FuseBox ~$300 CoreXY Printer

Posted by AlexY

|

Re: FuseBox ~$300 CoreXY Printer March 23, 2016 09:23AM |

Registered: 8 years ago Posts: 25 |

|

Re: FuseBox ~$300 CoreXY Printer March 23, 2016 09:29AM |

Registered: 9 years ago Posts: 251 |

|

Re: FuseBox ~$300 CoreXY Printer March 23, 2016 09:39AM |

Registered: 8 years ago Posts: 25 |

|

Re: FuseBox ~$300 CoreXY Printer March 23, 2016 09:52AM |

Registered: 8 years ago Posts: 25 |

|

Re: FuseBox ~$300 CoreXY Printer March 23, 2016 10:00AM |

Registered: 9 years ago Posts: 251 |

One of the nice things about the 15x15 extrusions is they can take regular hex m3 nuts!Quote

godefroi

And, here's one already. Do I need the fancy square nuts from MiSUMi, or can I buy cheap hex M3 nuts from just about anywhere?

Edited 1 time(s). Last edit at 03/23/2016 10:00AM by widespreaddeadhead.

|

Re: FuseBox ~$300 CoreXY Printer March 23, 2016 10:01AM |

Registered: 8 years ago Posts: 25 |

|

Re: FuseBox ~$300 CoreXY Printer March 23, 2016 10:20AM |

Registered: 8 years ago Posts: 25 |

AlexY mentions in the comments on Thingiverse that he's using 76 oz-in steppers. Judging by what's commonly available (say, at robotdigg), that seems pretty high. They, for example, have:

Also, flat or round shaft, or does it not matter?

- 40 oz-in (34mm body)

- 57 oz-in (40mm body)

- 57 oz-in (40mm body)

- 62 oz-in (48mm body)

- 92 oz-in (60mm body, labeled "high torque")

Also, flat or round shaft, or does it not matter?

|

Re: FuseBox ~$300 CoreXY Printer March 23, 2016 10:42AM |

Registered: 9 years ago Posts: 251 |

Quote

godefroi

AlexY mentions in the comments on Thingiverse that he's using 76 oz-in steppers. Judging by what's commonly available (say, at robotdigg), that seems pretty high. They, for example, have:

Should I go for the 92 oz-in steppers (they're only $1 more than the 62 oz-in), or should I stick with the 62 oz-in? Also, is there any advantage to using 400 steps/rev steppers, or would that just slow everything down by half? They're only $0.10 more in the 62 oz-in size. One of the commenters on Thingiverse mentioned they used the 400 spr stepper for the extruder, is there an advantage to be had there?

- 40 oz-in (34mm body)

- 57 oz-in (40mm body)

- 57 oz-in (40mm body)

- 62 oz-in (48mm body)

- 92 oz-in (60mm body, labeled "high torque")

Also, flat or round shaft, or does it not matter?

Bigger is better right? lol honestly I'm not sure, I ordered the 76oz ones on ebay that have a flat shaft but a round shaft would work fine too. He mentions that the bigger ones you get, the faster you can go, but I believe you'll end up having your speed limited by other factors than the motors. Not sure on this either, but when you place the jumpers under the stepper drivers, it bumps it up to 800steps/rev

|

Re: FuseBox ~$300 CoreXY Printer March 23, 2016 10:56AM |

Registered: 8 years ago Posts: 25 |

Yeah, placing the jumpers puts the motor drivers into microstepping mode, which moves the shaft a fraction of a step at a time instead of a full step. The disadvantage here is that the more microsteps per step you use, the less torque you have. For example, a 76 oz motor in 1/4 step mode (so, 800 steps per rev), only has 30 oz-in of effective torque. At 1/32 microstepping (the default if you're using DRV8825, which is all three jumpers connected), your 76 oz-in motor only has 3.7 oz-in of torque. That's why the drivers do acceleration and deceleration, because if they didn't, they'd miss steps.

The 62 oz-in 400 steps/rev motor at has more torque at 1/16 microstepping than the 76 oz-in 200 steps/rev motor at 1/32 microstepping (6 oz-in vs 3.7 oz-in), and the same effective steps per revolution, so in theory it'd actually be able to run faster? I dunno...

The 62 oz-in 400 steps/rev motor at has more torque at 1/16 microstepping than the 76 oz-in 200 steps/rev motor at 1/32 microstepping (6 oz-in vs 3.7 oz-in), and the same effective steps per revolution, so in theory it'd actually be able to run faster? I dunno...

|

redesigned bowden direct drive to E3D v6 3mm March 24, 2016 03:34PM |

Registered: 8 years ago Posts: 776 |

hi,

ok so i have a heck of a lot of 3mm PLA because i have a mendel90, so in the fusebox-derivative that i'm creating i had to get an E3D v6 3mm bowden extruder, which came with a bowden tube at 8mm OD as part of the kit. i printed up the direct-drive extruder parts in the fusebox zip archive... and.... i was not impressed. the load on the extruder arm was so high that i couldn't install the spring. the spring itself kept popping out. when i finally got it installed the spring load bent the extruder arm so hard that it lifted *five millimetres* off the top of the extruder body - enough to almost have the bearing clear the *top* of the drive gear. additionally, the amount of bend on the filament - when i actually managed to get it in - looked to be so extreme that i was concerned that the filament would break. in fact, some of the wood-fibre filament that i have _did_ actually break just trying to bend it to get it through into the bowden tube feeder.

by chance (by mistake) i happened to order one of those all-metal extruders from reprap.me, which i assembled only to find that it suits only 5mm OD bowden tubing! soooo, what i did was:

now, whilst the original extruder arm fit fine, i decided instead to use the all-metal one. overall, i have a better design: the all-metal extruder body has no way of capturing the filament on first install.

if anyone is interested in the designs, the git repository is at [hands.com] - you will need python2 and a recent version of openscad to generate the STL files.

ok so i have a heck of a lot of 3mm PLA because i have a mendel90, so in the fusebox-derivative that i'm creating i had to get an E3D v6 3mm bowden extruder, which came with a bowden tube at 8mm OD as part of the kit. i printed up the direct-drive extruder parts in the fusebox zip archive... and.... i was not impressed. the load on the extruder arm was so high that i couldn't install the spring. the spring itself kept popping out. when i finally got it installed the spring load bent the extruder arm so hard that it lifted *five millimetres* off the top of the extruder body - enough to almost have the bearing clear the *top* of the drive gear. additionally, the amount of bend on the filament - when i actually managed to get it in - looked to be so extreme that i was concerned that the filament would break. in fact, some of the wood-fibre filament that i have _did_ actually break just trying to bend it to get it through into the bowden tube feeder.

by chance (by mistake) i happened to order one of those all-metal extruders from reprap.me, which i assembled only to find that it suits only 5mm OD bowden tubing! soooo, what i did was:

- redesign the bowden extruder assembly to move the spring-holder back. this reduced the extreme pressure to manageable levels 9washers can be installed to increase the pressure)

- oversized the spring holder so that the spring fits *into* it (instead of having to insert a pin in the end of the spring)

- added a "capture channel" so that the filament can auto-feed

- moved the inlet and outlet holes over by 2mm so that there is less extreme bend on the 3mm filament.

now, whilst the original extruder arm fit fine, i decided instead to use the all-metal one. overall, i have a better design: the all-metal extruder body has no way of capturing the filament on first install.

if anyone is interested in the designs, the git repository is at [hands.com] - you will need python2 and a recent version of openscad to generate the STL files.

|

Re: FuseBox ~$300 CoreXY Printer March 26, 2016 08:50AM |

Registered: 8 years ago Posts: 47 |

Quote

godefroi

AlexY mentions in the comments on Thingiverse that he's using 76 oz-in steppers. Judging by what's commonly available (say, at robotdigg), that seems pretty high. They, for example, have:

Should I go for the 92 oz-in steppers (they're only $1 more than the 62 oz-in), or should I stick with the 62 oz-in? Also, is there any advantage to using 400 steps/rev steppers, or would that just slow everything down by half? They're only $0.10 more in the 62 oz-in size. One of the commenters on Thingiverse mentioned they used the 400 spr stepper for the extruder, is there an advantage to be had there?

- 40 oz-in (34mm body)

- 57 oz-in (40mm body)

- 57 oz-in (40mm body)

- 62 oz-in (48mm body)

- 92 oz-in (60mm body, labeled "high torque")

Also, flat or round shaft, or does it not matter?

keep an eye out on ebay. i got 5 84oz steppers for 42 bucks. 11 dollars shipping.

[www.ebay.com]

|

Re: FuseBox ~$300 CoreXY Printer March 26, 2016 08:53AM |

Registered: 8 years ago Posts: 47 |

one thing i noticed about the carriage. i have printed it a couple times. and had a friend print it. seems the belts dont fit in the slots. i have modified it and about to print it to see how well it works. i measured my belts and they were wider then what is designed on the stl. if it works i will upload it. I have also modified the y rod ends as they werent holding up. how did you all deal with the belts? and did anyone else have problems with the y rods?

|

Re: FuseBox ~$300 CoreXY Printer March 26, 2016 09:19AM |

Registered: 8 years ago Posts: 776 |

Quote

pen25

one thing i noticed about the carriage. i have printed it a couple times. and had a friend print it. seems the belts dont fit in the slots. i have modified it and about to print it to see how well it works. i measured my belts and they were wider then what is designed on the stl. if it works i will upload it. I have also modified the y rod ends as they werent holding up. how did you all deal with the belts? and did anyone else have problems with the y rods?

i've completely replaced the y rod ends, with types that have two bolts (one either side), as well as arranging so that both the idlers and the motor assemblies have a cover that they fit into, so as to push them downwards. also ive turned the *entire* topcorexy set of assemblies round so that the y rods are *ABOVE* the extrusions *NOT* below. this means a bit more PLA used in the idlers and motor assemblies but i can live with that.

the carriage... yeah i had to spend about 2 hours - maybe more - with an xacto craft knife and a 1mm jeweller's screwdriver, digging out the slots. i watched two episodes of mythbusters and a film, so it was a hell of a long time. if you're going to do this BE CAREFUL. basically you cut along the top in the gap for about 15 to 20 minutes, making sure that you're not cutting off the "teeth" in the process, for goodness sake watch your hands, then with the jeweller's screwdriver you push that down each gap between each of the teeth, and twist it gently. you need to clear out to a depth of *seven* millimetres - look carefully at the STL file, you'll soon see why.

basically the carriage belt-holders are not engineered well (anything that needs extremely fine tolerances on printing parts is, by definition, not well-designed. also, the gap is simply too small for the average 3d printer to cope with). for the mendel90, chris (nophead) created a much better design of belt-holder, which has two separate parts (actually three) - a clamp with "teeth" that fits into the belt is a separate part which is attached with an allen-key bolt. then also he arranged for a curved piece to be attached on the *end* of a bolt, to act as a belt-tightener.

overall this is a heck of a lot better design - if nothing else, if the "teeth" part doesn't come out right first time, you're not looking at wasting 2-3 metres of PLA, you can just reprint the teeth part in a few minutes.

*BUT*, here's the down-side: the mendel90 is a quite chunky design, with large, sturdy parts, and it's a standard extruder type. the fusebox is a high-speed corexy design where weight and size really matter on the carriage

bottom line... you're probably going to either have to print slow and at the finest resolution your printer can manage, and hope that it prints well, or try some different gcode-generating software (try cura), or, just be prepared to rework the part with a sharp knife.

|

Re: FuseBox ~$300 CoreXY Printer March 26, 2016 09:43AM |

Registered: 8 years ago Posts: 776 |

Quote

pen25

I have also modified the y rod ends as they werent holding up. how did you all deal with the belts? and did anyone else have problems with the y rods?

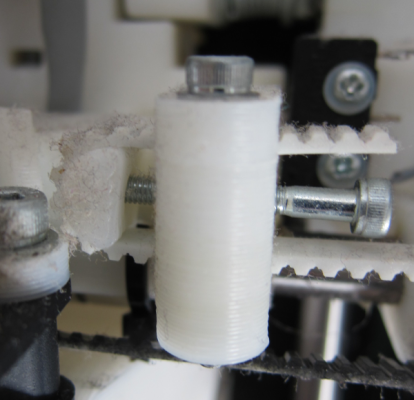

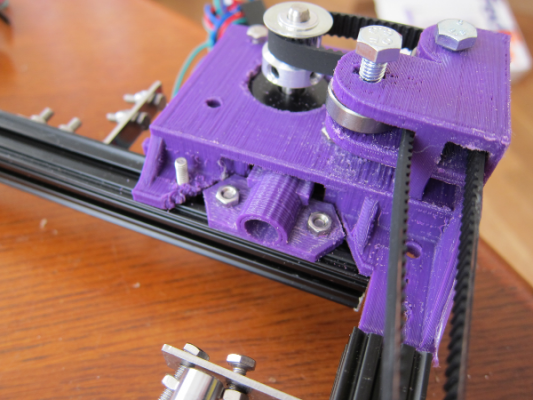

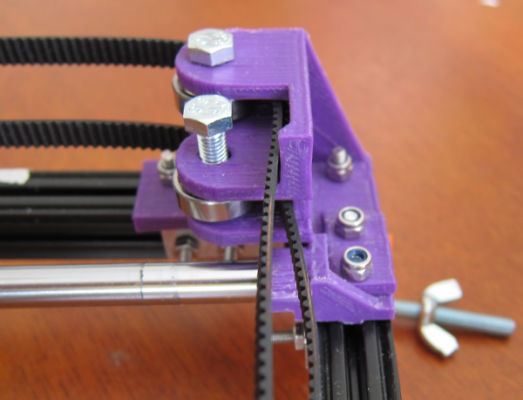

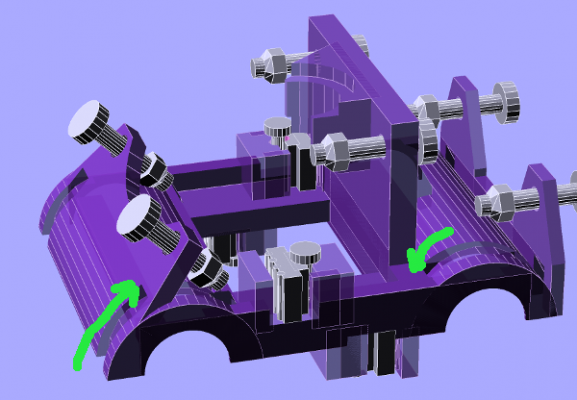

ok here you can see the alternative y-rod arrangement, with the motor assembly sitting on top of it and keeping it down:

this is an earlier iteration, i've since replaced this, but you can see that i have an extra piece of plastic on the (redesigned) idlers which sits *above* the YRodMount part, then a bolt goes through *both* pieces.

in this way the YRods ain't going anywhere.

|

Re: FuseBox ~$300 CoreXY Printer March 26, 2016 04:16PM |

Registered: 8 years ago Posts: 776 |

Quote

pen25

one thing i noticed about the carriage. i have printed it a couple times. and had a friend print it. seems the belts dont fit in the slots. i have modified it and about to print it to see how well it works. i measured my belts and they were wider then what is designed on the stl. if it works i will upload it.

just occurred to me: you *need* 6mm width belts. if you're trying to fit 8mm or wider you'll run into problems: the idlers require 6mm belts. the x and y ends require 6mm belts. the motors are set up so that you turn one of the gears upside-down... and they are both required to take 6mm width gears - GT20-6 - which only works because the motor shaft is 25mm high so they line up correctly each way up... basically if you haven't got 6mm width belt you're in for a massive task redesigning pretty much the entire corexy printer. you might have got the message by now: best get some 6mm width belt, eh?

Edited 1 time(s). Last edit at 03/26/2016 06:16PM by lkcl.

|

Re: FuseBox ~$300 CoreXY Printer March 26, 2016 07:23PM |

Registered: 8 years ago Posts: 47 |

well the gap is 1.2mm and only .7mm from tooth to edge on the original design. the one i edited is 1.8mm edge to edge and 1.3mm tooth to edge. i just printed it and the belts fit fine. and they are the 6mm belts specified in the bom. my belt measures 1.8mm on the calipers.and i just finished printing this new one and belts fit perfect. but those darn ears are curling up on me and breaking off. one more thing to mess with.

Edited 1 time(s). Last edit at 03/26/2016 07:26PM by pen25.

Edited 1 time(s). Last edit at 03/26/2016 07:26PM by pen25.

|

Re: FuseBox ~$300 CoreXY Printer March 27, 2016 06:23AM |

Registered: 8 years ago Posts: 776 |

Quote

pen25

well the gap is 1.2mm and only .7mm from tooth to edge on the original design. the one i edited is 1.8mm edge to edge and 1.3mm tooth to edge. i just printed it and the belts fit fine. and they are the 6mm belts specified in the bom. my belt measures 1.8mm on the calipers.and i just finished printing this new one and belts fit perfect. but those darn ears are curling up on me and breaking off. one more thing to mess with.

apologies, you said "width" - which, when used in context (i.e. relative to) the belt, i believe, by convention, has a different definition from what you may have intended to communicate. length (3 metres), width (in this case 6mm), so depth (or height) would refer to the 1.8mm you're taking about. doesn't help that when you refer to the gap i'd assume that by convention "deep" in this case would be the 7mm... but never mind, we got there

so i just measured the belt that i got from alfa-tech, and (with a ruler) it looks like when measuring the depth outer-part-of-tooth to outer-edge-of-belt it's 1.5mm, and on the inner-part-of-tooth to same inner-edge-of-belt it's maybe 0.7 maybe 0.8mm.

so that belt fits perfectly [once i've mashed the damn gaps for 1/2 an hour each with a scalpel and jeweller's screwdriver....]

the problem with the adaptation approach that you're taking is, the belt's depth may end up scraping or jamming in the idlers. i think you'll be ok in the x-ends.

apologies i don't know what you mean by "ears", and you've attached something which requires a proprietary application, and there is absolutely no way that i am going to install untrustworthy untrusted proprietary applications, nor encourage nor endorse such companies to continue to sell such software in any way by using any "free" versions. you have no doubt heard of software libre, and why it exists. so, if you'd like me to take a look at that, you'll need to export to a format which is unencumbered by patents, fully-documented and has good support in libre applications. STL files would meet those requirements.

|

Re: FuseBox ~$300 CoreXY Printer March 27, 2016 08:43PM |

Registered: 8 years ago Posts: 776 |

Quote

pen25

. but those darn ears are curling up on me and breaking off. one more thing to mess with.

ok if you're referring to the first layer not sticking, such that the fine detail of this design's parts are curling up, then may i suggest that you add a "brim" of around 5mm. i also use a heated bed *and* unscented hairspray. i'm developing a libre eco-conscious laptop: some of the parts are 230mm x 12 x 16mm so curling was a serious problem that i absolutely had to solve. brim. heat. hairspray. bye bye problem.

anyway, apologies for bringing it up: if you're not familiar with why it's... well, first you should google and read the "father sylvester response", and substitute for the proprietary software wherever you see "microsoft word" replace it with "whatever proprietary software you're using", and wherever you see "RTF" or "Text" replace it with "STL" or "DXF" or something. being blunt and direct, pen25, if you don't mind me being so, it's basically really rude to assume that the person you're talking to wishes to spend *their* personal funds on (a) proprietary software (b) proprietary operating systems (c) a replacement computer *capable* of running both (a) and (b).

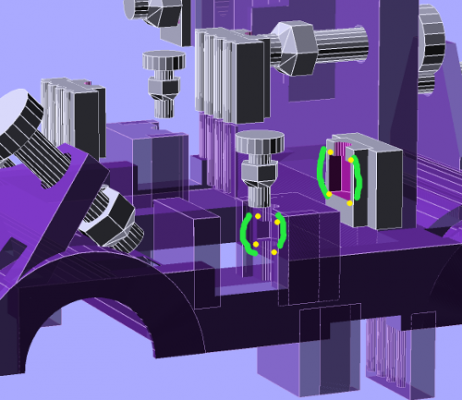

anyway, i thought you might appreciate knowing that i really couldn't stand the thought of hacking the carriage belt traps even more with an xacto knife, so i redesigned them [in pyopenscad], and i came up with a scheme which uses an M2 5mm pozi screw and M2 hex nut:

highlighted in the green brackets you can see a channel for the M2 holt, and highlighted by the yellow dots you can see a capture point for the M2 hex-nut. the belt grabbers are *separate* parts, such that (a) you can adjust them simply and easily if the belt happens to be a different thickness and (b) if they print incorrectly you're not wasting 2 hours and 3 metres of PLA and (c) there's a large gap such that the printer is far more likely to be accurate on the first go.

the second thing i found that was problematic about these designs is the cable-tie points. basically there's an assumption that the gcode-generation software used (or the printer itself) isn't going to leave bits of plastic inside the channels.. see arrows in green:

basically on this redesign what i've done is make the channels on the *outside* of the bearing-holders, not the inside. there's a couple of places which are bridged over, but from different angles you can definitely see clear air.

the reason why it's problematic to have totally-enclosed (curved) channels is illustrated by what i had to do when printing out the original parts. the cable-ties wouldn't go through: they were totally jammed. of course, normally, i would use an xacto-knife and jeweller's screwdriver.... but these are *curved* channels. so instead, i got a metal keyring, bent it open a bit, got a fine key-file, sharpened one end, and began jabbing and scraping around until bits started falling out.

TWO HOURS LATER i had managed to get all twelve cable-ties into the X-End, Y-End and Carriage parts.

all it takes is to have open channels like on the redesign.

anyway - if anyone would like to generate the STL files you can do so by downloading the source code with git. you'll need python2 and a recent version of openscad [these programs are entirely libre]. if anyone would like me to generate the STL files on their behalf, drop me a line.

git clone [hands.com]

|

Re: FuseBox ~$300 CoreXY Printer March 28, 2016 07:17PM |

Registered: 8 years ago Posts: 47 |

Quote

lkcl

Quote

pen25

. but those darn ears are curling up on me and breaking off. one more thing to mess with.

ok if you're referring to the first layer not sticking, such that the fine detail of this design's parts are curling up, then may i suggest that you add a "brim" of around 5mm. i also use a heated bed *and* unscented hairspray. i'm developing a libre eco-conscious laptop: some of the parts are 230mm x 12 x 16mm so curling was a serious problem that i absolutely had to solve. brim. heat. hairspray. bye bye problem.

anyway, apologies for bringing it up: if you're not familiar with why it's... well, first you should google and read the "father sylvester response", and substitute for the proprietary software wherever you see "microsoft word" replace it with "whatever proprietary software you're using", and wherever you see "RTF" or "Text" replace it with "STL" or "DXF" or something. being blunt and direct, pen25, if you don't mind me being so, it's basically really rude to assume that the person you're talking to wishes to spend *their* personal funds on (a) proprietary software (b) proprietary operating systems (c) a replacement computer *capable* of running both (a) and (b).

anyway, i thought you might appreciate knowing that i really couldn't stand the thought of hacking the carriage belt traps even more with an xacto knife, so i redesigned them [in pyopenscad], and i came up with a scheme which uses an M2 5mm pozi screw and M2 hex nut:

[attachment 75463 Untitled.png]

highlighted in the green brackets you can see a channel for the M2 holt, and highlighted by the yellow dots you can see a capture point for the M2 hex-nut. the belt grabbers are *separate* parts, such that (a) you can adjust them simply and easily if the belt happens to be a different thickness and (b) if they print incorrectly you're not wasting 2 hours and 3 metres of PLA and (c) there's a large gap such that the printer is far more likely to be accurate on the first go.

the second thing i found that was problematic about these designs is the cable-tie points. basically there's an assumption that the gcode-generation software used (or the printer itself) isn't going to leave bits of plastic inside the channels.. see arrows in green:

[attachment 75464 Untitled2.png]

basically on this redesign what i've done is make the channels on the *outside* of the bearing-holders, not the inside. there's a couple of places which are bridged over, but from different angles you can definitely see clear air.

the reason why it's problematic to have totally-enclosed (curved) channels is illustrated by what i had to do when printing out the original parts. the cable-ties wouldn't go through: they were totally jammed. of course, normally, i would use an xacto-knife and jeweller's screwdriver.... but these are *curved* channels. so instead, i got a metal keyring, bent it open a bit, got a fine key-file, sharpened one end, and began jabbing and scraping around until bits started falling out.

TWO HOURS LATER i had managed to get all twelve cable-ties into the X-End, Y-End and Carriage parts.

all it takes is to have open channels like on the redesign.

anyway - if anyone would like to generate the STL files you can do so by downloading the source code with git. you'll need python2 and a recent version of openscad [these programs are entirely libre]. if anyone would like me to generate the STL files on their behalf, drop me a line.

git clone [hands.com]

yea i didnt have any issues with the channels. and i took and measured belts from 4 different printers and they all measured 1.7 to 1.9mm thick and i was able to fit them into the 1.8mm gap. i will say though that the 1.7mm thick belt went in too easy so id probably use a bit of hotglue to secure the belt. and the 1.9mm belt took some coaxing. BTW i also uploaded the file to thingiverse allong with the updated carriage.

|

Re: FuseBox ~$300 CoreXY Printer March 29, 2016 01:40PM |

Registered: 8 years ago Posts: 776 |

Quote

pen25

yea i didnt have any issues with the channels. and i took and measured belts from 4 different printers and they all measured 1.7 to 1.9mm thick and i was able to fit them into the 1.8mm gap. i will say though that the 1.7mm thick belt went in too easy so id probably use a bit of hotglue to secure the belt. and the 1.9mm belt took some coaxing.

yeah that doesn't sound very sensible - like i said, these parts are not designed with engineering tolerances in mind, i've encountered a couple other instances of parts like that. the reason i say it doesn't sound very sensible is, what happens when the belt, which will vibrate, hit the X-Ends and Idler edges, and, under friction, eventually wear out - perhaps rather quickly? then you'd be looking at stripping out that belt, including possibly breaking the carriage if the belt is attached firmly by the glue - now you're looking at a major overhaul, yeah?

with the redesigned carriage at least the tolerances in the belt are taken up by the screws as they push in between the main carriage and the bolt-holders...

Quote

BTW i also uploaded the file to thingiverse allong with the updated carriage.

yay! could i ask you a favour, drop STL files in there as well? i've always found it easier to just download STL files (which go straight into all the gcode-generation software), i'm sure other people would too.

|

Re: FuseBox ~$300 CoreXY Printer March 29, 2016 08:00PM |

Registered: 8 years ago Posts: 47 |

Quote

lkcl

Quote

pen25

yea i didnt have any issues with the channels. and i took and measured belts from 4 different printers and they all measured 1.7 to 1.9mm thick and i was able to fit them into the 1.8mm gap. i will say though that the 1.7mm thick belt went in too easy so id probably use a bit of hotglue to secure the belt. and the 1.9mm belt took some coaxing.

yeah that doesn't sound very sensible - like i said, these parts are not designed with engineering tolerances in mind, i've encountered a couple other instances of parts like that. the reason i say it doesn't sound very sensible is, what happens when the belt, which will vibrate, hit the X-Ends and Idler edges, and, under friction, eventually wear out - perhaps rather quickly? then you'd be looking at stripping out that belt, including possibly breaking the carriage if the belt is attached firmly by the glue - now you're looking at a major overhaul, yeah?

with the redesigned carriage at least the tolerances in the belt are taken up by the screws as they push in between the main carriage and the bolt-holders...

Quote

BTW i also uploaded the file to thingiverse allong with the updated carriage.

yay! could i ask you a favour, drop STL files in there as well? i've always found it easier to just download STL files (which go straight into all the gcode-generation software), i'm sure other people would too.

the hot glue will give before the plastic of the carriage or the belt. and it wouldnt be difficult to modify the carriage to allow you to make a threaded hole on the backside and use an m3 screw to take up the gap. but right now my belts fit snug on the mod i made. and the 1.7mm thick belt fit fine just slid in a little too lose for my liking hence the use of a hot glue to secure it and prevent the movement of any of the belt. and there is an stl on the thingiverse page. i can upload the skp file when i get home which i normally do. this makes editing the file easier instead of having to import it.

|

Re: FuseBox ~$300 CoreXY Printer April 06, 2016 01:41AM |

Registered: 8 years ago Posts: 47 |

i have updated my BOM to include a few more things i have purchased. I am still under 400 USD but when i order some corner brackets i will be under 425. this isnt including a raspberry pi 3 for octoprint as it isnt needed. and i am thinking the L and t brackets can be left off as right now i am not seeing them doing much but i still havent completed the build fully. and of course i have some extra's i ordered that wasnt needed but better to have too many then not enough

[docs.google.com]

[docs.google.com]

|

Re: FuseBox ~$300 CoreXY Printer April 06, 2016 04:18AM |

Registered: 8 years ago Posts: 776 |

[update / summary: pen25, alex_f, the designer of the fusebox, is absolutely right about needing metal braces of some kind, please follow his advice!]

ahh that's a mistake. like, a really serious one. those misumi HLTBS3 (or whatever) right-angle corner braces are absolutely essential to keep the frame rigid. without them the entire design is... basically.... well, if you've ever seen something called the "buckminster fullerene" (google it), the frame's rigidity is pretty much like that.

the fusebox design as-is only has diagonal-braces - into *plastic* - on *two* faces. that is *nowhere near* enough to create rigidity. those misumi brackets have a very special design where they interlock into the rails on the frame, such that only with two nuts and bolts the two extrusions they are attached to have absolutely no movement in any direction or rotation. they're really impressive.

unless you have a company account by which you can place an order for the misumi brackets, the best substitute that i could find (on short notice) is this:

[www.ebay.co.uk]

they're by no means perfect - they're 50mm which is very large, they're 15mm height *but* the screw-holes are off at 8mm-6mm, not 7.5mm-7.5mm. you should however be able to source something similar from a local hardware store or ironmonger's very easily.

please do not underestimate how critical these are to stability of the frame. also if you are going to source your own steel corner brackets make absolutely certain that they take four screws. two on a bent-steel sheet will NOT be enough to give any kind of rigidity.

the other alternative is to fill in the open sides with MDF, hardboard or anything else you can obtain, but even there, you cannot fill in the top corexy part so you will at the very least need four right-angle corner brackets (of the misumi type or the ones like in the ebay link above).

if you're truly on a budget, at the absolute absolute minimum make sure you have four metal braces in the top corexy assembly, ok?

Edited 1 time(s). Last edit at 04/06/2016 08:14AM by lkcl.

Quote

pen25

i have updated my BOM to include a few more things i have purchased. I am still under 400 USD but when i order some corner brackets i will be under 425. this isnt including a raspberry pi 3 for octoprint as it isnt needed. and i am thinking the L and t brackets can be left off as right now i am not seeing them doing much

ahh that's a mistake. like, a really serious one. those misumi HLTBS3 (or whatever) right-angle corner braces are absolutely essential to keep the frame rigid. without them the entire design is... basically.... well, if you've ever seen something called the "buckminster fullerene" (google it), the frame's rigidity is pretty much like that.

the fusebox design as-is only has diagonal-braces - into *plastic* - on *two* faces. that is *nowhere near* enough to create rigidity. those misumi brackets have a very special design where they interlock into the rails on the frame, such that only with two nuts and bolts the two extrusions they are attached to have absolutely no movement in any direction or rotation. they're really impressive.

unless you have a company account by which you can place an order for the misumi brackets, the best substitute that i could find (on short notice) is this:

[www.ebay.co.uk]

they're by no means perfect - they're 50mm which is very large, they're 15mm height *but* the screw-holes are off at 8mm-6mm, not 7.5mm-7.5mm. you should however be able to source something similar from a local hardware store or ironmonger's very easily.

please do not underestimate how critical these are to stability of the frame. also if you are going to source your own steel corner brackets make absolutely certain that they take four screws. two on a bent-steel sheet will NOT be enough to give any kind of rigidity.

the other alternative is to fill in the open sides with MDF, hardboard or anything else you can obtain, but even there, you cannot fill in the top corexy part so you will at the very least need four right-angle corner brackets (of the misumi type or the ones like in the ebay link above).

if you're truly on a budget, at the absolute absolute minimum make sure you have four metal braces in the top corexy assembly, ok?

Edited 1 time(s). Last edit at 04/06/2016 08:14AM by lkcl.

|

Re: FuseBox ~$300 CoreXY Printer April 06, 2016 02:09PM |

Registered: 12 years ago Posts: 44 |

Quote

lkcl

anyway - if anyone would like to generate the STL files you can do so by downloading the source code with git. you'll need python2 and a recent version of openscad [these programs are entirely libre]. if anyone would like me to generate the STL files on their behalf, drop me a line.

git clone [hands.com]

I just finished redesigning the x-carriage in OpenScad myself. So far it's a straight clone, but I have plans to extend it with more options. I tried to look at your repo but it doesn't seem to exist in the link as published here.

git clone [hands.com]\~lkcl//foldable3dsandwich200 Cloning into 'foldable3dsandwich200'... fatal: repository 'http://hands.com/~lkcl//foldable3dsandwich200/' not found

Did it move?

You can find mine here: openscad-FuseBox on GitHub

|

Re: FuseBox ~$300 CoreXY Printer April 06, 2016 02:31PM |

Registered: 8 years ago Posts: 776 |

|

Re: FuseBox ~$300 CoreXY Printer April 07, 2016 01:24PM |

Registered: 12 years ago Posts: 44 |

@lkcl Thanks! That works. Also explains why the folder looked empty on the web interface.

I'm interested in your extruder you ended up with because I'm also using 3mm filament. You're right that the simple FuseBox extruder doesn't work for it at all. :-(

This is my first bowden extruder so I'm a newb here. I was hoping your redesign would include a useful extruder for 3mm, but it looks like you had one or bought one somewhere. Back to the drawing board for me, then. I can redesign the fb-extruder, but if I'm going that far I might just start with this one by schlotzz instead. At least it's already in OpenSCAD, it has a 3mm option and it has plenty of remixed versions including some NinjaFlex-capable mods. But I'm open to suggestions.

|

Re: FuseBox ~$300 CoreXY Printer April 07, 2016 03:27PM |

Registered: 8 years ago Posts: 269 |

Quote

phord

@lkcl Thanks! That works. Also explains why the folder looked empty on the web interface.

I'm interested in your extruder you ended up with because I'm also using 3mm filament. You're right that the simple FuseBox extruder doesn't work for it at all. :-(

This is my first bowden extruder so I'm a newb here. I was hoping your redesign would include a useful extruder for 3mm, but it looks like you had one or bought one somewhere. Back to the drawing board for me, then. I can redesign the fb-extruder, but if I'm going that far I might just start with this one by schlotzz instead. At least it's already in OpenSCAD, it has a 3mm option and it has plenty of remixed versions including some NinjaFlex-capable mods. But I'm open to suggestions.

Schlotzz's extruder works really well, it's what I run on the FB2020 combined with an E3D HobbGoblin drive gear.

|

Re: FuseBox ~$300 CoreXY Printer April 07, 2016 06:17PM |

Registered: 8 years ago Posts: 776 |

Quote

phord

@lkcl Thanks! That works. Also explains why the folder looked empty on the web interface.

yep

Quote

I'm interested in your extruder you ended up with because I'm also using 3mm filament. You're right that the simple FuseBox extruder doesn't work for it at all. :-(

nope. it's designed for a MK8 drive gear, and the arm has a hole only for a 1.75mm filament (easily fixed with a 3mm drill bit, it has to be pointed out...) - but the extra pressure required for 3mm is just too much, even for the low-diameter MK8.

Quote

This is my first bowden extruder so I'm a newb here. I was hoping your redesign would include a useful extruder for 3mm, but it looks like you had one or bought one somewhere.

yes i designed one. i'm currently redoing it to suit a MK8 drive gear. i did buy an "all aluminium kit" but ran into *exactly* the same problem - skipping - because it's based around a MK9 drive gear which is an 11mm OD so *even worse* gearing than a MK8 (which is only 9mm or so and has hobbing so the effective diameter is even less - around 7mm).

i basically got an E3Dv6 hotend bowden "kit" (can i recommend you get one fully-assembled? installing the thermistor is an utter pain) and it came with a huge 6mm OD PTFE 800mm tube, with a huuuge oversized (like, 12mm or so) attachment at the other end where you'd screw it into the geared extruder. of course, that bloody well didn't fit into the all-aluminium kit, did it?

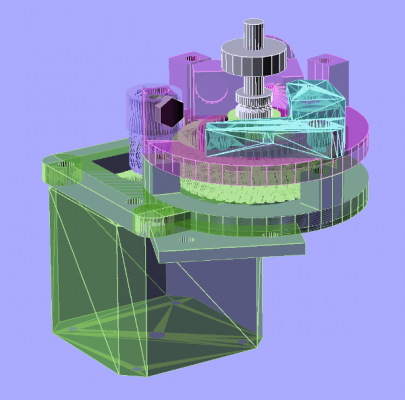

sooo... due to the unusual combination of bits that i had, i had to design my own, and it had to be geared. anyway compared to other geared extruders i've seen, which usually have really complex bearing arrangements (especially the ones with hobbed bolts), or they're absolutely huge, or they require double-spring sets, and... just... argh - i really like the one i came up with, it's really simple to assemble, it's compact despite being geared (25mm between gear axles), it uses an off-the-shelf MK8 drive gear (not a hobbed bolt, which you'd have to custom-machine or order on ebay.) and it doesn't involve a lot of parts. openscad render with the top off:

i haven't done the arm in PLA, yet, but i am planning to. you're welcome to help with that if you like.

the only niggle i've had is when jamming the MK8 drive gear into the gear: i'm using a nut and bolt to press it in (smooth shaft on most of it, then SLOWLY turn the nut a bit at a time), but if it goes off-centre that's it, you're hosed: cut the drive gear out, and re-print another gear. i messed up 2 that way before i worked out how to get it in cleanly. with the drive gear off-centre, as the 46-tooth gear turns, the filament feeds fine for 180 degrees, stops.... then carries on after another 180 degrees... argh whoops

Quote

Back to the drawing board for me, then. I can redesign the fb-extruder, but if I'm going that far I might just start with this one by schlotzz instead.

it's a direct drive. please: don't do it. really. the pressure caused by 3mm filament, especially if you're intending to use 0.3mm (or less) nozzles, is so high that you'll almost certainly get "skipping" even at 20mm/min filament rates.... just like i did. and it's cost me over a week - when time is critical - to get this sorted.

Quote

At least it's already in OpenSCAD, it has a 3mm option and it has plenty of remixed versions including some NinjaFlex-capable mods. But I'm open to suggestions.

i suggest seeing if you can find a geared one that you like the look of - you're welcome to try the one i've made, i'd certainly be interested to hear your thoughts, work with you to get good results, and also i could use the help clarifying the BOM. things that came with the "all-metal kit" i got from alfa-tech, i don't really know exactly what's in it, so wouldn't know where to order the parts. the spring's *enormously* strong, they supplied some sort of short hex bolt you drop in it then a 3mm screw can fit in the hex-hole and you can screw that down to pressurise the spring; the bearing is small (3mm ID, about 4mm high, about 11mm OD, and it has a semi-circular groove on the outer edge which helps keep the filament in place. great idea... i just have no idea what it's called! [update: it's a 604UU groove bearing]

Quote

AX

Schlotzz's extruder works really well, it's what I run on the FB2020 combined with an E3D HobbGoblin drive gear.

[e3d-online.com] i assume? ok so it's as effective-gearing as a MK8. cool. that's great to hear that people are getting along well with schlotzz's extruder - questions for you though:

- are you using 3mm filament

- what nozzle sizes do you use

- what's the rating on the motors that you've got

- what micro-stepping setting do you use

- and what max current have you set?

all these things i've found are critically linked to what kind of pressure you're likely to see. i have 3mm filament, i *did* have a 0.3mm nozzle (swapped it out for a 0.4), i've set 1/4 micro-stepping, 1.1A max current (at the moment), and 84oz-in NEMA17's... i was *still* getting skipping with two different direct-drive extruders that i tried.

Edited 1 time(s). Last edit at 04/08/2016 08:59AM by lkcl.

|

Re: FuseBox ~$300 CoreXY Printer April 07, 2016 06:49PM |

Registered: 8 years ago Posts: 269 |

Quote

lkcl

Quote

AX

Schlotzz's extruder works really well, it's what I run on the FB2020 combined with an E3D HobbGoblin drive gear.

[e3d-online.com] i assume? ok so it's as effective-gearing as a MK8. cool. that's great to hear that people are getting along well with schlotzz's extruder - questions for you though:

- are you using 3mm filament

- what nozzle sizes do you use

- what's the rating on the motors that you've got

- what micro-stepping setting do you use

- and what max current have you set?

all these things i've found are critically linked to what kind of pressure you're likely to see. i have 3mm filament, i *did* have a 0.3mm nozzle (swapped it out for a 0.4), i've set 1/4 micro-stepping, 1.1A max current (at the moment), and 84oz-in NEMA17's... i was *still* getting skipping with two different direct-drive extruders that i tried.

That's the one, was bought by accident, was left in the basket pricing things up along with a spare Lite6, so I thought I'd use it xD I use 1.75mm as it's what the rest of my printers use, it doesn't really make sense for me to use 3mm due to that. I stick with a stock 0.4mm nozzle on the E3D Lite6, the extruder motor is a 40Ncm ( I've no idea what the Imperial value is, I'm in the UK so I work in metric) running at 1/16 microstepping and as for the current, I've not really measured it, I've set the pot to where it extrudes well and left it, the extruder driver is a A4988, the rest are DRV8825s, I just got lazy when swapping out to the 8825s not wanting to do a full extruder recalibration.

|

Re: FuseBox ~$300 CoreXY Printer April 07, 2016 07:17PM |

Registered: 8 years ago Posts: 776 |

Quote

Ax

That's the one, was bought by accident, was left in the basket pricing things up along with a spare Lite6, so I thought I'd use it xDQuote

lkcl

Quote

AX

Schlotzz's extruder works really well, it's what I run on the FB2020 combined with an E3D HobbGoblin drive gear.

[e3d-online.com] i assume?

Quote

I use 1.75mm as it's what the rest of my printers use, it doesn't really make sense for me to use 3mm due to that.

yeah true - i'm using 3mm only because my other printer is a mendel90. i'll be converting to 1.75mm... later

Quote

I stick with a stock 0.4mm nozzle on the E3D Lite6, the extruder motor is a 40Ncm ( I've no idea what the Imperial value is, I'm in the UK so I work in metric) running at 1/16 microstepping and as for the current, I've not really measured it, I've set the pot to where it extrudes well and left it, the extruder driver is a A4988, the rest are DRV8825s, I just got lazy when swapping out to the 8825s not wanting to do a full extruder recalibration.

84oz-in is about 60Ncm. A4988s are quite beefy, they do about 1.7A i think, but it depends on your board. you're almost certainly using the default of 1/16th micro-stepping. you're probably doing about between.... 0.75A and 1A.... and you see, the thing is, the difference between 3.0 and 1.75 is like a factor of 1.7. so... i don't quite know the math but i suspect that the pressure is probably a square-law (it's cross-section based which is 2D which spells "square of diameter" to me...)

sooo.... that's a whopping *three* times increase in the amount of pressure needed! no wonder everyone's moving to 1.75mm filament, and no wonder the OD on 3mm bowden tubes is so large! the bowden tube itself as well as the motor/gearing eneds to be able to withstand three times the pressure. wow.

so, phord, can you see why a direct-drive extruder on 3.0mm filament would fail? you'd need like.... 4 to 5A to the motor! i hadn't actually done the math beforehand, but this explains why my first attempt (only a 2.6:1 gear ratio) also failed. when i went to 3.54:1 (46 to 13 teeth), it worked fine.

Edited 1 time(s). Last edit at 04/08/2016 04:23AM by lkcl.

Sorry, only registered users may post in this forum.