at least stand a chance because i have had to put in a whopping 75mm worth of linear bearings (one LM8UU and one LM8LUU).on each side.

|

Re: FuseBox ~$300 CoreXY Printer April 15, 2016 08:48PM |

Registered: 8 years ago Posts: 12 |

Quote

lkcl

Quote

ivo95

Quote

lkcl

z-rods to 10mm? mmm.... mehh. i wouldn't say that's a high priority. what completely overshadows that is a design flaw in the FuseBox, which i've documented here: [reprap.org]

I think that ax (http://www.thingiverse.com/thing:1313587) already fixed that problem in his design: [thingiverse-production-new.s3.amazonaws.com]

he's made an attempt to do so, but that's not diagonal bracing, is it? yes he's moved the bar back, yes it's 20mm extrusion, but... let me think.... if the crossbar was soundly attached using the trick that Edvardas recommended, which is to machine the ends of the crossbar to ABSOLUTELY dead-flat, then drill holes in the side-bars and put allen-key bolts through, it's described here:

[forums.reprap.org]

*if* he did that, *and* the forward-facing bars were somehow rigidly attached to the plastic in several places, *then* any push on one side would turn into a rotation of the linear bearings, which would be resisted by the z-rods and you've solved the problem.

but otherwise, ax's design is critically-dependent on the shear-strength of the plastic connecting the cross-bar, and i don't believe it's in any way sufficient.

diagonal cross-bracing from the very top *and* bottom of the linear z-rail parts, all the way to the middle z-nut on both left *AND* right sides is about the only way to stop see-sawing. and even then, with the Fusebox only having a single 45mm bearing spanning 140mm it's still pretty touch-and-go.

with the Sandwich200 i at least stand a chance because i have had to put in a whopping 75mm worth of linear bearings (one LM8UU and one LM8LUU).on each side.

He is also using longer supports with 4 LM8UU's.

BTW what do you think about removing printed z-rail parts and just use 50x20 angle bar (http://www.motedis.co.uk/shop/Semi-finished-products/Light-metal-profiles-not-anodized/Angle-bars-not-equal-sided/Angle-bar-not-anodized-50x20x2mm::999993422.html) with one SCS10LUU on each side (http://www.robotdigg.com/product/423/SCS10LUU+Slide+Unit)?

|

Re: FuseBox ~$300 CoreXY Printer April 16, 2016 04:54AM |

Registered: 8 years ago Posts: 776 |

Quote

ivo95

He is also using longer supports with 4 LM8UU's.

ohh ok. that would be better, then. still, the twisting moment is on the plastic, you can see there's some underneath the H-bar.

Quote

BTW what do you think about removing printed z-rail parts and just use 50x20 angle bar (http://www.motedis.co.uk/shop/Semi-finished-products/Light-metal-profiles-not-anodized/Angle-bars-not-equal-sided/Angle-bar-not-anodized-50x20x2mm::999993422.html) with one SCS10LUU on each side (http://www.robotdigg.com/product/423/SCS10LUU+Slide+Unit)?

those angle-bars are 2mm thick - monsters!

should be quite a bit of strength in those in the 50mm direction. but, i can't picture in my head how they would be arranged, would you be happy to do some drawings?

should be quite a bit of strength in those in the 50mm direction. but, i can't picture in my head how they would be arranged, would you be happy to do some drawings?

|

Re: FuseBox ~$300 CoreXY Printer April 16, 2016 08:15AM |

Registered: 8 years ago Posts: 12 |

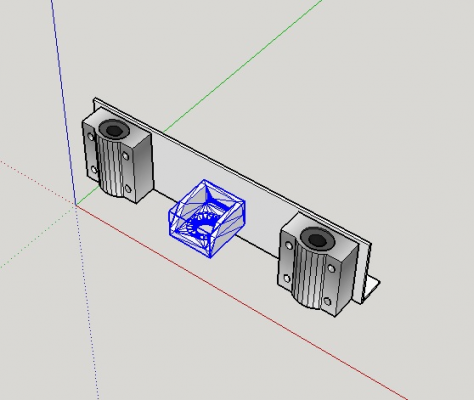

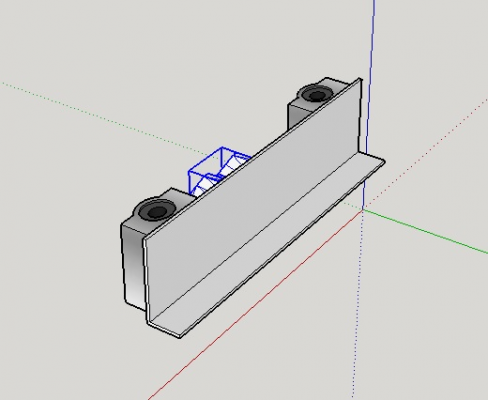

Something like this:

Or maybe 80x80x3mm (cut to 80x30) with 2 LM10UU per side in printed housing to reduce weight...

I never held those bearings in my hand so i don't know how stiff they are on the rods, so i would really like to hear your opinion.

Do we need one or two per side when they are connected with 2mm/3mm alu plate, is that to much weight for z motor to handle...?

Or maybe 80x80x3mm (cut to 80x30) with 2 LM10UU per side in printed housing to reduce weight...

I never held those bearings in my hand so i don't know how stiff they are on the rods, so i would really like to hear your opinion.

Do we need one or two per side when they are connected with 2mm/3mm alu plate, is that to much weight for z motor to handle...?

|

Re: FuseBox ~$300 CoreXY Printer April 16, 2016 08:35AM |

Registered: 8 years ago Posts: 776 |

aw yeah, that'd be awesome! yeah that wouldn't move at aaall

you could use the L-bit to mount the printbed forward extrusion, use those right-angle corner brackets to mount them if you used the 80mm L.

you could use the L-bit to mount the printbed forward extrusion, use those right-angle corner brackets to mount them if you used the 80mm L.Quote

Or maybe 80x80x3mm (cut to 80x30) with 2 LM10UU per side in printed housing to reduce weight...

yeah 80mm depth sounds more paranoid. i have a 75mm structure and i get about 2-3mm above and below and still have 200mm of travel in the z direction (300mm rods minus 10mm for the holders = 280mm, minus 75mm equals 5mm remaining travel!)

Quote

I never held those bearings in my hand so i don't know how stiff they are on the rods, so i would really like to hear your opinion.

me neither but regardless of ID you never, ever want to be doing "twisting" on a short linear bearing, that's Generally Bad. if you can increase the distance (use two like you're suggesting) then that's a greatly reduced "lever" effect on the bearing(s).

Quote

Do we need one or two per side when they are connected with 2mm/3mm alu plate,

i'd say 2, definitely.

Quote

is that too much weight for z motor to handle...?

i doubt it is, very much. if you were looking at 2kg i'd imagine you'd need to start to be concerned, but my finger-in-the-air "engineering problems radar" feels that the weight of the bed is more of a concern than the brackets. think about it: the centre of gravity of the bed is a full 120mm out from where the rods are, but the brackets are right there, mm away from the rods. so the bed will cause twisting, but the bracket won't. and the M8x1 rods themselves are pretty high-geared. you wanted to use one of those anti-backlash rods, didn't you?

cool idea with the L-bracket, i like it a lot!

|

Re: FuseBox ~$300 CoreXY Printer April 17, 2016 06:26AM |

Registered: 8 years ago Posts: 269 |

To clear things up with the FB2020. I've actually substituted out the plastic brace for another cross bar using the standard bracing brackets, however, this is likely to change again and I'm probably going to change the brackets out to a different design and shift the brace back when I have sorted 3 point levelling and use more bracing or recommend a 3rd brace in the middle to stiffen it up if keeping with the 4 point version. I may slip a couple of plastic braces in mine in the middle to try and tighten it up a bit more as I'm finding that while the front brace helps, there's still movement, which I want to get rid of. I may even look at getting an aluminium bed plate and brace cut, which would take a lot of the twist out as well.

As for the 10 or 12 mm Z smooth rods, I'm doing this too reduce wobble and stiffen the Z up further, after speaking to a few people 8mm rods on a cantilever bed = bad. Take a printer like the Ultimaker 2 or other higher end commercial printer that uses a cantilever design. The Z is will use 10 or 12mm rods. I'm yet to redesign things as I've not had time or money to get parts in, so it could be a little while, so I'd stick with the 8mm for the moment. I'll freely admit I have issues with the Z axis and levelling and I'm looking at improving it greatly.

As for the 10 or 12 mm Z smooth rods, I'm doing this too reduce wobble and stiffen the Z up further, after speaking to a few people 8mm rods on a cantilever bed = bad. Take a printer like the Ultimaker 2 or other higher end commercial printer that uses a cantilever design. The Z is will use 10 or 12mm rods. I'm yet to redesign things as I've not had time or money to get parts in, so it could be a little while, so I'd stick with the 8mm for the moment. I'll freely admit I have issues with the Z axis and levelling and I'm looking at improving it greatly.

|

Re: FuseBox ~$300 CoreXY Printer April 17, 2016 07:17AM |

Registered: 8 years ago Posts: 776 |

Quote

Ax

To clear things up with the FB2020. I've actually substituted out the plastic brace for another cross bar

photos would help, but i can tell you, right now, you're never *ever* going to get a stiff frame until you've braced *all five* frame faces (i filled them all in with hardboard, mounted on 16 points *per board*) and put original Misumi1515 brackets in the top corners or used those 50mm triangular folded steel right-angle brackets i mentioned earlier. they're a pain to find on ebay (keyword searches don't cut it) so here's a link [www.ebay.co.uk]

Quote

using the standard bracing brackets, however, this is likely to change again and I'm probably going to change the brackets out to a different design and shift the brace back when I have sorted 3 point levelling and use more bracing or recommend a 3rd brace in the middle to stiffen it up if keeping with the 4 point version. I may slip a couple of plastic braces in mine in the middle to try and tighten it up a bit more as I'm finding that while the front brace helps, there's still movement, which I want to get rid of.

it's not clear here if you're referring to the frame or to the printbed.

Quote

I may even look at getting an aluminium bed plate and brace cut, which would take a lot of the twist out as well.

yes i got an Alu MK3 from reprap.me, including the clear perspex mounting, and because of that i am wondering why the heck i put in the extrusion H (cross) bar under the middle of the bed. it's completely pointless where it is, and ineffective anyway. now with the Alu MK3 and perspex, the bed's absolutely rock-solid, the two forward-facing bars do not move *at* all.

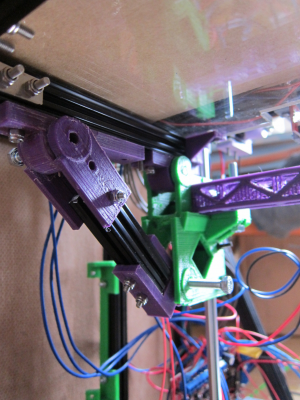

but, more than that, remember that i've done a "folding" design so there are additional bars, left and right, at an angle of 45 degrees running *forwards* to the middle of the bed, running to the bottom of a 75mm long linear assembly (see picture below). these are waaaay more effective than having bits of plastic sticking out of 45mm vertical linear assemblies, where there are only 2 M3 mount-points a few centimetres apart. don't even know how much it is, i completely ignored the original Z-Rail design.

howeverrrr... i can put even a screwdriver into the corner of one of the adjustment screws and i must be getting around 0.1mm of see-saw effect, the cantilevering around the Z-Nut (70mm each side) is so large.

Quote

As for the 10 or 12 mm Z smooth rods, I'm doing this too reduce wobble and stiffen the Z up further, after speaking to a few people 8mm rods on a cantilever bed = bad. Take a printer like the Ultimaker 2 or other higher end commercial printer that uses a cantilever design. The Z is will use 10 or 12mm rods. I'm yet to redesign things as I've not had time or money to get parts in, so it could be a little while, so I'd stick with the 8mm for the moment. I'll freely admit I have issues with the Z axis and levelling and I'm looking at improving it greatly.

ok that's good to know, about using 10 to 12mm rods.

Edited 2 time(s). Last edit at 04/17/2016 07:21AM by lkcl.

|

Re: FuseBox ~$300 CoreXY Printer April 17, 2016 10:37AM |

Registered: 8 years ago Posts: 269 |

Quote

lkcl

Quote

Ax

To clear things up with the FB2020. I've actually substituted out the plastic brace for another cross bar

photos would help, but i can tell you, right now, you're never *ever* going to get a stiff frame until you've braced *all five* frame faces (i filled them all in with hardboard, mounted on 16 points *per board*) and put original Misumi1515 brackets in the top corners or used those 50mm triangular folded steel right-angle brackets i mentioned earlier. they're a pain to find on ebay (keyword searches don't cut it) so here's a link [www.ebay.co.uk]

Quote

using the standard bracing brackets, however, this is likely to change again and I'm probably going to change the brackets out to a different design and shift the brace back when I have sorted 3 point levelling and use more bracing or recommend a 3rd brace in the middle to stiffen it up if keeping with the 4 point version. I may slip a couple of plastic braces in mine in the middle to try and tighten it up a bit more as I'm finding that while the front brace helps, there's still movement, which I want to get rid of.

it's not clear here if you're referring to the frame or to the printbed.

Quote

I may even look at getting an aluminium bed plate and brace cut, which would take a lot of the twist out as well.

yes i got an Alu MK3 from reprap.me, including the clear perspex mounting, and because of that i am wondering why the heck i put in the extrusion H (cross) bar under the middle of the bed. it's completely pointless where it is, and ineffective anyway. now with the Alu MK3 and perspex, the bed's absolutely rock-solid, the two forward-facing bars do not move *at* all.

but, more than that, remember that i've done a "folding" design so there are additional bars, left and right, at an angle of 45 degrees running *forwards* to the middle of the bed, running to the bottom of a 75mm long linear assembly (see picture below). these are waaaay more effective than having bits of plastic sticking out of 45mm vertical linear assemblies, where there are only 2 M3 mount-points a few centimetres apart. don't even know how much it is, i completely ignored the original Z-Rail design.

howeverrrr... i can put even a screwdriver into the corner of one of the adjustment screws and i must be getting around 0.1mm of see-saw effect, the cantilevering around the Z-Nut (70mm each side) is so large.

Quote

As for the 10 or 12 mm Z smooth rods, I'm doing this too reduce wobble and stiffen the Z up further, after speaking to a few people 8mm rods on a cantilever bed = bad. Take a printer like the Ultimaker 2 or other higher end commercial printer that uses a cantilever design. The Z is will use 10 or 12mm rods. I'm yet to redesign things as I've not had time or money to get parts in, so it could be a little while, so I'd stick with the 8mm for the moment. I'll freely admit I have issues with the Z axis and levelling and I'm looking at improving it greatly.

ok that's good to know, about using 10 to 12mm rods.

I was talking about the bed. I've actually just converted it to 3 point levelling, with an extra plastic brace in the middle. This has made the bed a lot more rigid, so it doesn't see-saw from the main bed legs and so much more easy to level compared to a 4 point bed. Like yours, I do get some movement around the Z nut, which will probably be changed out at some point.

I realise that things aren't as stiff as they could be for the main frame and yes there may be some flex, but it's not something I've actually noticed. I do have a plan to encase the bottom and sides with Acrylic sheet, which will stiffen the frame, but that's one of the last things to sort out.

|

Re: FuseBox ~$300 CoreXY Printer April 17, 2016 11:31AM |

Registered: 8 years ago Posts: 776 |

Quote

Ax

I was talking about the bed. I've actually just converted it to 3 point levelling, with an extra plastic brace in the middle. This has made the bed a lot more rigid, so it doesn't see-saw from the main bed legs and so much more easy to level compared to a 4 point bed.

cool - that would be good to see, can you take some pictures?

|

Re: FuseBox ~$300 CoreXY Printer April 17, 2016 11:55AM |

Registered: 8 years ago Posts: 269 |

Quote

lkcl

Quote

Ax

I was talking about the bed. I've actually just converted it to 3 point levelling, with an extra plastic brace in the middle. This has made the bed a lot more rigid, so it doesn't see-saw from the main bed legs and so much more easy to level compared to a 4 point bed.

cool - that would be good to see, can you take some pictures?

I'm planning on updating things on the Thingiverse page in a bit, once I have the RRD controller fixed properly. You can actually knock 15mm off the main legs of the bed with the 3 point system as they don't need to be as long, which may cause a little extra expense, due to them being shorter, but the pay off is that it's really simple to level.

|

Re: FuseBox ~$300 CoreXY Printer April 17, 2016 01:13PM |

Registered: 8 years ago Posts: 776 |

Quote

Ax

I'm planning on updating things on the Thingiverse page in a bit, once I have the RRD controller fixed properly. You can actually knock 15mm off the main legs of the bed with the 3 point system as they don't need to be as long, which may cause a little extra expense, due to them being shorter, but the pay off is that it's really simple to level.

yyeah, it's funny, isn't it - first time i saw 4-point bed levelling i was like, "unnff??" but then i thought some more and went, "hmmm, if the actual bed is twisted, a 4-point system could put a bit of bend on it and straighten it out, hmmm...." - so it's a kinda... 6 of 1, half a dozen of the other choice. if you've got a bed made of a material that's *guaranteed* to be dead-flat, you'd be fine with a 3-point system.

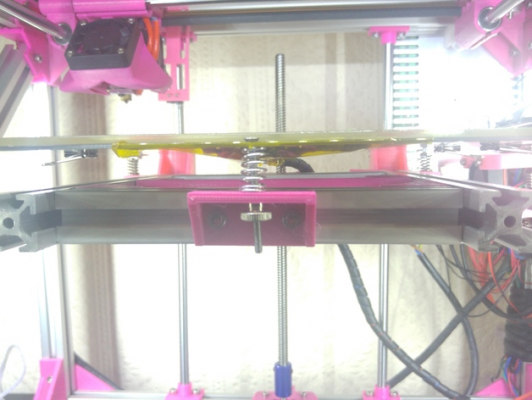

i stayed with the 4-point thing, and the Alu MK3 kit from reprap.me including the perspex meant i could stiffen up the bed rails. photo here, you can see, ok you can't see there are clips on the inner of the rails, they're on the other side on this photo, but the ones on the outside, you can see there's a nut embedded in the plastic, sandwiched between the perspex. that way, the top screw spring can be compressed and the screw head stays below the level of the glass.

|

Re: FuseBox ~$300 CoreXY Printer April 17, 2016 05:13PM |

Registered: 8 years ago Posts: 269 |

Quote

lkcl

Quote

Ax

I was talking about the bed. I've actually just converted it to 3 point levelling, with an extra plastic brace in the middle. This has made the bed a lot more rigid, so it doesn't see-saw from the main bed legs and so much more easy to level compared to a 4 point bed.

cool - that would be good to see, can you take some pictures?

Thingiverse updated. Bed images uploaded..

Front:

Underneath:

|

Re: FuseBox ~$300 CoreXY Printer April 17, 2016 05:29PM |

Registered: 8 years ago Posts: 776 |

Quote

Ax

Thingiverse updated. Bed images uploaded..

pppink - niiice! i'm a fan of bright colours too

ok so a long cross-piece to keep the cable out the way... what else is that for? if you have dual cross-bar (front and back it looks like) the plastic cross-piece shouuuldn't be needed.... instead of the corner-plastic pieces, have you thought to use the trick of drilling from the outside then putting an allen-key bolt down into the (self-tapping) end of the crossbars? edvardas tells me that that technique is amazingly strong, but you have to make sure the ends are machined (or filed) dead-level.

the bed looks pretty sturdy, so you'd not have the problem of bed-warping or twisting throwing the z-levelling out...

looks really nice, Ax.

|

Re: FuseBox ~$300 CoreXY Printer April 17, 2016 05:35PM |

Registered: 8 years ago Posts: 776 |

oh, oh, another way you could do this, without needing to cut (large) aluminium L-brackets, is, use these [www.ebay.co.uk] right-angle corner-braces in combination with 2 upright 75mm (or so) extrusions, and a long horizontal extrusion to make an H, you could create a simple, small z-nut holder which would mount a z-nut close to the horizontal extrusion, and then create mounting brackets for 4 linear bearings. or, use that aluminium-drilling technique instead (put an allen-key hex-bolt through one extrusion into the self-tapping hole down the middle of the other). i really like the L-bracket way, though the cutting and drilling is making me think twice about using it.

|

Re: FuseBox ~$300 CoreXY Printer April 17, 2016 05:55PM |

Registered: 8 years ago Posts: 269 |

Quote

lkcl

Quote

Ax

Thingiverse updated. Bed images uploaded..

pppink - niiice! i'm a fan of bright colours too

ok so a long cross-piece to keep the cable out the way... what else is that for? if you have dual cross-bar (front and back it looks like) the plastic cross-piece shouuuldn't be needed.... instead of the corner-plastic pieces, have you thought to use the trick of drilling from the outside then putting an allen-key bolt down into the (self-tapping) end of the crossbars? edvardas tells me that that technique is amazingly strong, but you have to make sure the ends are machined (or filed) dead-level.

the bed looks pretty sturdy, so you'd not have the problem of bed-warping or twisting throwing the z-levelling out...

looks really nice, Ax.

It's just extra stiffening, not needed, but tbh better than not being there. The whole point of using brackets is that someone with minimal tools can assemble it.

|

Re: FuseBox ~$300 CoreXY Printer April 17, 2016 06:57PM |

Registered: 8 years ago Posts: 12 |

Quote

lkcl

oh, oh, another way you could do this, without needing to cut (large) aluminium L-brackets, is, use these [www.ebay.co.uk] right-angle corner-braces in combination with 2 upright 75mm (or so) extrusions, and a long horizontal extrusion to make an H, you could create a simple, small z-nut holder which would mount a z-nut close to the horizontal extrusion, and then create mounting brackets for 4 linear bearings. or, use that aluminium-drilling technique instead (put an allen-key hex-bolt through one extrusion into the self-tapping hole down the middle of the other). i really like the L-bracket way, though the cutting and drilling is making me think twice about using it.

filipe solution is the best: G&C Printer, you can probably sit on that bed

, so i will do it like him.

, so i will do it like him.12mm rods, 4xSCV12UU bolted to 20x60 profile

|

Re: FuseBox ~$300 CoreXY Printer April 17, 2016 07:54PM |

Registered: 8 years ago Posts: 776 |

Quote

ivo95

filipe solution is the best: G&C Printer, you can probably sit on that bed, so i will do it like him.

12mm rods, 4xSCV12UU bolted to 20x60 profile

good find - looks monstrous

|

belt judder due to teeth being on bearings April 17, 2016 07:57PM |

Registered: 8 years ago Posts: 776 |

[forums.reprap.org] just fyi.

|

Re: FuseBox ~$300 CoreXY Printer April 17, 2016 08:40PM |

Registered: 8 years ago Posts: 269 |

Quick heads up, if you're interested, I've got a stream up of the FB2020 in action, can be seen at [home.axmod.co.uk]

|

Re: FuseBox ~$300 CoreXY Printer April 20, 2016 11:39AM |

Registered: 9 years ago Posts: 251 |

|

Re: FuseBox ~$300 CoreXY Printer April 20, 2016 11:09PM |

Registered: 8 years ago Posts: 25 |

Sorry, only registered users may post in this forum.