FuseBox ~$300 CoreXY Printer

Posted by AlexY

|

Re: FuseBox ~$300 CoreXY Printer April 30, 2016 08:12PM |

Registered: 8 years ago Posts: 776 |

Quote

AlexY

and a new z-axis design with 3 point leveling and dual belt-driven leadscrews.

one other observation: the skate bearings (608) that i'm using, i have done several thousand miles on them since i bought the skates 10 years ago. i don't know if that's relevant, but a quick test shows *significant* lateral movement on the central hub.

when used in a precision engineering tool such as a 3d printer, even a 0.005mm variation is huge (and i'm seeing something like 0.3mm in the 608 skating bearings). in the diagram that you've got, it's very unclear, but i can see that the top of the lead screw rods are open (meaning that there can be upwards lateral movement), and i suspect that, from the fact that the bearing holders look to be level with the bottom of the 2020 extrusion in the picture, the lead screw is probably also open at the bottom as well.

what that will mean is, the level of the printbed will either be critically dependent on the quality of the bearings, friction in the travel of the printbed assembly, the speed of travel of the printbed, and potentially whether the printer is on a dead-flat surface.... or not (because the bottom of the rods may happen to be resting on that surface... or not), and many other random unaccountable factors.

in the sandwich200v2, i will at least be relying on the end of the lead screw resting against the 1515 extrusion. it's not ideal (as it will, over time, grind both the rod and the extrusion). so you and i both need to work out a way to stop that lateral motion in a reasonable fashion.

one possibility to rely on is the fact that two bearings would (with grub screws pushing the rod against the bearings as earlier suggested), if the person doing the assembly remembers to do it, potentially be used to take up lateral slack as well. the idea is to push one against the rod first, then to lift the rod up whilst at the same time push the centre hub *down*, hard, before tightening the second grub screw. thus, the lateral play of both bearings would be at their maximum extent and would hold each other there, using the rod to ensure that happens. however i don't believe it's such a good idea as it could result in increased wear of the balls inside the bearing, end-result being that the rod would end up moving about *anyway*.

so whilst i appreciate you're busy with other things, can i suggest using the resources of the people here on the forum, as well as doing some research yourself, and to collaborate together on working out what the best engineering practice is *before* finalising this aspect of the fusebox v2 design?

Edited 2 time(s). Last edit at 04/30/2016 08:13PM by lkcl.

|

Re: FuseBox ~$300 CoreXY Printer May 01, 2016 03:55AM |

Registered: 8 years ago Posts: 776 |

started discussion here asking about lead screw lateral support [forums.reprap.org]

Edited 1 time(s). Last edit at 05/01/2016 04:07AM by lkcl.

Edited 1 time(s). Last edit at 05/01/2016 04:07AM by lkcl.

|

Re: FuseBox ~$300 CoreXY Printer May 01, 2016 01:24PM |

Registered: 8 years ago Posts: 166 |

Thanks for the suggestions!

The z-axis is completely experimental at this point, and the design of the frame makes it easy to swap out different print bed designs.

Would a cantilever design as in the original Fusebox, with thicker rods and bearings, be sufficient? I've noticed that a lot of printers like the Ultimaker use a cantilever design without much issue.

The z-axis is completely experimental at this point, and the design of the frame makes it easy to swap out different print bed designs.

Would a cantilever design as in the original Fusebox, with thicker rods and bearings, be sufficient? I've noticed that a lot of printers like the Ultimaker use a cantilever design without much issue.

|

Re: FuseBox ~$300 CoreXY Printer May 01, 2016 01:46PM |

Registered: 8 years ago Posts: 776 |

Quote

AlexY

Thanks for the suggestions!

The z-axis is completely experimental at this point, and the design of the frame makes it easy to swap out different print bed designs.

cool

Quote

Would a cantilever design as in the original Fusebox, with thicker rods and bearings, be sufficient? I've noticed that a lot of printers like the Ultimaker use a cantilever design without much issue.

i've been tracking designs now for 2-3 months: there's one group of people who say that upgrading the rods&bearings, and a good cantilever design, you get really good results - i can't remember exactly but the ultimaker is inspired by an open design that was extremely good. then, a couple of people here (page 6-7) have been doing extremely effective cantilever upgrades: following the design of the "G&C" all-aluminium printer, which uses an L-shaped extrusion spanning across four bearings - you *can* do it, basically.

but, there is another group who point out that if when you pull a part (hard) off the printbed after it's done, if the bed moves *at all* you're basically asking for trouble, and so those people all do delrin rollers and/or 3-leadscrew designs and so on.

so this is why i've just abandoned the cantilevered bed approach and am going for the 3 (geared) lead screws and 2 large (12mm) rods.... but all still folding of course because of the amount of travelling i'll be doing. i want to experiment with running at 500mm/sec as i am getting a Flex3Drive, and i just feel that a cantilevered bed just wouldn't cope.

but... it's up to you. i'm pushing the boundaries because i feel like doing so: that's fun for me. you may have a different set of criteria (reliability, reproducibility, cost) so it's your decision based on what you feel is best.

|

Re: FuseBox ~$300 CoreXY Printer May 01, 2016 01:55PM |

Registered: 8 years ago Posts: 776 |

Quote

dgcaste

Does the extruder run at other than 1/16 microstepping? Extruder is skipping occasionally and my driver is maxed out. I don't think it's the tension either.

[forums.reprap.org] - link for you to a CAD model for the Titan extruder, that digital_dentist made, so you can work on the mount points part before/whilst ordering, and generally check it out before you buy one. hth.

Edited 2 time(s). Last edit at 05/02/2016 09:20AM by lkcl.

|

Re: FuseBox ~$300 CoreXY Printer May 01, 2016 07:22PM |

Registered: 8 years ago Posts: 166 |

Other things I still need to figure out include endstops and possibly a new extruder design, since although it works pretty well, the old one does look a bit tacky with the binder clip springs.

Any suggestions for endstop placement? Ideally I'd like to keep them all stationary to minimize the amount of moving wires, but this means homing will have to be done in a specific order to avoid crashes.

Edited 1 time(s). Last edit at 05/01/2016 07:23PM by AlexY.

Any suggestions for endstop placement? Ideally I'd like to keep them all stationary to minimize the amount of moving wires, but this means homing will have to be done in a specific order to avoid crashes.

Edited 1 time(s). Last edit at 05/01/2016 07:23PM by AlexY.

|

Re: FuseBox ~$300 CoreXY Printer May 01, 2016 08:05PM |

Registered: 8 years ago Posts: 776 |

Quote

AlexY

Other things I still need to figure out include endstops and possibly a new extruder design, since although it works pretty well, the old one does look a bit tacky with the binder clip springs.

binder clip springs... where? i didn't see none! mind you i went for the "all-aluminium extruder"... and it was rubbish. how about just using the e3d titan that's just out - digital_dentist kindly just made a model of it (see previous message for a link). i designed an extruder: it had to be a geared one (i'm using 3mm bowden). it took me 10 days and 3 redesign attempts, increasing the gear ratio each time (2:1 and 3.5:1 were the failed ratios) mind you i was going for compact as well as fairly high gear ratio (53:13) *and* modularity.

Quote

Any suggestions for endstop placement? Ideally I'd like to keep them all stationary to minimize the amount of moving wires, but this means homing will have to be done in a specific order to avoid crashes.

i thought about this for a while, bear in mind that the hotend (and 1/2 the carriage, etc.) has to be removable in the printer i'm doing because when using a Flex3Drive it's too tall, when stowed. also, having the endstops poke upwards when the corexy part is folded down: again, too tall. and yeah i really don't like the x-endstop on the x-end thing, i nearly ended up ripping the wires off and wrecking the endstop at least twice because i didn't notice the wires catching.

so the solution there i figured was, put the x endstop on the *carriage*, not the x-end. in the case of the sandwich200v2, that means it will be detachable along with the hotend. but, it has the nice side-effect that the wires can be attached to the same bundle as the hotend heater, thermistor, and the two fans. you already have a bunch of wires, there: three more ain't gonna make any odds, and as far as weight is concerned, an extra 5 grams or so ain't a lot either: this isn't a delta printer design.

second thing: about homing carriage-crashes: RepRapFirmware, which is for the 32-bit printers like the duet 0.8.5 (thoroughly recommended btw - great board) you program all those kinds of things in gcode files, *not* c code, assembler or c++. and that means you can simply edit the "homeall.g" file (no recompiles needed, in fact no firmware "build" environment needed at all) to get it to do a very very specific sequence, end-result is, you safely homed all axes.... *depending on your type of printer* [there are several example configs - for deltas, cartesian, corexy - and several variants of all of those].

so, for the corexy homeall.g example files that come with RepRapFirmware, it first of all drops the z height by 10mm. *then* it travels across listening for the x-endstop, *then* the y one, and then finally, knowing that x and y are at 0, does the z-axis homing.

now, in the sandwich200v1, turns out that x is mirrored, so i had to invert that by turning the connector round... *but* that resulted in the x minstop turning into an x *max* stop... so all i did was, in the homeall.g file, edited the G1 command on line... 5 or whatever it was... to get it to travel +ve not -ve, and then to reset the X absolute position value to 220.0, instead of 0.0: job done, x axis thinks it's at maximum travel position not min.

all this was done *safely* without recompiling a single line of firmware source code. i only had to emergency-power-down just the once

in other words, head-crashing can be solved... in software. and the duet 0.8.5 is pretty damn good. dc42 knows where you can get a $65 china replica of the duet 0.6 if the GBP 95 cost of the duet 0.8.5 is an issue, but honestly it's worth it. ethernet port on a printer controller board, and a web server built-in to the firmware... and this is an embedded processor with no virtual memory? ha! cool!

|

Re: FuseBox ~$300 CoreXY Printer May 01, 2016 08:51PM |

Registered: 8 years ago Posts: 269 |

Quote

lkcl

Quote

AlexY

Other things I still need to figure out include endstops and possibly a new extruder design, since although it works pretty well, the old one does look a bit tacky with the binder clip springs.

binder clip springs... where? i didn't see none! mind you i went for the "all-aluminium extruder"... and it was rubbish. how about just using the e3d titan that's just out - digital_dentist kindly just made a model of it (see previous message for a link). i designed an extruder: it had to be a geared one (i'm using 3mm bowden). it took me 10 days and 3 redesign attempts, increasing the gear ratio each time (2:1 and 3.5:1 were the failed ratios) mind you i was going for compact as well as fairly high gear ratio (53:13) *and* modularity.

Quote

Any suggestions for endstop placement? Ideally I'd like to keep them all stationary to minimize the amount of moving wires, but this means homing will have to be done in a specific order to avoid crashes.

i thought about this for a while, bear in mind that the hotend (and 1/2 the carriage, etc.) has to be removable in the printer i'm doing because when using a Flex3Drive it's too tall, when stowed. also, having the endstops poke upwards when the corexy part is folded down: again, too tall. and yeah i really don't like the x-endstop on the x-end thing, i nearly ended up ripping the wires off and wrecking the endstop at least twice because i didn't notice the wires catching.

so the solution there i figured was, put the x endstop on the *carriage*, not the x-end. in the case of the sandwich200v2, that means it will be detachable along with the hotend. but, it has the nice side-effect that the wires can be attached to the same bundle as the hotend heater, thermistor, and the two fans. you already have a bunch of wires, there: three more ain't gonna make any odds, and as far as weight is concerned, an extra 5 grams or so ain't a lot either: this isn't a delta printer design.

second thing: about homing carriage-crashes: RepRapFirmware, which is for the 32-bit printers like the duet 0.8.5 (thoroughly recommended btw - great board) you program all those kinds of things in gcode files, *not* c code, assembler or c++. and that means you can simply edit the "homeall.g" file (no recompiles needed, in fact no firmware "build" environment needed at all) to get it to do a very very specific sequence, end-result is, you safely homed all axes.... *depending on your type of printer* [there are several example configs - for deltas, cartesian, corexy - and several variants of all of those].

so, for the corexy homeall.g example files that come with RepRapFirmware, it first of all drops the z height by 10mm. *then* it travels across listening for the x-endstop, *then* the y one, and then finally, knowing that x and y are at 0, does the z-axis homing.

now, in the sandwich200v1, turns out that x is mirrored, so i had to invert that by turning the connector round... *but* that resulted in the x minstop turning into an x *max* stop... so all i did was, in the homeall.g file, edited the G1 command on line... 5 or whatever it was... to get it to travel +ve not -ve, and then to reset the X absolute position value to 220.0, instead of 0.0: job done, x axis thinks it's at maximum travel position not min.

all this was done *safely* without recompiling a single line of firmware source code. i only had to emergency-power-down just the once

in other words, head-crashing can be solved... in software. and the duet 0.8.5 is pretty damn good. dc42 knows where you can get a $65 china replica of the duet 0.6 if the GBP 95 cost of the duet 0.8.5 is an issue, but honestly it's worth it. ethernet port on a printer controller board, and a web server built-in to the firmware... and this is an embedded processor with no virtual memory? ha! cool!

Tbh, if you want to stay with standard firmware Marlin 1.1 pretty much does the same. You can drop the Z before homing then choose to home X or Y first or do it at the same time. Yes, Marlin 1.1 is still beta, on RC6, however, it's very close to full release, it has good CoreXY support as well. I have both FB2020s (yes I now have 2) running on RC6 and it's damn smooth. X is on the Carriage, Y homes to YMAX, so the home position is at the back left of the printer. Took a bit of fiddling to get right and using Omron Switches, lightens the load. Yes, they have to be soldered, but it's a minor thing.

And here's a pic of the new FB2020 (excuse the mess, I can't work cleanly), dubbed the FB2020 Plus, 200x200x280(ish) Build volume. It's missing it's diagonal braces (I derped on ordering) and having 8mm rods on the Z is really sub-optimal, but there's very little, if any flex in the bed. I'll get around to moving the Z to 12mm rods soon. I Say 280-ish on the Z as I don't know exactly the full volume as the lead screw that's in there is too short, so it's jerry-rigged to loose about 20-30mm off of the Z, you can see the risers underneath the bed springs and the Z limit switch has a dog-leg in. Yes there's probably some sort of maths wizardry that could help me work it out, but a)my maths is horrendous, simple sums like 7+5 I can't work out and b) I like having the surprise of how big the Z volume will be. It's also missing the RRD Controller, as I don't have a connector for the RAMPS. It did have the MKS Base Board connected but it needs heatsinks and I'm not really a fan of the A4988 drivers on the X & Y as I've found they don't really put out enough power without getting the motors way too hot.

Edited 1 time(s). Last edit at 05/01/2016 08:59PM by Ax.

|

Re: FuseBox ~$300 CoreXY Printer May 02, 2016 05:33PM |

Registered: 8 years ago Posts: 776 |

Quote

Ax

Quote

lkcl

in other words, head-crashing can be solved... in software. and the duet 0.8.5 is pretty damn good. dc42 knows where you can get a $65 china replica of the duet 0.6 if the GBP 95 cost of the duet 0.8.5 is an issue, but honestly it's worth it. ethernet port on a printer controller board, and a web server built-in to the firmware... and this is an embedded processor with no virtual memory? ha! cool!

Tbh, if you want to stay with standard firmware Marlin 1.1 pretty much does the same.

yeahhhh.... but note exactly what you said: you said, "maybe RC6 has good support for corexy, maybe it's coming out of RC6 soon, maybe maybe"... all that says to me that you're critically relying on *other people* to program in c code... whereas the RepRapFirmware has been deliberately designed so that you - right now - can take responsibility and can take actuion - *right now* - to simply fire up a text editor, enter some g-code commands, and have the job done in... well... it took me about 4-5 hours from start to finish, from zero knowledge, to unpack and put the duet 0.8.5 in, work out the axes and connectors, work out the stepper orientation, and to get a first print - that includes searches online, looking for examples of corexy configs to copy and start from.

Quote

And here's a pic of the new FB2020 (excuse the mess, I can't work cleanly), dubbed the FB2020 Plus, 200x200x280(ish) Build volume

i love it! especially love the dragon, that's huge - my daughter loved it, too. any chance of taking a picture from the back, to see how you've done the bed-support and rods?

|

Re: FuseBox ~$300 CoreXY Printer May 03, 2016 11:49AM |

Registered: 9 years ago Posts: 251 |

|

Re: FuseBox ~$300 CoreXY Printer May 04, 2016 03:51AM |

Registered: 8 years ago Posts: 269 |

Quote

lkcl

Quote

Ax

Quote

lkcl

in other words, head-crashing can be solved... in software. and the duet 0.8.5 is pretty damn good. dc42 knows where you can get a $65 china replica of the duet 0.6 if the GBP 95 cost of the duet 0.8.5 is an issue, but honestly it's worth it. ethernet port on a printer controller board, and a web server built-in to the firmware... and this is an embedded processor with no virtual memory? ha! cool!

Tbh, if you want to stay with standard firmware Marlin 1.1 pretty much does the same.

yeahhhh.... but note exactly what you said: you said, "maybe RC6 has good support for corexy, maybe it's coming out of RC6 soon, maybe maybe"... all that says to me that you're critically relying on *other people* to program in c code... whereas the RepRapFirmware has been deliberately designed so that you - right now - can take responsibility and can take actuion - *right now* - to simply fire up a text editor, enter some g-code commands, and have the job done in... well... it took me about 4-5 hours from start to finish, from zero knowledge, to unpack and put the duet 0.8.5 in, work out the axes and connectors, work out the stepper orientation, and to get a first print - that includes searches online, looking for examples of corexy configs to copy and start from.

Quote

And here's a pic of the new FB2020 (excuse the mess, I can't work cleanly), dubbed the FB2020 Plus, 200x200x280(ish) Build volume

i love it! especially love the dragon, that's huge - my daughter loved it, too. any chance of taking a picture from the back, to see how you've done the bed-support and rods?

Same as the FB2020, I have re-designed the Rod mounts to have more meat around the where the cylinder joins the flat cube. Everything is up on the Github

As for the firmware, you're way off. Yes I'm waiting for a full release of 1.1, but for those of us that are running 8 Bit boards, It's one of the few choices, and frankly after digging around in Repetier for a while, give me Marlin any day. RC6 has FULL CoreXY support, RC6 IS out, but, yes it's not a full release, but frankly, it's there. I don't have any issues with it at all. If you're running a 32 Bit board, by all means run RepRap firmware, however, for those not, it's slim pickings and Marlin is about the best choice imo.

Quote

widespreaddeadhead

Ax:

What would it take to redesign your 3 point mount at the end of the bed for the original 15x15 extrusions? Resize the end caps and the mounting piece?

Very little. The 3 pieces needed, the brace brackets and the bed standoff, took around 45 mins to design. You could either scale them or grab the CAD files on the github [github.com]

Edited 1 time(s). Last edit at 05/04/2016 03:51AM by Ax.

|

Re: FuseBox ~$300 CoreXY Printer May 09, 2016 09:18PM |

Registered: 8 years ago Posts: 269 |

This may interest some of you. I've gone for full overkill on the Z Axis of the FB2020. They'll shortly be converted to using 12mm rods and bearings, probably won't work for the standard Fusebox, but any 2020 versions, it'll drop right in

Edited 1 time(s). Last edit at 05/09/2016 09:18PM by Ax.

Edited 1 time(s). Last edit at 05/09/2016 09:18PM by Ax.

|

Re: FuseBox ~$300 CoreXY Printer May 10, 2016 03:10PM |

Registered: 8 years ago Posts: 31 |

Hi Ax,

I'm getting ready to start building one of these. Just want to make sure I have the most current parts list before I go out to get the 2020 cut. Can you point me in the right direction.

Thanks,

Jeff

oops, sorry, for the larger 200x200x280.

Edited 2 time(s). Last edit at 05/10/2016 03:13PM by Canadian Geek.

I'm getting ready to start building one of these. Just want to make sure I have the most current parts list before I go out to get the 2020 cut. Can you point me in the right direction.

Thanks,

Jeff

oops, sorry, for the larger 200x200x280.

Edited 2 time(s). Last edit at 05/10/2016 03:13PM by Canadian Geek.

|

Re: FuseBox ~$300 CoreXY Printer May 11, 2016 07:50PM |

Registered: 8 years ago Posts: 269 |

Quote

Canadian Geek

Hi Ax,

I'm getting ready to start building one of these. Just want to make sure I have the most current parts list before I go out to get the 2020 cut. Can you point me in the right direction.

Thanks,

Jeff

oops, sorry, for the larger 200x200x280.

Hey Jeff, the BOM on the Github is current. I'm still in the testing phase for the 12mm Z axis rods atm, I've got the parts print tested, I'm waiting on parts from China atm. However, the full BOM for the Plus including the lengths for the extrusions are at [github.com]

|

Re: FuseBox ~$300 CoreXY Printer May 13, 2016 12:04AM |

Registered: 8 years ago Posts: 31 |

I like the idea of 12mm rods. Just checking, these are the right sizes for the larger 2020 CoreXY:

2020 Extrusion lengths

4 x 445 mm (Frame, vertical)

4 x 380 mm (Frame, X Axis)

2 x 465 mm (Frame, Diagonal)

2 x 340 mm (Frame, Y Axis top)

2 x 300 mm (Frame, Y Axis bottom)

2 x 235 mm (Bed, Z Axis)

2 x 147mm (Bed ties)

If so, I've got an order to place.

Jeff

2020 Extrusion lengths

4 x 445 mm (Frame, vertical)

4 x 380 mm (Frame, X Axis)

2 x 465 mm (Frame, Diagonal)

2 x 340 mm (Frame, Y Axis top)

2 x 300 mm (Frame, Y Axis bottom)

2 x 235 mm (Bed, Z Axis)

2 x 147mm (Bed ties)

If so, I've got an order to place.

Jeff

|

Re: FuseBox ~$300 CoreXY Printer May 13, 2016 05:06PM |

Registered: 8 years ago Posts: 269 |

Quote

Canadian Geek

I like the idea of 12mm rods. Just checking, these are the right sizes for the larger 2020 CoreXY:

2020 Extrusion lengths

4 x 445 mm (Frame, vertical)

4 x 380 mm (Frame, X Axis)

2 x 465 mm (Frame, Diagonal)

2 x 340 mm (Frame, Y Axis top)

2 x 300 mm (Frame, Y Axis bottom)

2 x 235 mm (Bed, Z Axis)

2 x 147mm (Bed ties)

If so, I've got an order to place.

Jeff

Yup, that looks right - just as a note I've kicked off a FB2020 thread - here to separate things out as really, there are only 3 part models that are original to the Fusebox design, everything else is either modified or redesigned from the ground up.

|

Re: FuseBox ~$300 CoreXY Printer May 14, 2016 01:42AM |

Registered: 8 years ago Posts: 25 |

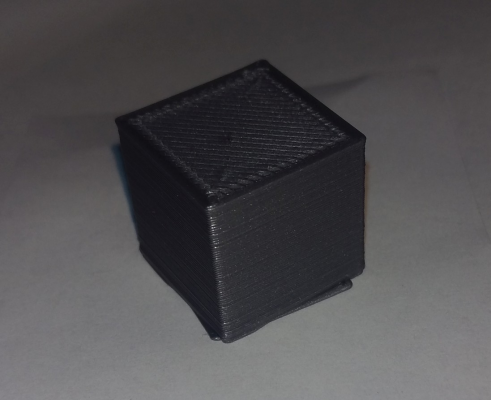

I got mine put together enough to actually make it to "print" stage. My first print only made it to two layers before the nozzle caught it and started dragging it around, but I'd say, for the very first print from my very first printer (having had no prior 3d printing experience), on cold unprepped glass after eyeballing the bed level and nozzle gap, I'm pretty proud of myself! My second print (after adding some blue tape) is mostly done, I'll post some pictures when I finish. Thanks to the awesome design, for the fantastic community, and a huge thank-you goes to os3dp who graciously offered to print my parts for me. THANK YOU!

Here's the full cube (we'll call it print #2 just for nostalgia's sake). The bottom's a little wonky, because the brim (brim? the first surrounding ring?) didn't adhere, and got dragged into the print area. There's also some warping at the edges on the bottom. I'm pleased as punch. Each side is pretty much exactly 20.16mm.

Edited 1 time(s). Last edit at 05/14/2016 02:01AM by godefroi.

Here's the full cube (we'll call it print #2 just for nostalgia's sake). The bottom's a little wonky, because the brim (brim? the first surrounding ring?) didn't adhere, and got dragged into the print area. There's also some warping at the edges on the bottom. I'm pleased as punch. Each side is pretty much exactly 20.16mm.

Edited 1 time(s). Last edit at 05/14/2016 02:01AM by godefroi.

|

Re: FuseBox ~$300 CoreXY Printer May 14, 2016 04:35AM |

Registered: 8 years ago Posts: 776 |

Quote

godefroi

I got mine put together enough to actually make it to "print" stage.

yay well done!

suggestions, look up the whole "sugar water solution" thing, nice thing about a 10-15% sugar water solution is, when the heated bed cools off the sugar crystallises and becomes brittle.... parts easily come off. the alternative is lacquer-free hairspray. it's extreme, and it really *really* works.

the prints are probably coming off because the bed isn't level. bed level calibration is really important, do a z-switch "Home" then switch OFF the printer . make sure the printhead is cool before beginning.

you should get a really thin piece of paper (a shopping receipt is perfect) then put that underneath the printhead, and "drag" it. if it doesn't move you have the screw down too tight. if it's loose, bring the screw back up again. then move the printhead manually to the next corner, keep the paper underneath it cos it's a pain to get it back underneath. if the printhead jams on the paper on move STOP, undo the screw loose *then* move. cycle through *ALL FOUR* corners at least THREE TIMES. why? because with a 4-corner bed levelling, alterations in one corner affect all other 3 corners in ways that will take you a bit of time to get used to.

oh - one thing: the FB's z-axis arrangement is not stable. you can see this by pressing down on the left side of the printbed, the right side *WILL* go up, see-sawing about that middle z-nut. so when doing levelling, bear that in mind. even just resting a screwdriver or spanner in the printbed's screw-and-spring will affect the height, and that will mean the printbed calibration will be out.

not bad

|

Re: FuseBox ~$300 CoreXY Printer May 16, 2016 03:15PM |

Registered: 8 years ago Posts: 25 |

Quote

lkcl

the prints are probably coming off because the bed isn't level. bed level calibration is really important, do a z-switch "Home" then switch OFF the printer . make sure the printhead is cool before beginning.

you should get a really thin piece of paper (a shopping receipt is perfect) then put that underneath the printhead, and "drag" it. if it doesn't move you have the screw down too tight. if it's loose, bring the screw back up again. then move the printhead manually to the next corner, keep the paper underneath it cos it's a pain to get it back underneath. if the printhead jams on the paper on move STOP, undo the screw loose *then* move. cycle through *ALL FOUR* corners at least THREE TIMES. why? because with a 4-corner bed levelling, alterations in one corner affect all other 3 corners in ways that will take you a bit of time to get used to.

I hooked up the heated bed, and I haven't had any warping since then. I also did mount the bed with 3 points instead of four, by simply moving the Z-axis cross-brace out to the end of the arms, and putting one of the supports that are supposed to go at the ends of the arms in the middle of the cross-brace. Seemed easier to level, to my untrained brain.

Quote

lkcl

oh - one thing: the FB's z-axis arrangement is not stable. you can see this by pressing down on the left side of the printbed, the right side *WILL* go up, see-sawing about that middle z-nut. so when doing levelling, bear that in mind. even just resting a screwdriver or spanner in the printbed's screw-and-spring will affect the height, and that will mean the printbed calibration will be out.

Yeah, I noticed that. I think the Fuse Box is a fantastic design, and _AlexY has done excellent work with it, but the cantilevered bed designs that are common on CoreXY machines are definitely the weak spot.

Here's a few pictures of my second 3DBenchy, using .2mm layers with silver Hatchbox PLA. Notice that the writing on the bottom is mirrored in the X direction. Any idea why that is, and how to fix it?

|

Re: FuseBox ~$300 CoreXY Printer May 16, 2016 04:12PM |

Registered: 10 years ago Posts: 14,672 |

If your whole print is mirrored then you have your X and Y axes the wrong way round. The +Y direction should be 90 degrees anticlockwise, viewed from above, from the +X direction. If it'a 90 degrees clockwise instead, then you need to:

1. Swap your X and Y motor connectors over (always turn the power off before messing with motor connectors). This will get the X and Y axes in the correct orientation with respect to each other.

2. Then get the +X direction the way you want it by reversing one or both motor directions, if necessary.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Swap your X and Y motor connectors over (always turn the power off before messing with motor connectors). This will get the X and Y axes in the correct orientation with respect to each other.

2. Then get the +X direction the way you want it by reversing one or both motor directions, if necessary.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: FuseBox ~$300 CoreXY Printer May 16, 2016 04:33PM |

Registered: 8 years ago Posts: 776 |

Quote

dc42

If your whole print is mirrored then you have your X and Y axes the wrong way round. The +Y direction should be 90 degrees anticlockwise, viewed from above, from the +X direction. If it'a 90 degrees clockwise instead, then you need to:

1. Swap your X and Y motor connectors over (always turn the power off before messing with motor connectors). This will get the X and Y axes in the correct orientation with respect to each other.

2. Then get the +X direction the way you want it by reversing one or both motor directions, if necessary.

yeah i had this problem as well, and it was very confusing. i think i cycled through these combinations you recommended, dc42, several times

what i particularly didn't get was that i had designed the printer to have the x endstop in the wrong corner, and, not being able to move it i had to tell the firmware that the x endstop was a "max" *not* a "min". godefri, what controller are you using?

what i particularly didn't get was that i had designed the printer to have the x endstop in the wrong corner, and, not being able to move it i had to tell the firmware that the x endstop was a "max" *not* a "min". godefri, what controller are you using?

|

Re: FuseBox ~$300 CoreXY Printer May 16, 2016 04:37PM |

Registered: 8 years ago Posts: 776 |

Quote

godefroi

I hooked up the heated bed, and I haven't had any warping since then. I also did mount the bed with 3 points instead of four, by simply moving the Z-axis cross-brace out to the end of the arms, and putting one of the supports that are supposed to go at the ends of the arms in the middle of the cross-brace. Seemed easier to level, to my untrained brain.

yay good for you.

Quote

lkcl

oh - one thing: the FB's z-axis arrangement is not stable. you can see this by pressing down on the left side of the printbed, the right side *WILL* go up, see-sawing about that middle z-nut. so when doing levelling, bear that in mind. even just resting a screwdriver or spanner in the printbed's screw-and-spring will affect the height, and that will mean the printbed calibration will be out.

Yeah, I noticed that. I think the Fuse Box is a fantastic design, and _AlexY has done excellent work with it, but the cantilevered bed designs that are common on CoreXY machines are definitely the weak spot.

[/quote]

there was some discussion here about exactly that, cycle back to around page 6 or 7 or so of this sub-forum, you'll find it. Ax was talking about an awesome simple change to L-shaped easily-available metal, and upgrading to 10mm or 12mm rods, which he found from the "G&C" all-aluminium 3d printer. with 12mm rods and 4 linear bearings spaced out sufficiently (75mm or so) you'd have noooo problems either. it can and has been done, basically, but 8mm rods and relying on plastic spanning 140mm is asking for trouble. we live and learn, eh?

|

Re: FuseBox ~$300 CoreXY Printer May 16, 2016 06:31PM |

Registered: 8 years ago Posts: 25 |

Quote

lkcl

yeah i had this problem as well, and it was very confusing. i think i cycled through these combinations you recommended, dc42, several timeswhat i particularly didn't get was that i had designed the printer to have the x endstop in the wrong corner, and, not being able to move it i had to tell the firmware that the x endstop was a "max" *not* a "min". godefri, what controller are you using?

I'm using Marlin 1.1-RC6 on RAMPS 1.4.

Wait a second, the X endstop is a MAX endstop? Like, +X is toward the endstop? I guess that'd make sense, but the question is, how do I configure Marlin for this situation, I wonder?

Edited 1 time(s). Last edit at 05/16/2016 06:31PM by godefroi.

|

Re: FuseBox ~$300 CoreXY Printer May 16, 2016 07:11PM |

Registered: 12 years ago Posts: 44 |

My X endstop seems to be on the wrong end, too. But that's also how it appears to be on the sketchup shown in the video, too. So, to be clear, I put the X-endstop on the X-end which presses against the Y-endstop. There seems to be a mount place for it. But when I home to X and Y in that back corner, it seems like "plus X" moves in what is traditionally the negative direction.

Is everyone having to use max-X instead of min-X for endstops?

Is everyone having to use max-X instead of min-X for endstops?

|

Re: FuseBox ~$300 CoreXY Printer May 16, 2016 07:20PM |

Registered: 8 years ago Posts: 25 |

For those using Marlin, here's what I just did.

Under @homing:

Under @homing:

Under @machine:

Under @homing:

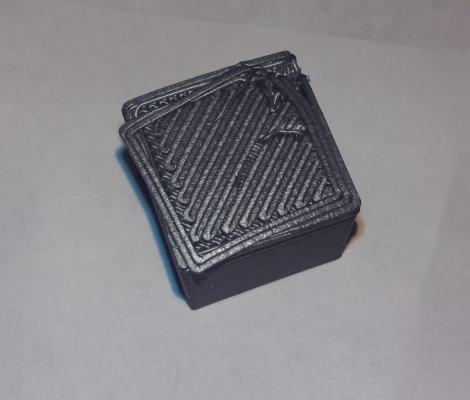

Everything's moving in the right direction, now (assuming the X endstop is indeed MAX and not MIN), but I haven't printed benchy to make sure, yet. I did just print this bridge test (at 60mm/s), of which I am super proud:

Edited 1 time(s). Last edit at 05/16/2016 07:24PM by godefroi.

Under @homing:

//#define USE_XMIN_PLUG #define USE_YMIN_PLUG #define USE_ZMIN_PLUG #define USE_XMAX_PLUG //#define USE_YMAX_PLUG //#define USE_ZMAX_PLUG

Under @homing:

const bool X_MIN_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop. const bool Y_MIN_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop. const bool Z_MIN_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop. const bool X_MAX_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop. const bool Y_MAX_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop. const bool Z_MAX_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

Under @machine:

#define INVERT_X_DIR false #define INVERT_Y_DIR false #define INVERT_Z_DIR false

Under @homing:

#define X_HOME_DIR 1 #define Y_HOME_DIR -1 #define Z_HOME_DIR -1

Everything's moving in the right direction, now (assuming the X endstop is indeed MAX and not MIN), but I haven't printed benchy to make sure, yet. I did just print this bridge test (at 60mm/s), of which I am super proud:

Edited 1 time(s). Last edit at 05/16/2016 07:24PM by godefroi.

|

Re: FuseBox ~$300 CoreXY Printer May 17, 2016 03:28AM |

Registered: 8 years ago Posts: 776 |

Quote

phord

My X endstop seems to be on the wrong end, too. But that's also how it appears to be on the sketchup shown in the video, too. So, to be clear, I put the X-endstop on the X-end which presses against the Y-endstop. There seems to be a mount place for it. But when I home to X and Y in that back corner, it seems like "plus X" moves in what is traditionally the negative direction.

Is everyone having to use max-X instead of min-X for endstops?

yes. see attached patch file. slightly different from what godefroi uses, but achieves the same effect. i have a set of configs for the Duet 0.8.5 as well. [hands.com] you'll want home*.g as well as to start carefully with config.g

|

Re: FuseBox ~$300 CoreXY Printer May 17, 2016 03:30AM |

Registered: 8 years ago Posts: 776 |

Quote

godefroi

Everything's moving in the right direction, now (assuming the X endstop is indeed MAX and not MIN), but I haven't printed benchy to make sure, yet. I did just print this bridge test (at 60mm/s), of which I am super proud:

wow, that's a heck of a long way - that's.. what... 100mm??!

|

Re: FuseBox ~$300 CoreXY Printer May 17, 2016 10:21AM |

Registered: 8 years ago Posts: 25 |

Quote

lkcl

wow, that's a heck of a long way - that's.. what... 100mm??!

No, it's about 50mm. It's available here: [www.thingiverse.com] and I made a video of the print of the bridge: [www.youtube.com]

Next up will be this one, I guess: [www.thingiverse.com]

Edited 1 time(s). Last edit at 05/17/2016 10:23AM by godefroi.

|

Re: FuseBox ~$300 CoreXY Printer May 17, 2016 05:56PM |

Registered: 12 years ago Posts: 44 |

Quote

lkcl

Quote

phord

My X endstop seems to be on the wrong end, too. But that's also how it appears to be on the sketchup shown in the video, too. So, to be clear, I put the X-endstop on the X-end which presses against the Y-endstop. There seems to be a mount place for it. But when I home to X and Y in that back corner, it seems like "plus X" moves in what is traditionally the negative direction.

Is everyone having to use max-X instead of min-X for endstops?

yes. see attached patch file. slightly different from what godefroi uses, but achieves the same effect. i have a set of configs for the Duet 0.8.5 as well. [hands.com] you'll want home*.g as well as to start carefully with config.g

Thanks for the tips. I wish it had been mentioned in the project. Homing to MAX is just as good as homing to MIN. Maybe I shouldn't care so much, but it occurs to me that these could both be MIN without any hardware changes if the origin were moved from the back right corner to the back left corner, and then the "X" and "Y" axes were swapped. That is, the carriage would move on the Y-axis rods (left to right) and the Y-axis itself would move on the X-axis (back to front). This should map a nice Quadrant-I orientation without any hardware or software changes.

As it happens I use Teacup firmware, so I can't use your patch except for reference. But someone else will surely find it directly useful.

|

Re: FuseBox ~$300 CoreXY Printer May 17, 2016 11:20PM |

Registered: 8 years ago Posts: 47 |

Quote

Ax

Quote

Canadian Geek

Hi Ax,

I'm getting ready to start building one of these. Just want to make sure I have the most current parts list before I go out to get the 2020 cut. Can you point me in the right direction.

Thanks,

Jeff

oops, sorry, for the larger 200x200x280.

Hey Jeff, the BOM on the Github is current. I'm still in the testing phase for the 12mm Z axis rods atm, I've got the parts print tested, I'm waiting on parts from China atm. However, the full BOM for the Plus including the lengths for the extrusions are at [github.com]

alex. have you considered using guideways and shuttles? i have been looking and you can pick up 3 rails and shuttles on amazon for just under 100 usd. yes its more money but would keep the printer stout and quiet. also makes mounting on the alum extrusions allot easier.

Sorry, only registered users may post in this forum.