corexy with 2 or 3 direct drive extruders

Posted by hucilu

|

corexy with 2 or 3 direct drive extruders December 13, 2015 10:00AM |

Registered: 8 years ago Posts: 13 |

Hi iam planing to build printer similar to this Vulcanus Max V1.1 with almost same size and few changes.

Now i need some advices from more experienced peoples.

As title sugests i want use in this printer direct extruders with Cyclops or in future try Diamond extruder.

Now everyone is talking about speed with corexy and that direct drive isnt good for corexy platform.

I have bad experiences with my old printer and bowden setup so i wanted to try something better and also move to dual color/material.

So what do you people think about dual/triple direct extruder on corexy?

Now i need some advices from more experienced peoples.

As title sugests i want use in this printer direct extruders with Cyclops or in future try Diamond extruder.

Now everyone is talking about speed with corexy and that direct drive isnt good for corexy platform.

I have bad experiences with my old printer and bowden setup so i wanted to try something better and also move to dual color/material.

So what do you people think about dual/triple direct extruder on corexy?

|

Re: corexy with 2 or 3 direct drive extruders December 13, 2015 02:03PM |

Registered: 9 years ago Posts: 346 |

It really depends a lot about what kind of bed size you are going for.

If you want to make a huge print size then I think the CoreXY may still be superior. But really, there are few solid experiences. The best "attack" on the CoreXY I have ever read, is from Alan Richard and I repost his objections here, it is from this thread.

I particular like his proposal in the last post with putting a motor directly on on the axis and it may be very relevant for you as you already have a very heavy carriage.

If you want to make a huge print size then I think the CoreXY may still be superior. But really, there are few solid experiences. The best "attack" on the CoreXY I have ever read, is from Alan Richard and I repost his objections here, it is from this thread.

I particular like his proposal in the last post with putting a motor directly on on the axis and it may be very relevant for you as you already have a very heavy carriage.

Quote

alan richard

Forget CoreXY go with cartesian, or maybe even something of the prusa style.

I say this from the perspective of having successfully built a coreXY.

I think I too was 'seduced' by the idea of having a high speed, low mass printhead churning out super fast prints.

I don't think moving mass is the limit to speed; It is partly the ability to extrude plastic quick enough and mainly the desire by most people to have a half decent looking print at the end of it and turning the speed down.

They are a pain to set up. You have to have 10 pulleys (including the motors) bang on square in 3 planes. If they're not parallel there are issues of belts riding off idlers or binding on pulley edges, If they are not perfectly square to the moving elements then the equations of motion above are not correct.

Compared to 4 pulleys in cartesian where each pair (or axis) of which can be considered and assembled as separate entities, then you need only get the 2 sub assemblies at 90 degrees.

I reckon they are also more prone to generate noise and resonance with so many points of contact between belt idlers/ motors and framework. Maybe that's just my cheap bearings. You can't skimp on components. The moving axis needs to be fairly substantial to cope with the torsion of setting up belt tensions (tho' it is equal when they are set up)

I used v-slot to build mine, I know using that for a cartesian build would have been a doddle in comparison, with so many easy ways to drive it (check out 'fixed belt in the slot like rack and pinion' - You can't get it wrong and nothing needs alignment)

CoreXY isn't fully and correctly implemented in Marlin (and probably others) firmware. I think there are bugs. Some features are not available - babystepping for one.

If using Ramps and Marlin, there is a problem with driving them at 1/32 step - there is an absolute limit of 125mm/s or 7500mm/min. feedrate on X or Y axis.

Set it to 7501mm/min and it does some horrible things to the sync of the motors. Print with it at real world sub 100mm/s type speed with 1/32 and there are occasional noises that don't inspire confidence.

Diagnosing motor issues is awkward even if you set it to cartesian to move only one motor, you're still dragging the other belt about and its hard to measure diagonal moves.

I mention Prusa's - Beauty is in the eye of the beholder they say, but I think that the one thing that Core XY and cartesians do have in common is they end up looking ugly big cubes that must contain the entire print volume, whether they're printing or not.

At least with a Mendel or Prusa style the print volume is out in fresh air that can be shared by other domestic appliances when they're not printing. And they can be prettied up a bit. And there's a lot of know how behind them.

Sure, the pro's make boxed in printers of the Core/ Cart variety -the motion control is better but would a home made effort be any better at printing than a well established reprap mendel style design?

There's a reason Stratasys spends millions of $ and thousands of man hours developing a printer - 'cos that's what it takes.

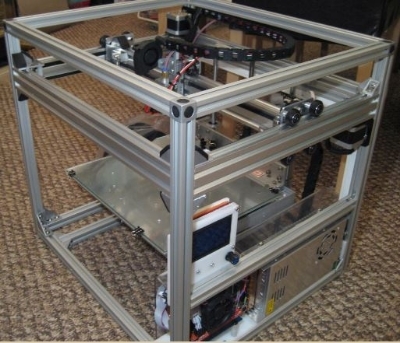

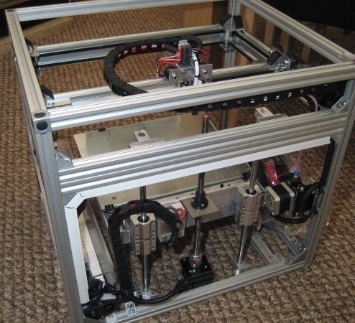

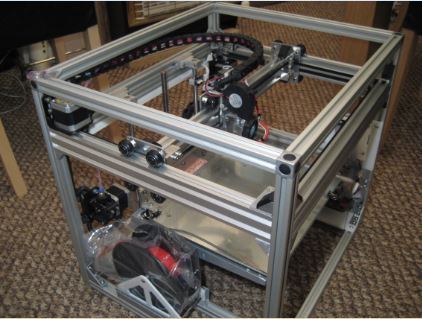

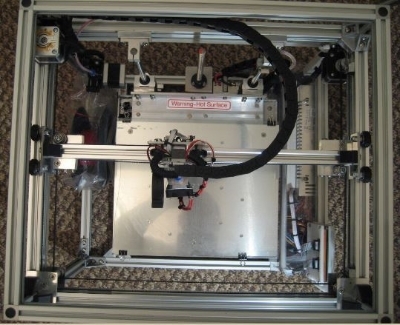

Anyway, enough moaning, here's mine if you want to see it. Just don't bother making one.

Love it really. Prints great. 304x214x220 print area in a box 420x480x450. Just waiting for the covers to arrive and its done.

-a

Quote

alan richard

Hi Andrew. You are quite right, its not optimal.

It does print ok so far with PLA up to 80mm/s but something rougher like Timberfill wouldn't go up there.

I expect the friction on the filament will vary depending where the print head is which may show itself on bigger prints.

I don't usually do; 'form over function' but that was one case on this build to try and keep it all within the box.

I'll probably get some more ptfe tube tube to loop up and over in a conventional way.

(I could have taken 60 or 70mm off that cantilevered Z axis too - another sop to aesthetics to have the hotend visible from the 'front window' of the machine.)

@J.A.C. - 'Scuse me having an anti-CoreXY rant on your thread, especially here on the CoreXY forum! I was a bit tired and cross at the time.

CoreXY is a lovely quirky mechanism, set up right it works fine. Its a nice engineering challenge.

I just feel that in the 3D printing subculture there is unfair bias towards it being the answer to every problem without much focus on some if its negatives.

My own conclusion from doing this is that it is better suited to either mass production, fast non 3D printing applications, or a printer that has a huge span where every spare gram needs trimming off.

I am a printing newbie but familiar with machines. As a one-off 'build it in your shed' reprap, I think you could make a printer that's just as capable but a lot easier to put together using other methods and you did say 'simple is better' in your first post.

That's a handy looking stack of extrusion in your first picture. I used 20x20 standard extrusion and bought a couple of metres of Openbuilds V slot 40x20 for linear motion. I already had the round bar and SC10UU bearings (It started out as a Mendelmax 2 lookie like and evolved!)

With hindsight, a cartesian using this method

would have gone together easier, saved a lot of workshop time, cost less, run quieter and I'd feel more comfortable about firmware.

I can't really think of any downsides now I understand the printing side better.

Good luck whatever you build.

Alan

|

Re: corexy with 2 or 3 direct drive extruders December 13, 2015 03:28PM |

Registered: 8 years ago Posts: 13 |

yes i want print bigger(40*40cm) than my current setup 20*20cm.

Alan build is good but i like the basic corexy layout better.

Iam choosing smooth rods as guide but what diameter to chose so it will not bend? 16mm or more?i plan to use igus bearings for XY

Edited 1 time(s). Last edit at 12/13/2015 03:28PM by hucilu.

Alan build is good but i like the basic corexy layout better.

Iam choosing smooth rods as guide but what diameter to chose so it will not bend? 16mm or more?i plan to use igus bearings for XY

Edited 1 time(s). Last edit at 12/13/2015 03:28PM by hucilu.

|

Re: corexy with 2 or 3 direct drive extruders December 13, 2015 04:26PM |

Registered: 9 years ago Posts: 346 |

To build 400x400 with 3 extruders you will need a printer with outer dimensions ranging from 600x600 (if you are very good) to 800 x 800.

Smooth rods are being abandoned for CoreXY. They are inferior for a number of reasons. You should use linear guides instead as they are particularly good on the CoreXY due to how the load works (no twisting) and they are lighter. If you despite this stick to rods then you will be OK with Ø12.

The Vulcanus Max V1.1 seems like much of a work in progress build. Read up on the various thread in this forum and you will learn a lot. There are other builds around.

In particular I think you can benefit from reading this thread as it boils down a lot of the starter concepts.

What is your budget and do you have access to mills or lathes?

Smooth rods are being abandoned for CoreXY. They are inferior for a number of reasons. You should use linear guides instead as they are particularly good on the CoreXY due to how the load works (no twisting) and they are lighter. If you despite this stick to rods then you will be OK with Ø12.

The Vulcanus Max V1.1 seems like much of a work in progress build. Read up on the various thread in this forum and you will learn a lot. There are other builds around.

In particular I think you can benefit from reading this thread as it boils down a lot of the starter concepts.

What is your budget and do you have access to mills or lathes?

|

Re: corexy with 2 or 3 direct drive extruders December 13, 2015 06:15PM |

Registered: 8 years ago Posts: 13 |

I set myself to 60*60*60cm outer size of printer and size of HB isn that important.30*30 in enough too.

Linear guides arent bad but 5times or more expensive than smooth rods.Well maybe i could go for linear but can i manufacture parts strong enough from PLA to make it work?

Budget isnt set but i dont want expensive stuf if i get just a little to nothing better results.

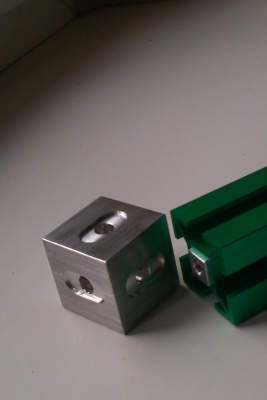

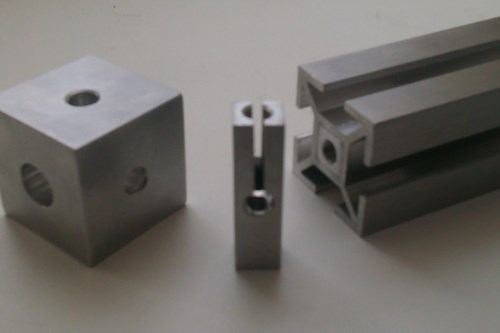

And no o dont have acess to lathe or mill .But i found guy from my country who is selling this corner cubes:

.But i found guy from my country who is selling this corner cubes:

Linear guides arent bad but 5times or more expensive than smooth rods.Well maybe i could go for linear but can i manufacture parts strong enough from PLA to make it work?

Budget isnt set but i dont want expensive stuf if i get just a little to nothing better results.

And no o dont have acess to lathe or mill

.But i found guy from my country who is selling this corner cubes:

.But i found guy from my country who is selling this corner cubes:|

Re: corexy with 2 or 3 direct drive extruders December 13, 2015 06:48PM |

Registered: 9 years ago Posts: 346 |

Hey, well, it is better to buy an overall good printer then to buy a few very good components and go cheap on the rest. But it is a lot of money for a very expensive hotend and then I think the mechanics should follow.

I think you should spend some money on your existing printer first - In my opinion you need it to print ABS if you wanna print parts for your new printer.

I think you should spend some money on your existing printer first - In my opinion you need it to print ABS if you wanna print parts for your new printer.

|

Re: corexy with 2 or 3 direct drive extruders December 13, 2015 09:39PM |

Registered: 10 years ago Posts: 553 |

Check eBay for relatively cheap linear guides. You can usually fine brand name guides for a lot cheaper than new.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: corexy with 2 or 3 direct drive extruders December 13, 2015 11:20PM |

Registered: 8 years ago Posts: 13 |

Thats one of the reasons i want New printer,because this one melts x carriage when printing ABS without fanQuote

LarsK

Hey, well, it is better to buy an overall good printer then to buy a few very good components and go cheap on the rest. But it is a lot of money for a very expensive hotend and then I think the mechanics should follow.

I think you should spend some money on your existing printer first - In my opinion you need it to print ABS if you wanna print parts for your new printer.

|

Re: corexy with 2 or 3 direct drive extruders December 14, 2015 01:22AM |

Registered: 11 years ago Posts: 5,780 |

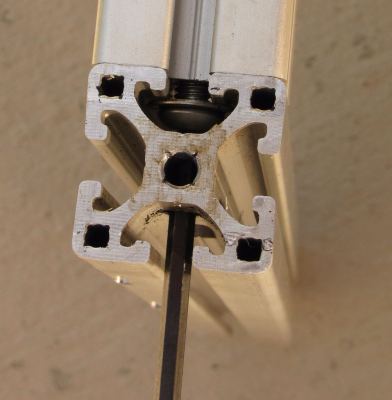

Do you realize that the corner cubes are unnecessary? T-slot extrusions are easy to connect together by tapping the center hole and using the screw size that the slot is designed to fit.

All you need are a tap and a drill. No precision is required- hand tools are fine. Use the tap to thread the center hole and use the drill to make a tool-access hole to tighten the screw. 1.5" square 8020 is designed for 5/16-18 tap and button head screws and carriage bolts. Check the appropriate sizes for whatever you're using.

I'm a big fan of rigid frames, but I doubt corner gussets do anything for rigidity. My printer's frame is big, and the machine is heavy, but it has neither corner cubes nor gussets, yet is very rigid. The money you don't spend on corner cubes and gussets can be put into using larger size T slot extrusions. THAT will get you more rigidity.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

All you need are a tap and a drill. No precision is required- hand tools are fine. Use the tap to thread the center hole and use the drill to make a tool-access hole to tighten the screw. 1.5" square 8020 is designed for 5/16-18 tap and button head screws and carriage bolts. Check the appropriate sizes for whatever you're using.

I'm a big fan of rigid frames, but I doubt corner gussets do anything for rigidity. My printer's frame is big, and the machine is heavy, but it has neither corner cubes nor gussets, yet is very rigid. The money you don't spend on corner cubes and gussets can be put into using larger size T slot extrusions. THAT will get you more rigidity.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: corexy with 2 or 3 direct drive extruders December 14, 2015 04:09AM |

Registered: 10 years ago Posts: 179 |

I was printing for the last couple of years on a Prusa i3 that is made of high quality components (original Prusa alu frame, original j-head hotend). Maximum acceleration is around 50mm/s after which quality of the parts is just unacceptable. I usually (99% of time) print at 30mm/s maximum.

I have built a Vulcanus V1. Its direct drive extruder X-carriage weights 650 grams. What surprised me is how printing quality does not suffer by high accelerations. Parts printed at 30mm/s and 100mm/s accelerations look just as good.

Now I am turning my Vulcanus X-carriage into a one that has 3 nozzles runned by a single stepper motor. X carriage should weight around 1000 grams so around the same as dual direct drive extruder carriage. I will let you know in a couple of the days on how printer copes with an extra weight.

BTW I have used metal corner brackets on my Vulcanus V1. I do not like the threaded rods on the Z-axis but the X-Y axis runned by TMC2100 stepper drivers work like a piece of art.

I have built a Vulcanus V1. Its direct drive extruder X-carriage weights 650 grams. What surprised me is how printing quality does not suffer by high accelerations. Parts printed at 30mm/s and 100mm/s accelerations look just as good.

Now I am turning my Vulcanus X-carriage into a one that has 3 nozzles runned by a single stepper motor. X carriage should weight around 1000 grams so around the same as dual direct drive extruder carriage. I will let you know in a couple of the days on how printer copes with an extra weight.

BTW I have used metal corner brackets on my Vulcanus V1. I do not like the threaded rods on the Z-axis but the X-Y axis runned by TMC2100 stepper drivers work like a piece of art.

|

Re: corexy with 2 or 3 direct drive extruders December 14, 2015 09:13AM |

Registered: 8 years ago Posts: 13 |

Quote

the_digital_dentist

Do you realize that the corner cubes are unnecessary? T-slot extrusions are easy to connect together by tapping the center hole and using the screw size that the slot is designed to fit.

All you need are a tap and a drill. No precision is required- hand tools are fine. Use the tap to thread the center hole and use the drill to make a tool-access hole to tighten the screw. 1.5" square 8020 is designed for 5/16-18 tap and button head screws and carriage bolts. Check the appropriate sizes for whatever you're using.

I'm a big fan of rigid frames, but I doubt corner gussets do anything for rigidity. My printer's frame is big, and the machine is heavy, but it has neither corner cubes nor gussets, yet is very rigid. The money you don't spend on corner cubes and gussets can be put into using larger size T slot extrusions. THAT will get you more rigidity.

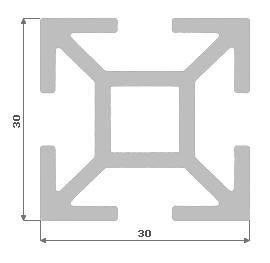

I have acces to 30*30 extrusions of this type:

so i cant tap them.BUT i could use part of his connector and screw it like on your pictures

Quote

Edvardas

...

I have built a Vulcanus V1. Its direct drive extruder X-carriage weights 650 grams. What surprised me is how printing quality does not suffer by high accelerations. Parts printed at 30mm/s and 100mm/s accelerations look just as good.

Now I am turning my Vulcanus X-carriage into a one that has 3 nozzles runned by a single stepper motor. X carriage should weight around 1000 grams so around the same as dual direct drive extruder carriage. I will let you know in a couple of the days on how printer copes with an extra weight.

BTW I have used metal corner brackets on my Vulcanus V1. I do not like the threaded rods on the Z-axis but the X-Y axis runned by TMC2100 stepper drivers work like a piece of art.

That would be great! I wil be eagerly waiting for your answer

To be sure,you are building it with smooth rods?

To be sure,you are building it with smooth rods?I also considered using alu corner brackets simultaneiously with those corner cubes to get best possible results.

And i want use lead 2 lead screws connected with belt to stepper motor on the bottom of frame.

|

Re: corexy with 2 or 3 direct drive extruders December 14, 2015 12:10PM |

Registered: 8 years ago Posts: 346 |

I changing my printer to have two E3D v6 hotend and two direct mk8 extruder, the carriage will have +/- 800gr.

This is my first try and i will try to use the 8mm rodds one both x and y axis, not sure if the weight of the carriage will give me problems or not.

But my printer was an small print area (20x20), so i hope the 8mm rodds will be ok.

In my case if i found artifacts problems i the prints i will use one direct mk8 and change the other one to an bowden setup.

But if you are planning to have the double the size them you must go a least 12mm rodds, linear rails or use wheels.

This is my first try and i will try to use the 8mm rodds one both x and y axis, not sure if the weight of the carriage will give me problems or not.

But my printer was an small print area (20x20), so i hope the 8mm rodds will be ok.

In my case if i found artifacts problems i the prints i will use one direct mk8 and change the other one to an bowden setup.

But if you are planning to have the double the size them you must go a least 12mm rodds, linear rails or use wheels.

|

Re: corexy with 2 or 3 direct drive extruders December 17, 2015 05:23PM |

Registered: 10 years ago Posts: 179 |

Quote

hucilu

That would be great! I wil be eagerly waiting for your answerTo be sure,you are building it with smooth rods?

I also considered using alu corner brackets simultaneiously with those corner cubes to get best possible results.

And i want use lead 2 lead screws connected with belt to stepper motor on the bottom of frame.

Yes, I use 8mm rods all around. I wanted to get the printer running before I start modifying things.

My X carriage mechanics are finished and it weights 1300 grams (twice as the one on Vulcanus V1).

Tomorrow I will finish electronics and update the firmware and then it will be a testing time

I can see you are really strugling with a way to connect 2020 profiles. I guess you are not from Europe?

|

Re: corexy with 2 or 3 direct drive extruders December 17, 2015 11:22PM |

Registered: 8 years ago Posts: 13 |

Quote

Edvardas

Quote

hucilu

That would be great! I wil be eagerly waiting for your answerTo be sure,you are building it with smooth rods?

I also considered using alu corner brackets simultaneiously with those corner cubes to get best possible results.

And i want use lead 2 lead screws connected with belt to stepper motor on the bottom of frame.

Yes, I use 8mm rods all around. I wanted to get the printer running before I start modifying things.

My X carriage mechanics are finished and it weights 1300 grams (twice as the one on Vulcanus V1).

Tomorrow I will finish electronics and update the firmware and then it will be a testing time

I can see you are really strugling with a way to connect 2020 profiles. I guess you are not from Europe?

Yes iam from Europě.We have localy avaiable 3030 profiles but i wasnt sure how get sturdiest construction/connection.

|

Re: corexy with 2 or 3 direct drive extruders December 18, 2015 03:49AM |

Registered: 10 years ago Posts: 179 |

Quote

hucilu

Yes iam from Europě.We have localy avaiable 3030 profiles but i wasnt sure how get sturdiest construction/connection.

Well then why not use Motedis?

I have been using these corner brackets [www.motedis.com] They do make a sturdy construction but make it hard to make things square. Now I would use these cubes for the corners of the frame and corners of the bed: [www.motedis.com]

And as for sturdiness... Vulcanus has extra 2020 beams where Z-axis motors mount and where corexy mechanism mounts. This makes it really stiff (look how some people make corexy printers by just having cube without any such bracing beams). If I had to build a printer again I would stay with 2020 profiles.

Oh and do yourself a favor and go with T-nuts instead of filing normal nuts. These without guidance work great with corners brackets [www.motedis.com] and these with guidance works well in mounting printed parts to the 2020 profile [www.motedis.com]

|

Re: corexy with 2 or 3 direct drive extruders December 18, 2015 10:17AM |

Registered: 8 years ago Posts: 13 |

Quote

Edvardas

Quote

hucilu

Yes iam from Europě.We have localy avaiable 3030 profiles but i wasnt sure how get sturdiest construction/connection.

Well then why not use Motedis?

I have been using these corner brackets [www.motedis.com] They do make a sturdy construction but make it hard to make things square. Now I would use these cubes for the corners of the frame and corners of the bed: [www.motedis.com]

And as for sturdiness... Vulcanus has extra 2020 beams where Z-axis motors mount and where corexy mechanism mounts. This makes it really stiff (look how some people make corexy printers by just having cube without any such bracing beams). If I had to build a printer again I would stay with 2020 profiles.

Oh and do yourself a favor and go with T-nuts instead of filing normal nuts. These without guidance work great with corners brackets [www.motedis.com] and these with guidance works well in mounting printed parts to the 2020 profile [www.motedis.com]

If you read whole topic i mentioned corner cubes and corner brackets but "the_digital_dentist" sugested better connecting method.

I did some math and you are right those 2020 will be better.Half the weight and price of 3030 so i can reinforce it more if needed.

BTW that shop is good

so many items

so many items

|

Re: corexy with 2 or 3 direct drive extruders January 26, 2016 08:07AM |

Registered: 9 years ago Posts: 1,035 |

Beware of the deflection on smooth rods caused by heavy carriages. I see big numbers here.

I have attempted to calculate the maximum weight of something at the middle of smooth rods (static weight that is) and i got much smaller numbers being safe for deflection-free (or within reason) system. Please read that post I have linked. There are other guys around that confirmed the numbers with different approaches for calculation.

I believe it's true that CoreXYs should go linear guide route and leave rods behind but there is room for carefully designed printers with rods. You just have to know a lot more and be twice as attentive with your design. I wouldn't dismiss supported rods rails for a better/cheaper approach.

Regards.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I have attempted to calculate the maximum weight of something at the middle of smooth rods (static weight that is) and i got much smaller numbers being safe for deflection-free (or within reason) system. Please read that post I have linked. There are other guys around that confirmed the numbers with different approaches for calculation.

I believe it's true that CoreXYs should go linear guide route and leave rods behind but there is room for carefully designed printers with rods. You just have to know a lot more and be twice as attentive with your design. I wouldn't dismiss supported rods rails for a better/cheaper approach.

Regards.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: corexy with 2 or 3 direct drive extruders January 28, 2016 04:25AM |

Registered: 8 years ago Posts: 3,525 |

Its interesting looking at the pros/cons argument for corexy, I've got a cartesian axis printer (i3) and a delta (Kossel Mini). I'm expecting a smartrapcore alu kit next week as I want to see what corexy is all about. It might replace the i3 if it performs well enough.

However it seems that when you consider the fundamentals i.e. fixed motors, bed moving in z axis only which is relatively easier to do accurately than a bed moving in y (or x planes), a light print head for speed. Then its hard at this point not to conclude that the delta beats it on all of these fronts. The motors are fixed, it has a very light print head far less compromised with a flying extruder or flex3drive instead of a long bowden setup, its fast and the bed is completely fixed. I accept that they are hard to calibrate and technically more challenging to operate and get good results.

That being said, if you want to have a much larger printer or have designs on enclosed printing I can see how corexy might be the way to go, in fact both of these things are of interest to me.

I am hoping my actual experience with the new printer exceeds my expectations (which are quite low so there is hope).

Edited 1 time(s). Last edit at 01/28/2016 04:29AM by DjDemonD.

However it seems that when you consider the fundamentals i.e. fixed motors, bed moving in z axis only which is relatively easier to do accurately than a bed moving in y (or x planes), a light print head for speed. Then its hard at this point not to conclude that the delta beats it on all of these fronts. The motors are fixed, it has a very light print head far less compromised with a flying extruder or flex3drive instead of a long bowden setup, its fast and the bed is completely fixed. I accept that they are hard to calibrate and technically more challenging to operate and get good results.

That being said, if you want to have a much larger printer or have designs on enclosed printing I can see how corexy might be the way to go, in fact both of these things are of interest to me.

I am hoping my actual experience with the new printer exceeds my expectations (which are quite low so there is hope).

Edited 1 time(s). Last edit at 01/28/2016 04:29AM by DjDemonD.

|

Re: corexy with 2 or 3 direct drive extruders February 10, 2016 11:03AM |

Registered: 8 years ago Posts: 13 |

Quote

realthor

Beware of the deflection on smooth rods caused by heavy carriages. I see big numbers here.

I have attempted to calculate the maximum weight of something at the middle of smooth rods (static weight that is) and i got much smaller numbers being safe for deflection-free (or within reason) system. Please read that post I have linked. There are other guys around that confirmed the numbers with different approaches for calculation.

I believe it's true that CoreXYs should go linear guide route and leave rods behind but there is room for carefully designed printers with rods. You just have to know a lot more and be twice as attentive with your design. I wouldn't dismiss supported rods rails for a better/cheaper approach.

Regards.

Well thanks for link but it only gived me more things to worry about and headache from that math because iam bad at it.

Can you do that math for 16mm or 20mm rods?600mm length

|

Re: corexy with 2 or 3 direct drive extruders February 10, 2016 11:20AM |

Registered: 9 years ago Posts: 1,035 |

Considering that I have 8mm for about 300+mm your values should be double for X carriage.

I believe I gave quite step by step how I did it ... it should be easy to follow. Am on phone now if I have time will check some values.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I believe I gave quite step by step how I did it ... it should be easy to follow. Am on phone now if I have time will check some values.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: corexy with 2 or 3 direct drive extruders May 08, 2016 12:40PM |

Registered: 8 years ago Posts: 13 |

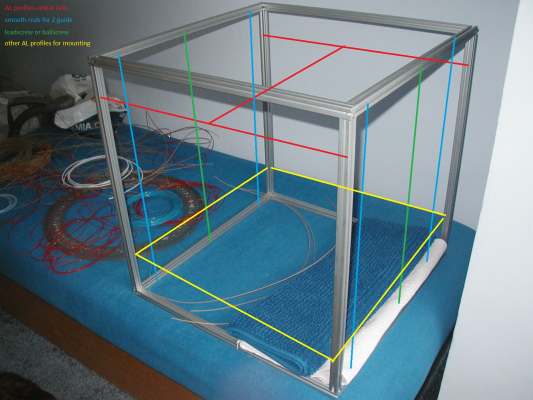

So after few months of thinking i decided i will go for linear rails.I have builded bare construction and iam advancing to buy rails.

Next in question is leadscrew or ballscrew?I think i can get both in same price so what is better?

Next in question is leadscrew or ballscrew?I think i can get both in same price so what is better?

|

Re: corexy with 2 or 3 direct drive extruders May 14, 2016 01:27PM |

Registered: 8 years ago Posts: 3,525 |

This seems to cover it [blog.helixlinear.com]

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: corexy with 2 or 3 direct drive extruders May 15, 2016 11:40AM |

Registered: 8 years ago Posts: 13 |

Thanks.So iam going for leadscrew

|

Re: corexy with 2 or 3 direct drive extruders May 15, 2016 12:03PM |

Registered: 13 years ago Posts: 268 |

If you can get both for he same price, and the ballscrew is of passable quality go ballscrew. Better efficiency and typically better precision. Either way, if using for x and y you will need to deal with backlash inherent in both. Frequently this is done with two nuts that are spring loaded against each other.

|

Re: corexy with 2 or 3 direct drive extruders May 15, 2016 12:06PM |

Registered: 8 years ago Posts: 13 |

I want it use only in ZQuote

Koko76

If you can get both for he same price, and the ballscrew is of passable quality go ballscrew. Better efficiency and typically better precision. Either way, if using for x and y you will need to deal with backlash inherent in both. Frequently this is done with two nuts that are spring loaded against each other.

edit: I am also concerned about the need of brake system for that ballscrew

Edited 1 time(s). Last edit at 05/15/2016 12:19PM by hucilu.

Sorry, only registered users may post in this forum.