Foldable, portable CoreXY (Fusebox derivative)

Posted by lkcl

|

Re: Foldable, portable CoreXY (Fusebox derivative) May 25, 2016 07:25AM |

Registered: 8 years ago Posts: 776 |

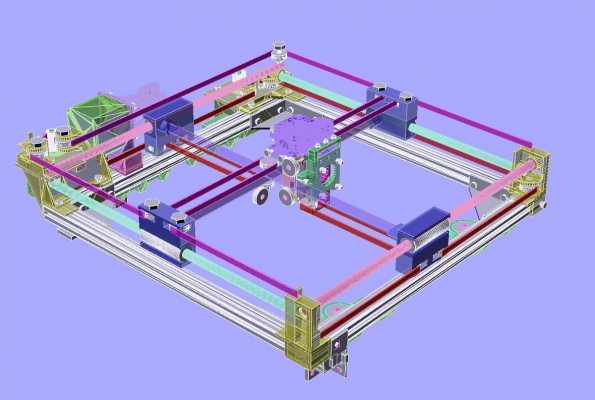

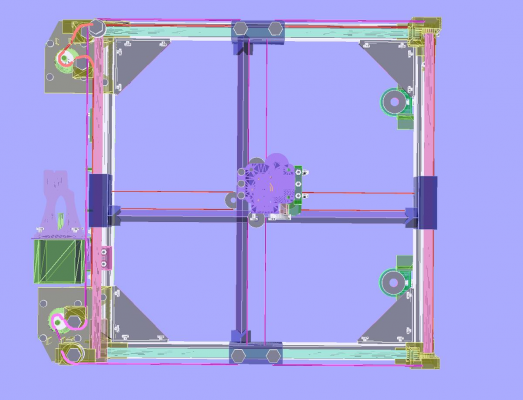

i apologise to people who prefer words and static images, i am finding it much easier to do these video walkthroughs, i will include a photo here as well. in the latest video [www.youtube.com] i am pleased and greatly relieved to be able to say with confidence that the belt lengths (sub-1500mm) are okay. one has only 25mm to spare but that is enough. if this was a larger 3d printer, even by 10mm on one side, a 3m belt simply would not be enough, it would be necessary to buy an off-the-shelf 5m length and throw away 1.7 to 1.8 metres. so it is a lucky fluke.

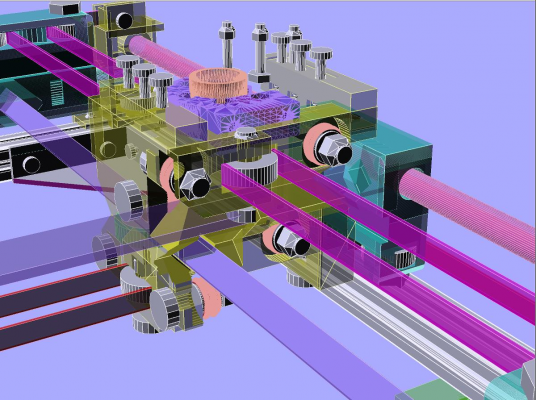

these show the top and bottom belt paths, which are separated (offset) by something like 30mm. this was unfortunately literally the only way to stay within the size and height pre-existing constraints, and it is less than ideal, but that's just how it is.

round the GT2-6-16t motor gears i've marked the path with curves. i was able today to add to the python source code a class which "collects" belt segments. i didn't add in the arcs because that's complicated maths and i haven't time to do it, so i am just using the fact that there are two full revolutions worth of "arcs" round a 16mm diameter bearing, per belt, which comes to 100mm extra per belt. the python class adds up the length of the belt segments, end-result is that those lengths come out to 1332 and 1374mm respectively: manually add 100mm to each and one belt length has literally 25mm to spare and the other has 107.

the discrepancy can be attributed to the fact that the carriage is wider than it is long, where you end up with a *four-fold* multiplication of any extensions to width or height being added/subtracted from the belt. why four-fold? because the belt is doubled-up and has to go round to attach to opposite sides. total: four times back and forth.

in other words if the carriage bearings had to be even 6.5 mm closer together on the X direction, or if the X-ends had to be as little as 6.5mm further apart, this project could have failed!

in short, i am one jammy b*s****d

Edited 2 time(s). Last edit at 05/25/2016 07:51AM by lkcl.

these show the top and bottom belt paths, which are separated (offset) by something like 30mm. this was unfortunately literally the only way to stay within the size and height pre-existing constraints, and it is less than ideal, but that's just how it is.

round the GT2-6-16t motor gears i've marked the path with curves. i was able today to add to the python source code a class which "collects" belt segments. i didn't add in the arcs because that's complicated maths and i haven't time to do it, so i am just using the fact that there are two full revolutions worth of "arcs" round a 16mm diameter bearing, per belt, which comes to 100mm extra per belt. the python class adds up the length of the belt segments, end-result is that those lengths come out to 1332 and 1374mm respectively: manually add 100mm to each and one belt length has literally 25mm to spare and the other has 107.

the discrepancy can be attributed to the fact that the carriage is wider than it is long, where you end up with a *four-fold* multiplication of any extensions to width or height being added/subtracted from the belt. why four-fold? because the belt is doubled-up and has to go round to attach to opposite sides. total: four times back and forth.

in other words if the carriage bearings had to be even 6.5 mm closer together on the X direction, or if the X-ends had to be as little as 6.5mm further apart, this project could have failed!

in short, i am one jammy b*s****d

Edited 2 time(s). Last edit at 05/25/2016 07:51AM by lkcl.

|

Re: Foldable, portable CoreXY (Fusebox derivative) May 25, 2016 02:44PM |

Registered: 9 years ago Posts: 1,035 |

That's some departure from your initial design. It's interesting to see your development going at such an alert peace ... (as opposed to my mostly digital endeavor - I am so slow with actually building anything  )

)

Now let's see the real thing...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

)

)Now let's see the real thing...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Foldable, portable CoreXY (Fusebox derivative) May 25, 2016 03:02PM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

That's some departure from your initial design.

it's not even corexy, and apart from a plotter and a few experimental 3d printers it's entirely new (or, what's old is new.... again) but belts for this layout? that's not been done before.

Quote

It's interesting to see your development going at such an alert peace ... (as opposed to my mostly digital endeavor - I am so slow with actually building anything)

Now let's see the real thing...

yeah tell me about it

no i learned the fast pace from software development with scripted programming languages. you have to iterate... *fast* and in as small increments as possible (just very very quickly). also i'm not particularly tied to one specific architecture - i am however tied to some specific *requirements* - i am quite happy to rip out anything that doesn't work, assess something new and try it.

no i learned the fast pace from software development with scripted programming languages. you have to iterate... *fast* and in as small increments as possible (just very very quickly). also i'm not particularly tied to one specific architecture - i am however tied to some specific *requirements* - i am quite happy to rip out anything that doesn't work, assess something new and try it.

|

Re: Foldable, portable CoreXY (Fusebox derivative) May 25, 2016 03:30PM |

Registered: 9 years ago Posts: 1,035 |

I have never considered to dimension the belt routing to achieve standard lengths... that's a nice tip. Am calculating it as we speak

With rods and most other stuff we can get the lengths we require but with belts I don't think to have seen vendors that cut it to length and keep the same price. I may be mistaken of course.

Edit: well, I wasn't as lucky as you ... attached...

... attached...

Edited 1 time(s). Last edit at 05/25/2016 03:43PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

With rods and most other stuff we can get the lengths we require but with belts I don't think to have seen vendors that cut it to length and keep the same price. I may be mistaken of course.

Edit: well, I wasn't as lucky as you

... attached...

... attached...Edited 1 time(s). Last edit at 05/25/2016 03:43PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Foldable, portable CoreXY (Fusebox derivative) May 25, 2016 03:54PM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

I have never considered to dimension the belt routing to achieve standard lengths... that's a nice tip. Am calculating it as we speak

With rods and most other stuff we can get the lengths we require but with belts I don't think to have seen vendors that cut it to length and keep the same price. I may be mistaken of course.

i hadn't really consciously thought about it, i know that alfa-tech3d.com supply pre-cut lengths and kits with GT2 gears already in them, but mostly i understand they cut to 1m lengths.

|

Re: Foldable, portable CoreXY (Fusebox derivative) May 25, 2016 05:14PM |

Registered: 9 years ago Posts: 1,035 |

Now that I think of it it is really stupid that they sell by standard sizes because they must have rolls of hundreds of meters and by cutting to the wildest values they end up anyways with little scrap, while the customers usually waste much more. So if the designer of the 3D printer doesn't account for that, there can be substantial loss especially if you buy the steel reinforced belt, which is expensive.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Foldable, portable CoreXY (Fusebox derivative) May 26, 2016 07:13PM |

Registered: 8 years ago Posts: 776 |

ok so i have idlers, motor holders and x-ends that i'm well... not exactly happy with but close enough. the last key part is the carriage, which i am, putting it simply, doing as a rush-job: it looks like somebody threw up on the keyboard, or a small child had a tantrum and mashed all its toy wooden blocks together with that spray-can expanding foam, BOOF. heyyy, yeah that's err... a cool modern art sculpture, but y'know if you put a 3d printer hotend in it you could use it in a sandwich200v2, did you know that? wooow, what a coincidence, that's amaaaziiing!

movers are coming tomorrow to take 14+ boxes away.

photos when i have time.

movers are coming tomorrow to take 14+ boxes away.

photos when i have time.

|

Re: Foldable, portable CoreXY (Fusebox derivative) May 27, 2016 04:22AM |

Registered: 8 years ago Posts: 776 |

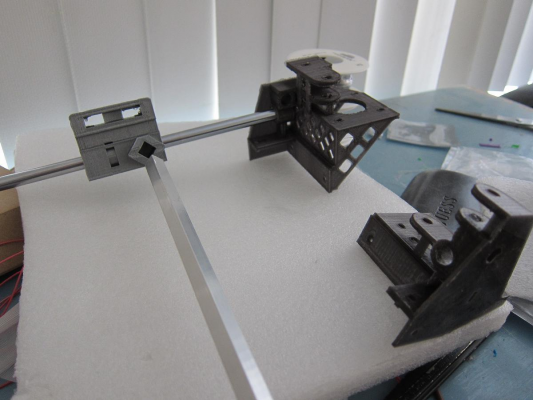

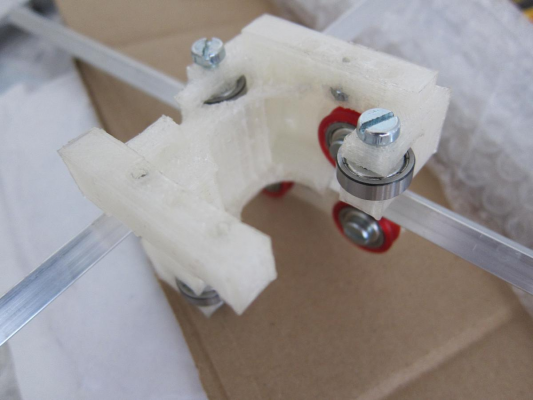

first three parts, left x-end and 2 motor holders, they're really quite high-stacked but just about fit into the box when stowed. had to put in an LM8UU not an LM8LUU into carriage ends so that the square rods have a bit more to go through and be more stable.

|

Re: Foldable, portable CoreXY (Fusebox derivative) May 27, 2016 04:31AM |

Registered: 9 years ago Posts: 1,035 |

Will you be using ALU tubes for the active XY driving linear elements?

Check this out: https://www.youtube.com/watch?v=AD1-YF7_s8g

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Check this out: https://www.youtube.com/watch?v=AD1-YF7_s8g

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Foldable, portable CoreXY (Fusebox derivative) May 27, 2016 05:01AM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

Will you be using ALU tubes for the active XY driving linear elements?

i found a company in holland, aluminium-shop.nl i think it was, which is local and they do solid 8mm aluminium bar. i will replace it with solid 8mm square carbon fibre later, but the bars are i think are 114 grams and the same in carbon fibre is like *twelve* (12).

basically i initially avoided the solid 8mm square rods because i thought they would be not as strong as solid 8mm *round* rods.... when in fact the cross-section is larger and when put at 45 degrees there is more height... doh.

yeah saw that i love the carriage holder it's very elegant, nothing like the dog's dinner i've rush-jobbed...

|

Re: Foldable, portable CoreXY (Fusebox derivative) May 27, 2016 05:17AM |

Registered: 9 years ago Posts: 1,035 |

Why not use 1515 T-slot it's lighter and stronger than solid bar... and better than square alu tube...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Foldable, portable CoreXY (Fusebox derivative) May 27, 2016 05:27AM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

Why not use 1515 T-slot it's lighter and stronger than solid bar... and better than square alu tube...

this is solid square bar not square tube i'm using.

15x15 as the name suggests would be 15mm wide and 15mm high. that would mean that when crossing one over the other there would need to be about 31 to 32mm between top and bottom extent... i would run outside of the box when stowed.

also, the further apart the centre of gravity is when pushing side-to-side and the bars are offset in height the more torquing there can be on the carriage. push on X and it torques more around the X-axis. push on Y and it torques around the Y-axis. i'm already unhappy with how far up the belts are compared to the centre of gravity, but have to go with what i have for now.

|

Re: Foldable, portable CoreXY (Fusebox derivative) May 27, 2016 05:29AM |

Registered: 9 years ago Posts: 1,035 |

Is the alu solid bar smaller in cross-section than 1515?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Foldable, portable CoreXY (Fusebox derivative) May 27, 2016 06:51AM |

Registered: 8 years ago Posts: 776 |

|

Re: Foldable, portable CoreXY (Fusebox derivative) May 29, 2016 04:57AM |

Registered: 8 years ago Posts: 776 |

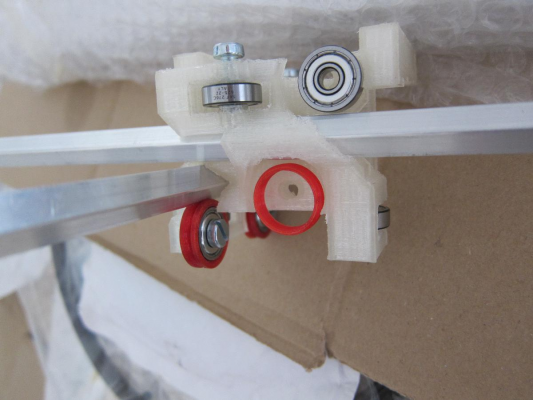

okaaaaay, here's where i am with the carriage:

aaand i'm going to have to stop work on it for a while. the reason is: 625 bearings for double-v rollers are just far too big to fit in the available space. luckily, after speaking to jason from mutley3d, because i have one of the flex3drives he designed, i now know that there exist something called MR95ZZ bearings (9mm OD, 5mm ID, 3mm width). i've tried these out in the CAD and they are *perfect*. in fact, i've been able to undo some of the horrible compromises i was going to put in:

you can see there i've put back the 3rd rail bearing on the y-axis that i had to remove due to lack of space (sort-of bright reddish round things). also, i can now put in much thicker v-rollers, the ones i made for the 625 bearings were.... well, they were pathetic to be honest. cracked at the first opportunity.

what i learned from this first carriage attempt is that the positioning of the roller bearings is critical: they *have* to be evenly spaced. distance between the 2 above and the 1 below *must* be equal. if you put them too close together you get a lever effect which can easily put enough force on the double-v rollers to split them in half. but, because of the oversized bearings i couldn't *put* them equally spaced.

with the 625 bearings they are not only too close to the outside (so can smack into the rod holders) but one on each axis is far too close to the belt bearing holders. by going to MR95ZZ bearings all those problems go away. they can be evenly spaced, i can have 3 per square rod, they can even go a bit further apart to give better stability, and many other things.

one thing you can see on those images, the belt bearing holders actually stick out by nearly 3mm from the carriage. there is a corresponding slot in each of the rod holders for this bearing to fit into! space is so stupidly tight here that i am having to do those kinds of tricks. clearances are literally 1mm in more places than i can count.

y'know... it's so silly, i only need about 1.2 metres of PC or Delrin to make the double-v rollers, they're so small

Edited 2 time(s). Last edit at 05/30/2016 02:00PM by lkcl.

aaand i'm going to have to stop work on it for a while. the reason is: 625 bearings for double-v rollers are just far too big to fit in the available space. luckily, after speaking to jason from mutley3d, because i have one of the flex3drives he designed, i now know that there exist something called MR95ZZ bearings (9mm OD, 5mm ID, 3mm width). i've tried these out in the CAD and they are *perfect*. in fact, i've been able to undo some of the horrible compromises i was going to put in:

you can see there i've put back the 3rd rail bearing on the y-axis that i had to remove due to lack of space (sort-of bright reddish round things). also, i can now put in much thicker v-rollers, the ones i made for the 625 bearings were.... well, they were pathetic to be honest. cracked at the first opportunity.

what i learned from this first carriage attempt is that the positioning of the roller bearings is critical: they *have* to be evenly spaced. distance between the 2 above and the 1 below *must* be equal. if you put them too close together you get a lever effect which can easily put enough force on the double-v rollers to split them in half. but, because of the oversized bearings i couldn't *put* them equally spaced.

with the 625 bearings they are not only too close to the outside (so can smack into the rod holders) but one on each axis is far too close to the belt bearing holders. by going to MR95ZZ bearings all those problems go away. they can be evenly spaced, i can have 3 per square rod, they can even go a bit further apart to give better stability, and many other things.

one thing you can see on those images, the belt bearing holders actually stick out by nearly 3mm from the carriage. there is a corresponding slot in each of the rod holders for this bearing to fit into! space is so stupidly tight here that i am having to do those kinds of tricks. clearances are literally 1mm in more places than i can count.

y'know... it's so silly, i only need about 1.2 metres of PC or Delrin to make the double-v rollers, they're so small

Edited 2 time(s). Last edit at 05/30/2016 02:00PM by lkcl.

|

Re: Foldable, portable CoreXY (Fusebox derivative) May 29, 2016 12:07PM |

Registered: 8 years ago Posts: 776 |

y'know.... when i started this project, i never imagined that the BOM would start off like this:

it's a 3D printer for god's sake! what the hell are materials like these doing in a 3D printer? oh wait... it's portable, i'm out of time, and it has to be packed in a hurry...

just my luck... there wasn't enough time for me to work out where to fit the 2 front lead screws. yes those are carpet-tiles. the rubber bath-mat has been cut in half, and double-sided duct-tape used to stick it to the bottom of the hardboard. the carpet tiles we happened also to have lying around, i haven't time to attach them yet but will do so once i have worked out how to firmly attach them. the nice thing is, all these wooly rubbery materials act as dampening on the hardboard.

that's a 500mm ruler on the top so you can see scale, it's a suit bag we happen to have. i hadn't time to do internal photos as i was packing it up, but i basically dropped styrofoam pieces into the bags that various 3d printer filaments arrived in, flattened them out and used them as internal padding. the pieces move so i will have to work out some time how to make them stick or just find a more suitable material later.

there is a clear need for doing a version 3 of this printer, but what i want now is an experimental design to see how far things can be pushed. can you *really* make a decent compact 3d printer which survives transit on airplanes as normal-sized stowed luggage in the hold? we'll find out - i'll do a video of when it gets unpacked at the other end, to see if i worked out where best to put the foam packaging...

- QTY1: rubber bath-mat

- QTY4: 18in carpet tiles

- QTY1: 50m duct tape

- QTY200: packing styrofoam bubbles

- QTY4: ultra-thick polythene bags

- ...

it's a 3D printer for god's sake! what the hell are materials like these doing in a 3D printer? oh wait... it's portable, i'm out of time, and it has to be packed in a hurry...

just my luck... there wasn't enough time for me to work out where to fit the 2 front lead screws. yes those are carpet-tiles. the rubber bath-mat has been cut in half, and double-sided duct-tape used to stick it to the bottom of the hardboard. the carpet tiles we happened also to have lying around, i haven't time to attach them yet but will do so once i have worked out how to firmly attach them. the nice thing is, all these wooly rubbery materials act as dampening on the hardboard.

that's a 500mm ruler on the top so you can see scale, it's a suit bag we happen to have. i hadn't time to do internal photos as i was packing it up, but i basically dropped styrofoam pieces into the bags that various 3d printer filaments arrived in, flattened them out and used them as internal padding. the pieces move so i will have to work out some time how to make them stick or just find a more suitable material later.

there is a clear need for doing a version 3 of this printer, but what i want now is an experimental design to see how far things can be pushed. can you *really* make a decent compact 3d printer which survives transit on airplanes as normal-sized stowed luggage in the hold? we'll find out - i'll do a video of when it gets unpacked at the other end, to see if i worked out where best to put the foam packaging...

|

Re: Foldable, portable CoreXY (Fusebox derivative) June 05, 2016 10:55AM |

Registered: 8 years ago Posts: 776 |

ok very limited internet access, have taken a video of the unpacking, it survived reasonably well - only 2 pieces of plastic broken. one holding the PSU which wasn't beefy enough and used 123-3d.nl's apollo series plastic (which i cannot in any way possibly recommend AT ALL - not for anything. to their credit 123-3d.nl did refund the PLA on a pro-rata basis and arranged collection) and also the corner corexy lock down onto the frame which takes a wing-nut. i have jury-rigged that corner with a 20mm OD x 5mm ID washer which actually i feel would be better anyway.

i need to redo the z-assembly bottom extrusion holders, they stick out far too much. also i think the belt must have been catching on something as it was extremely loose and needed retightening. so much to sort out.

oh, i think i worked out an offset corexy rod arrangement that could fit the removable flex3drive. bit tricky but doable. not horizontal x-rods, not vertical x-rods, but offset in *both* x *and* y.

for the plotter arrangement the 9x5x3mm bearings i was given don't look like they'll work, there is simply too little space. i am likely going to need to use 6x3x2.5mm or 6x3x2 bearings, these go into RC helicopters and RC motors so are actually very high spec and mass-produced so prices should not be completely mad.

i need to redo the z-assembly bottom extrusion holders, they stick out far too much. also i think the belt must have been catching on something as it was extremely loose and needed retightening. so much to sort out.

oh, i think i worked out an offset corexy rod arrangement that could fit the removable flex3drive. bit tricky but doable. not horizontal x-rods, not vertical x-rods, but offset in *both* x *and* y.

for the plotter arrangement the 9x5x3mm bearings i was given don't look like they'll work, there is simply too little space. i am likely going to need to use 6x3x2.5mm or 6x3x2 bearings, these go into RC helicopters and RC motors so are actually very high spec and mass-produced so prices should not be completely mad.

|

Re: Foldable, portable CoreXY (Fusebox derivative) June 10, 2016 07:22AM |

Registered: 8 years ago Posts: 776 |

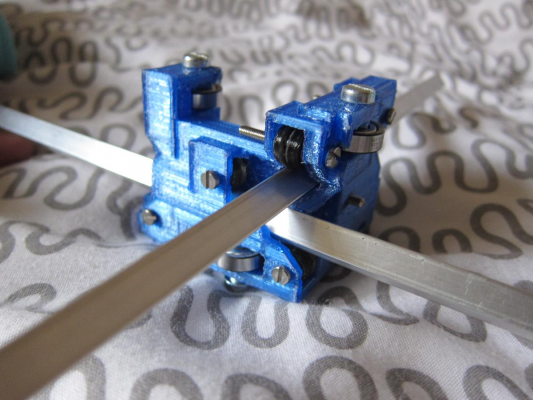

very slow internet connection here (affected by rain) video to upload of unpacking later, but here's the new plotter carriage with 6x3x2.5mm bearings and 7mm v-rollers printed from Polycarbonate. they're actually a mix of 7.0mm and 7.2mm rollers as i am still experimenting working out what size will result in there being both no play but no binding in the bearings. my feeling is that it's going to be something between 7.05 and 7.1mm which is a bit of a pain.

at the moment with mostly 7.0mm rollers and one 7.2mm roller on each the rods slide reasonably cleanly but i can definitely feel them stalling at different points as they move. this might still actually be okay but i will have to see.

still to print out is the idlers, and still to design is a fan holder. will be going to boston on the 15th and also need to print out a new arrangement for the top to fit cleanly without breaking. so much still to do.

Edited 1 time(s). Last edit at 06/10/2016 07:22AM by lkcl.

Sorry, only registered users may post in this forum.