Heated enclosure - What kind of heaters and power?

Posted by LarsK

|

Heated enclosure - What kind of heaters and power? December 03, 2015 09:08AM |

Registered: 9 years ago Posts: 346 |

Hello,

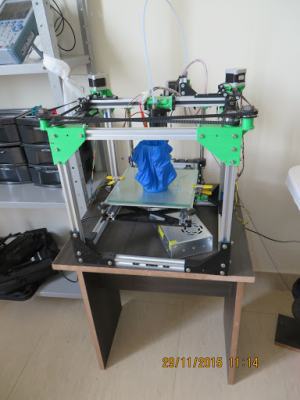

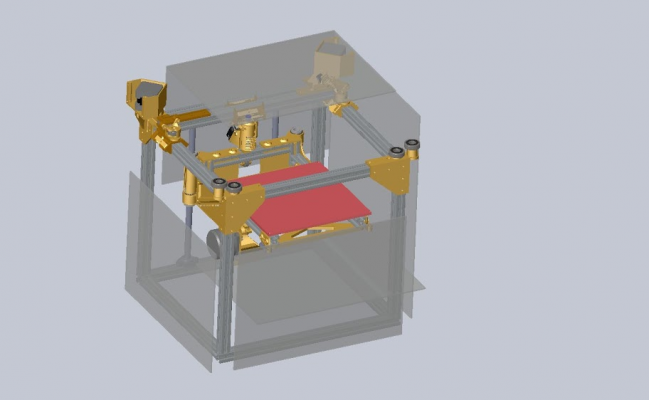

I am looking for someone with experience from heat enclosures. I would like to make a heat enclosure using acrylic panels. My motors will be enclosed in niches as shown in the photos below (so they will be outside).

Ideally I would like to have up-to 70 C in the build area.

My question is:

- What is typically heater power required (aka, how many watts do I need to heat and keep warm)

- Does anybody have any good/bad experiences with methods? I am thinking to just install another heated bed and put a fan blowing on it - combined with my existing bed that will deliver ~250W ish to the enclosure.

- Any other comments? Material about heated enclosures is very sparse

I am looking for someone with experience from heat enclosures. I would like to make a heat enclosure using acrylic panels. My motors will be enclosed in niches as shown in the photos below (so they will be outside).

Ideally I would like to have up-to 70 C in the build area.

My question is:

- What is typically heater power required (aka, how many watts do I need to heat and keep warm)

- Does anybody have any good/bad experiences with methods? I am thinking to just install another heated bed and put a fan blowing on it - combined with my existing bed that will deliver ~250W ish to the enclosure.

- Any other comments? Material about heated enclosures is very sparse

|

Re: Heated enclosure - What kind of heaters and power? December 03, 2015 09:25AM |

Registered: 11 years ago Posts: 5,780 |

I have a couple heaters from a stratasys printer- the heated volume in the printer they came from was about 3-4 cuft. The heaters are a pair of 400W rated resistors that have heat sink fins on them. They run directly from 117VAC under PID control. Stratasys runs the machines at 70C when printing ABS. If you have a similar enclosed volume, there you go.

You may be able to get away with less additional heat if you use insulation panels to enclose most of the sides of the machine and maybe use one panel of clear plastic so you can see what's going on inside the machine.

I wouldn't use a second bed heater- those things are expensive- I'd use something like this: [www.walmart.com] (there was something similar for about $10 a month ago, but cold weather has descended upon us and the low prices have disappeared). Either use a second extruder connection on your controller board to regulate the temperature with PID, or get a separate controller. You'll need an SSR to switch power to it and a thermistor to read the enclosure temperature.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You may be able to get away with less additional heat if you use insulation panels to enclose most of the sides of the machine and maybe use one panel of clear plastic so you can see what's going on inside the machine.

I wouldn't use a second bed heater- those things are expensive- I'd use something like this: [www.walmart.com] (there was something similar for about $10 a month ago, but cold weather has descended upon us and the low prices have disappeared). Either use a second extruder connection on your controller board to regulate the temperature with PID, or get a separate controller. You'll need an SSR to switch power to it and a thermistor to read the enclosure temperature.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Heated enclosure - What kind of heaters and power? December 03, 2015 05:32PM |

Registered: 9 years ago Posts: 346 |

|

Re: Heated enclosure - What kind of heaters and power? December 04, 2015 07:25AM |

Registered: 9 years ago Posts: 346 |

Right.

I am looking at this heating element. It is meant to go in an oven.

[produto.mercadolivre.com.br]

Will the heat radiation be too extreme to control or what do people think?

I am looking at this heating element. It is meant to go in an oven.

[produto.mercadolivre.com.br]

Will the heat radiation be too extreme to control or what do people think?

|

Re: Heated enclosure - What kind of heaters and power? December 04, 2015 07:59AM |

Registered: 11 years ago Posts: 5,780 |

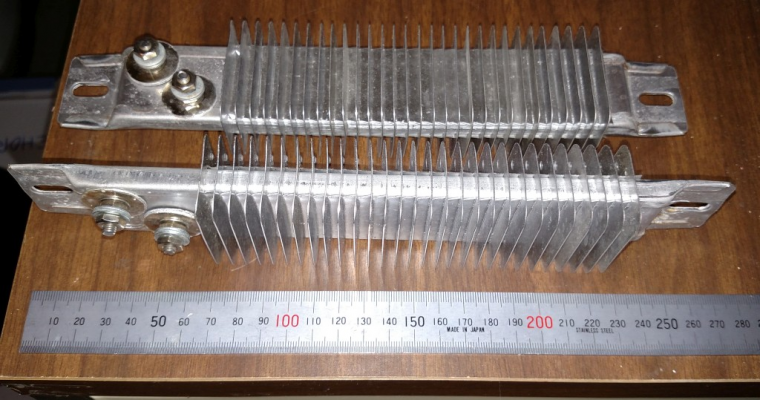

That's a radiant heater, designed to heat everything near it by getting instensely hot in a small volume. I don't think it would be good- you want something that doesn't get quite so hot so that most of the heat is transferred to the air instead of to the machine's frame and other parts. Maybe you could drop the power into it by putting two of them in series- then you'd get only 1/2 (1/4 of the rated power in each device) of the power and they wouldn't radiate as much to the surrounding machine parts. You want low temperature and large surface area...

Here's are the Stratasys heaters:

This is similar to the controller that Stratasys uses in their machines to control the enclosure temperature (and the extruder temperatures). I have one of these and use it to control the temperature of a water jacket for a chocolate extruder. It drives an SSR directly and has programmable high and low temperature alarm outputs. It has a lot of functions for a cheap device!

Edited 3 time(s). Last edit at 12/04/2015 08:29AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Here's are the Stratasys heaters:

This is similar to the controller that Stratasys uses in their machines to control the enclosure temperature (and the extruder temperatures). I have one of these and use it to control the temperature of a water jacket for a chocolate extruder. It drives an SSR directly and has programmable high and low temperature alarm outputs. It has a lot of functions for a cheap device!

Edited 3 time(s). Last edit at 12/04/2015 08:29AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Heated enclosure - What kind of heaters and power? December 08, 2015 08:48AM |

Registered: 8 years ago Posts: 47 |

i am taking it you want radiant heat to prevent any air currents or at least reduce it. remember heat rises so you can probably get an electric space heater that has the nichrome wire. take an aluminum plate and mount the nichrome on the bottom. use a thermister and relay to turn the heat plate on and off. 1500 watts should be plenty as it will heat a 10'x10' room to 80*f with no problem. if you can take that aluminum plate and create ridges in it like a sink it will give more surface area allowing it to dissipate more heat and allow it to heat faster.

|

Re: Heated enclosure - What kind of heaters and power? December 08, 2015 09:18AM |

Registered: 9 years ago Posts: 346 |

Quote

pen25

i am taking it you want radiant heat to prevent any air currents or at least reduce it. remember heat rises so you can probably get an electric space heater that has the nichrome wire. take an aluminum plate and mount the nichrome on the bottom. use a thermister and relay to turn the heat plate on and off. 1500 watts should be plenty as it will heat a 10'x10' room to 80*f with no problem. if you can take that aluminum plate and create ridges in it like a sink it will give more surface area allowing it to dissipate more heat and allow it to heat faster.

Yes that is a good idea. Só what you are saing is that i can harvest the wire from a Space heater? Hmm, how about a hairdrier? Is that the same thing?

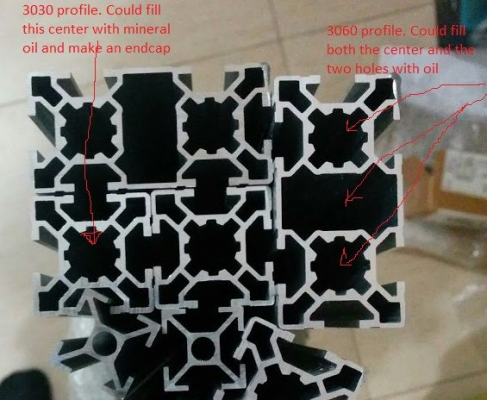

I think if I can get the wire I will wrap it in on a 30x30 extrusion that I can then suspend inside the printer. I think that will look nice and have a lot of area.

|

Re: Heated enclosure - What kind of heaters and power? December 08, 2015 09:39AM |

Registered: 8 years ago Posts: 233 |

Is there a reason why you would not want lots of air current inside a heated chamber? In my thought experiments, I thought it would be better to have a construct more like a convection oven. High amounts of air current allow the air in the entire chamber to be the same temperature; and because the air is moving, you always have the same air temperature next to your object which normalizes temperature of extruded plastic faster than stationary air. You could potentially cool extruded plastic enough to provide structure for the next layer with higher temperature accuracy and a higher temperature which may increase layer adhesion consistency and eliminate the need for carriage/effector mounted filament cooling fans.

Disadvantage of the Convection idea might be that you actually want to keep the temperature differential between older printed layers and the most recent few printed layers for a longer time so that layers stick better while allowing the lower layers to provide more rigid print support.

Edited 1 time(s). Last edit at 12/08/2015 11:27AM by patrickrio.

Disadvantage of the Convection idea might be that you actually want to keep the temperature differential between older printed layers and the most recent few printed layers for a longer time so that layers stick better while allowing the lower layers to provide more rigid print support.

Edited 1 time(s). Last edit at 12/08/2015 11:27AM by patrickrio.

|

Re: Heated enclosure - What kind of heaters and power? December 08, 2015 12:40PM |

Registered: 9 years ago Posts: 346 |

I think turbulence is not done because the forced convection (heat transfer forced by air flows) would be bigger at the outer walls, especially on complicated shapes. Even as the heated chamber is 70C the plastic exiting the nozzle is still significantly hotter so it would result in uneven cooling.

If it is an advantage to have 70C air blowing on the parts, then I think the better option would be a nozzle fan inside the heat chamber (like on PLA). I obviously say this without any experience with heated chambers what so ever

If it is an advantage to have 70C air blowing on the parts, then I think the better option would be a nozzle fan inside the heat chamber (like on PLA). I obviously say this without any experience with heated chambers what so ever

|

Re: Heated enclosure - What kind of heaters and power? December 08, 2015 06:04PM |

Registered: 8 years ago Posts: 233 |

yes, differential inside an object versus outside could be a problem. I think you would use higher chamber temperatures with convection though, since it can be quite accurate. I think your goal with Forced Convection Heating would be to try to keep an object JUST structurally sound enough to support the layers above without sloughing or bending due to weight or extruder forces. You might then SLOWLY drop the chamber temp once done to give the whole object time to cool uniformly.

|

Re: Heated enclosure - What kind of heaters and power? December 08, 2015 07:17PM |

Registered: 8 years ago Posts: 47 |

Quote

LarsK

Quote

pen25

i am taking it you want radiant heat to prevent any air currents or at least reduce it. remember heat rises so you can probably get an electric space heater that has the nichrome wire. take an aluminum plate and mount the nichrome on the bottom. use a thermister and relay to turn the heat plate on and off. 1500 watts should be plenty as it will heat a 10'x10' room to 80*f with no problem. if you can take that aluminum plate and create ridges in it like a sink it will give more surface area allowing it to dissipate more heat and allow it to heat faster.

Yes that is a good idea. Só what you are saing is that i can harvest the wire from a Space heater? Hmm, how about a hairdrier? Is that the same thing?

I think if I can get the wire I will wrap it in on a 30x30 extrusion that I can then suspend inside the printer. I think that will look nice and have a lot of area.

hair drier would work but they are usually coils and harder to straighten. the key with what ever you are using will act as a radiator and dont know of the 3030 extrusion would work. worth a try

|

Re: Heated enclosure - What kind of heaters and power? December 08, 2015 07:18PM |

Registered: 8 years ago Posts: 47 |

Quote

patrickrio

yes, differential inside an object versus outside could be a problem. I think you would use higher chamber temperatures with convection though, since it can be quite accurate. I think your goal with Forced Convection Heating would be to try to keep an object JUST structurally sound enough to support the layers above without sloughing or bending due to weight or extruder forces. You might then SLOWLY drop the chamber temp once done to give the whole object time to cool uniformly.

from what i have read the air currents, though there is heat in the chamber, allow parts to cool and will start to warp or shrink.

|

Re: Heated enclosure - What kind of heaters and power? December 09, 2015 07:21AM |

Registered: 9 years ago Posts: 346 |

Turns out I can buy 10 m NiChrome wire (N80/20) for just ~4$

Here in Brazil the houses rarely have running hot water, instead they use electrical water heaters directly mounted as shower heads. Inside those heaters they use NiChrome wire, so there is an aftermarket for it.

Now, that sorted out. Next thing - How to install it.

For safety reasons I want to avoid having anything in my printer that in normal operation can ignite paper / plastics or whatever. This is also why I did not jump directly on the radiation heaters I mentioned earlier.

I see two methods:

1) Tape the NiChrome wire with Kapton tape to the 3030 profile and dimension such that the wire never reaches an undesired high temperature. That will maybe not be so easy without having to do a lot of relay switching (?)

2) Fill the inner 3030 or 3060 with mineral oil and have the NiChrome wire heat the oil - Basically an oil radiator. From an engineering perspective I have no doubt that this is both the best and the safest approach. But making this setup is a lot more work then just wire and capton tape : /

With both approaches I can design for a series of independent parallel circuits each with their own relay. The idea being that I can roughly regulate heat output and temperatures by choosing the number of active circuits..

I am going to order those 10m of NiChrome and then I will have some time to think about it before it gets here.

Here in Brazil the houses rarely have running hot water, instead they use electrical water heaters directly mounted as shower heads. Inside those heaters they use NiChrome wire, so there is an aftermarket for it.

Now, that sorted out. Next thing - How to install it.

For safety reasons I want to avoid having anything in my printer that in normal operation can ignite paper / plastics or whatever. This is also why I did not jump directly on the radiation heaters I mentioned earlier.

I see two methods:

1) Tape the NiChrome wire with Kapton tape to the 3030 profile and dimension such that the wire never reaches an undesired high temperature. That will maybe not be so easy without having to do a lot of relay switching (?)

2) Fill the inner 3030 or 3060 with mineral oil and have the NiChrome wire heat the oil - Basically an oil radiator. From an engineering perspective I have no doubt that this is both the best and the safest approach. But making this setup is a lot more work then just wire and capton tape : /

With both approaches I can design for a series of independent parallel circuits each with their own relay. The idea being that I can roughly regulate heat output and temperatures by choosing the number of active circuits..

I am going to order those 10m of NiChrome and then I will have some time to think about it before it gets here.

|

Re: Heated enclosure - What kind of heaters and power? December 09, 2015 08:28AM |

Registered: 11 years ago Posts: 5,780 |

The Stratasys machine that the two heaters came from had two 5.25" fans blowing air over them, so I don't think that a little air movement inside is going to cause any print problems. I wouldn't direct the air flow at the print, but in a closed box the air is going to move if there's a fan. It doesn't seem to hurt Stratasys any...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Heated enclosure - What kind of heaters and power? December 09, 2015 10:50AM |

Registered: 9 years ago Posts: 346 |

Quote

the_digital_dentist

The Stratasys machine that the two heaters came from had two 5.25" fans blowing air over them, so I don't think that a little air movement inside is going to cause any print problems. I wouldn't direct the air flow at the print, but in a closed box the air is going to move if there's a fan. It doesn't seem to hurt Stratasys any...

Sounds like the right thing to do. Will try to get some of the more high-end types so I have some room for PWM control. Could be nice to have it running really aggressive at heat-up and then have it more relaxed in operation.

I am really feeling that the oil thing is the way to do, but it is just so much more complicated. These days I have been working on my water-cooled laser (water cools a TEG which cools the alu-block with the laser) and I really have had to step up my design to stop the head from leaking... Still not there. With the oil heater I will have all the thermals (including oil visc) to deal with - But then I will have no moving parts... Hmmm...

Also I plan to order 0.2mm wire. It will be running at 127V and each 3030-element will be 300mm long, then by winding it 4 times up and down I come at 1200mm wire length giving me 1100C bare wire temperature and ~375W. Then 4 series like that. 1x 3030 for each corner of the printer.

|

Re: Heated enclosure - What kind of heaters and power? December 09, 2015 12:57PM |

Registered: 11 years ago Posts: 5,780 |

What sort of oil withstands 1100C without boiling/burning?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Heated enclosure - What kind of heaters and power? December 09, 2015 02:47PM |

Registered: 9 years ago Posts: 346 |

Maybe I got it wrong - It is my understanding that the wire temperature calculated is what I would get if suspended in air (?). The heat-transfer should be magnitudes higher in the oil.

The wire will be 10.16 Ohms / Foot. Mine will be almost 4 feet so that is 40.64 Ohm total resistance. At 127V that is 3.125A or 396.875W (as calculated with the real NiCr A numbers)

For estimates I am using [www.jacobs-online.biz] to play with the numbers - Although that is for NiCr B not A as what I will be buying. Difference is small.

A different approach is to make it 2400 mm (8 complete winding's) and stick to gage 32 - Then the wire temperature will only go to 600 C and it will still deliver some 200W. That would be the way to do it, if I were to just do the Kapton tape thing.

The wire will be 10.16 Ohms / Foot. Mine will be almost 4 feet so that is 40.64 Ohm total resistance. At 127V that is 3.125A or 396.875W (as calculated with the real NiCr A numbers)

For estimates I am using [www.jacobs-online.biz] to play with the numbers - Although that is for NiCr B not A as what I will be buying. Difference is small.

A different approach is to make it 2400 mm (8 complete winding's) and stick to gage 32 - Then the wire temperature will only go to 600 C and it will still deliver some 200W. That would be the way to do it, if I were to just do the Kapton tape thing.

|

Re: Heated enclosure - What kind of heaters and power? December 09, 2015 03:30PM |

Registered: 10 years ago Posts: 14,672 |

I don't have any experience in heated chambers for 3D printers other than a passive chamber heated by the bed, but what I know about space heating and 3D printing suggests to me that you need fans to blow air slowly overt the heaters and inject the warm air into the bottom of the chamber.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Heated enclosure - What kind of heaters and power? December 09, 2015 04:11PM |

Registered: 11 years ago Posts: 5,780 |

Quote

LarsK

Maybe I got it wrong - It is my understanding that the wire temperature calculated is what I would get if suspended in air (?). The heat-transfer should be magnitudes higher in the oil.

Even if that is the free-air temperature and the heat transfer to oil is very rapid, I would be concerned about anything that gets hot enough to boil/burn the oil. You don't have to run the wire that hot- you only need the enclosure to get to 50-70C- I'd check the boiling point of the oil and try to size the wire to stay below that temperature. That should give you plenty of margin to heat the system up quickly without having to worry about an explosion that throws burning or boiling oil all over anyone standing nearby.

I think you'd be better off buying a second-hand toaster, pulling the heaters out, and running them under PID control with a small fan blowing over them.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Heated enclosure - What kind of heaters and power? December 09, 2015 04:47PM |

Registered: 8 years ago Posts: 233 |

I modified a convection toaster oven with PID control for testing the melting point of tin alloys. It had a maximum tested temperature of 600F/315C. I used Kiln wool insulation inside the toaster (outside the heater coils) to keep the radiated heat loss low.

I was keeping 2 degreeF/1degeeC accuracy throughout the heated volume. The toaster idea will work great... maybe buy a cheap toaster convection oven to get more useful parts for your money. The fan you need will maybe be included that way....you will also get all the wire connections you need as well as a few good switches....

Edited 2 time(s). Last edit at 12/09/2015 04:53PM by patrickrio.

I was keeping 2 degreeF/1degeeC accuracy throughout the heated volume. The toaster idea will work great... maybe buy a cheap toaster convection oven to get more useful parts for your money. The fan you need will maybe be included that way....you will also get all the wire connections you need as well as a few good switches....

Edited 2 time(s). Last edit at 12/09/2015 04:53PM by patrickrio.

|

Re: Heated enclosure - What kind of heaters and power? December 09, 2015 05:23PM |

Registered: 9 years ago Posts: 346 |

Quote

the_digital_dentist

Quote

LarsK

Maybe I got it wrong - It is my understanding that the wire temperature calculated is what I would get if suspended in air (?). The heat-transfer should be magnitudes higher in the oil.

Even if that is the free-air temperature and the heat transfer to oil is very rapid, I would be concerned about anything that gets hot enough to boil/burn the oil. You don't have to run the wire that hot- you only need the enclosure to get to 50-70C- I'd check the boiling point of the oil and try to size the wire to stay below that temperature. That should give you plenty of margin to heat the system up quickly without having to worry about an explosion that throws burning or boiling oil all over anyone standing nearby.

I think you'd be better off buying a second-hand toaster, pulling the heaters out, and running them under PID control with a small fan blowing over them.

The boiling point of mineral oil is ~300 C (and maybe more relevant, flash point ~200 ish) . It is very hard to design a way with NiCr wire that gets the wire that cold while still outputting a decent power. I would need 6m of wire to get just 200W out (while bare wire temp 300C). The correct approach is to install a thermal fuse. Remember oil heaters are used extensively all around the world.

About just getting a toaster - The problem is that I want a printer I can leave alone. I simply do not think I can convince my wife to trust my printer, if it has red hot glowing wires in it. If I am buying a second-hand something, then it will be a space heater which I can control directly without any modifications to the assembly it self. But it wont be a nice solution.

I am going to buy 20m of this wire and then I will see. If I just hide away the wire inside the alu profiles then I guess I can run it at 600C without problems.

@DC - Yes, that sounds like a good way to do it.

|

Re: Heated enclosure - What kind of heaters and power? December 10, 2015 09:17AM |

Registered: 8 years ago Posts: 47 |

|

Re: Heated enclosure - What kind of heaters and power? December 10, 2015 01:37PM |

Registered: 11 years ago Posts: 5,780 |

Call me nuts, but I don't think skimping on the heater wire to try to save a couple dollars is anything like the correct approach to making a heater. If you have to run a hot wire in oil, use enough wire to do it at a temperature that doesn't run the risk of boiling/burning the oil.

With so many heaters in consumer appliances (toasters, room heaters, hair dryers, coffee makers, etc.) readily available at any garage sale for just a couple $, I don't know why you'd want to mess around with oil and trying to make end caps that seal the extrusions. To me the possibility of a leak spilling oil all over my printer and the cleanup effort that would follow would be enough to dissuade me from attempting that approach. But I'm sort of lazy that way...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

With so many heaters in consumer appliances (toasters, room heaters, hair dryers, coffee makers, etc.) readily available at any garage sale for just a couple $, I don't know why you'd want to mess around with oil and trying to make end caps that seal the extrusions. To me the possibility of a leak spilling oil all over my printer and the cleanup effort that would follow would be enough to dissuade me from attempting that approach. But I'm sort of lazy that way...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Heated enclosure - What kind of heaters and power? December 10, 2015 02:06PM |

Registered: 8 years ago Posts: 233 |

LarsK,

I thought about your problem a bit more, and the biggest problem you have is availability of a cheap, small and durable heat source. I think pulling nichrome wire from a Brazilian electric shower is not the best idea either, and when you combine it with all the work of making an oil heater.... kind of too much I think.

When I think about it, the cheapest small heating devices that are everywhere in Brazil are hair blow dryers and electric hair straighteners. As I remember from my time there, every single woman has a box full of this equipment and probably has an old one lying around somewhere. I bet one of those "low frizz" hair dryers would be great because you could have several lower heat level settings and several lower fan settings, all in a very small package. You could locate the whole setup easily in your design because it is small.

Then all you need is a Solid State Relay and a PID connection from your controller.

Fala com a mulherada da casa... provivelmente voce ja tem quasi tudo que voce preciso.

I thought about your problem a bit more, and the biggest problem you have is availability of a cheap, small and durable heat source. I think pulling nichrome wire from a Brazilian electric shower is not the best idea either, and when you combine it with all the work of making an oil heater.... kind of too much I think.

When I think about it, the cheapest small heating devices that are everywhere in Brazil are hair blow dryers and electric hair straighteners. As I remember from my time there, every single woman has a box full of this equipment and probably has an old one lying around somewhere. I bet one of those "low frizz" hair dryers would be great because you could have several lower heat level settings and several lower fan settings, all in a very small package. You could locate the whole setup easily in your design because it is small.

Then all you need is a Solid State Relay and a PID connection from your controller.

Fala com a mulherada da casa... provivelmente voce ja tem quasi tudo que voce preciso.

|

Re: Heated enclosure - What kind of heaters and power? December 10, 2015 04:03PM |

Registered: 9 years ago Posts: 346 |

Quote

patrickrio

...

When I think about it, the cheapest small heating devices that are everywhere in Brazil are hair blow dryers and electric hair straighteners. As I remember from my time there, every single woman has a box full of this equipment and probably has an old one lying around somewhere. I bet one of those "low frizz" hair dryers would be great because you could have several lower heat level settings and several lower fan settings, all in a very small package. You could locate the whole setup easily in your design because it is small.

Then all you need is a Solid State Relay and a PID connection from your controller.

Fala com a mulherada da casa... provivelmente voce ja tem quasi tudo que voce preciso.

Haha, that would be hilarious, I can just imagine her reaction when I tell her that I "borrowed" her hair dryer for my 3d printer

- Maybe I can tell her that I will print a new one for her!

- Maybe I can tell her that I will print a new one for her!You are right though - It is certainly a way to go. It will however have to be a high-end one. The one of my wife uses get extremely hot if left on for just a little more than "normal". Be careful not to overestimating the quality of cheap household appliances - Remember I am putting these inside a 50 to 70 deg chamber and expect it to run continuously for 8 hours and more. A reliable known brand should be OK for it I think.

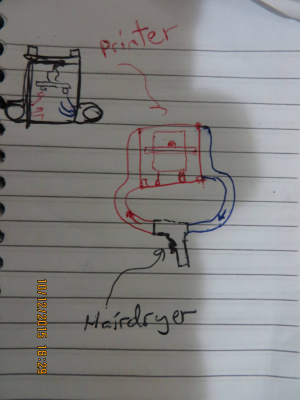

I will think about it. One cool thing to do, would be to put a ducting on it and separate it from the printer. Like this:

Link to sketch as it wont show it directly here for some reason

That will also solve a lot of safety issues because monitoring the hairdryer for overheating and other abnormal behavior will be easier. Finally it will be possible to establish a more fireproof closure around it.

Definitely a viable approach. I like this more than the space heater because the space heater requires bigger volumes of air to be moved.

@ the_digital_dentist - I read and understand your objections to the oil and 3030 extrusion idea. I am also loosing fate in it. I seriously doubt that I will be able to seal the extrusion proper, at least without actual machining parts for the purpose. If I want to do the oil thing, I will need to get a cylinder that is already closed in the bottom or get the 3030 TIG welded.

Finally, two clarifications:

1) The NiCr wire I am getting now is not from a shower head. It is pure brand-new wire on a roll, and I am getting 20m of it. I just mentioned the shower head because that is what it is used for (among others)

2) I am not a "low budget" builder. I think it is fun to find cheap ways to do things that otherwise cost lots of money but I have no ambition or requirement about up-cycling. If the only solution is some expensive component then I will also get that. Aka,I am purchasing this NiCr wire because I think I can solve the problem with it, not because it is the cheapest in a number of options.

Edited 2 time(s). Last edit at 12/10/2015 05:17PM by LarsK.

|

Re: Heated enclosure - What kind of heaters and power? December 10, 2015 05:00PM |

Admin Registered: 16 years ago Posts: 13,884 |

... when I was a child I've used heater wires out from old flat-irons - a long wire, embedded in ceramic beads ...

My father used glass tubes filled with quicksilver in the '70er years to conduct heat ...

My last 'non-air' transfer-heater was filled with Galinstan (a pretty expensive, but less toxic replacement for quicksilver) - boils at >1300 degC ...

But you can try with simply waterglass too, if the containment is airtight enough, so the water won't exit over time ... otherwise the residue will solidify to silicate ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

My father used glass tubes filled with quicksilver in the '70er years to conduct heat ...

My last 'non-air' transfer-heater was filled with Galinstan (a pretty expensive, but less toxic replacement for quicksilver) - boils at >1300 degC ...

But you can try with simply waterglass too, if the containment is airtight enough, so the water won't exit over time ... otherwise the residue will solidify to silicate ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Heated enclosure - What kind of heaters and power? December 10, 2015 07:44PM |

Registered: 9 years ago Posts: 346 |

Quote

VDX

... when I was a child I've used heater wires out from old flat-irons - a long wire, embedded in ceramic beads ...

My father used glass tubes filled with quicksilver in the '70er years to conduct heat ...

My last 'non-air' transfer-heater was filled with Galinstan (a pretty expensive, but less toxic replacement for quicksilver) - boils at >1300 degC ...

But you can try with simply waterglass too, if the containment is airtight enough, so the water won't exit over time ... otherwise the residue will solidify to silicate ...

Hey VDX,

As always I am amazed by your vast knowledge of... Well, pretty much everything.

I was aware of industrial heating blankets for preheating but did not know that they were made out of ceramic beads.

I will have to pick up some of these. No doubt about it. That is so cool.

Inside the Statasys heater that the_digital_dentist showed us earlier, - What kind of heating technology would I expect to find if I opened that?

|

Re: Heated enclosure - What kind of heaters and power? December 10, 2015 08:15PM |

Registered: 11 years ago Posts: 5,780 |

I would guess that those heaters have nichrome wire wrapped on a ceramic or mica core that's probably over-wrapped with a couple layers of glass fiber cloth to keep it from shorting against the metal casing, but your guess is as good as mine. I doubt there's any oil inside them, but who knows?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Heated enclosure - What kind of heaters and power? December 10, 2015 11:25PM |

Registered: 8 years ago Posts: 233 |

Hey LarsK,

For putting pics directly into text, I have been posting fotos to Imgur.com and then copying the "direct" link URL into the button for pictures on the taskbar above the message you are writing. works great.

For putting pics directly into text, I have been posting fotos to Imgur.com and then copying the "direct" link URL into the button for pictures on the taskbar above the message you are writing. works great.

|

Re: Heated enclosure - What kind of heaters and power? December 11, 2015 03:38AM |

Admin Registered: 16 years ago Posts: 13,884 |

... I've opened some of the glue-gun heads or toaster-heaters to see their heaters - some are wound NiCr-wires, isolated and hold in place by ceramic elements ... others are embedded in high-temp silikone (fine for up to 400degC I guess) or in Ceran-glass (up to 900degC) ... some are simply metal chunks, connected at the two sides, without any other measures - could be some special high resistance material.

Have somewhere an inductive heater plate too, what's much more interesting for me as heater, as it's measuring the temp in the heated metal surface too!

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Have somewhere an inductive heater plate too, what's much more interesting for me as heater, as it's measuring the temp in the heated metal surface too!

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Sorry, only registered users may post in this forum.