Two colours and moving the not used hotend?

Posted by LarsK

|

Two colours and moving the not used hotend? September 17, 2015 03:01PM |

Registered: 9 years ago Posts: 346 |

Hello, anybody have any experience with more then one extruder?

I see most designs out there have both the nozzles fixed. Some people say that this can give problems with the not used nozzle which contaminates the active nozzle. I can imagine just a little oozing can give problems.

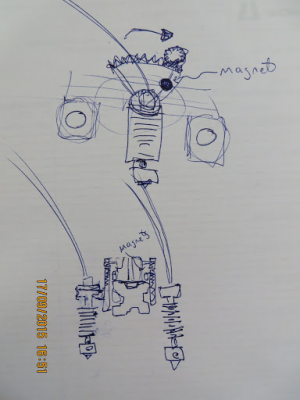

I was thinking about a design where I can tilt the not used nozzle with a servo. When being used the nozzle is held in place by a magnet (and the servo).

Very quick sketch:

I imagine both nozzles mounted on an alu profile and a 1/4 gear to turn it.

What do you think? Should the nozzles just be fixed and overcomming the problems or is this a path to walk down?

Edited 2 time(s). Last edit at 09/17/2015 03:22PM by LarsK.

I see most designs out there have both the nozzles fixed. Some people say that this can give problems with the not used nozzle which contaminates the active nozzle. I can imagine just a little oozing can give problems.

I was thinking about a design where I can tilt the not used nozzle with a servo. When being used the nozzle is held in place by a magnet (and the servo).

Very quick sketch:

I imagine both nozzles mounted on an alu profile and a 1/4 gear to turn it.

What do you think? Should the nozzles just be fixed and overcomming the problems or is this a path to walk down?

Edited 2 time(s). Last edit at 09/17/2015 03:22PM by LarsK.

|

Re: Two colours and moving the not used hotend? September 17, 2015 04:14PM |

Registered: 9 years ago Posts: 722 |

Hi,

This is interesting, but you will need some guides for a perfect mount/move/repeatability.

Complicated and expensive IMHO.

What about a pendulum swap system ?

It's possible on a single shaft with one motor.

Repeatability should be great because of the fixed nozzles

And each unused hotend can lay by a fixed cap plate/cleaning pad to prevent extra squeeze out.

++JM

Edited 1 time(s). Last edit at 09/17/2015 04:15PM by J-Max.

This is interesting, but you will need some guides for a perfect mount/move/repeatability.

Complicated and expensive IMHO.

What about a pendulum swap system ?

It's possible on a single shaft with one motor.

Repeatability should be great because of the fixed nozzles

And each unused hotend can lay by a fixed cap plate/cleaning pad to prevent extra squeeze out.

++JM

Edited 1 time(s). Last edit at 09/17/2015 04:15PM by J-Max.

|

Re: Two colours and moving the not used hotend? September 21, 2015 02:01PM |

Registered: 9 years ago Posts: 346 |

Hey J-Max.

I will do like you suggest. I am making it for 3 hotends. Still in the designing and layout phase. Thinking about how to do the electronics. Saw a post by DC42 suggesting to put a local board on the carriage to reduce all the wiring, though that leaves some open electronics questions ( [forums.reprap.org] ).

I think I am ready with a prototype tomorrow or day after. Biggest problem is that the hotends have to be pretty far from the center of rotation to have enough space, so it must all be pretty stiff or held in place somehow. Obviously it only have to be like that, if I want each hotend to center on the same spot when rotated. I am not so sure that is actually a priority to have, and I might just go to something more like your sketch and handle the X,Y displacement in software.

I will do like you suggest. I am making it for 3 hotends. Still in the designing and layout phase. Thinking about how to do the electronics. Saw a post by DC42 suggesting to put a local board on the carriage to reduce all the wiring, though that leaves some open electronics questions ( [forums.reprap.org] ).

I think I am ready with a prototype tomorrow or day after. Biggest problem is that the hotends have to be pretty far from the center of rotation to have enough space, so it must all be pretty stiff or held in place somehow. Obviously it only have to be like that, if I want each hotend to center on the same spot when rotated. I am not so sure that is actually a priority to have, and I might just go to something more like your sketch and handle the X,Y displacement in software.

|

Re: Two colours and moving the not used hotend? September 21, 2015 04:47PM |

Registered: 9 years ago Posts: 722 |

Hi larsk

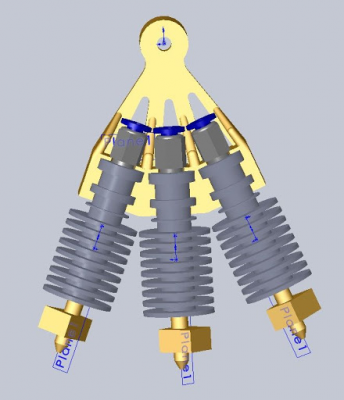

Wow ! 3 hotends !

I'm so excited to see your prototype working.

I dunno if this will help, but it's possible to use

and arc instead of a pivot point (like on tablesaw's tilting).

But an unique pivot point is totaly possible.

To hold the pendulum plate in place,

it's posible to insert rare earth magnets in the yellow plate,

and make it slide on a fixed metal plate.

I always insert a circuit plate on the print carriage,

because it's easy to plug/unplug from here

instead than to deal with the board connexions,

and free a long wiring from its sleeving.

Through, it's light enough.

What is your think for pendulum movement ?

Just a small servo on the axis ?

I remember some tilting extruder project here and there.

It was just some Marlin coding changes.

Maybe it's so close from your needs.

Tilting dual extruder on a delta

Dual extruder with a single motor.

There were an IRC project too, but I can't remember where to get it.

++JM

Wow ! 3 hotends !

I'm so excited to see your prototype working.

I dunno if this will help, but it's possible to use

and arc instead of a pivot point (like on tablesaw's tilting).

But an unique pivot point is totaly possible.

To hold the pendulum plate in place,

it's posible to insert rare earth magnets in the yellow plate,

and make it slide on a fixed metal plate.

I always insert a circuit plate on the print carriage,

because it's easy to plug/unplug from here

instead than to deal with the board connexions,

and free a long wiring from its sleeving.

Through, it's light enough.

What is your think for pendulum movement ?

Just a small servo on the axis ?

I remember some tilting extruder project here and there.

It was just some Marlin coding changes.

Maybe it's so close from your needs.

Tilting dual extruder on a delta

Dual extruder with a single motor.

There were an IRC project too, but I can't remember where to get it.

++JM

|

Re: Two colours and moving the not used hotend? September 21, 2015 04:54PM |

Registered: 10 years ago Posts: 14,672 |

Oozing from inactive nozzles is not a problem, you just need to set the temperature of the inactive nozzle low enough. I use 150C when printing PLA. RepRapFirmware can do this automatically for you, I don't know about other firmwares. For faster tool changes, tell the firmware not to wait for the old nozzle to cool down fully, just to wait for the new nozzle to heat up.

The main problem I found is that if the non printing nozzle crosses filament that has just been laid down by the printing nozzle and not fully cooled yet, it drags the filament slightly, leaving a mark. The closer together the nozzles are, the more of a problem this is. Lifting the inactive nozzle slightly would solve it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The main problem I found is that if the non printing nozzle crosses filament that has just been laid down by the printing nozzle and not fully cooled yet, it drags the filament slightly, leaving a mark. The closer together the nozzles are, the more of a problem this is. Lifting the inactive nozzle slightly would solve it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Two colours and moving the not used hotend? September 23, 2015 09:46PM |

Registered: 9 years ago Posts: 346 |

Hey,

First of all, I really like that dual extruder ( [hackaday.com] ) - Really simple idea, yet very powerfull.

Adressing DC42 comment - Regarding if 2 extruders is actually really a problem or not - Well, I am honestly concerned that I am trying to solve a problem, that is not a problem. It is always so that those who have problems complain and the rest don't come and tell how theirs are working great. I might have gotten a skewed impression from reading forums.

I don't think I will be using multi color so much. Probably just to select one color for a print but changing print to print so that I don't burn through one color too quickly. I am often too lazy to change my filament with the result that I exhaust my color options one by one - Would like to avoid that. So it is really a priority that my printer can print just with one nozzle without any hazzle from the idle ones.

As for my progress;

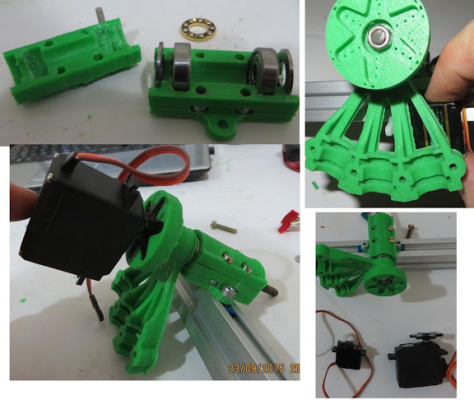

I am still working on the same design and finished some early design prints. Still far from printing anything but tested some concepts.

In upper left corner is the bearing block. I use two ball bearings to center the shaft and in each end a thrust bearing. This allows me to clamp and tighten the pendulum part onto.

Lower left corner the assembly with the servo motor. Servo motor attaches directly to the other side of the shaft in a coupling like setup, but it is printed really tight so there is no play. Unfotunately the gears in the servo has some microscopic play and because the nozzle is so far from center, even a very small play gives a rather big movement. There are some friction to overcome so I am not sure it will be a problem. I am continuing towards testing it as it is shown there.

Upper right corner; My alternative plan - See the small servo behind the pendulum. It has a small arm. I want to create a guide that this arm locks down onto, to fix the pendulum firmly in place.

Lower right corner - I have two servos - Big and small ones. If I go for the alternative plan I will test if the small one can manage the turn job (there is not much bearing friction due to the thrust bearings) - That will create a neater setup.

I have abandoned the magnets. Mostly because I am not sure they will add enough precision and secondly because making a steel frame or similar rail that follows the curvature that I want seems pretty difficult actually. I have more faith in using two servos together even as that will complicate the software setup.

First of all, I really like that dual extruder ( [hackaday.com] ) - Really simple idea, yet very powerfull.

Adressing DC42 comment - Regarding if 2 extruders is actually really a problem or not - Well, I am honestly concerned that I am trying to solve a problem, that is not a problem. It is always so that those who have problems complain and the rest don't come and tell how theirs are working great. I might have gotten a skewed impression from reading forums.

I don't think I will be using multi color so much. Probably just to select one color for a print but changing print to print so that I don't burn through one color too quickly. I am often too lazy to change my filament with the result that I exhaust my color options one by one - Would like to avoid that. So it is really a priority that my printer can print just with one nozzle without any hazzle from the idle ones.

As for my progress;

I am still working on the same design and finished some early design prints. Still far from printing anything but tested some concepts.

In upper left corner is the bearing block. I use two ball bearings to center the shaft and in each end a thrust bearing. This allows me to clamp and tighten the pendulum part onto.

Lower left corner the assembly with the servo motor. Servo motor attaches directly to the other side of the shaft in a coupling like setup, but it is printed really tight so there is no play. Unfotunately the gears in the servo has some microscopic play and because the nozzle is so far from center, even a very small play gives a rather big movement. There are some friction to overcome so I am not sure it will be a problem. I am continuing towards testing it as it is shown there.

Upper right corner; My alternative plan - See the small servo behind the pendulum. It has a small arm. I want to create a guide that this arm locks down onto, to fix the pendulum firmly in place.

Lower right corner - I have two servos - Big and small ones. If I go for the alternative plan I will test if the small one can manage the turn job (there is not much bearing friction due to the thrust bearings) - That will create a neater setup.

I have abandoned the magnets. Mostly because I am not sure they will add enough precision and secondly because making a steel frame or similar rail that follows the curvature that I want seems pretty difficult actually. I have more faith in using two servos together even as that will complicate the software setup.

|

Re: Two colours and moving the not used hotend? September 24, 2015 06:00AM |

Registered: 9 years ago Posts: 722 |

|

Re: Two colours and moving the not used hotend? September 27, 2015 01:23PM |

Registered: 9 years ago Posts: 722 |

Hi LarsK,

There's a similar project (2 hotends only)

on the french section of the forum :

Dual extruder A shape

Youtube deme

Thingiverse, the complete thing.

++JM

Edited 1 time(s). Last edit at 09/27/2015 01:25PM by J-Max.

There's a similar project (2 hotends only)

on the french section of the forum :

Dual extruder A shape

Youtube deme

Thingiverse, the complete thing.

++JM

Edited 1 time(s). Last edit at 09/27/2015 01:25PM by J-Max.

|

Re: Two colours and moving the not used hotend? September 27, 2015 09:58PM |

Registered: 9 years ago Posts: 346 |

Hey, that is really interesting.

Gotta say his looks a lot simpler then what I am moving towards now. I did eventually print a design where I would just turn and secure the position using one servo - Like what I understand Forange is doing.

The good thing for my design was that the thrust bearings keeps it very firmly from moving in all unwanted directions. The rotation, however, should be handled by the servo. The servo play, although microscopic when you feel the servo, is multiplied by the more then 100 mm arm. So a 0.05 deg play on the servo gives close to 0.1 mm difference at the nozzle.

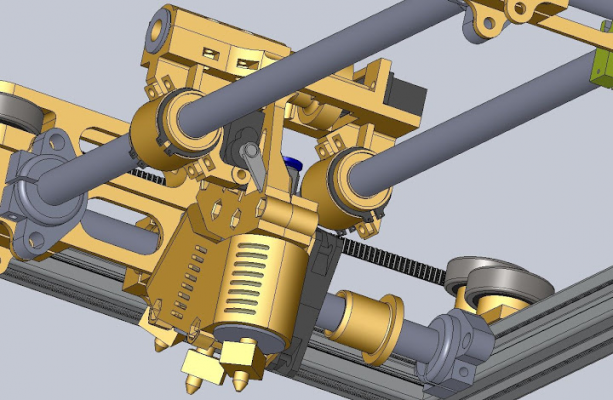

Long story short, I am wrapping up the CAD model now. Just need belt clamps implemented and put in some support material to make the most complicated of the parts printable;

Knowing my self it will probably take a couple of prints before I get anything usable.

I do hope the Forange will post some more prints and comparisons. In my point of view what is really a critical factor is that you can change back and fourth the colors without having any layer shift and that using just one color gives same quality as if you had just had one nozzle.

Gotta say his looks a lot simpler then what I am moving towards now. I did eventually print a design where I would just turn and secure the position using one servo - Like what I understand Forange is doing.

The good thing for my design was that the thrust bearings keeps it very firmly from moving in all unwanted directions. The rotation, however, should be handled by the servo. The servo play, although microscopic when you feel the servo, is multiplied by the more then 100 mm arm. So a 0.05 deg play on the servo gives close to 0.1 mm difference at the nozzle.

Long story short, I am wrapping up the CAD model now. Just need belt clamps implemented and put in some support material to make the most complicated of the parts printable;

Knowing my self it will probably take a couple of prints before I get anything usable.

I do hope the Forange will post some more prints and comparisons. In my point of view what is really a critical factor is that you can change back and fourth the colors without having any layer shift and that using just one color gives same quality as if you had just had one nozzle.

|

Re: Two colours and moving the not used hotend? September 28, 2015 06:19AM |

Registered: 9 years ago Posts: 722 |

|

Re: Two colours and moving the not used hotend? October 03, 2015 08:20PM |

Registered: 8 years ago Posts: 45 |

|

Re: Two colours and moving the not used hotend? October 04, 2015 07:39PM |

Registered: 9 years ago Posts: 346 |

Yes, I could use a servo like that. For now my design is simpler. Current status looks like this, electronic control not yet implemented and obviously not yet installed in a printer:

As can be seen this is a first revision with a couple of tolerances here and there not quite good enough and here and there I had to use my Dremel. The problem is that it can also not be lose.

The servo with the arm goes in and lock. It is not as good as a spring loaded conical pin but it will do for my test. The problem about this solution and the pin with a spring is that it requires pre-made holes to be used. This means that I cannot calibrate the mechanical position and any offset must be handled in software. Not a very big thing but it does defeat the purposes of having it rotating about a shared axis anyways. But the rotating head was also mostly a gimmicky thing I wanted. It could be nice to have a button to press that selects a different color without having to mess with anything in the printer firmware or anything. A kinda simple workaround of advanced G-code stuff and look more cool also I think.

But honestly the feasibility study is looking worse and worse when compared to some other solutions. The part that rotates is not stiff enough in the direction perpendicular to the rotation. I don't have a lot of space for the bowden tubes and the electronics with two servos is already pretty complicated. Further, due to the rotating movement the carriage needs a lot of free space in the direction where it turns which reduces print area.

This have to be weighted against the solution with 3 independent moving nozzles (as I think DC42 was also refering to). Here I sketch a solution where each nozzle is pushed upwads by a spring. Then one servo for each nozzle that pushes the nozzle we want down. This will obviously require that the X and Y offset is handled in software and there is still problem in getting it stiff enough. But I think it will be simpler alone for the fact that I can use guides much easier.

That said, I plan to implement what I got now. It might not be the simplest solution but it will work and allow me to test out multicolor and learn more about upsides and downsides.

[Edit and edit... Photos keep not working]

Edited 3 time(s). Last edit at 10/05/2015 07:27AM by LarsK.

As can be seen this is a first revision with a couple of tolerances here and there not quite good enough and here and there I had to use my Dremel. The problem is that it can also not be lose.

The servo with the arm goes in and lock. It is not as good as a spring loaded conical pin but it will do for my test. The problem about this solution and the pin with a spring is that it requires pre-made holes to be used. This means that I cannot calibrate the mechanical position and any offset must be handled in software. Not a very big thing but it does defeat the purposes of having it rotating about a shared axis anyways. But the rotating head was also mostly a gimmicky thing I wanted. It could be nice to have a button to press that selects a different color without having to mess with anything in the printer firmware or anything. A kinda simple workaround of advanced G-code stuff and look more cool also I think.

But honestly the feasibility study is looking worse and worse when compared to some other solutions. The part that rotates is not stiff enough in the direction perpendicular to the rotation. I don't have a lot of space for the bowden tubes and the electronics with two servos is already pretty complicated. Further, due to the rotating movement the carriage needs a lot of free space in the direction where it turns which reduces print area.

This have to be weighted against the solution with 3 independent moving nozzles (as I think DC42 was also refering to). Here I sketch a solution where each nozzle is pushed upwads by a spring. Then one servo for each nozzle that pushes the nozzle we want down. This will obviously require that the X and Y offset is handled in software and there is still problem in getting it stiff enough. But I think it will be simpler alone for the fact that I can use guides much easier.

That said, I plan to implement what I got now. It might not be the simplest solution but it will work and allow me to test out multicolor and learn more about upsides and downsides.

[Edit and edit... Photos keep not working]

Edited 3 time(s). Last edit at 10/05/2015 07:27AM by LarsK.

|

Re: Two colours and moving the not used hotend? October 05, 2015 08:13AM |

Registered: 9 years ago Posts: 722 |

Hi LarsK,

You're probably right for the pendulum idea.

Your system with spring and servos might be simpler to engineer.

Even the Forange 2 head version is large.

I work actualy on a plotter CNC for a friend.

There's no Z axis and we need to raise quickly the tool prior any machine move.

All the tests with servo was too slow and the precision was not good enough

to move the tool at the same position.

We decided to use solenoIids.

The spring is directly on the solenoid.

It's an on/off contact, it's very quick.

Through, solenoïds are a bit heavyer compares to 9g servos,

but they're much stronger too.

I dunno if that system could be usefull for you.

++JM

You're probably right for the pendulum idea.

Your system with spring and servos might be simpler to engineer.

Even the Forange 2 head version is large.

I work actualy on a plotter CNC for a friend.

There's no Z axis and we need to raise quickly the tool prior any machine move.

All the tests with servo was too slow and the precision was not good enough

to move the tool at the same position.

We decided to use solenoIids.

The spring is directly on the solenoid.

It's an on/off contact, it's very quick.

Through, solenoïds are a bit heavyer compares to 9g servos,

but they're much stronger too.

I dunno if that system could be usefull for you.

++JM

|

Re: Two colours and moving the not used hotend? October 05, 2015 11:08AM |

Registered: 9 years ago Posts: 346 |

Quote

J-Max

We decided to use solenoIids.

The spring is directly on the solenoid.

It's an on/off contact, it's very quick.

Through, solenoïds are a bit heavyer compares to 9g servos,

but they're much stronger too.

I dunno if that system could be usefull for you.

++JM

Hey,

Solenoids are nice for linear motion. But there are some limitations;

High force solenoids should only be held constant energized in safety critical system. In our industry we use them to disengage brakes. If power fails the solenoid turns off and a heavy loaded spring engages the brake. Simple, but having the solenoid constant energized means it needs to be pretty big to not overheat.

What I was thinking was then to make a ball-pen like design. When I press the "ball pen" (nozzle) it latches and locks and the solenoid can be de-energized.

What I diden't know until this morning, is that I can actually buy a ready solution which seems much nicer; A solenoid that latches in a low-power state with residual magnetism.

Have a look at this one:

[www.ledex.com]

STA-Mini 13 x 16 Pull-Latching

That will do 1mm movement with 5.5N (0.56 kg) pull at maximum power (where it can be left on for max. 2s.). That one weights 14.7g. The latching force from the magnet is 3.2N where 1.2N is not available as it is used to overcome the return spring foce - So it can latch and hold a 2N force de-energized.

But that just opens a bunch of new questions - Like - Where to get it, if it will be enough force. Etc... But yeah, solenoids seems like a really strong option.

Sure something to think about.

|

Re: Two colours and moving the not used hotend? October 05, 2015 12:18PM |

Registered: 9 years ago Posts: 722 |

Sorry, only registered users may post in this forum.