alternative belt routing strategies

Posted by palatis

|

alternative belt routing strategies January 27, 2016 05:10PM |

Registered: 8 years ago Posts: 2 |

Hello Core-XY lovers (or haters?), I'm kinda new to the 3d printing world (bought a commercial 3d printer 9 month ago), and just recently built my own Core-XY printer (printing 430x300x400 mm^3, outer frame is around 700x500x600 mm^3, really want to print something BIG).

After it prints, I'm looking for some alternative belt routing stratigies.

I've seen

1. slightly tilt the belt (as seen on the original Core-XY reference implementation)

2. move the belt into different planes so they don't cross

3. rotate the belt (but this is more or less NOT recommended)

I think 2 is a good idea, but for me it's not an option.

I'm having 2 direct drive mk8 extruders on the X cartridge, similar to this:

[www.flashforge-usa.com]

it's nozzle tip is around 26mm to the aluminum mounting bar, and I have difficulties arrange 2 belts on different planes.

so 3 is my current option, but feels like the belt wears out a lot faster than I thought it would...

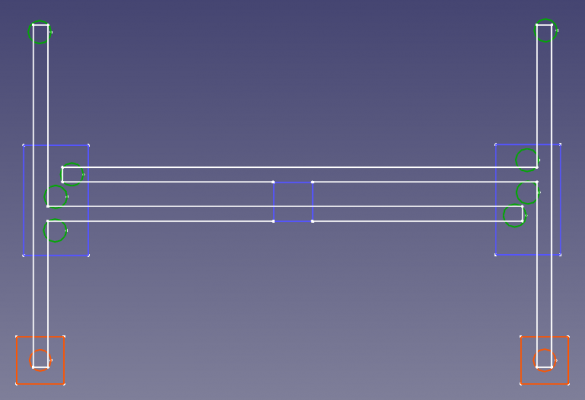

so I came up with something like this:

had anyone tried this before? would it work? the goal is:

1. the motors are stationary (yeah!)

2. the x/y motion arithmetic can be done entirely in integer step space (no fancy trigonometric or hyperbolic calculations), just like in H-gantry and Core-XY (dX = (dA + d / 2. dY = (dA - d

/ 2. dY = (dA - d / 2).

/ 2).

3. the orthogonality of X and Y axis are compensated automatically by belt tension (depends mostly on the orthogonality of the outer mounting frame), anti-racking like in Core-XY.

I'm building the frame with aluminum extrusion, and the cartridges are running on carbon steel shaft.

I'm not going to go for profiled rails, they're just too expansive and requires more maintenance.

Edited 3 time(s). Last edit at 01/27/2016 05:13PM by palatis.

After it prints, I'm looking for some alternative belt routing stratigies.

I've seen

1. slightly tilt the belt (as seen on the original Core-XY reference implementation)

2. move the belt into different planes so they don't cross

3. rotate the belt (but this is more or less NOT recommended)

I think 2 is a good idea, but for me it's not an option.

I'm having 2 direct drive mk8 extruders on the X cartridge, similar to this:

[www.flashforge-usa.com]

it's nozzle tip is around 26mm to the aluminum mounting bar, and I have difficulties arrange 2 belts on different planes.

so 3 is my current option, but feels like the belt wears out a lot faster than I thought it would...

so I came up with something like this:

had anyone tried this before? would it work? the goal is:

1. the motors are stationary (yeah!)

2. the x/y motion arithmetic can be done entirely in integer step space (no fancy trigonometric or hyperbolic calculations), just like in H-gantry and Core-XY (dX = (dA + d

/ 2. dY = (dA - d

/ 2. dY = (dA - d / 2).

/ 2).3. the orthogonality of X and Y axis are compensated automatically by belt tension (depends mostly on the orthogonality of the outer mounting frame), anti-racking like in Core-XY.

I'm building the frame with aluminum extrusion, and the cartridges are running on carbon steel shaft.

I'm not going to go for profiled rails, they're just too expansive and requires more maintenance.

Edited 3 time(s). Last edit at 01/27/2016 05:13PM by palatis.

|

Re: alternative belt routing strategies January 27, 2016 10:57PM |

Registered: 8 years ago Posts: 2 |

|

Re: alternative belt routing strategies January 28, 2016 10:00PM |

Registered: 9 years ago Posts: 83 |

You're overthinking it.

Parallel, crossing, whatever. Truth is, the belts are running at such a light load compared with what they're designed for, you might shorten the belt's life by a few months... out of 3-4 years.

By the time the belts wear down, you'll be working on a completely different printer anyway.

Parallel, crossing, whatever. Truth is, the belts are running at such a light load compared with what they're designed for, you might shorten the belt's life by a few months... out of 3-4 years.

By the time the belts wear down, you'll be working on a completely different printer anyway.

|

Re: alternative belt routing strategies March 12, 2016 01:45PM |

Registered: 8 years ago Posts: 3,525 |

Might be worth using the often white coloured steel reinforced belts. Whilst I've only been using them a short while they seem incredibly robust compared to the fibre reinforced belt gt2 belt. I'd be surprised if they didn't have a long life, they are hard to cut. At around $3-4/m they're not ridiculously expensive.

Edited 1 time(s). Last edit at 03/12/2016 01:46PM by DjDemonD.

Edited 1 time(s). Last edit at 03/12/2016 01:46PM by DjDemonD.

Sorry, only registered users may post in this forum.