FuseBox ~$300 CoreXY Printer

Posted by AlexY

|

Re: FuseBox ~$300 CoreXY Printer April 21, 2016 05:24AM |

Registered: 8 years ago Posts: 269 |

Quote

widespreaddeadhead

Has anyone put together a build guide or set of videos? I just received all my parts for 2 fuseboxes, and I might build one to get the feel for it, and document the 2nd build for a guide.

I'm waiting on the extrusions to arrive for the next FB2020 iteration, I'm starting to convert my Prusas over. This will be the documentation one, it should be similar to the Fusebox.

|

Re: FuseBox ~$300 CoreXY Printer April 21, 2016 10:36AM |

Registered: 9 years ago Posts: 251 |

Quote

Ax

I'm waiting on the extrusions to arrive for the next FB2020 iteration, I'm starting to convert my Prusas over. This will be the documentation one, it should be similar to the Fusebox.

Awesome! I follow your 2020 iteration, and would love to build one. I also happen to have my Prusa making parts for the fuseboxes, but then want to convert it into something else. Looking forward to your build!

Edited 1 time(s). Last edit at 04/21/2016 10:52AM by widespreaddeadhead.

|

Re: FuseBox ~$300 CoreXY Printer April 21, 2016 04:29PM |

Registered: 8 years ago Posts: 776 |

Quote

Ax

Quick heads up, if you're interested, I've got a stream up of the FB2020 in action, can be seen at [home.axmod.co.uk]

looked at it a couple days ago ax, it looks really good. is it stable? on the sandwich200v1 the bed can be seen to be pushed around quite a bit if the filament ends up getting higher than it should (over-extrusion at the corners being the usual culprit).

oh btw alfa-tech3d.com started stocking 20x20mm extrusion as well as sliding T-locks and cast aluminium corner braces with interlocks into the extrusion rails. looks really effective and strong, i may get some next time for a rev3.

Edited 1 time(s). Last edit at 04/21/2016 05:00PM by lkcl.

|

Re: FuseBox ~$300 CoreXY Printer April 21, 2016 04:58PM |

Registered: 8 years ago Posts: 269 |

Quote

lkcl

Quote

Ax

Quick heads up, if you're interested, I've got a stream up of the FB2020 in action, can be seen at [home.axmod.co.uk]

looked at it a couple days ago ax, it looks really good. is it stable? on the sandwich200v1 the bed can be seen to be pushed around quite a bit if the filament ends up getting higher than it should (over-extrusion at the corners being the usual culprit).

oh btw alfa-tech.com started stocking 20x20mm extrusion as well as sliding T-locks and cast aluminium corner braces with interlocks into the extrusion rails. looks really effective and strong, i may get some next time for a rev3.

Bed is damn stable, the 3 point levelling has made it a breeze to level out and it stays. I had to tweak it today after about 30 hours of printing, but that was just me being anal about the first layers, it also could have just been the filament, old ColorFabb XT that's just been stored in a box, so I could have left it and it would have been fine. I'm still tweaking settings for my everyday filament, ColorFabb NGEN as I'm getting random bobbing on corners and layer ends. I'm probably going to bring the flow rate down a few percent to see what happens. Other that that, I'm to the point with it that I don't even have to look at it after kicking off a print, so, so far it's damn reliable, although it's only spent 4 days in the farm, so time will tell. All my printers run pretty much 24/7 and the FB2020 has been no exception and really doesn't need touching.

That link seems to lead to a dead site or holding page, for extrusions I go to Misumi, they don't deal with the public in the EU, but I get them all through my business. I'd like to check prices though. A full extrusion set with the a bag of 100 cheap T-Nuts from Misumi is £46.30, the nuts being the most expensive part at £12.07 ex VAT. The 147mm extrusions being the most expensive at £1.90 ex VAT. Basically the Extrusions cost me peanuts at a total of £26.84 ex VAT. The brackets from Misumi on the other hand are expensive as hell.

|

Re: FuseBox ~$300 CoreXY Printer April 21, 2016 05:07PM |

Registered: 8 years ago Posts: 776 |

Quote

Ax

Quote

lkcl

Quote

Ax

Quick heads up, if you're interested, I've got a stream up of the FB2020 in action, can be seen at [home.axmod.co.uk]

looked at it a couple days ago ax, it looks really good. is it stable? on the sandwich200v1 the bed can be seen to be pushed around quite a bit if the filament ends up getting higher than it should (over-extrusion at the corners being the usual culprit).

oh btw alfa-tech3d.com started stocking 20x20mm extrusion as well as sliding T-locks and cast aluminium corner braces with interlocks into the extrusion rails. looks really effective and strong, i may get some next time for a rev3.

Bed is damn stable, the 3 point levelling has made it a breeze to level out and it stays.

cooool.

Quote

I had to tweak it today after about 30 hours of printing, but that was just me being anal about the first layers, it also could have just been the filament, old ColorFabb XT that's just been stored in a box, so I could have left it and it would have been fine. I'm still tweaking settings for my everyday filament, ColorFabb NGEN as I'm getting random bobbing on corners and layer ends. I'm probably going to bring the flow rate down a few percent to see what happens.

yeah i get that too - i don't get it with repsnapper because repsnapper has an option to add "curves" automatically at corners. it's the only gcode-generating software i've found that does it, and it's extremely effective at stopping the corner-blobbing. repsnapper however didn't suit me for other reasons - the parts i was printing at the time were too complex for it.

Quote

Other that that, I'm to the point with it that I don't even have to look at it after kicking off a print, so, so far it's damn reliable, although it's only spent 4 days in the farm, so time will tell. All my printers run pretty much 24/7 and the FB2020 has been no exception and really doesn't need touching.

!!

Quote

That link seems to lead to a dead site or holding page, for extrusions I go to Misumi, they don't deal with the public in the EU, but I get them all through my business. I'd like to check prices though. A full extrusion set with the a bag of 100 cheap T-Nuts from Misumi is £46.30, the nuts being the most expensive part at £12.07 ex VAT. The 147mm extrusions being the most expensive at £1.90 ex VAT. Basically the Extrusions cost me peanuts at a total of £26.84 ex VAT. The brackets from Misumi on the other hand are expensive as hell.

i noticed - it's alfa-tech3d.com. he's quoting $EUR 18 for 600mm - and $EUR 0.62 per M3 T-Nut. T-slot brackets $EUR 1.15 each.

... i don't have a company account.... next time (sandwich200 v3) can i order 2020 misumi extrusion sets through you?

|

Re: FuseBox ~$300 CoreXY Printer April 21, 2016 05:26PM |

Registered: 8 years ago Posts: 269 |

Quote

lkcl

Quote

Ax

Quote

lkcl

Quote

Ax

Quick heads up, if you're interested, I've got a stream up of the FB2020 in action, can be seen at [home.axmod.co.uk]

looked at it a couple days ago ax, it looks really good. is it stable? on the sandwich200v1 the bed can be seen to be pushed around quite a bit if the filament ends up getting higher than it should (over-extrusion at the corners being the usual culprit).

oh btw alfa-tech3d.com started stocking 20x20mm extrusion as well as sliding T-locks and cast aluminium corner braces with interlocks into the extrusion rails. looks really effective and strong, i may get some next time for a rev3.

Bed is damn stable, the 3 point levelling has made it a breeze to level out and it stays.

cooool.

Quote

I had to tweak it today after about 30 hours of printing, but that was just me being anal about the first layers, it also could have just been the filament, old ColorFabb XT that's just been stored in a box, so I could have left it and it would have been fine. I'm still tweaking settings for my everyday filament, ColorFabb NGEN as I'm getting random bobbing on corners and layer ends. I'm probably going to bring the flow rate down a few percent to see what happens.

yeah i get that too - i don't get it with repsnapper because repsnapper has an option to add "curves" automatically at corners. it's the only gcode-generating software i've found that does it, and it's extremely effective at stopping the corner-blobbing. repsnapper however didn't suit me for other reasons - the parts i was printing at the time were too complex for it.

Quote

Other that that, I'm to the point with it that I don't even have to look at it after kicking off a print, so, so far it's damn reliable, although it's only spent 4 days in the farm, so time will tell. All my printers run pretty much 24/7 and the FB2020 has been no exception and really doesn't need touching.

!!

Quote

That link seems to lead to a dead site or holding page, for extrusions I go to Misumi, they don't deal with the public in the EU, but I get them all through my business. I'd like to check prices though. A full extrusion set with the a bag of 100 cheap T-Nuts from Misumi is £46.30, the nuts being the most expensive part at £12.07 ex VAT. The 147mm extrusions being the most expensive at £1.90 ex VAT. Basically the Extrusions cost me peanuts at a total of £26.84 ex VAT. The brackets from Misumi on the other hand are expensive as hell.

i noticed - it's alfa-tech3d.com. he's quoting $EUR 18 for 600mm - and $EUR 0.62 per M3 T-Nut. T-slot brackets $EUR 1.15 each.

... i don't have a company account.... next time (sandwich200 v3) can i order 2020 misumi extrusion sets through you?

Drop me a message, I'm sure we can sort something

|

Re: FuseBox ~$300 CoreXY Printer April 24, 2016 10:57PM |

Registered: 8 years ago Posts: 47 |

Quote

widespreaddeadhead

Has anyone put together a build guide or set of videos? I just received all my parts for 2 fuseboxes, and I might build one to get the feel for it, and document the 2nd build for a guide.

i was going to. but honestly it isnt really necessary. it really does just go together. you will be pulling it apart several times. the only recommendation i can make. is get the stamped nuts rather then the hex nuts. yes it is more but makes sliding the pieces together easier. id also pick up some drop in t-nuts if you can find some.

oh. lay everything out and use the pdf i uploaded with all the different extrusion lengths. then put screws and nuts on all the fittings. i built the front and back then mounted the side rails. of course i forgot to add the rod holders and motor mounts. if you cant find drop in tnuts. you can add a couple nuts into the slots and get some of those foam ear plugs. cut them down and stuff them on each side. i plan on doing this when i pull the frame apart one last time once i get everything together and moving.

|

Re: FuseBox ~$300 CoreXY Printer April 24, 2016 11:01PM |

Registered: 8 years ago Posts: 47 |

someone was asking about the belt path. i took a picture of mine and uploaded it to my carriage remix if anyone is needed to see how it routes. its a crude paint edit. thankfully inventor draws straight lines

[www.thingiverse.com]

[www.thingiverse.com]

|

Re: FuseBox ~$300 CoreXY Printer April 27, 2016 02:15PM |

Registered: 8 years ago Posts: 7 |

|

Re: FuseBox ~$300 CoreXY Printer April 27, 2016 07:31PM |

Registered: 8 years ago Posts: 776 |

Quote

dgcaste

Does the extruder run at other than 1/16 microstepping? Extruder is skipping occasionally and my driver is maxed out. I don't think it's the tension either.

try the compact 53:13 geared bowden design that i made, or can i suggest you get yourself an E3D "Titan" for GBP 45. if you're using 1.75mm filament you can make a replacement block for the filament exit in the extruder i designed, with a few simple geometric shapes: build instructions are here::[hands.com] - please bear in mind that it's GPLv3+ so if you sell or distribute the printer you're required to release the source code of modifications that you make to that person. if you're not familiar with the GPLv3+ please make sure you understand it fully.

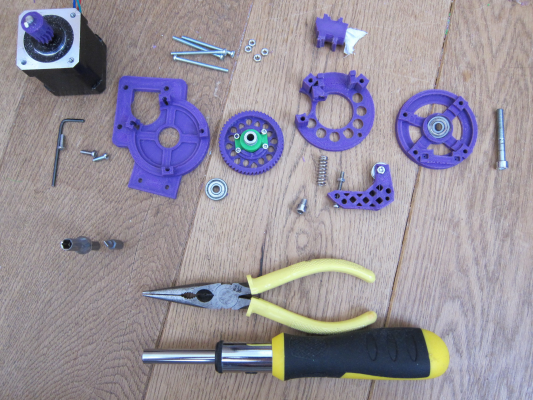

if you're interested i can re-run the STL file generation for you, as i reorganised the website recently. if you ask *really nicely* i can look at doing a 1.75mm adapter fitting for you, i have some 1.75mm bowden tube fittings here so could make sure those fit, beforehand. here's the parts and tools, laid out:

reducing micro-stepping does *not* actually increase torque, it merely reduces the PWM rate at which the Embedded Controller (and the stepper IC) have to operate at. this is a mistake that i did not understand, and i think it was dc42 who kindly explained it to me on the duet/ormerod forum. what it does is, it allows you to use coarser steps so that your EC and drivers can operate at a slower PWM rate and thus the motor can potentially be made to run at a higher RPM. so, instead of trying to drive your stepper at 100,000 pulses per second on 1/16th microstepping, you can drop to 50,000 at 1/8th, or 25,000 at 1/4 and so on, which means that you can then (if your EC can do it), look at doubling the RPM, then doubling it again, and so on. merely changing the microstepping rate DOES NOT INCREASE AVAILABLE TORQUE.

so if you do not *have* any gearing to be *able* to run at a slower PWM rate to achieve a faster motor RPM, all that will happen is that you create cruder (coarser) pulses.... at exactly the same RPM. WITH NO CHANGE IN TORQUE.

welcome to ungeared extruders they're s***t. took me two weeks to sort out a compact geared design i was happy with, and i'm now going with a flex3drive, designed by jason.

|

Re: FuseBox ~$300 CoreXY Printer April 27, 2016 07:43PM |

Registered: 8 years ago Posts: 269 |

|

Re: FuseBox ~$300 CoreXY Printer April 27, 2016 10:32PM |

Registered: 9 years ago Posts: 83 |

Quote

Ax

Personally, I'd take the Titan option. Injection moulded is far more accurate than a printed part.

Depends on the quality of the mold, and how much the manufacturer cared, but typically, yes, I'd agree.

Of course, you can ram as much torque as you can into a piece of filament, but if you're not melting it fast enough to go through the hotend, or if your hotend is jamming for some other reason, you're just wasting your time and filament.

Likewise, if you've got a bowden tube with more than one bend in it, or too sharp a bend, your enemy is friction, not a lack of torque.

@dgcaste: with your hot end at normal temperature, can you reliably push through filament by hand? Should take a little force, but you shouldn't have to really jam it.

|

Re: FuseBox ~$300 CoreXY Printer April 28, 2016 03:45AM |

Registered: 8 years ago Posts: 776 |

Quote

Ax

Personally, I'd take the Titan option. Injection moulded is far more accurate than a printed part.

in no particular order here's a quick "yes" and "no" - i'm agreeing with you buuuut it's not the full story. you can't make your own replacement injection-molded spare parts at home [yet!]. i've got 2 older revisions of the geared extruder and 1 extra spare set sitting in a bag just in case something breaks or wears out, i can bootstrap back to "working". on the other hand: if you've read jason's writeup on the Flex3Drive, wow that guy clearly knows what he's doing. he used a special type of plastic that's designed for injection-molding gears, where it's pre-treated and mixed with a lubricant that will work its way to the surface of the plastic during its (long) lifetime. i'm just spraying the PLA herringbone gears every week with silicone, and i'm happy with that for now until the Flex3Drive arrives. i haven't found a similar report from E3D (yet) on how they made the gears on the Titan, and i don't see a "lifetime warranty" offer from E3D like jason offers for the Flex3Drive's gears. maybe i haven't looked hard enough?

|

Re: FuseBox ~$300 CoreXY Printer April 28, 2016 05:11AM |

Registered: 8 years ago Posts: 269 |

Quote

lkcl

Quote

Ax

Personally, I'd take the Titan option. Injection moulded is far more accurate than a printed part.

in no particular order here's a quick "yes" and "no" - i'm agreeing with you buuuut it's not the full story. you can't make your own replacement injection-molded spare parts at home [yet!]. i've got 2 older revisions of the geared extruder and 1 extra spare set sitting in a bag just in case something breaks or wears out, i can bootstrap back to "working". on the other hand: if you've read jason's writeup on the Flex3Drive, wow that guy clearly knows what he's doing. he used a special type of plastic that's designed for injection-molding gears, where it's pre-treated and mixed with a lubricant that will work its way to the surface of the plastic during its (long) lifetime. i'm just spraying the PLA herringbone gears every week with silicone, and i'm happy with that for now until the Flex3Drive arrives. i haven't found a similar report from E3D (yet) on how they made the gears on the Titan, and i don't see a "lifetime warranty" offer from E3D like jason offers for the Flex3Drive's gears. maybe i haven't looked hard enough?

[e3d-online.com] - Moving Plastic parts are Self lubricating Delrin. As for Guarantee, you get E3D's backup and customer service, which is on a par with Amazon.

|

Re: FuseBox ~$300 CoreXY Printer April 28, 2016 08:25AM |

Registered: 8 years ago Posts: 7 |

I won't go into much detail right now because I'm at work, but enabling microstepping does reduce holding torque (and therefore turning torque) on a stepper motor. Stepper motors are synchronous DC motors, a magnet that aligns to a magnetic flux. In a two phase system, we simply adjust the current through the two phases to create a flux for the magnet to align to. What microstepping does is further refines the currents that we put in through the two phases. The more the two phases fight with each other to create an "in between" flux the lower the holding torque is going to be. The highest torque will exist when both phases contribute to the same flux, the lowest torque when the two phases oppose each other. So microstepping, in effect, trades torque for accuracy. It's not about PWM, but about magnetic fields.

|

Re: FuseBox ~$300 CoreXY Printer April 28, 2016 08:43AM |

Registered: 8 years ago Posts: 776 |

Quote

dgcaste

I won't go into much detail right now because I'm at work, but enabling microstepping does reduce holding torque (and therefore turning torque) on a stepper motor. Stepper motors are synchronous DC motors, a magnet that aligns to a magnetic flux. In a two phase system, we simply adjust the current through the two phases to create a flux for the magnet to align to. What microstepping does is further refines the currents that we put in through the two phases. The more the two phases fight with each other to create an "in between" flux the lower the holding torque is going to be. The highest torque will exist when both phases contribute to the same flux, the lowest torque when the two phases oppose each other. So microstepping, in effect, trades torque for accuracy. It's not about PWM, but about magnetic fields.

... someone'd better let dc42 know - he's under the impression that the work done (watts) per revolution remains the same, based on the supplied current, regardless of the stepping rate. the amount of work *per step* may increase. i had heard about the reduced holding torque thing. buuut... let's think it through. what you're saying is that the amount of torque is based on *subtraction* of - the difference between - two phases (sine-waves). if so, that would make a lot of sense. ok, so now i have some actual physics to let dc42 know about, which i wasn't aware of before, so thank you dgcaste.

ok, dgcaste, so yes, you might want to try reducing the microstepping. grat, thanks for that tip about just "pushing" the filament, not sure it'll work for me (i have 3mm bowden).

|

Re: FuseBox ~$300 CoreXY Printer April 28, 2016 09:02AM |

Registered: 8 years ago Posts: 7 |

Quote

lkcl

... someone'd better let dc42 know - he's under the impression that the work done (watts) per revolution remains the same, based on the supplied current, regardless of the stepping rate. the amount of work *per step* may increase. i had heard about the reduced holding torque thing. buuut... let's think it through. what you're saying is that the amount of torque is based on *subtraction* of - the difference between - two phases (sine-waves). if so, that would make a lot of sense. ok, so now i have some actual physics to let dc42 know about, which i wasn't aware of before, so thank you dgcaste.

Work is a funny thing in synchronous DC motors. It's called holding torque because it's the force at which you would break away from the established step and into the next synchronous step, which is what happens when the motor skips due to opposing forces. When you weaken the magnetic field because you fiddle with it to increase precision, you dilute the holding torque. There's other things happening in the motor such as friction, and if you remember from physics class static friction is higher than dynamic friction, so it's possible for the rotor to stop just before or after the synchronous step because the holding torque is not strong enough to overcome the static even though it was enough for the dynamic. Due to this, accuracy can suffer too and the rotor can lag.

Here's more:

[users.ece.utexas.edu]

[machinedesign.com]

|

Re: FuseBox ~$300 CoreXY Printer April 28, 2016 10:28AM |

Registered: 8 years ago Posts: 7 |

I have another question. The hotend fan on this has to be fairly thin in order to not hit the belt when the Y axis is maxed out, but using a thin fan that's already cropped by over 50% because of the design of the hot end air nozzle ends up giving very little airflow. Any suggestions on what kind of fan to use, or does anyone know of a remix that makes this less of a problem?

|

Re: FuseBox ~$300 CoreXY Printer April 28, 2016 11:40AM |

Registered: 8 years ago Posts: 269 |

Quote

dgcaste

I have another question. The hotend fan on this has to be fairly thin in order to not hit the belt when the Y axis is maxed out, but using a thin fan that's already cropped by over 50% because of the design of the hot end air nozzle ends up giving very little airflow. Any suggestions on what kind of fan to use, or does anyone know of a remix that makes this less of a problem?

You'll have to change the Y carriers as well, by my FB2020 carraige'll work. You'll be able to use your layer fan of choice then ot use the FB one..

|

Re: FuseBox ~$300 CoreXY Printer April 28, 2016 12:33PM |

Registered: 8 years ago Posts: 7 |

Quote

Ax

You'll have to change the Y carriers as well, by my FB2020 carraige'll work. You'll be able to use your layer fan of choice then ot use the FB one..

Can I keep the corner bearing and motor mounts? I like the idea of having the fan clear the bottom of the extrusions so I can achieve full airflow. Alternatively, I can design an angled interface part that does this with AlexY's design at least for the time being, and slice off your fan nozzle which is cool looking

|

Re: FuseBox ~$300 CoreXY Printer April 28, 2016 12:44PM |

Registered: 8 years ago Posts: 269 |

Quote

dgcaste

Quote

Ax

You'll have to change the Y carriers as well, by my FB2020 carraige'll work. You'll be able to use your layer fan of choice then ot use the FB one..

Can I keep the corner bearing and motor mounts? I like the idea of having the fan clear the bottom of the extrusions so I can achieve full airflow. Alternatively, I can design an angled interface part that does this with AlexY's design at least for the time being, and slice off your fan nozzle which is cool looking

Check the Mounts and idlers.. they're the same, just scaled up

So yup all you need is the Carriers and Carriage.. There's a newer version of the Carriage on the github repo at https://github.com/AxMod3DPrint/FB2020.

So yup all you need is the Carriers and Carriage.. There's a newer version of the Carriage on the github repo at https://github.com/AxMod3DPrint/FB2020.I'm actually in the midst of building a tall FB2020 now.. should end up with about 250-300 mm Z height. I leave the actual number until I have it running, so it's a surprise, although the parts came from a donor Prusa i3 and the Leadscrew is about 50-100mmmm too short.. things have been jury rigged until I sort out a 350-400mm one

|

Re: FuseBox ~$300 CoreXY Printer April 28, 2016 06:49PM |

Registered: 10 years ago Posts: 14,672 |

Quote

lkcl

... someone'd better let dc42 know - he's under the impression that the work done (watts) per revolution remains the same, based on the supplied current, regardless of the stepping rate. the amount of work *per step* may increase..

I am certain that I have never made such a statement, because it is so obviously untrue. Kindly link to the post which gave you that impression. The work done per revolution will depend on the load. Higher loads will result in a greater angle of slip, which will change the phase relationship between the back emf and the current, which in turn will increase the electrical power input.

Quote

dgcaste

Work is a funny thing in synchronous DC motors. It's called holding torque because it's the force at which you would break away from the established step and into the next synchronous step, which is what happens when the motor skips due to opposing forces. When you weaken the magnetic field because you fiddle with it to increase precision, you dilute the holding torque. There's other things happening in the motor such as friction, and if you remember from physics class static friction is higher than dynamic friction, so it's possible for the rotor to stop just before or after the synchronous step because the holding torque is not strong enough to overcome the static even though it was enough for the dynamic. Due to this, accuracy can suffer too and the rotor can lag.

Here's more:

[users.ece.utexas.edu]

[machinedesign.com]

The first of those references goes into a lot of useful detail. On page 4 is the start of a section on "Holding torque ripple", which includes this text: "The magnitude of the microstepping holding torque ripple, which is a function of the nominal stator and rotor-tooth geometry, is normally in the range 10 to 30% of the nominal 2-phase-on holding torque.".

I am happy to concede that when using microstepping, the holding torque at some microstep positions is likely to be somewhat lower (perhaps 30%) than at the full-step positions. Looking at figure 8, the holding torque is lowest at the half step positions. Therefore, if that graph is typical, you may be able to get around 30% more torque by using full steps instead of 1/2, 1/4, 1/8. 1/16, 1/32 etc. steps. You will not gain extra torque by changing from (say) 1/16 to 1/4 steps. The most common situation in which more torque is required is when using an un-geared extruder, and and such extruders typically have a resolution of 100 steps/mm at 1/16 microstepping. Is going to full steps and 12.5 steps/mm acceptable in this situation? I don't think so, bearing in mind that 1.75mm filament going in to a 0.4mm nozzle at 12.5 steps/mm comes out at more than 1mm per step.

The second of those references deals with the incremental torque per microstep. Bearing in mind that the angle per microstep halves each time you double the microstepping, the table supports my point that as you increase microstepping, the torque per unit angular error remains essentially constant, at least as you increase microstepping beyond 1/4 steps.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: FuseBox ~$300 CoreXY Printer April 28, 2016 06:58PM |

Registered: 8 years ago Posts: 7 |

|

Re: FuseBox ~$300 CoreXY Printer April 28, 2016 06:59PM |

Registered: 8 years ago Posts: 776 |

Quote

dc42

Quote

lkcl

... someone'd better let dc42 know - he's under the impression that the work done (watts) per revolution remains the same, based on the supplied current, regardless of the stepping rate. the amount of work *per step* may increase..

I am certain that I have never made such a statement, because it is so obviously untrue. Kindly link to the post which gave you that impression.

i can't remember! so many things to deal with, so many posts, i am losing track, i apologise - and, it appears, misunderstanding as well. or, i just didn't make myself clear enough. don't know. happy to learn here. will read up a bit more.

|

Re: FuseBox ~$300 CoreXY Printer April 28, 2016 07:06PM |

Registered: 10 years ago Posts: 14,672 |

Quote

lkcl

Quote

dc42

Quote

lkcl

... someone'd better let dc42 know - he's under the impression that the work done (watts) per revolution remains the same, based on the supplied current, regardless of the stepping rate. the amount of work *per step* may increase..

I am certain that I have never made such a statement, because it is so obviously untrue. Kindly link to the post which gave you that impression.

i can't remember! so many things to deal with, so many posts, i am losing track, i apologise - and, it appears, misunderstanding as well. or, i just didn't make myself clear enough. don't know. happy to learn here. will read up a bit more.

Apology accepted - but it could be that I too need to apologise for not making myself clearer.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: FuseBox ~$300 CoreXY Printer April 28, 2016 09:46PM |

Registered: 8 years ago Posts: 166 |

Hi all,

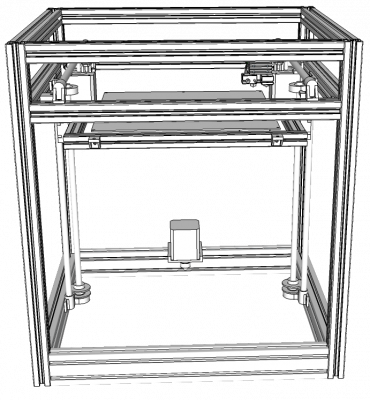

I've been working on and off lately on a new CoreXY design, which aims to make several improvements over the FuseBox.

Here's what I have so far:

Differences include dual extrusion with the E3D Chimera, linear rails instead of rods on the x axis (to save weight), 2020 construction (should be easier to source and is more rigid), and a new z-axis design with 3 point leveling and dual belt-driven leadscrews. With all these changes, it'll probably cost a fair bit more than the FB, but it should make up for that with faster speeds and potentially better print quality.

Been busy with school recently, so for now getting parts and assembling will have to wait.

I've been working on and off lately on a new CoreXY design, which aims to make several improvements over the FuseBox.

Here's what I have so far:

Differences include dual extrusion with the E3D Chimera, linear rails instead of rods on the x axis (to save weight), 2020 construction (should be easier to source and is more rigid), and a new z-axis design with 3 point leveling and dual belt-driven leadscrews. With all these changes, it'll probably cost a fair bit more than the FB, but it should make up for that with faster speeds and potentially better print quality.

Been busy with school recently, so for now getting parts and assembling will have to wait.

|

Re: FuseBox ~$300 CoreXY Printer April 28, 2016 10:13PM |

Registered: 8 years ago Posts: 47 |

Quote

AlexY

Hi all,

I've been working on and off lately on a new CoreXY design, which aims to make several improvements over the FuseBox.

Here's what I have so far:

[attachment 77272 FuseBoxTwo.png]

Differences include dual extrusion with the E3D Chimera, linear rails instead of rods on the x axis (to save weight), 2020 construction (should be easier to source and is more rigid), and a new z-axis design with 3 point leveling and dual belt-driven leadscrews. With all these changes, it'll probably cost a fair bit more than the FB, but it should make up for that with faster speeds and potentially better print quality.

Been busy with school recently, so for now getting parts and assembling will have to wait.

looks good. i think if and when i build my next one i will be using guideways and shuttles on all axis. you can pick up 400mm guideways and shuttles on amazon for under 100 bucks for 3. so for 200 dollars with both ways and shuttles comes out to 200 for all axis and using 2020 as the supports the 400mm span would would work perfect.

|

Re: FuseBox ~$300 CoreXY Printer April 28, 2016 10:45PM |

Registered: 8 years ago Posts: 47 |

|

Re: FuseBox ~$300 CoreXY Printer April 30, 2016 07:22AM |

Registered: 8 years ago Posts: 776 |

Quote

dgcaste

Makes perfect sense too that the holding torque at the full stop positions is the strongest regardless of microstepping, because the current is strongest in one coil and essentially off in the other.

yeah... it does now!

also, the articles explained that there's also static friction as well as dynamic friction to take into account, which is why the torque curves drop off dramatically in a non-linear fashion as the microstepping goes up. like, 100%, 30% (!!!), 12% - something mad like that.

also, the articles explained that there's also static friction as well as dynamic friction to take into account, which is why the torque curves drop off dramatically in a non-linear fashion as the microstepping goes up. like, 100%, 30% (!!!), 12% - something mad like that.

|

Re: FuseBox ~$300 CoreXY Printer April 30, 2016 07:33AM |

Registered: 8 years ago Posts: 776 |

Quote

AlexY

Hi all,

Differences include dual extrusion with the E3D Chimera, linear rails instead of rods on the x axis (to save weight), 2020 construction (should be easier to source and is more rigid), and a new z-axis design with 3 point leveling and dual belt-driven leadscrews. With all these changes, it'll probably cost a fair bit more than the FB, but it should make up for that with faster speeds and potentially better print quality.

Been busy with school recently, so for now getting parts and assembling will have to wait.

awesome - enjoy and stay focussed

thanks for inspiring all of us to tinker, btw. yeah "whew" on the 2020, honestly getting makerbeam 15x15 and cutting it myself was - and still is - bloody dangerous. can i make a suggestion about the leadscrews? make it triple lead screws and get a 900mm closed GT2-6mm belt. the difference for that extra $15 (or so) worth of components is just... ridiculous in the effectiveness.

thanks for inspiring all of us to tinker, btw. yeah "whew" on the 2020, honestly getting makerbeam 15x15 and cutting it myself was - and still is - bloody dangerous. can i make a suggestion about the leadscrews? make it triple lead screws and get a 900mm closed GT2-6mm belt. the difference for that extra $15 (or so) worth of components is just... ridiculous in the effectiveness.i'm literally just in the process of converting the sandwich200v2 redesign to triple lead screws and 12mm OD rods with LM12UU bearings (12mm just to be on the safe and paranoid side). i'll have some photos shortly but here's a cross-reference [forums.reprap.org] - note the bits about needing *two* 608 bearings to "clamp" the TR8 lead screws, this is really important! if you're going over 300mm you'll need to put 4 in, that's also very important.

when you use triple lead screws (and two rigid bars with linear bearings - don't try rails because you need stability in X and Y (no bend on *either* bar), and rails would bend too much in one direction), you don't need to put a huge amount of strength or infrastructure into holding the bed up at the mid-point. just some edge mount-points is perfectly sufficient.

also in particular, it looks like you're still using 8mm z-rods on the bed... don't do that

it's one of the main design flaws of the fusebox 1. upgrade them to 10 or 12mm and don't worry about "extra cost" - it really isn't that much, and the difference in stability is massive.

it's one of the main design flaws of the fusebox 1. upgrade them to 10 or 12mm and don't worry about "extra cost" - it really isn't that much, and the difference in stability is massive.

Sorry, only registered users may post in this forum.