Coffeetable CoreXY:: new build :: small apartment rep-strap solutions

Posted by realthor

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 28, 2016 06:35AM |

Registered: 9 years ago Posts: 1,035 |

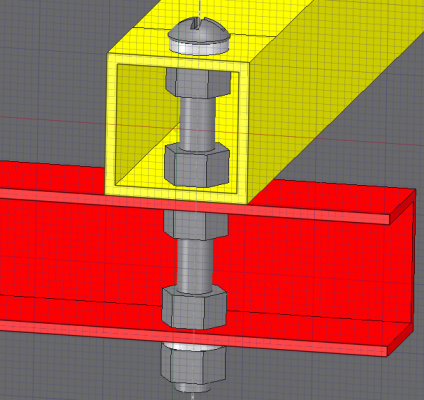

If there would be such thing as a way to fasten nuts inside the tube actually all one would have to do is fasten some nuts against the square tube walls, most importantly clamping the adjacent walls of the two tubes, something like this:

, and there will be no need for tolerances of an insert of sorts.

But as long as there is no way (unless a clever tool can be designed/printed/used) to fasten the nuts inside the square tube this idea is moot.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

, and there will be no need for tolerances of an insert of sorts.

But as long as there is no way (unless a clever tool can be designed/printed/used) to fasten the nuts inside the square tube this idea is moot.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 28, 2016 12:34PM |

Registered: 9 years ago Posts: 83 |

Take a section of metal tubing slightly larger in diameter than your bolt and slightly shorter in length than the inside dimensions of your square tubing, thread the outside ends, attach bolts, slide into place, drop bolt through.

For ease of positioning, wrap some solid core wire around the middle of the tube while you're positioning it, and pull the wire loose once the bolt's through.

Or just spend the extra few dollars on some 2020 extrusions and either some cube corners or some cast aluminum 90 degree angles.

For ease of positioning, wrap some solid core wire around the middle of the tube while you're positioning it, and pull the wire loose once the bolt's through.

Or just spend the extra few dollars on some 2020 extrusions and either some cube corners or some cast aluminum 90 degree angles.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 28, 2016 03:53PM |

Registered: 9 years ago Posts: 1,035 |

Quote

grat

Take a section of metal tubing slightly larger in diameter than your bolt and slightly shorter in length than the inside dimensions of your square tubing, thread the outside ends, attach bolts, slide into place, drop bolt through.

For ease of positioning, wrap some solid core wire around the middle of the tube while you're positioning it, and pull the wire loose once the bolt's through.

Or just spend the extra few dollars on some 2020 extrusions and either some cube corners or some cast aluminum 90 degree angles.

All great and common sense advise, BUT: "slightly shorter" is what @lkcl says should be within +-0.1mm, which is something i can't really cut and file to tolerances (by hand); ALU extruusion is what most will use because it is readily available in many areas. Not here though. So thinking of strange ways to do it... not in a real hurry so i have time exploring possibilities.

Quote

lkcl

oo. duh. yes. sorry, didn't realise the significance of this earlier - yes, that would work great.Quote

realthor

On the other hand I have just noticed that an M10 Nut is 16mm between flats ... so a printed part with an M10 Nut space ....interesting.

I think I'm back to this idea for now. The tolerances of the M10 nuts are Max 16mm, which is great, and minimum of 15.73 ... worst case scenario would be 0.27mm off. Would this be acceptable to prevent crushing or it's already too loose? I can always buy a bag of nuts and most probably i'll find there enough to fit the required tolerances. I'll probably be able to arrange to return the rest based on the receipt.

For that matter, one nut should suffice to support the area around the bolt right? Or should I be thinking of using two nuts and the bolt should go in between them...

Edited 1 time(s). Last edit at 04/28/2016 04:31PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 28, 2016 04:49PM |

Registered: 13 years ago Posts: 268 |

At the risk of adding fuel to an already ridiculous fire, how well do you think tolerances are held on the inside of a tube? Outside of extruded stock? Not all that great, I would not count at all on a 16mm sq bar fitting inside a tube 20mm tube with 2mm thick walls. Insides of structural tube is generally not held to any sort of tolerance, especially welded tubing. I realize you are most likely talking about extruded aluminum tubes, but it's worth noting for those that might consider welded tubing, there's a seam to contend with there. Even if the parts were on size exactly you would still have a line to line fit, which you won't assemble easily.

You are making a huge deal out of nothing. If you want to get crazy, get something close and then add shims. You can get actual shim stock (cut with scissors, they even have plastic shim) or cut up soft drink cans or similar. But I wouldn't worry that much, as warp and twist in the cheaply available tube is going to hurt more than .1 of crush at the end. Steel fasteners and aluminum tubing is not at all a concern.

You are making a huge deal out of nothing. If you want to get crazy, get something close and then add shims. You can get actual shim stock (cut with scissors, they even have plastic shim) or cut up soft drink cans or similar. But I wouldn't worry that much, as warp and twist in the cheaply available tube is going to hurt more than .1 of crush at the end. Steel fasteners and aluminum tubing is not at all a concern.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 28, 2016 05:01PM |

Registered: 8 years ago Posts: 776 |

Quote

grat

Take a section of metal tubing slightly larger in diameter than your bolt and slightly shorter in length than the inside dimensions of your square tubing, thread the outside ends, attach bolts, slide into place, drop bolt through.

niiiiice. i like that idea.

Quote

Or just spend the extra few dollars on some 2020 extrusions and either some cube corners or some cast aluminum 90 degree angles.

.... y'know... after seeing the prices on motedis.com, i was wondering, realthor, why you just don't go with 2020. it would save an awful lot of hassle.

basically, i think what we're all trying to say is (after a long time working through it, because we're fascinated by ideas and assessing them), you're using parts that are not designed for any kind of precision engineering, and it's really not going to work out very well. boards (MDF or HDF) is fine because it's really very solid, especially when you create a hollow cube out of it. when i say "not going to work out well", it's the fact that you have to evaluate *twenty four* sets of bolts, *twenty four* sets of nuts - forty eight if you go with the 2 bolts per extrusion per corner idea - for engineering tolerances in a material that's not even designed with engineering precision. that's just mad.

Edited 2 time(s). Last edit at 04/28/2016 05:08PM by lkcl.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 28, 2016 05:02PM |

Registered: 9 years ago Posts: 1,035 |

@Koko76: I agree it's getting pretty ridiculous that we got caught in this matter  ...Thanks for setting us straight

...Thanks for setting us straight

Edited 1 time(s). Last edit at 04/28/2016 05:03PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

...Thanks for setting us straight

...Thanks for setting us straight

Edited 1 time(s). Last edit at 04/28/2016 05:03PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 28, 2016 05:17PM |

Registered: 9 years ago Posts: 1,035 |

I intended this whole frame for steel square tubing actually but then somehow i got convinced that ALU is easier to work with ... seems it's not all that easy and I agree, if ALU is to be considered, extrusion is the way to go. I tried to come up with something after being told that it can easily get crushed by over-fastening ... so yeah, steel tubing or alu extrusion.

Edited 1 time(s). Last edit at 04/28/2016 05:17PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Edited 1 time(s). Last edit at 04/28/2016 05:17PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 28, 2016 06:07PM |

Registered: 9 years ago Posts: 1,035 |

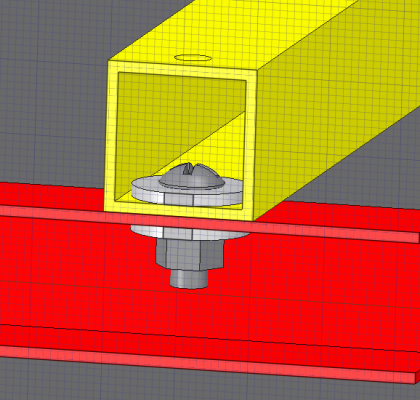

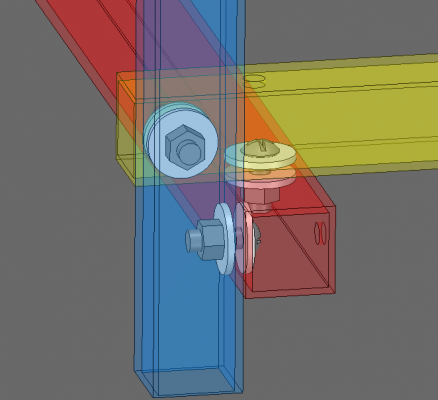

Ok, one last idea for ALU square tube. Considering the forces involved in a 3D printer frame and the fact that I'll be having 3 such connections per corner, I think the following will work just fine:

No tolerances involved, the large washers should spread the clamping force and the tubes should be prevented to pivot around the bolt hole. Plus the other 2 such connections should restrict even more any movement. What do you think?

This could be a great way to make a frame with no visible bolts, adding some good clean looks to the package

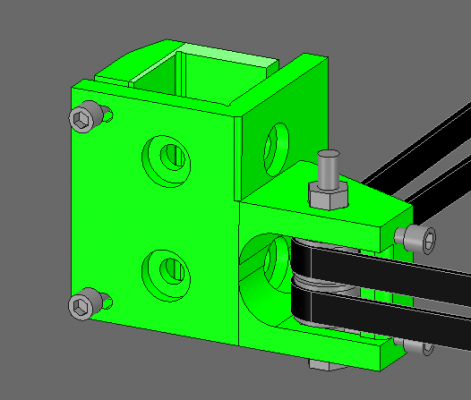

Here's how a "Node" will look like:

View the 3D model @Sketchfab: [skfb.ly]

Edited 4 time(s). Last edit at 04/28/2016 06:49PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

No tolerances involved, the large washers should spread the clamping force and the tubes should be prevented to pivot around the bolt hole. Plus the other 2 such connections should restrict even more any movement. What do you think?

This could be a great way to make a frame with no visible bolts, adding some good clean looks to the package

Here's how a "Node" will look like:

View the 3D model @Sketchfab: [skfb.ly]

Edited 4 time(s). Last edit at 04/28/2016 06:49PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 28, 2016 07:21PM |

Registered: 11 years ago Posts: 1,049 |

Pouring used french fry grease on the fire

Butt joints with joint plates

See

[forums.reprap.org]

eBay -- $20 --- 25 triangle 304 Stainless steel 3"x3"+- 24 gage Plate flat metal weld gusset

eBay -- $20 --- 30xCorner Gusset 3.5 x 3.5 5/16 plate alum heavy hot rod rat custom off road

Can't afford a drill press $70 - 20% ( use 20% off coupon) $56 usd

[www.harborfreight.com]

Drill Guide and Chuck General Tools Model # 36/37 Internet # 100349264

[www.homedepot.com]

oops --- your across the pond ---- drill press 10000 euro

Butt joints with joint plates

See

[forums.reprap.org]

eBay -- $20 --- 25 triangle 304 Stainless steel 3"x3"+- 24 gage Plate flat metal weld gusset

eBay -- $20 --- 30xCorner Gusset 3.5 x 3.5 5/16 plate alum heavy hot rod rat custom off road

Can't afford a drill press $70 - 20% ( use 20% off coupon) $56 usd

[www.harborfreight.com]

Drill Guide and Chuck General Tools Model # 36/37 Internet # 100349264

[www.homedepot.com]

oops --- your across the pond ---- drill press 10000 euro

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 29, 2016 03:26AM |

Registered: 9 years ago Posts: 1,035 |

Quote

cozmicray

oops --- your across the pond ---- drill press 10000 euro

Exactly

) . + Frequent mover to rentals as of late (with job) ... home is far away.

) . + Frequent mover to rentals as of late (with job) ... home is far away.BTW: you're so spoiled over there

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 29, 2016 06:35PM |

Registered: 11 years ago Posts: 1,049 |

Not spoiled --- You took the Neadanerthal path

I guess no makerspaces (or whatever you call them) over there

Apartment warrior might look for

Dremel 220-01 Rotary Tool Work Station $40 + Dremel tool

[www.dremel.com]

Quote

realthor

BTW: you're so spoiled over there

I guess no makerspaces (or whatever you call them) over there

Apartment warrior might look for

Dremel 220-01 Rotary Tool Work Station $40 + Dremel tool

[www.dremel.com]

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions May 04, 2016 12:57PM |

Registered: 8 years ago Posts: 776 |

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions May 04, 2016 01:01PM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

[attachment 77270 ScoutCoreXY_IntraTubeConnection.png]

yehhhh, niiiice - i like it. no squashing. tubes won't twist. if you can use a bit of square plate with a tapped hole instead, you'd not need a washer, or a nut, which would be a heck of a lot easier. maybe you can find some biiiig square nuts... or just some big hex nuts.

now why didn't i think of the idea of just going through one side of the extrusion, ehn? oh - use allen-key bolts, so the access hole you drill is smaller.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions May 04, 2016 01:21PM |

Registered: 9 years ago Posts: 1,035 |

Quote

lkcl

Quote

realthor

[attachment 77270 ScoutCoreXY_IntraTubeConnection.png]

yehhhh, niiiice - i like it. no squashing. tubes won't twist. if you can use a bit of square plate with a tapped hole instead, you'd not need a washer, or a nut, which would be a heck of a lot easier. maybe you can find some biiiig square nuts... or just some big hex nuts.

now why didn't i think of the idea of just going through one side of the extrusion, ehn? oh - use allen-key bolts, so the access hole you drill is smaller.

Lol... you can use it now... it's there in the wild, that's why I like the freeconomy concepts ....

BTW, this is one more reason I post a load of stuff, most of it useless and quickly proven wrong but sometimes there's a gem in there waiting to be spilled out. This one can prove a bad idea too but I keep trying

Nuts and bolts and washers are all common hardware anybody can easily find, so I insist on that. I thought of hex head bolts for the in-tube-bolt too but I had those sketches at hand and used them for a quick render

.

.That's the Quadrap you're showing me there... stumbled on it while searching for a name for the "side-by-side-tubes-node" I "invented (lol)", until I found the Scout Tower that uses the same technique, hence the name SCOUTcorexy

Edited 3 time(s). Last edit at 05/04/2016 02:01PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions May 04, 2016 05:53PM |

Registered: 9 years ago Posts: 1,035 |

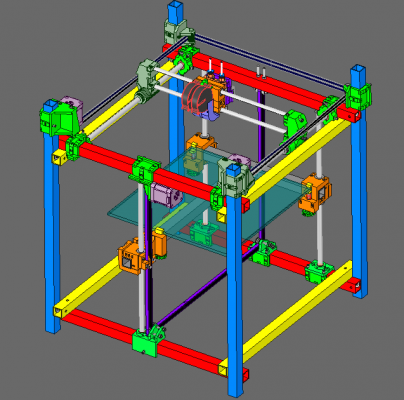

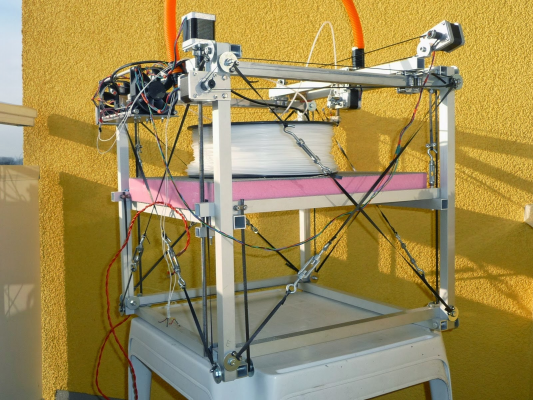

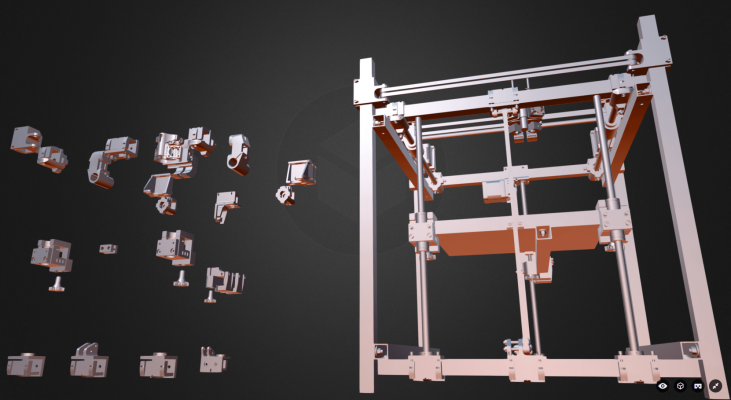

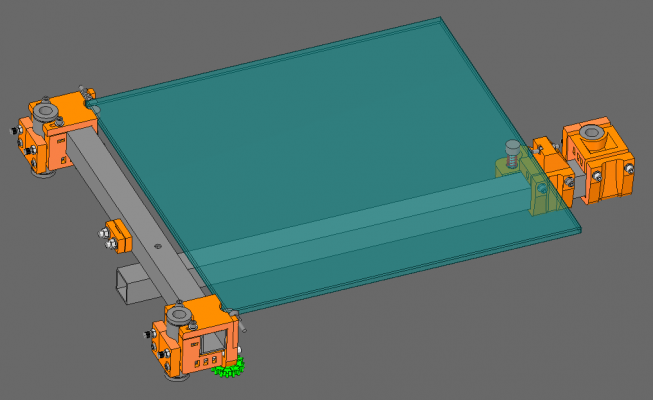

Now this should be about all that SCOUTcorexy will be for the first iteration. I have combed quite a bit the fine details of the parts and added a Z_Idler_Printed_Clamp (it was eyelets in metal previously but I wasn't happy about it) but still have to add the end-stops and the bowden extruders:

Check the model here: [sketchfab.com]

Note: DoubleClick on a part centers the view around it so orbiting with left mouse will rotate around that very part; DoubleCLick in an empty area will reset the view. These are nice tips to know.

I have also started a Wiki page for SCOUTcorexy here on reprap: http://reprap.org/wiki/SCOUTcorexy. It's pretty barren at this time but I am new with that but will fill it in time.

Edited 2 time(s). Last edit at 05/04/2016 07:22PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Check the model here: [sketchfab.com]

Note: DoubleClick on a part centers the view around it so orbiting with left mouse will rotate around that very part; DoubleCLick in an empty area will reset the view. These are nice tips to know.

I have also started a Wiki page for SCOUTcorexy here on reprap: http://reprap.org/wiki/SCOUTcorexy. It's pretty barren at this time but I am new with that but will fill it in time.

Edited 2 time(s). Last edit at 05/04/2016 07:22PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions May 05, 2016 02:59AM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

I have also started a Wiki page for SCOUTcorexy here on reprap: http://reprap.org/wiki/SCOUTcorexy.

looks like a pretty damn good start to me, rthor.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions May 14, 2016 10:03AM |

Registered: 9 years ago Posts: 1,035 |

I have addressed over the last weeks (as time permitted), the shortcomings of the design that I was not happy about.

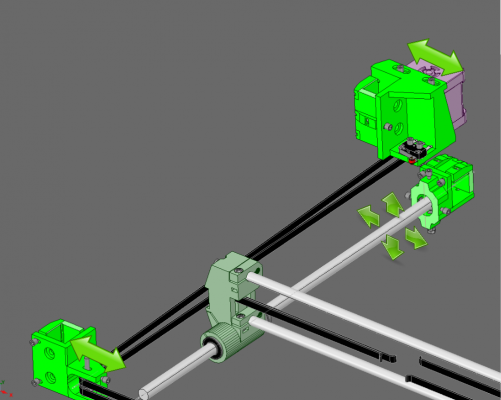

For once, I have full adjustability in all components that deal with the squareness of the XY gantry:

So, the motor can move left-right a bit to accommodate the position of the Y Carriage, the position of which is dependent on the Y Rods as they are being adjusted to square the XY gantry. The belt redirect piece on the opposite side can now also be adjusted via 2 M3 screws that push the bearings spindle. I admit this is a bit overkill but I wanted to ensure perfect 90 deg of everything, rods and belts alike.

Then I had the X Carriage re-designed to also perform the function of adjusting belts tension. See here: [www.thingiverse.com] (also discussion in this thread: [forums.reprap.org])

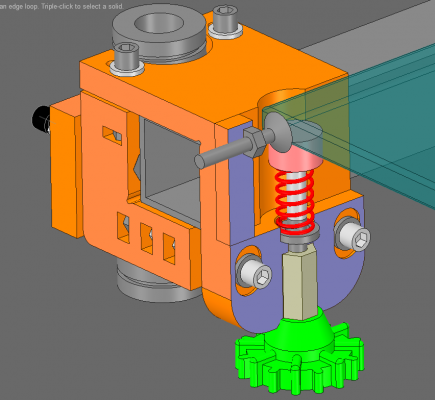

On the moving Z I have redesigned quite a bit the multi-function parts that are 3 things: bearing-blocks, square-tube clamps and shock-absorbers for crashing situations. I am not trully happy because they are a bit on the large side but they couldn't be smaller for what they are supposed to do. Here below is just a section through the shock-absorber on the side where I have two smooth rods:

Now I have a lateral wall with an inversed flat-headed bolt that will clamp the bed from the side even if the size of the bed will not be exact. The front-to-back clamping is done by the single shock-absorber on the "leg" of the T(ee) bed support, one that can slide on the tube before being fastened:

The current design has the frame again in the asymmetrical vertical tubes position where 2 of them are outsede and 2 of them are on the inside (see here: [forums.reprap.org]) because I like it better and with the tube connections now made between the adjacent walls the frame will not be skewed in any way (i think ).

).

The better part is that is is very easy to put on the other side, no modification needed apart from a tad longer belt to accommodate the difference. But I like having the motors outside as it will be much easier to enclose and only heat the bed not the motors/electronics/etc.

That's about it so far ... any concerns are totally welcomed.

vvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvv

Link to the Sketchfab 3D model (better than thingiverse's and many others)

^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^

Edit: I am in the process to adapt all the parts with holes to be accepted in T-slot 2020 and I have a question: what sizes bolts and what sizes hole|recess are used with 2020? Is M5 the standard of bolts that go best in the T-slot?

Ex:

Edited 4 time(s). Last edit at 05/15/2016 09:20AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

For once, I have full adjustability in all components that deal with the squareness of the XY gantry:

So, the motor can move left-right a bit to accommodate the position of the Y Carriage, the position of which is dependent on the Y Rods as they are being adjusted to square the XY gantry. The belt redirect piece on the opposite side can now also be adjusted via 2 M3 screws that push the bearings spindle. I admit this is a bit overkill but I wanted to ensure perfect 90 deg of everything, rods and belts alike.

Then I had the X Carriage re-designed to also perform the function of adjusting belts tension. See here: [www.thingiverse.com] (also discussion in this thread: [forums.reprap.org])

On the moving Z I have redesigned quite a bit the multi-function parts that are 3 things: bearing-blocks, square-tube clamps and shock-absorbers for crashing situations. I am not trully happy because they are a bit on the large side but they couldn't be smaller for what they are supposed to do. Here below is just a section through the shock-absorber on the side where I have two smooth rods:

Now I have a lateral wall with an inversed flat-headed bolt that will clamp the bed from the side even if the size of the bed will not be exact. The front-to-back clamping is done by the single shock-absorber on the "leg" of the T(ee) bed support, one that can slide on the tube before being fastened:

The current design has the frame again in the asymmetrical vertical tubes position where 2 of them are outsede and 2 of them are on the inside (see here: [forums.reprap.org]) because I like it better and with the tube connections now made between the adjacent walls the frame will not be skewed in any way (i think

).

).The better part is that is is very easy to put on the other side, no modification needed apart from a tad longer belt to accommodate the difference. But I like having the motors outside as it will be much easier to enclose and only heat the bed not the motors/electronics/etc.

That's about it so far ... any concerns are totally welcomed.

vvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvvv

Link to the Sketchfab 3D model (better than thingiverse's and many others)

^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^

Edit: I am in the process to adapt all the parts with holes to be accepted in T-slot 2020 and I have a question: what sizes bolts and what sizes hole|recess are used with 2020? Is M5 the standard of bolts that go best in the T-slot?

Ex:

Edited 4 time(s). Last edit at 05/15/2016 09:20AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Sorry, only registered users may post in this forum.