Building a No Name big printer

Posted by bonmotwang

|

Building a No Name big printer October 07, 2015 04:56PM |

Registered: 8 years ago Posts: 78 |

I am going to share my journey of thinking, designing and building a big 3D printer.

Who am I:

I am an electronics guy, have been designing hardware and firmware for many many years. But also interested in mechanical design. My whole house and furnitures are modeled in Solidworks.

Related experience for this type of machine:

Designed and built a few solid desktop CNCs.

Experience on 3D printer:

Owned a Prusa i3 for about 6 weeks.

Have read a few machine build logs. Was fun to read, and thanks for sharing.

Starting point:

Very very new into 3D printers.

Learning while designing.

Learning things about structure.

Learning things about printing.

Learning things about firmware.

Plan:

From the previous section, you can see my main task right now is learning, doing my homework.

Show the community what I am thinking.

Will get into changing the firmware to do some customization for my printer. (Good news is I do this type of things for living).

Have my buddy's CNC shop do all the aluminum parts. I will do the final assembly.

Printer is designed to print some full size toys, tools, etc ...

Purpose of this build is for building the machine. Not so much of planning to print specific items.

Budget:

Don't know yet. If goes more than $5000, I may need to think about the what is the next step seriously, otherwise just experimenting.

Timeline:

Hopefully, 12 months to print the first 10x10x10 cube, in millimeters. LoL

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

Who am I:

I am an electronics guy, have been designing hardware and firmware for many many years. But also interested in mechanical design. My whole house and furnitures are modeled in Solidworks.

Related experience for this type of machine:

Designed and built a few solid desktop CNCs.

Experience on 3D printer:

Owned a Prusa i3 for about 6 weeks.

Have read a few machine build logs. Was fun to read, and thanks for sharing.

Starting point:

Very very new into 3D printers.

Learning while designing.

Learning things about structure.

Learning things about printing.

Learning things about firmware.

Plan:

From the previous section, you can see my main task right now is learning, doing my homework.

Show the community what I am thinking.

Will get into changing the firmware to do some customization for my printer. (Good news is I do this type of things for living).

Have my buddy's CNC shop do all the aluminum parts. I will do the final assembly.

Printer is designed to print some full size toys, tools, etc ...

Purpose of this build is for building the machine. Not so much of planning to print specific items.

Budget:

Don't know yet. If goes more than $5000, I may need to think about the what is the next step seriously, otherwise just experimenting.

Timeline:

Hopefully, 12 months to print the first 10x10x10 cube, in millimeters. LoL

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

|

Re: Building a No Name big printer October 07, 2015 05:06PM |

Registered: 8 years ago Posts: 78 |

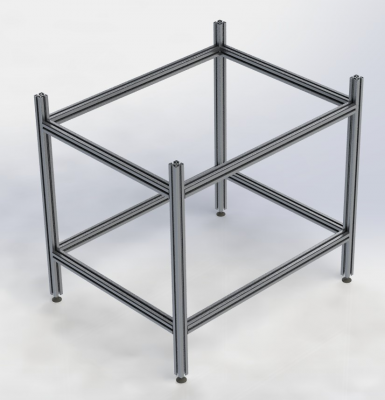

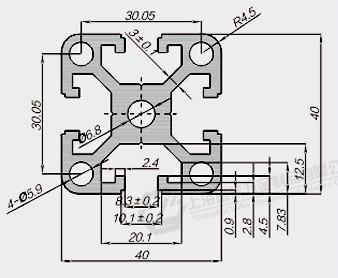

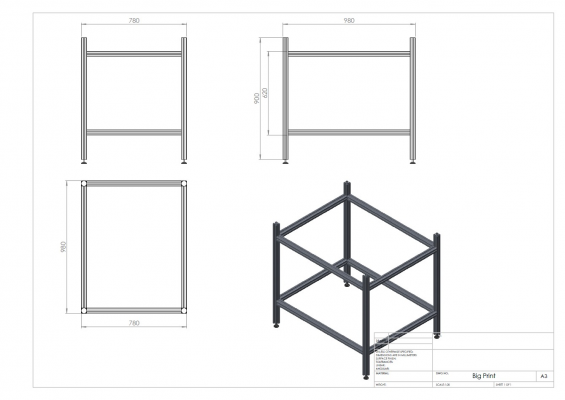

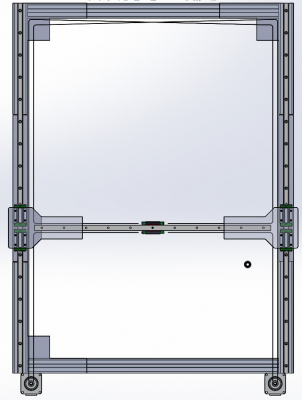

Here is dimensions I put down to start.

4040 aluminum extrusions will be CNC to length and squared.

The bottom section is planned to store electronics as Mark did in his SoM.

Top is using the similar structure just for growing or shrinking the height in the future without design pattern change.

Edited 1 time(s). Last edit at 10/07/2015 05:07PM by bonmotwang.

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

4040 aluminum extrusions will be CNC to length and squared.

The bottom section is planned to store electronics as Mark did in his SoM.

Top is using the similar structure just for growing or shrinking the height in the future without design pattern change.

Edited 1 time(s). Last edit at 10/07/2015 05:07PM by bonmotwang.

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

|

Re: Building a No Name big printer October 07, 2015 11:25PM |

Registered: 8 years ago Posts: 78 |

Just found a great design:

[forums.reprap.org]

I think I will capture it in Solidworks and go from there.

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

[forums.reprap.org]

I think I will capture it in Solidworks and go from there.

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

|

Re: Building a No Name big printer October 09, 2015 08:54PM |

Registered: 8 years ago Posts: 78 |

|

Re: Building a No Name big printer October 10, 2015 08:46AM |

Registered: 8 years ago Posts: 233 |

This is very similar to my design. If you have any questions about using the linear guides, please don't hesitate to ask. I actually have several suggestions on your brackets and guide placement that I think will improve your design, based on my build experiences. It will be easier if we can real time talk or chat. Where are you located?

|

Re: Building a No Name big printer October 10, 2015 09:57AM |

Registered: 8 years ago Posts: 78 |

Quote

patrickrio

This is very similar to my design. If you have any questions about using the linear guides, please don't hesitate to ask. I actually have several suggestions on your brackets and guide placement that I think will improve your design, based on my build experiences. It will be easier if we can real time talk or chat. Where are you located?

I am in Burlington Ontario, Canada. That will be great if we go real time.

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

|

Re: Building a No Name big printer October 11, 2015 08:57AM |

Registered: 8 years ago Posts: 233 |

|

Re: Building a No Name big printer October 11, 2015 03:20PM |

Registered: 9 years ago Posts: 722 |

|

Re: Building a No Name big printer October 13, 2015 10:28AM |

Registered: 8 years ago Posts: 78 |

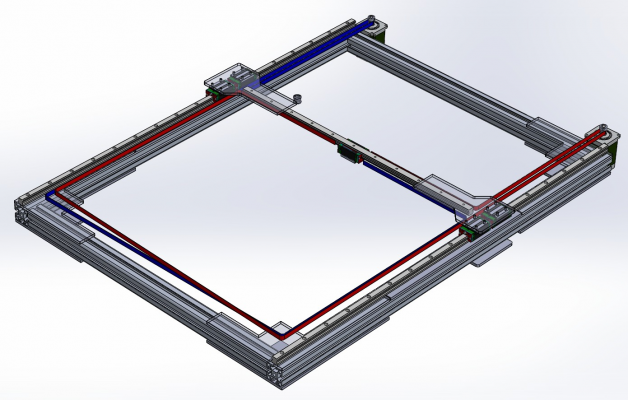

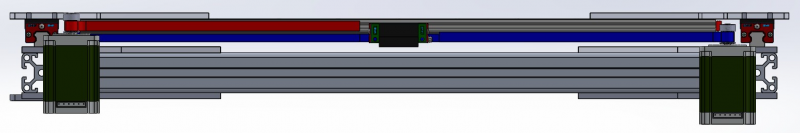

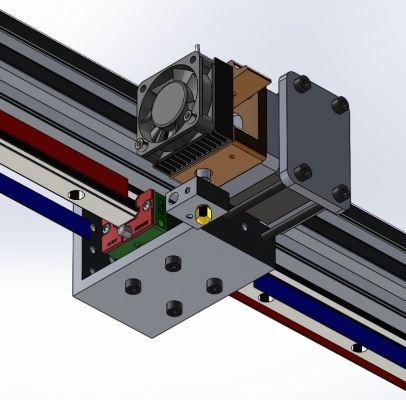

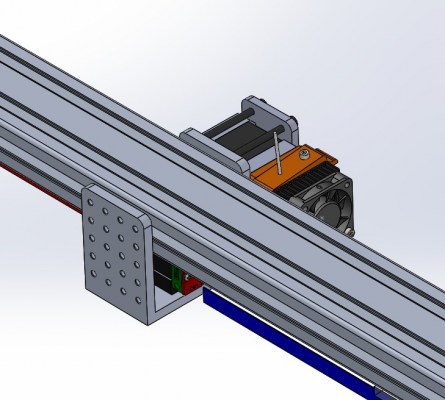

Final XY plan is coming together very well.

Here is some weight information:

The whole XY structure is 14.5Kg.

X Carriage is 2.7Kg.

No extruder yet. (could be another 1Kg if go with a dual direct drive)

With the deflection simulator, even by using 4040 aluminum profile, there is about 0.13mm deflection in the middle.

But if the XY frame is assembled with the whole frame, the deflection become 0.0275mm.

Tons of details need to be finalized before I kick off the orders and CNC machining.

My plan is to order the parts and verify the dimensions first, check against my drawings, then start CNC.

Edited 2 time(s). Last edit at 10/13/2015 10:30AM by bonmotwang.

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

Here is some weight information:

The whole XY structure is 14.5Kg.

X Carriage is 2.7Kg.

No extruder yet. (could be another 1Kg if go with a dual direct drive)

With the deflection simulator, even by using 4040 aluminum profile, there is about 0.13mm deflection in the middle.

But if the XY frame is assembled with the whole frame, the deflection become 0.0275mm.

Tons of details need to be finalized before I kick off the orders and CNC machining.

My plan is to order the parts and verify the dimensions first, check against my drawings, then start CNC.

Edited 2 time(s). Last edit at 10/13/2015 10:30AM by bonmotwang.

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

|

Re: Building a No Name big printer October 13, 2015 03:23PM |

Registered: 9 years ago Posts: 344 |

|

Re: Building a No Name big printer October 13, 2015 04:20PM |

Registered: 8 years ago Posts: 78 |

Quote

cristian

Quote

bonmotwang

With the deflection simulator, even by using 4040 aluminum profile, there is about 0.13mm deflection in the middle.

But if the XY frame is assembled with the whole frame, the deflection become 0.0275mm.

Are you doing these calculations with Solidworks?

I am so envious!

Yes, it gives all the deformation by colors. Not the master yet.

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

|

Re: Building a No Name big printer October 13, 2015 05:01PM |

Registered: 9 years ago Posts: 344 |

|

Re: Building a No Name big printer October 13, 2015 05:55PM |

Registered: 8 years ago Posts: 78 |

Quote

cristian

Quote

bonmotwang

Yes, it gives all the deformation by colors. Not the master yet.

I saw the pictures online indeed. I am really envious...

Don't google "heat simulation", otherwise you would go crazy. LoL.

I have seen my customer modeling and simulating heat transfer in their product. It is awesome, and the software worth $20K.

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

|

Re: Building a No Name big printer October 14, 2015 09:56AM |

Registered: 8 years ago Posts: 78 |

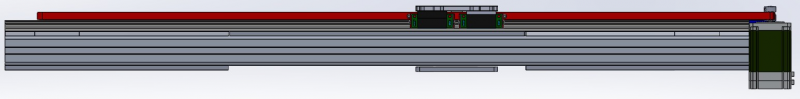

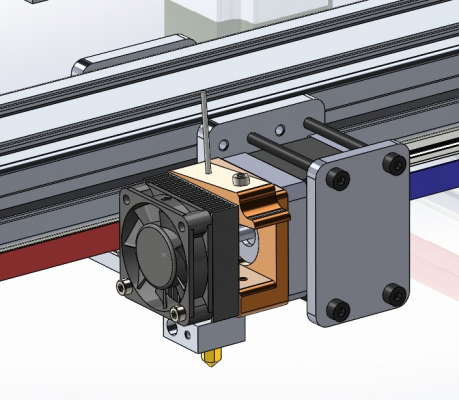

It is the time to decide on the extruder mounting block now.

I am planning to design a mounting plate/block which is able to take two extruders: 2 direct or 2 bowdens

Normal view of the mounting location:

Bottom view of the mounting location:

I am planning to have a U shape aluminum block CNCed for mounting the extruders.

Just need some opinions from the forum for some "good" direct and bowden extruders models, so that I can try my best to plan for them into my mounting block design.

Thanks

Edited 1 time(s). Last edit at 10/14/2015 09:56AM by bonmotwang.

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

I am planning to design a mounting plate/block which is able to take two extruders: 2 direct or 2 bowdens

Normal view of the mounting location:

Bottom view of the mounting location:

I am planning to have a U shape aluminum block CNCed for mounting the extruders.

Just need some opinions from the forum for some "good" direct and bowden extruders models, so that I can try my best to plan for them into my mounting block design.

Thanks

Edited 1 time(s). Last edit at 10/14/2015 09:56AM by bonmotwang.

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

|

Re: Building a No Name big printer October 14, 2015 10:07AM |

Registered: 8 years ago Posts: 346 |

With this super rigid and heavy corexy mechanism you are planning to put together i will say the best option is to go with an direct extruder and forget bowden.

The bowden extruder are difficult to setup correctly, in my case i have build my corexy printer with an mk8 bowden extruder and spend many many many hours to try to get good result. At the end i have changed to an mk8 direct extruder.

There are several good direct extruder. I using mk8 direct and is work fine for 1.75 mm filament, never have any jam and getting pretty good print results.

With 3mm filament i think is better to go with an greg extruder, the mk8 can not have enough troque.

Edited 1 time(s). Last edit at 10/14/2015 10:08AM by filipeCampos.

The bowden extruder are difficult to setup correctly, in my case i have build my corexy printer with an mk8 bowden extruder and spend many many many hours to try to get good result. At the end i have changed to an mk8 direct extruder.

There are several good direct extruder. I using mk8 direct and is work fine for 1.75 mm filament, never have any jam and getting pretty good print results.

With 3mm filament i think is better to go with an greg extruder, the mk8 can not have enough troque.

Edited 1 time(s). Last edit at 10/14/2015 10:08AM by filipeCampos.

|

Re: Building a No Name big printer October 14, 2015 10:56AM |

Registered: 8 years ago Posts: 78 |

Thanks. I will take a look at MK8 direct extruder and the greg.

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

|

Re: Building a No Name big printer October 14, 2015 02:57PM |

Registered: 10 years ago Posts: 553 |

Why not use a Flex3Drive? Supposedly it is the best of both worlds; lightweight of a bowden, but performance of a direct drive.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Building a No Name big printer October 15, 2015 12:30AM |

Registered: 10 years ago Posts: 179 |

Quote

gmh39

Why not use a Flex3Drive? Supposedly it is the best of both worlds; lightweight of a bowden, but performance of a direct drive.

There are masses of posts recommending flexi drive but I have not seen a single build incorporating it. So as you say "supposedly".. What about practically? I would expect some unexpected problems with it.

|

Re: Building a No Name big printer October 15, 2015 11:44AM |

Registered: 8 years ago Posts: 233 |

since we have not been able to connect via voice, I will attempt to give you some of my design suggestions based on my build experience.

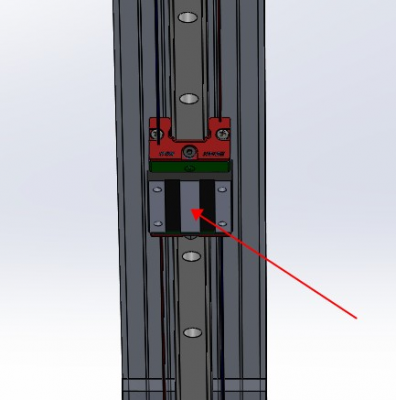

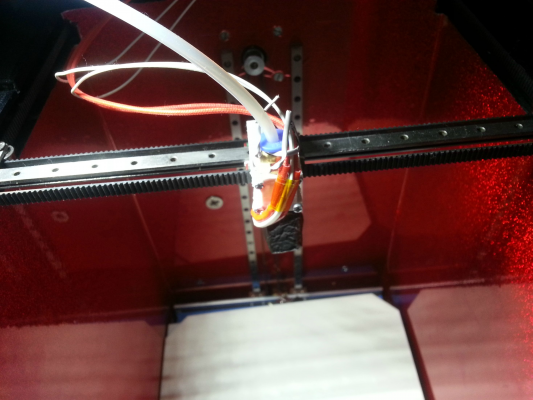

1. you have the x axis block facing downward, just like I do, which I think is the correct choice. HOWEVER, you should think about how you are going to locate the filament and nozzle assembly. I think you will find that having the nozzle close to one side of the linear guide block will reduce mass and potential vibration. your beam above the linear guide would be moved to give access to one side of the block or the other and would not be located exactly in the center. BETTER YET, I think that having that support bar above the linear guide is unnecessary for increased structural integrity. see the picture of my extruder on a 7mm rail. My structure does not vibrate or flex significantly even without the support you have. granted, the LENGTH of my run is shorter than yours, but you can just select a larger rail and block, MGN9C, MGN12C or even MGN15C if you need more stiffness for your longer run. doing this also reduces parts and makes the build easier.

2. It is VERY critical that your two X axis slides are perfectly parallel. This is the biggest weakness of using linear guides for this construct because it is HARD to get them really parallel. There is not much "play" in the bearings of these slides, so if your system is not parallel enough, the system will bind and reduce the life of the bearings dramatically. Get some white lithium soap grease if your bearings have some openness to the air (not sealed linear bearings). You can create a better protection from dust by packing the bearings with a small overabundance of lithium grease. Lithium grease is the longest acting lubricant you can safely use on open linear guides. Remember, once you pick a lubricant, you should stick with that same lubricant for the life of the bearings, so choose wisely. DO NOT mix lithium grease and WD-40 for sure!!!! I got my grease at Home Depot because it is walking distance from me..... Make sure to get the squeeze bottle thick grease and NOT the spray on or watery/drippy lithium grease.

3. make sure that the belt pull puts the x axis in compression instead of pulling your two y guide blocks together (attach pulleys strongly to the x axis rail more than the y axis blocks and make it so you can adjust the attachment of the whole X guide and pulleys assembly to the Y blocks so you can adjust the distance between Y blocks slightly..) pulling the guide blocks together will increase the pressure on the bearing surfaces and reduce the life of bearings in your parallel guide blocks. if you have questions on how to do this, we need to talk as there is a list of things to check to accomplish this.

4. design a way to put in some shims to adjust the 2 Y slides for flatness. The slides are very accurate but once again, since they have no "play" you have to be very precise in leveling them to be perfectly flat. Having some "twist" between the two guides will make bed leveling impossible, let me tell you, and the longer the slides are, the harder it is to keep level. My next design iteration is going to have a single machined plate to make parallel and level easier to accomplish....leveling and parallel were the hardest parts of my build. If you do this right, you get vibration free travel the whole length of your slides, and your leveling can be more accurate that FDM printing can handle with the surface tension of extruded plastics....

5. the length of belt increases a lot the larger you make the frame. As a result, you may want to make it so the slides are shorter and movements go all the way to pulleys to reduce belt length for a given print bed size. I also reduced the size of my nozzle assembly and distance between the belts on the X axis for the same reason. You can see this in the attached picture. My nozzle carriage is 15mm wide and 35mm in the Y direction. The belts in my design clamp directly to the sides of the linear guide block.

6. consider using a LONG block on the Y axis guides instead of 2 short blocks (H blocks instead of C blocks). Cheaper, simpler construction! block sizes of the blocks: MGN7H=17x30.8mm, MGN9H=20x39.9mm, MGN12H=27x45.4mm, MGN15H=32x58.8mm

Feel free to ask any other questions...

Edited 2 time(s). Last edit at 10/15/2015 11:56AM by patrickrio.

1. you have the x axis block facing downward, just like I do, which I think is the correct choice. HOWEVER, you should think about how you are going to locate the filament and nozzle assembly. I think you will find that having the nozzle close to one side of the linear guide block will reduce mass and potential vibration. your beam above the linear guide would be moved to give access to one side of the block or the other and would not be located exactly in the center. BETTER YET, I think that having that support bar above the linear guide is unnecessary for increased structural integrity. see the picture of my extruder on a 7mm rail. My structure does not vibrate or flex significantly even without the support you have. granted, the LENGTH of my run is shorter than yours, but you can just select a larger rail and block, MGN9C, MGN12C or even MGN15C if you need more stiffness for your longer run. doing this also reduces parts and makes the build easier.

2. It is VERY critical that your two X axis slides are perfectly parallel. This is the biggest weakness of using linear guides for this construct because it is HARD to get them really parallel. There is not much "play" in the bearings of these slides, so if your system is not parallel enough, the system will bind and reduce the life of the bearings dramatically. Get some white lithium soap grease if your bearings have some openness to the air (not sealed linear bearings). You can create a better protection from dust by packing the bearings with a small overabundance of lithium grease. Lithium grease is the longest acting lubricant you can safely use on open linear guides. Remember, once you pick a lubricant, you should stick with that same lubricant for the life of the bearings, so choose wisely. DO NOT mix lithium grease and WD-40 for sure!!!! I got my grease at Home Depot because it is walking distance from me..... Make sure to get the squeeze bottle thick grease and NOT the spray on or watery/drippy lithium grease.

3. make sure that the belt pull puts the x axis in compression instead of pulling your two y guide blocks together (attach pulleys strongly to the x axis rail more than the y axis blocks and make it so you can adjust the attachment of the whole X guide and pulleys assembly to the Y blocks so you can adjust the distance between Y blocks slightly..) pulling the guide blocks together will increase the pressure on the bearing surfaces and reduce the life of bearings in your parallel guide blocks. if you have questions on how to do this, we need to talk as there is a list of things to check to accomplish this.

4. design a way to put in some shims to adjust the 2 Y slides for flatness. The slides are very accurate but once again, since they have no "play" you have to be very precise in leveling them to be perfectly flat. Having some "twist" between the two guides will make bed leveling impossible, let me tell you, and the longer the slides are, the harder it is to keep level. My next design iteration is going to have a single machined plate to make parallel and level easier to accomplish....leveling and parallel were the hardest parts of my build. If you do this right, you get vibration free travel the whole length of your slides, and your leveling can be more accurate that FDM printing can handle with the surface tension of extruded plastics....

5. the length of belt increases a lot the larger you make the frame. As a result, you may want to make it so the slides are shorter and movements go all the way to pulleys to reduce belt length for a given print bed size. I also reduced the size of my nozzle assembly and distance between the belts on the X axis for the same reason. You can see this in the attached picture. My nozzle carriage is 15mm wide and 35mm in the Y direction. The belts in my design clamp directly to the sides of the linear guide block.

6. consider using a LONG block on the Y axis guides instead of 2 short blocks (H blocks instead of C blocks). Cheaper, simpler construction! block sizes of the blocks: MGN7H=17x30.8mm, MGN9H=20x39.9mm, MGN12H=27x45.4mm, MGN15H=32x58.8mm

Feel free to ask any other questions...

Edited 2 time(s). Last edit at 10/15/2015 11:56AM by patrickrio.

|

Re: Building a No Name big printer October 15, 2015 12:02PM |

Registered: 9 years ago Posts: 83 |

|

Re: Building a No Name big printer October 15, 2015 01:06PM |

Registered: 8 years ago Posts: 233 |

Yes, WD-40 is a cleaner... but, some of the Chinese manufacturers still recommend it as a lubricant. I don't agree and believe the best choice is the recommendation by Hiwin for general use in non sealed bearings-white lithium soap grease. It is long lasting, and if applied liberally, protects against dust. mixing WD-40 with the grease makes a huge mess that is hard to fix.

|

Re: Building a No Name big printer October 15, 2015 01:46PM |

Registered: 9 years ago Posts: 893 |

|

Re: Building a No Name big printer October 15, 2015 03:54PM |

Registered: 8 years ago Posts: 78 |

Thanks Patrick for your notes.

Yes, this machine needs to be flat, straight and square.

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

Yes, this machine needs to be flat, straight and square.

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

|

Re: Building a No Name big printer October 15, 2015 03:58PM |

Registered: 8 years ago Posts: 78 |

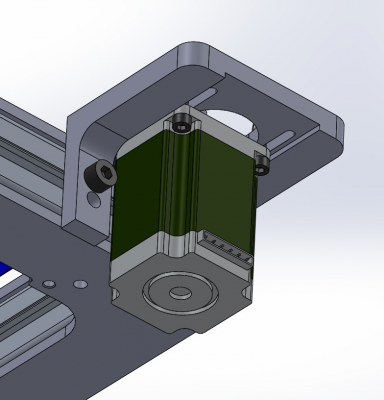

This is the preliminary design for mounting one MK8 direct extruder.

Normal view:

Bottom view:

Back view:

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

Normal view:

Bottom view:

Back view:

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

|

Re: Building a No Name big printer October 15, 2015 04:09PM |

Registered: 8 years ago Posts: 78 |

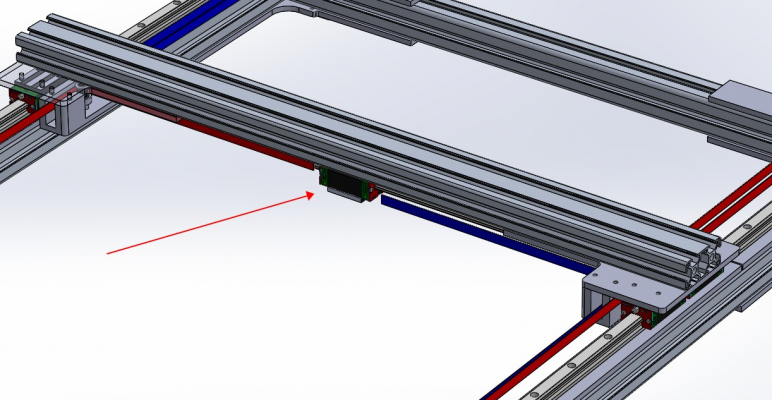

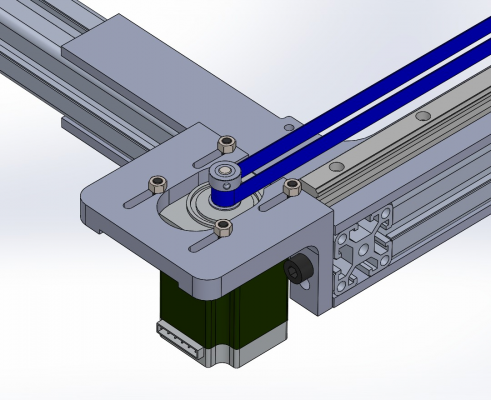

I designed a simple slider for adjusting the belt tension.

Here it is

The adjustment is about 20mm.

I am using 10mm belt, so 20mm should be enough.

This is my very first 3D printer design. Feel free to comment. Thanks

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

Here it is

The adjustment is about 20mm.

I am using 10mm belt, so 20mm should be enough.

This is my very first 3D printer design. Feel free to comment. Thanks

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

|

Re: Building a No Name big printer October 15, 2015 06:06PM |

Registered: 8 years ago Posts: 233 |

For your carriage design, it looks like the back part of your U shaped mount that attaches to the guide block is not connected to anything. I think you could either safely convert that to an L and remove the back, or make it into an O that goes all the way around the beam for added rigidity. The U appears to have extra weight for no reason. My carriage forms an O, but I really needed the added rigidity since my carriage is plastic and not aluminum like yours. It is also VERY convenient to mount the X limit switch right on the carriage itself, the wiring and mechanics are easier to implement that way.

That direct drive is going to weigh a bit, so if you want it to move fast you are going to need to make it rigid. Any vibrations you do have will be minimized the closer you can get the center of carriage gravity to the 4 block mounting points AND by getting the nozzle tip as close to those mounting points as possible.

With a large printer like this, you may want to consider larger diameter nozzles too so you can print at adequate speeds. Consider the E3D Volcano and clones for this, they work well for me. Your direct extruder will have to be upgraded to a gear motor or geared extrusion to use the bigger nozzles at high speed though, as I think you will need more extrusion pressure than that direct drive can provide. Look at the Bondtech gearmotor extruder for inspiration. My Bowden extruder mechanicals are almost an exact clone of your direct drive setup, and I max out at about 200mm/sec with a 4mm nozzle and 100mm/sec with a 1.2mm nozzle. I am going to install a gearmotor so I can go faster.

you may also consider using a shaft drive system to move the motor off the carriage to reduce rapidly moving weight. The advantages of CoreXY for fast movement and acceleration are easier to accomplish with light weights. I used a Bowden extruder to reduce total moving weight to 150gm.... but I think this is less practical for a large printer like yours.

Also, those nema 23 motors are REEELY BIG. Are they withing the amp limits of operation for a normal 3d printer board and drivers? I would consider going to 24 volts to get the most power you can out of those. Are you sure they are not a bit of overkill????

Edited 1 time(s). Last edit at 10/15/2015 06:10PM by patrickrio.

That direct drive is going to weigh a bit, so if you want it to move fast you are going to need to make it rigid. Any vibrations you do have will be minimized the closer you can get the center of carriage gravity to the 4 block mounting points AND by getting the nozzle tip as close to those mounting points as possible.

With a large printer like this, you may want to consider larger diameter nozzles too so you can print at adequate speeds. Consider the E3D Volcano and clones for this, they work well for me. Your direct extruder will have to be upgraded to a gear motor or geared extrusion to use the bigger nozzles at high speed though, as I think you will need more extrusion pressure than that direct drive can provide. Look at the Bondtech gearmotor extruder for inspiration. My Bowden extruder mechanicals are almost an exact clone of your direct drive setup, and I max out at about 200mm/sec with a 4mm nozzle and 100mm/sec with a 1.2mm nozzle. I am going to install a gearmotor so I can go faster.

you may also consider using a shaft drive system to move the motor off the carriage to reduce rapidly moving weight. The advantages of CoreXY for fast movement and acceleration are easier to accomplish with light weights. I used a Bowden extruder to reduce total moving weight to 150gm.... but I think this is less practical for a large printer like yours.

Also, those nema 23 motors are REEELY BIG. Are they withing the amp limits of operation for a normal 3d printer board and drivers? I would consider going to 24 volts to get the most power you can out of those. Are you sure they are not a bit of overkill????

Edited 1 time(s). Last edit at 10/15/2015 06:10PM by patrickrio.

|

Re: Building a No Name big printer October 15, 2015 06:18PM |

Registered: 8 years ago Posts: 78 |

The stepper motors will have independent drivers. Control board just output control signals.

Not sure it is an overkill. But if it turned out to be overkill, we can always change them to something else.

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

Not sure it is an overkill. But if it turned out to be overkill, we can always change them to something else.

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

|

Re: Building a No Name big printer October 15, 2015 06:44PM |

Registered: 8 years ago Posts: 233 |

I am using 400 step 78 oz inch 1.8 amp nema 17 motors, and I am only using .8 amps at 24v... I am almost certain that these would have enough power for your setup too... especially if you turned them up in amps. Then you can use standard control boards and drivers... I highly recommend the Duet board as it has a wonderful ethernet interface that I operate with my telephone.

I bought them on ebay, this is the description:

Nema17 stepper motor 0.9 deg /48mm/ 78 Oz-in / 1.8A CNC stepper motor

( 151660524251 ) ITEM PRICE: US $13.84 free shipping from China

I bought them on ebay, this is the description:

Nema17 stepper motor 0.9 deg /48mm/ 78 Oz-in / 1.8A CNC stepper motor

( 151660524251 ) ITEM PRICE: US $13.84 free shipping from China

|

Re: Building a No Name big printer October 15, 2015 06:49PM |

Registered: 8 years ago Posts: 233 |

By the way, you were looking for recommendations on belt width on another thread. I am using 6mm width on mine and it is way stronger than I need. 12mm or 10 mm will for sure be more than you need. I am pretty sure that even 6mm will be more than you need.

Edited 2 time(s). Last edit at 10/15/2015 06:50PM by patrickrio.

Edited 2 time(s). Last edit at 10/15/2015 06:50PM by patrickrio.

|

Re: Building a No Name big printer October 15, 2015 07:10PM |

Registered: 8 years ago Posts: 78 |

Great! Thanks Patrick, One more thing not to be worried :-D

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

Printer I bought: 2015 Sunhokey Prusa i3

Printer I am designing: Another big CoreXY machine

Sorry, only registered users may post in this forum.