How to set up belt tension

Posted by appjaws1

|

How to set up belt tension April 20, 2016 12:15PM |

Registered: 10 years ago Posts: 780 |

I am way on my way to completing my D-Bot variant and have just threaded the GT2 belts, attached one end of each to the X carriage and was about to attach the other ends when it dawned on me that I didn't have a clue how tight they should be and indeed how to adjust the belts after some use?

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: How to set up belt tension April 20, 2016 01:23PM |

Registered: 9 years ago Posts: 83 |

|

Re: How to set up belt tension April 21, 2016 01:14PM |

Registered: 11 years ago Posts: 1,049 |

By industry guides:

I would not use longest or shortest span.

Lock down carrige(s) while tensioning

I would not use longest or shortest span.

Lock down carrige(s) while tensioning

|

Anonymous User

Re: How to set up belt tension April 26, 2016 02:00PM |

Quote

cozmicray

By industry guides:

I would not use longest or shortest span.

Lock down carrige(s) while tensioning

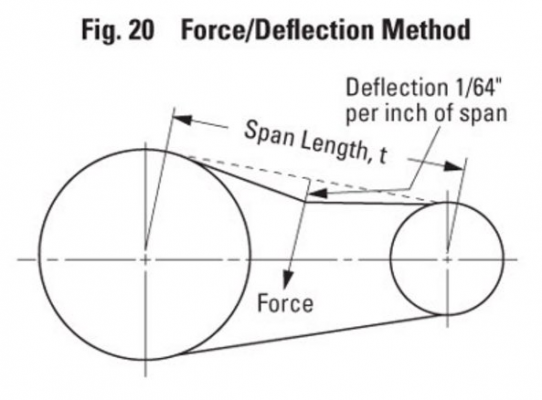

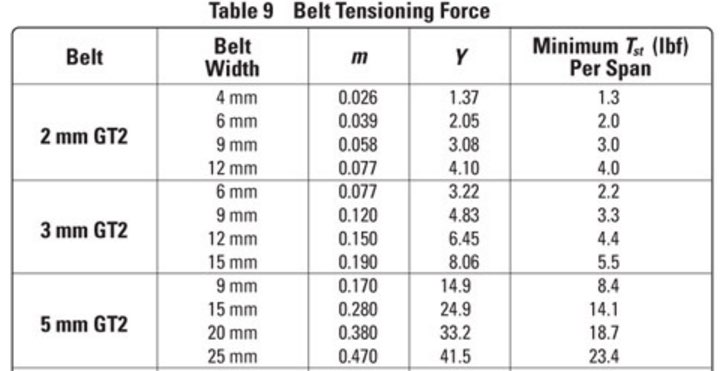

[attachment 76834 Belt_deflection.jpg]

[attachment 76835 Belt_force.jpg]

Very strange numbers. You know we are in the 21° century

Just use a portable small scale with a hook.

You attach it to an unfastened idler pulley and pull till you read the tension value then fasten it. If the two belts strand are //, a value of 26N is fine (13N per strand is good for a 6mm wide GT2). If not //, just pull in the direction that bisects the angle formed by the strands. The force you will have to reach is 26N x cosine (angle/2).

It is accurate enough.

In our case, it is more convenient than to use the deflection method and better with long belts.

Edited 4 time(s). Last edit at 04/27/2016 12:20AM by MKSA.

Sorry, only registered users may post in this forum.