New design for coreXY

Posted by idegraaf

|

New design for coreXY December 29, 2015 01:32PM |

Registered: 8 years ago Posts: 9 |

Hi,

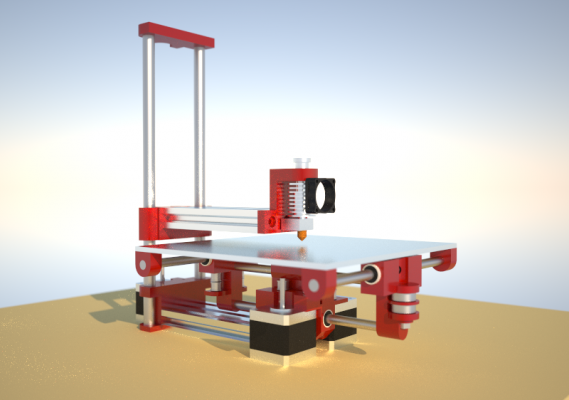

I started new design with coreXY kinematics for bed. It uses 8mm linear bearing for XY-axis and 12mm Z-axis. What you think about this idea.

Edited 1 time(s). Last edit at 12/29/2015 01:34PM by idegraaf.

I started new design with coreXY kinematics for bed. It uses 8mm linear bearing for XY-axis and 12mm Z-axis. What you think about this idea.

Edited 1 time(s). Last edit at 12/29/2015 01:34PM by idegraaf.

|

Re: New design for coreXY December 29, 2015 03:35PM |

Registered: 11 years ago Posts: 5,780 |

One of corexy's benefits is the relatively small footprint because the bed normally only moves in the Z axis. You've thrown that benefit away by moving the bed in both X and Y. Why would you choose to move the relatively heavy bed instead of the usually much lighter extruder carriage? The way it's drawn, it looks like you won't be able to print on the front half of the bed because it can't move back any further.

I'm not a fan of anything cantilevered. CoreXY lends itself to being built using a nearly cubic frame that makes it quite rigid which is ultimately good for print quality. It also makes it easy to enclose in case you want to print with ABS. You've thrown away the rigid and easily enclosable frame design in favor of one that uses the Z axis rails as structural members. You're also cantileveling the bed on its rails and the extruder on an arm attached to the Z axis rails. What's the benefit of doing that? I predict poor stability and great difficulty leveling and zeroing the bed.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I'm not a fan of anything cantilevered. CoreXY lends itself to being built using a nearly cubic frame that makes it quite rigid which is ultimately good for print quality. It also makes it easy to enclose in case you want to print with ABS. You've thrown away the rigid and easily enclosable frame design in favor of one that uses the Z axis rails as structural members. You're also cantileveling the bed on its rails and the extruder on an arm attached to the Z axis rails. What's the benefit of doing that? I predict poor stability and great difficulty leveling and zeroing the bed.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: New design for coreXY December 29, 2015 04:26PM |

Registered: 9 years ago Posts: 569 |

|

Re: New design for coreXY December 29, 2015 04:28PM |

Registered: 8 years ago Posts: 9 |

|

Re: New design for coreXY December 29, 2015 04:50PM |

Registered: 11 years ago Posts: 5,780 |

Look at the hot-end- it is at the end of a long arm with support from only one direction. That support comes from the Z axis rails and that long arm. As the extruder goes higher up the Z rails, they will bend more and more.

It isn't so obvious with the X and Y axes, but look how they are supported when the bed moves so the extruder is at one corner of the bed. The mass of the bed is hanging out in space with support coming only from the narrowly spaced bearings on their guide rails at one corner of the bed. As the mass shifts along the rails they are going to flex and the bed isn't going to move in a planar path.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

It isn't so obvious with the X and Y axes, but look how they are supported when the bed moves so the extruder is at one corner of the bed. The mass of the bed is hanging out in space with support coming only from the narrowly spaced bearings on their guide rails at one corner of the bed. As the mass shifts along the rails they are going to flex and the bed isn't going to move in a planar path.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: New design for coreXY December 30, 2015 02:54PM |

Registered: 9 years ago Posts: 569 |

Quote

the_digital_dentist

Look at the hot-end- it is at the end of a long arm with support from only one direction. That support comes from the Z axis rails and that long arm. As the extruder goes higher up the Z rails, they will bend more and more.

It isn't so obvious with the X and Y axes, but look how they are supported when the bed moves so the extruder is at one corner of the bed. The mass of the bed is hanging out in space with support coming only from the narrowly spaced bearings on their guide rails at one corner of the bed. As the mass shifts along the rails they are going to flex and the bed isn't going to move in a planar path.

That makes sense now, thank you.

|

Re: New design for coreXY January 13, 2016 05:25AM |

Registered: 8 years ago Posts: 3,525 |

Quote

Kurzaa

Sorry, I am a little slow some times, what do you mean by "cantilevered" design?

Cantilevered is "supported on one side" , it applies also to bridges which can either be supported at both ends or in the case of a lifting bridge like London's Tower Bridge the road decks on each side are cantilevered.

The only advantage of cantilevering printer axes is to make a printer small or possibly for aesthetic reasons but mechanically it's never going to be as rigid as support on both sides. So you have to decide do you want your printer to print well, or be small and look cool?

|

Re: New design for coreXY January 13, 2016 06:09AM |

Registered: 8 years ago Posts: 346 |

The use of cantilevered bed depends to size of the bed and is weight. When you have small bed (up to 30x30 cm) cantilevering bed is the best option, most of the times is the simplest solution and the cheapest. I have an cantilevering bed of 20x20cm with 12mm aluminium rods and linear bearings, the bed just work fine. With bigger beds like 30x30 you can simple use bigger rods of 14 or 16mm.

Sorry, only registered users may post in this forum.