What CoreXY design to choose?

Posted by Amoniak

|

What CoreXY design to choose? April 26, 2016 10:35AM |

Registered: 7 years ago Posts: 33 |

Hi,

I’m turning to this forum for some advice.

I’ve been scouting the web for I don’t know how many hours now trying to decide what 3D printer to build.

I’m a complete novice to 3D printers but I’m a tinkerer thus my plan is to source and build it myself.

Not to have a super good 3D printer up and running as soon as possible, but rather enjoying the project of building one.

The biggest hinder in this is that I have no printer, thus I cannot print any parts myself.

There is a Zyyx printer at work, but I’m not sure I’m even allowed to use it.

The CoreXY concept has caught my attention since for many reasons but one is that by it design looks to be easily enclosed.

My first idea was to build the SmartRapCore using the wood box design. This was mainly due to the fast that the printed parts sells of their site.

And wood is cheap and easily customizable.

But since they are not responding to any e-mail I’m not sure this will be the final decision.

The Fusebox, or rather the rework of it FB2020 by AxMod has caught my interest (Basically Misumi 15x15 is to hard/expensive to get in Europe, but 2020 extrusions are more easily acquired).

But here’s where I’m stuck and hope for some advice on what design to choose.

• Simple design, but upgradable.

• Low amount of printed parts needed to get up and running.

• Low budget. I’d like the “core” (meaning to get it up and running) of the printer be within 3-400 €

• Only off the shelf parts (no special CNC’d aluminum brackets or whatever)

• Build volume of ~ 200x200x200

• Heated bed

• Possibility to print ABS/PETG

• Structure that can be enclosed (Similar to the G&C Printer)

• Cubic footprint of about 40-50mm.

• I intend to print mostly functional stuff, replacements parts etc, and not so much models of Yoda or what ever

Thanks in advance for any advice and tips. Highly appreciated.

I’m turning to this forum for some advice.

I’ve been scouting the web for I don’t know how many hours now trying to decide what 3D printer to build.

I’m a complete novice to 3D printers but I’m a tinkerer thus my plan is to source and build it myself.

Not to have a super good 3D printer up and running as soon as possible, but rather enjoying the project of building one.

The biggest hinder in this is that I have no printer, thus I cannot print any parts myself.

There is a Zyyx printer at work, but I’m not sure I’m even allowed to use it.

The CoreXY concept has caught my attention since for many reasons but one is that by it design looks to be easily enclosed.

My first idea was to build the SmartRapCore using the wood box design. This was mainly due to the fast that the printed parts sells of their site.

And wood is cheap and easily customizable.

But since they are not responding to any e-mail I’m not sure this will be the final decision.

The Fusebox, or rather the rework of it FB2020 by AxMod has caught my interest (Basically Misumi 15x15 is to hard/expensive to get in Europe, but 2020 extrusions are more easily acquired).

But here’s where I’m stuck and hope for some advice on what design to choose.

• Simple design, but upgradable.

• Low amount of printed parts needed to get up and running.

• Low budget. I’d like the “core” (meaning to get it up and running) of the printer be within 3-400 €

• Only off the shelf parts (no special CNC’d aluminum brackets or whatever)

• Build volume of ~ 200x200x200

• Heated bed

• Possibility to print ABS/PETG

• Structure that can be enclosed (Similar to the G&C Printer)

• Cubic footprint of about 40-50mm.

• I intend to print mostly functional stuff, replacements parts etc, and not so much models of Yoda or what ever

Thanks in advance for any advice and tips. Highly appreciated.

|

Re: What CoreXY design to choose? April 26, 2016 11:50AM |

Registered: 8 years ago Posts: 346 |

the SmartRapCore design.

reasons:

- the wood frame provide a good rigidity, absorve some of the noise and vibrations.

- cheap: +/- 350 euros

- already semi enclosed

- easy to build

ps: for printing well with abs you need to have a full enclosure, and put all the electronics (minus motors) outside the enclosure.

Edited 1 time(s). Last edit at 04/26/2016 11:53AM by filipeCampos.

reasons:

- the wood frame provide a good rigidity, absorve some of the noise and vibrations.

- cheap: +/- 350 euros

- already semi enclosed

- easy to build

ps: for printing well with abs you need to have a full enclosure, and put all the electronics (minus motors) outside the enclosure.

Edited 1 time(s). Last edit at 04/26/2016 11:53AM by filipeCampos.

|

Re: What CoreXY design to choose? April 26, 2016 02:51PM |

Registered: 11 years ago Posts: 1,049 |

Get your mom to read you this topic

Which core XY should I build?

[forums.reprap.org]

The less you spend the crappier your prints will be

Your requirements are the "holy grail" for 3D printer

$450 USD good luck

First printer --- buy a kit or ready built machine

learn 3D printing first then building a 3D printer

Which core XY should I build?

[forums.reprap.org]

The less you spend the crappier your prints will be

Your requirements are the "holy grail" for 3D printer

$450 USD good luck

First printer --- buy a kit or ready built machine

learn 3D printing first then building a 3D printer

|

Re: What CoreXY design to choose? April 27, 2016 06:09AM |

Registered: 9 years ago Posts: 893 |

That's a bit harsh - many people would appreciate some guidance when starting in 3D printing, if only knowing which sort of printer to avoid, or which kit manufacturer ships junk and/or has poor support. Telling people to learn 3D printing before building a printer is also poor advice, as many people (including myself) have no easy access to a printer unless they build one themselves.

My advice to the OP would be to build something relatively simple and inexpensive to start with such as the SmartRapCore, or even a Prusa i3 (but get a good steel-framed kit). You won't need a heated bed initially, while you learn how things work when printing in PLA. Build experience by printing the parts for a much better printer, e.g. the G&C CoreXY design by filipeCampos (see above). You can eventually use the motors, extruder, hot-end and other parts from your first printer to reduce the cost of the second one. The only thing I'd recommend for the first printer is not to skimp on the important components such as the hot-end - spend a bit of cash and get an E3Dv6 or E3Dv6 lite, or a genuine J-head if you can find one. Also consider stretching your budget to get a good-quality control board, if you can... I spent so much money on rubbish RAMPS boards that I could have bought a 32-bit board in the first place (now I have a Duet board).

In my case, I bought a Prusa i3 kit, got some experience with it, realised that many of the components were badly made so printed some replacements (often to improved designs), used information gathered from these forums to overcome the shortcomings of the printer's design, and finally got to the point where I had a reliable and useful printer. I then used that printer to produce the plastic parts for my G&C CoreXY printer - although I didn't reuse the parts from the Prusa, as I still find that machine useful. The G&C printer is outside your budget as it uses a load of metal extrusions that aren't cheap, but it has proved to be a good step forward for me.

If you're handy with wood (actually MDF) then the SmartRapCore may well be a good starting point - there's also an active user forum on this site that can talk you through any problems. Kits containing all the plastic parts are available, and not expensive (I looked, because I nearly built one!).

HTH,

David

My advice to the OP would be to build something relatively simple and inexpensive to start with such as the SmartRapCore, or even a Prusa i3 (but get a good steel-framed kit). You won't need a heated bed initially, while you learn how things work when printing in PLA. Build experience by printing the parts for a much better printer, e.g. the G&C CoreXY design by filipeCampos (see above). You can eventually use the motors, extruder, hot-end and other parts from your first printer to reduce the cost of the second one. The only thing I'd recommend for the first printer is not to skimp on the important components such as the hot-end - spend a bit of cash and get an E3Dv6 or E3Dv6 lite, or a genuine J-head if you can find one. Also consider stretching your budget to get a good-quality control board, if you can... I spent so much money on rubbish RAMPS boards that I could have bought a 32-bit board in the first place (now I have a Duet board).

In my case, I bought a Prusa i3 kit, got some experience with it, realised that many of the components were badly made so printed some replacements (often to improved designs), used information gathered from these forums to overcome the shortcomings of the printer's design, and finally got to the point where I had a reliable and useful printer. I then used that printer to produce the plastic parts for my G&C CoreXY printer - although I didn't reuse the parts from the Prusa, as I still find that machine useful. The G&C printer is outside your budget as it uses a load of metal extrusions that aren't cheap, but it has proved to be a good step forward for me.

If you're handy with wood (actually MDF) then the SmartRapCore may well be a good starting point - there's also an active user forum on this site that can talk you through any problems. Kits containing all the plastic parts are available, and not expensive (I looked, because I nearly built one!).

HTH,

David

|

Re: What CoreXY design to choose? April 27, 2016 08:00AM |

Registered: 10 years ago Posts: 780 |

I started in total ignorance 2 years ago. I bought an ormerod 1 and over the past 2 years have spent a lot of time modifying and improving the plastic parts to give a higher print quality.

I can remember wondering what I do with a gcode or a stl file and how to set up the firmware config file whilst coming to terms with the jargon of the 3D world.. The learning went on and on and now I use openscad for designing models and exporting as stl files, simplify3d or slic3r for slicing the stl file into a gcode file and the gcode file sent to the printer to produce the item.

These forums have been invaluable to me, asking questions and overcoming problems is the way to learn. I am in the middle of building a D-Bot variant which is a coreXY type and hope to have it running in a month or so. I will be posting progress on this forum.

Well best of luck, we are all here to help.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I can remember wondering what I do with a gcode or a stl file and how to set up the firmware config file whilst coming to terms with the jargon of the 3D world.. The learning went on and on and now I use openscad for designing models and exporting as stl files, simplify3d or slic3r for slicing the stl file into a gcode file and the gcode file sent to the printer to produce the item.

These forums have been invaluable to me, asking questions and overcoming problems is the way to learn. I am in the middle of building a D-Bot variant which is a coreXY type and hope to have it running in a month or so. I will be posting progress on this forum.

Well best of luck, we are all here to help.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: What CoreXY design to choose? April 27, 2016 11:24AM |

Registered: 8 years ago Posts: 776 |

Quote

Amoniak

I’m a complete novice to 3D printers but I’m a tinkerer thus my plan is to source and build it myself.

cool - welcome.

Quote

Not to have a super good 3D printer up and running as soon as possible, but rather enjoying the project of building one.

sounds like a great goal to me

Quote

The biggest hinder in this is that I have no printer, thus I cannot print any parts myself

well, you could always ask, or use shapeways, or 3dhubs.com, or find a local makerspace - there's loads of ways to get a stack of parts printed up. or, you pick one that you like the look of - a popular design (like david suggests) - and go with that.

.

Quote

There is a Zyyx printer at work, but I’m not sure I’m even allowed to use it.

well... you won't know until you ask

Quote

My first idea was to build the SmartRapCore using the wood box design. This was mainly due to the fact that the printed parts sells on their site.

And wood is cheap and easily customizable.

i like wood - strong, easy to cut, and it's fairly obvious what you need to do to strengthen things up. there's an older guy on here who's started looking on the forums, been doing wooden structures all his life, and the experience he's had there is standing him in really good stead when it comes to evaluating printer designs.

Quote

But since they are not responding to any e-mail I’m not sure this will be the final decision.

whoops....

well, if the full design inc. 3d printed parts is online, see above

well, if the full design inc. 3d printed parts is online, see above

Quote

The Fusebox, or rather the rework of it FB2020 by AxMod has caught my interest (Basically Misumi 15x15 is to hard/expensive to get in Europe, but 2020 extrusions are more easily acquired).

they are? huh. cool. well, i just got a stack of 1m 15x15 extrusions from openbeam, and they're based in holland. cut them up in about an hour or so... done. the only thing is with the Fusebox (original design), the z-bed uses 8mm uprights and it "see-saws" around the central z-thread bar. whoops. we've been discussing ways to solve that, and yes, Ax has done a fantastic job with 2020 extrusion, and someone else is copying the idea used by the G&C printer: an L-shaped bar which the bearings are mounted to. just needs a drill with a metal bit to poke some holes - sorted. you could even use steel, sourced from down at the local ironmonger's.

Quote

But here’s where I’m stuck and hope for some advice on what design to choose.

well, david's advice is really good: please do make sure you spend that little bit extra on decent parts (a Duet 0.8.5, an E3Dv6 hotend - can i recommend going straight for the "volcano" set, and get an extra 0.4mm nozzle?) i started with the Fusebox and replaced the Misumi corner-extrusions with a wood corner-brace bracket i found on ebay, they're cheap and incredibly strong. then, also, alfa-tech3d.com has just got some 20x20 and corner-braces in, which will also be amazingly strong, again just bolt-together.

regarding printing PETG and ABS etc. in an enclosure, you might want to think about that later, after you've got happy with PLA - but prepare for it by getting a decent heated printbed. i really like the reprap.me "Alu Mk 3", but its specific heat capacity is quite high (meaning it takes a long time to heat up). that doesn't bother me as i am only doing PLA at the moment.

also can i suggest going straight for 24V? i made the mistake of going with 12V and am now converting to 24V. oh well. the Duet can handle up to 30V which is great.

yeah don't worry about cozmicray, he's a bit grumpy but is extremely knowledgeable and actually reads datasheets and technical reports on materials n stuff... *and then tells us* about it when it's relevant.

anyway, yeah - good luck, and enjoy.

|

Re: What CoreXY design to choose? April 27, 2016 01:12PM |

Registered: 9 years ago Posts: 893 |

|

Re: What CoreXY design to choose? April 27, 2016 02:09PM |

Registered: 11 years ago Posts: 5,780 |

When I built my first 3D printer there were some critical things I didn't know about that would have saved me a lot of wasted time, effort, and money. Some are things that aren't obvious, others are things that you usually only find out about after you've been struggling for a while. Here's a few to get you started:

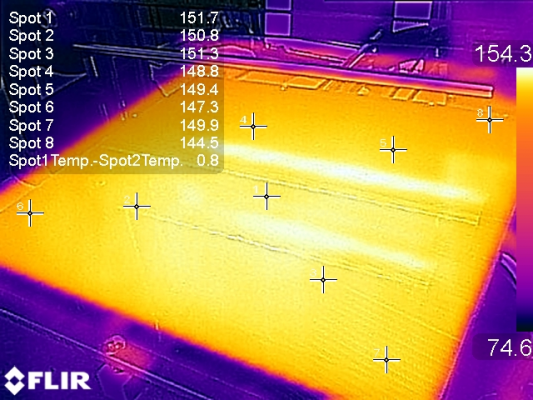

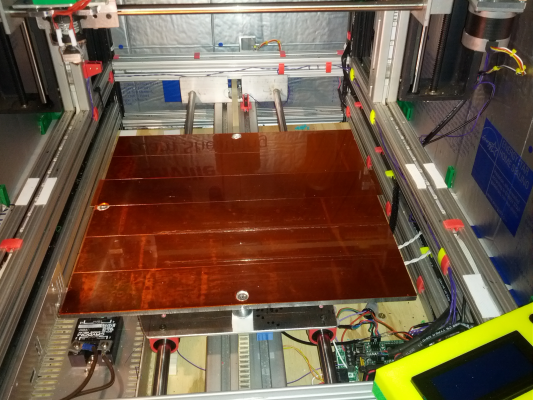

1) Printing ABS: the bed needs to get to 105C. The heaters supplied with most kits (PCB type) are under-powered (as are the power supplies) and may get to 105C only if you cover the bottom of the bed with insulation and wait what seems like forever for the bed to warm up. Look for a heater that has an areal power density of 0.4 W/cm^2 or more to ensure quick heating. The power supply needs to be able to support that high powered heater (or easier, use a line powered heater and SSR). The controller board needs to be able to switch power to that heater without blowing MOSFETs or burning up PCB traces. Once you have taken care of all that, prints will have a good chance of sticking to the bed.

Now you have another problem- keeping them from delaminating (ABS only). You need to enclose the printer and keep the enclosure at 45-50C to prevent delamination. The bed heater alone may get the build chamber up to that temperature, or you may have to add additional heat. If you intend to ever print ABS, design the printer so the electronics will be outside the heated volume of the machine. The frame of the machine should be designed to make it easy to enclose it. Box type frames are preferred for both rigidity and ease of enclosure (just add flat side panels). Enclosures can be as simple and cheap as a cardboard box or a trash bag, or a transparent plastic box.

The hot-end has to be able to operate at 245C for a long time without jamming. Make sure you get a hot-end that has a heatsink and a cooling fan, preferably an all-metal type. Avoid clones of well reputed hot-ends sold on ebay and other ultra cheap sites. They may look like them, but they generally don't perform like the originals. The E3D v6 has been very reliable for me.

2) Getting prints to stick to the bed: If the print lets go, it fails. Everyone struggles with this when they start 3D printing. There are many factors that determine whether prints will stick. You need the right temperature, a flat and level surface, and the right surface "coating".

See comments about heaters above.

There are many different ways to achieve a flat surface. I started with a heater glued directly to glass and it was awful- it wasn't flat and it had hot and cool spots because glass is a thermal insulator. Some people glue a heater to a thin aluminum "heat spreader" then put a piece of glass on top of it because the thin aluminum isn't flat enough to print on. I prefer a simple approach- use cast aluminum tooling plate. It is flat, rigid, and thermally conductive and therefore even heating. Here's an example:

Leveling the bed is best done with a 3 point system, not the typical four point system (one screw in each corner of the bed) seen on so many printers. The 4 point systems bend the bed plate and undercarriage more than they level it. 3 point systems level the bed without bending it or the undercarriage and generally require only two adjustments.

Autoleveling is becoming pretty common. That's because most printers are so poorly constructed that they can't maintain the level and zero positions from one print to the next. Build your printer with a rigid frame. Use adequately sized guide rails or better yet, linear guides, and you won't have to adjust the level and zero position before every print, and you won't need autoleveling.

You'll see a lot of posts about people using glue, hairspray, ABS juice, and all sorts of other stuff to try to get prints to stick to the bed plate. Those things are only necessary because their bed plates are not flat, level, and evenly heated. You can print ABS, PLA, and TPU on clean Kapton or PET tape with the bed heated to appropriate temperatures and prints will stick. PLA will print on unheated blue painter's tape. PEI is another supposedly miraculous bed surface covering that most common filaments will stick to.

3) Electronics: for most people an afterthought which is why you see electronics bolted on to the weirdest places on many printers. Plan the location of the electronics and the cabling for easy access for service and upgrades while you're planning everything else. If you plan to enclose the printer figure out how you're going to isolate the electronics from the warm enclosure but still have it accessible.

I recommend you skip over the cheapo 8 bit controllers and go right to 32 bit controllers. They are easier to use, more reliable, easier to wire, easier to modify, and have added features such a networking (if you have a use for it). Configuration changes are as easy as editing a text file then rebooting the controller. I have experience with and like Smoothieboard, but Duet appears to be pretty good, too.

4) Host software: don't. Many will disagree with me, but having your printer depend on a computer during long prints is a recipe for disaster. Computers, and in particular USB interfaces, are very unreliable, especially if your computer runs Windows. Get an LCD panel with an SD card reader and print via SD cards. I don't know if there is anything you can do to improve the reliability of your printer as much as getting rid of the computer. Many will say you need to run host software so you can tweak the print on-th-fly. I think that if you have to tweak the print on-the-fly, you aren't using the slicer software right.

You can see some of the other things I did in my printer by clicking the link in my sig, below.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

1) Printing ABS: the bed needs to get to 105C. The heaters supplied with most kits (PCB type) are under-powered (as are the power supplies) and may get to 105C only if you cover the bottom of the bed with insulation and wait what seems like forever for the bed to warm up. Look for a heater that has an areal power density of 0.4 W/cm^2 or more to ensure quick heating. The power supply needs to be able to support that high powered heater (or easier, use a line powered heater and SSR). The controller board needs to be able to switch power to that heater without blowing MOSFETs or burning up PCB traces. Once you have taken care of all that, prints will have a good chance of sticking to the bed.

Now you have another problem- keeping them from delaminating (ABS only). You need to enclose the printer and keep the enclosure at 45-50C to prevent delamination. The bed heater alone may get the build chamber up to that temperature, or you may have to add additional heat. If you intend to ever print ABS, design the printer so the electronics will be outside the heated volume of the machine. The frame of the machine should be designed to make it easy to enclose it. Box type frames are preferred for both rigidity and ease of enclosure (just add flat side panels). Enclosures can be as simple and cheap as a cardboard box or a trash bag, or a transparent plastic box.

The hot-end has to be able to operate at 245C for a long time without jamming. Make sure you get a hot-end that has a heatsink and a cooling fan, preferably an all-metal type. Avoid clones of well reputed hot-ends sold on ebay and other ultra cheap sites. They may look like them, but they generally don't perform like the originals. The E3D v6 has been very reliable for me.

2) Getting prints to stick to the bed: If the print lets go, it fails. Everyone struggles with this when they start 3D printing. There are many factors that determine whether prints will stick. You need the right temperature, a flat and level surface, and the right surface "coating".

See comments about heaters above.

There are many different ways to achieve a flat surface. I started with a heater glued directly to glass and it was awful- it wasn't flat and it had hot and cool spots because glass is a thermal insulator. Some people glue a heater to a thin aluminum "heat spreader" then put a piece of glass on top of it because the thin aluminum isn't flat enough to print on. I prefer a simple approach- use cast aluminum tooling plate. It is flat, rigid, and thermally conductive and therefore even heating. Here's an example:

Leveling the bed is best done with a 3 point system, not the typical four point system (one screw in each corner of the bed) seen on so many printers. The 4 point systems bend the bed plate and undercarriage more than they level it. 3 point systems level the bed without bending it or the undercarriage and generally require only two adjustments.

Autoleveling is becoming pretty common. That's because most printers are so poorly constructed that they can't maintain the level and zero positions from one print to the next. Build your printer with a rigid frame. Use adequately sized guide rails or better yet, linear guides, and you won't have to adjust the level and zero position before every print, and you won't need autoleveling.

You'll see a lot of posts about people using glue, hairspray, ABS juice, and all sorts of other stuff to try to get prints to stick to the bed plate. Those things are only necessary because their bed plates are not flat, level, and evenly heated. You can print ABS, PLA, and TPU on clean Kapton or PET tape with the bed heated to appropriate temperatures and prints will stick. PLA will print on unheated blue painter's tape. PEI is another supposedly miraculous bed surface covering that most common filaments will stick to.

3) Electronics: for most people an afterthought which is why you see electronics bolted on to the weirdest places on many printers. Plan the location of the electronics and the cabling for easy access for service and upgrades while you're planning everything else. If you plan to enclose the printer figure out how you're going to isolate the electronics from the warm enclosure but still have it accessible.

I recommend you skip over the cheapo 8 bit controllers and go right to 32 bit controllers. They are easier to use, more reliable, easier to wire, easier to modify, and have added features such a networking (if you have a use for it). Configuration changes are as easy as editing a text file then rebooting the controller. I have experience with and like Smoothieboard, but Duet appears to be pretty good, too.

4) Host software: don't. Many will disagree with me, but having your printer depend on a computer during long prints is a recipe for disaster. Computers, and in particular USB interfaces, are very unreliable, especially if your computer runs Windows. Get an LCD panel with an SD card reader and print via SD cards. I don't know if there is anything you can do to improve the reliability of your printer as much as getting rid of the computer. Many will say you need to run host software so you can tweak the print on-th-fly. I think that if you have to tweak the print on-the-fly, you aren't using the slicer software right.

You can see some of the other things I did in my printer by clicking the link in my sig, below.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: What CoreXY design to choose? April 27, 2016 04:10PM |

Registered: 9 years ago Posts: 83 |

If you're starting out, I'd get the SmartCore aluminum kit. It's a kit, which is good-- it's not a terrible coreXY implementation, and you'll learn a great deal by building one someone else designed.

[smartfriendz.com]

Definitely add the LCD panel if you buy the kit version.

Then once you've got it up and running, and tuned, you can either upgrade parts of this one, or use it to print parts for a new printer.

Either way, understanding how someone else did it first is better than trying to design your own from the start.

[smartfriendz.com]

Definitely add the LCD panel if you buy the kit version.

Then once you've got it up and running, and tuned, you can either upgrade parts of this one, or use it to print parts for a new printer.

Either way, understanding how someone else did it first is better than trying to design your own from the start.

|

Re: What CoreXY design to choose? April 27, 2016 10:07PM |

Registered: 11 years ago Posts: 1,049 |

Great advise BUT for 300-400euro

and

a first printer

Aluminum tool plate for the pro

but glass good enough for starter

After 5 years of 3D printing --- building 3D printer

minimize frustration --- pay more --- don't get a dust collector, closet king

Buy a printer from someone who has moved on to a better machine

discover the fun, frustration, science, art and magic in 3Dprinting

better experience, knowledge and temperament to get into a build

and

a first printer

Aluminum tool plate for the pro

but glass good enough for starter

After 5 years of 3D printing --- building 3D printer

minimize frustration --- pay more --- don't get a dust collector, closet king

Buy a printer from someone who has moved on to a better machine

discover the fun, frustration, science, art and magic in 3Dprinting

better experience, knowledge and temperament to get into a build

Quote

the_digital_dentist

When I built my first 3D printer there were some critical things I didn't know about that would have saved me a lot of wasted time, effort, and money. Some are things that aren't obvious, others are things that you usually only find out about after you've been struggling for a while. Here's a few to get you started:

You can see some of the other things I did in my printer by clicking the link in my sig, below.

|

Re: What CoreXY design to choose? April 27, 2016 11:16PM |

Registered: 11 years ago Posts: 5,780 |

Why should someone have to struggle with getting prints to stick to the bed when the solution to the problem is known and will cost less to do right the first time than to start by doing it wrong and spending additional time and money trying to fix it?

Learning from others so you can avoid costly mistakes is the whole point of forums like this.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Learning from others so you can avoid costly mistakes is the whole point of forums like this.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: What CoreXY design to choose? April 28, 2016 06:50AM |

Registered: 7 years ago Posts: 33 |

Thanks to everyone who spent time responding to my thread, really appreciate it!

There’s definitely good advice in here!

And Dave J, I could kill for your printer in the pictures! Pure awesomeness

I know my specs may be in the Ferrari range when my budget is for a fiat.

And as a quality engineer I certainly know quality costs…

But with the funds, time and not to mention space and tools I have available it’s just not possible….

My hopes is to find a middle ground, where the “back bones” are good enough to upgrade as I progress in learning to get decent prints.

I the end I want a project were I can learn 3D printers and printing trying not to fall into too many obvious pits, like choosing a bad design to begin with or cheaping out on replica hot ends etc etc.

Maybe sounds stupid, but making bad decisions is ok, if you know you’re making them.

Let’s say I choose the SmartRapCore, would building it in a MDF box be a terrible idea compare to alu extrusions?

What would be the affordable option to a 8-bit RAMPS system for such a printer? How would it work with the firmware?

With RAMPS there preconfigured marlin for the smartrapcore.

Thanks in advance.

There’s definitely good advice in here!

And Dave J, I could kill for your printer in the pictures! Pure awesomeness

I know my specs may be in the Ferrari range when my budget is for a fiat.

And as a quality engineer I certainly know quality costs…

But with the funds, time and not to mention space and tools I have available it’s just not possible….

My hopes is to find a middle ground, where the “back bones” are good enough to upgrade as I progress in learning to get decent prints.

I the end I want a project were I can learn 3D printers and printing trying not to fall into too many obvious pits, like choosing a bad design to begin with or cheaping out on replica hot ends etc etc.

Maybe sounds stupid, but making bad decisions is ok, if you know you’re making them.

Let’s say I choose the SmartRapCore, would building it in a MDF box be a terrible idea compare to alu extrusions?

What would be the affordable option to a 8-bit RAMPS system for such a printer? How would it work with the firmware?

With RAMPS there preconfigured marlin for the smartrapcore.

Thanks in advance.

|

Re: What CoreXY design to choose? April 28, 2016 07:34AM |

Registered: 8 years ago Posts: 12 |

So many replies, ranging from cozmicray's :"@#$%&! NOOB, don't even think about building 3d printer unless you have PhD in 3d printing", to the_digital_dentist: "You need about €3000 euro's to build a printer".

I have started to build Ax FB2020 with few modifications. It will have bed like filipe's G&C (thick 12mm rods/10mm leadscrew & no printed parts), and i will make it a little bit taller (all electronics will go down because i want to enlose it).

If you look at FB2020 printed parts, you only need 4 parts to get printer running: 1_Carriage.stl, 1_Carriage_clamp.stl, 1_Carrier_Left.stl & 1_Carrier_right.stl.

Motor holders, idler holders can be easily made from aluminium plates (really cheap at motedis), and they will also make frame stronger.

My current BOM is around €350 (shipping included), and that is with genuine e3d lite6, one extra stepper (5pcs pack was cheaper then 4 seperate motors ), motedis leadscrew/nut, 20A PSU...

), motedis leadscrew/nut, 20A PSU...

IMO buying kit is stupid, especially for printer that is based on standard alu profiles.

If you look at that SmartrapCore Alu basic kit (€325 shipped with LCD controller), you are getting underpowered PSU (10A), hotend that looks like $5 e3d clone, unknow steppers...

I have started to build Ax FB2020 with few modifications. It will have bed like filipe's G&C (thick 12mm rods/10mm leadscrew & no printed parts), and i will make it a little bit taller (all electronics will go down because i want to enlose it).

If you look at FB2020 printed parts, you only need 4 parts to get printer running: 1_Carriage.stl, 1_Carriage_clamp.stl, 1_Carrier_Left.stl & 1_Carrier_right.stl.

Motor holders, idler holders can be easily made from aluminium plates (really cheap at motedis), and they will also make frame stronger.

My current BOM is around €350 (shipping included), and that is with genuine e3d lite6, one extra stepper (5pcs pack was cheaper then 4 seperate motors

), motedis leadscrew/nut, 20A PSU...

), motedis leadscrew/nut, 20A PSU...IMO buying kit is stupid, especially for printer that is based on standard alu profiles.

If you look at that SmartrapCore Alu basic kit (€325 shipped with LCD controller), you are getting underpowered PSU (10A), hotend that looks like $5 e3d clone, unknow steppers...

|

Re: What CoreXY design to choose? April 28, 2016 09:01AM |

Registered: 8 years ago Posts: 776 |

Quote

ivo95

So many replies, ranging from cozmicray's :"@#$%&! NOOB, don't even think about building 3d printer unless you have PhD in 3d printing", to the_digital_dentist: "You need about €3000 euro's to build a printer".

well it's true! you've sucked all your life into 3d printing, maaan

basically we're all saying the same thing, just in different ways, with different levels of grumpiness: don't skimp on parts, you'll regret it.

basically we're all saying the same thing, just in different ways, with different levels of grumpiness: don't skimp on parts, you'll regret it.Quote

I have started to build Ax FB2020 with few modifications.

oo, i found a company in europe for you that does 20x20 extrusion: motedis.com - someone else mentioned they're buying from there, thought you'd appreciate knowing about it. use the 20x40 corner brackets, pleaaase, especially in the four corners of the top corexy [www.motedis.com]

please don't underestimate how important these are. you could get away with using diagonal cross-bracing instead (in all 5 other faces) but the top corexy, you can't put a diagonal brace across that (duh) so pleaaase, for goodness sake, if you want a decent printer get at least four those 40x40 corner brackets, you'll be amazed at how stiff the frame becomes.

Quote

IMO buying kit is stupid, especially for printer that is based on standard alu profiles.

If you look at that SmartrapCore Alu basic kit (€325 shipped with LCD controller), you are getting underpowered PSU (10A), hotend that looks like $5 e3d clone, unknow steppers...

yaay, someone who clearly has a brain on top of their shoulders and has done some research, yay!

see you on the Fusebox forum with build pictures? best place, i feel, if you've picked a Fusebox derivative. [edit: wait.... ivo95... i recognise that handle.... you're already on there haha, sorry, i thought you were the OP

]

]Edited 1 time(s). Last edit at 04/28/2016 09:02AM by lkcl.

|

Re: What CoreXY design to choose? April 28, 2016 09:10AM |

Registered: 7 years ago Posts: 33 |

Regarding kits, yes that’s the reason I don’t want to buy them. You’re not in control of what components you get. If I already know the hotend and PSU is rubbish straight of the box then it’s not so cheap anymore…

You got me intrigued regarding the FB2020 build, I’ve looked it several times but came to the conclusion that I would blow past 400Euro easily just to get it up and running if you’re not printing all those parts. Just a basic frame with it’s components from motedis would be around 100€ (inc shipping) when I quickly checked.

Not sure how you could substitute the motor and idler holder with aluminum plates without access to machinery (Drill press etc). I if I would have had access to that kind of tools it would be a different story.

This 350€ BOM you have, is it something you could share?

You got me intrigued regarding the FB2020 build, I’ve looked it several times but came to the conclusion that I would blow past 400Euro easily just to get it up and running if you’re not printing all those parts. Just a basic frame with it’s components from motedis would be around 100€ (inc shipping) when I quickly checked.

Not sure how you could substitute the motor and idler holder with aluminum plates without access to machinery (Drill press etc). I if I would have had access to that kind of tools it would be a different story.

This 350€ BOM you have, is it something you could share?

|

Re: What CoreXY design to choose? April 28, 2016 09:12AM |

Registered: 8 years ago Posts: 776 |

Quote

Amoniak

Let’s say I choose the SmartRapCore, would building it in a MDF box be a terrible idea compare to alu extrusions?

i don't see why not. if you run it a bit quick, you'll get vibrations running through the MDF, but that's easily dampened with the right creative mindset. alu extrusion is used i think because you can get a good all-round view, and assembly is a leetle easier because you've got access. but, that's solved by cutting out holes (not too big!) from the middle of the MDF.... bad idea if you want an enclosed box though

but, before making that decision, take a look at motedis.com, evaluate the cost of their extrusions, is it really that much extra?

Quote

What would be the affordable option to a 8-bit RAMPS system for such a printer?

DON'T get a kit that has separate steppers on tiny boards, for goodness sake. i don't know why people think that RAMPS and their ilke are good. i explained why, with lots of emphasis, to davedavedave, here: [forums.reprap.org]

i've got a Rumba v1.2g that you can have if you get stuck finding something, and are happy to pay postage and maaybe a little bit extra (like $EUR 10 or something. i live in Den Haag). caveat: i had to create a separate set of circuits (voltage dividers) because there's a component flaw in the v1.2g where the protection diodes are at the wrong voltage. it's a heath robinson job, but it works well. there's no voltage protection diodes though, so just bear that in mind and take a lot of care.

Quote

How would it work with the firmware?

With RAMPS there preconfigured marlin for the smartrapcore.

if you get a duet 0.8.5 you use dc42's excellent firmware, i've got a configuration set for that which works well with my corexy design, i can point you at. marlin is extremely well-documented, there's plenty of stuff online, and there's always people around who can walk you through it in the right sub-forum.

Edited 1 time(s). Last edit at 04/28/2016 09:19AM by lkcl.

-- sandwich200: compact portable folding corexy printer [reprap.org]

|

Re: What CoreXY design to choose? April 28, 2016 11:18AM |

Registered: 7 years ago Posts: 33 |

Quote

lkcl

Quote

Amoniak

Let’s say I choose the SmartRapCore, would building it in a MDF box be a terrible idea compare to alu extrusions?

i don't see why not. if you run it a bit quick, you'll get vibrations running through the MDF, but that's easily dampened with the right creative mindset. alu extrusion is used i think because you can get a good all-round view, and assembly is a leetle easier because you've got access. but, that's solved by cutting out holes (not too big!) from the middle of the MDF.... bad idea if you want an enclosed box though

but, before making that decision, take a look at motedis.com, evaluate the cost of their extrusions, is it really that much extra?

Quote

What would be the affordable option to a 8-bit RAMPS system for such a printer?

DON'T get a kit that has separate steppers on tiny boards, for goodness sake. i don't know why people think that RAMPS and their ilke are good. i explained why, with lots of emphasis, to davedavedave, here: [forums.reprap.org]

MDF vs Alu, yes quite big price difference.

My rough calculations:

MDF frame ~40EUR (including material, screws, glue etc all found localy)

Alu from Motedis is ~100EUR including shipping (shipping alone is 32EUR...)

Now my thinking was that maybe it's better to spend that 60EUR on something that would affect printing quality more, like a genuine hotend... I dono maybe I'm just an idiot

Would a RAMBO controller board be an option? or are the Asian eBay (presumably clones) just as much crap as the RAMPS?

|

Re: What CoreXY design to choose? April 28, 2016 11:34AM |

Registered: 11 years ago Posts: 5,780 |

I suppose you're right. Why spend $40 on a cast bed plate that's flat, rigid, heats evenly, and prints stick, when you can spend $30 on a thin, flexible piece of aluminum and a piece of glass to try to flatten it? You saved $10! So what if you're going to be messing around for many hours over the life of the printer, trying to get prints to stick. Life is long, you have nothing better to do, and that $10 you saved is worth at least a couple cups of coffee you can sip while you're struggling with your 3D printer.

And why plan for eventualities like enclosing the machine? Planning is too much work. It's much less trouble to just rewire the whole machine later when you decide to enclose the machine. Besides, you may not like 3D printing enough to bother with enclosing the machine later.

Maybe the struggle to get prints to stick to the bed and all the other problems you're going to have to solve will convince you that 3D printing isn't for you and you'll be glad you didn't waste more than $300 on the machine.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

And why plan for eventualities like enclosing the machine? Planning is too much work. It's much less trouble to just rewire the whole machine later when you decide to enclose the machine. Besides, you may not like 3D printing enough to bother with enclosing the machine later.

Maybe the struggle to get prints to stick to the bed and all the other problems you're going to have to solve will convince you that 3D printing isn't for you and you'll be glad you didn't waste more than $300 on the machine.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: What CoreXY design to choose? April 28, 2016 12:28PM |

Registered: 9 years ago Posts: 83 |

Quote

the_digital_dentist

I suppose you're right. Why spend $40 on a cast bed plate that's flat, rigid, heats evenly, and prints stick, when you can spend $30 on a thin, flexible piece of aluminum and a piece of glass to try to flatten it? You saved $10! So what if you're going to be messing around for many hours over the life of the printer, trying to get prints to stick. Life is long, you have nothing better to do, and that $10 you saved is worth at least a couple cups of coffee you can sip while you're struggling with your 3D printer.

While my next printer will almost certainly have a cast bed + PEI (or possibly printbite) print surface, there's absolutely no reason you can't get a print to stick to a borosilicate plate + heat-bed, if your bed is level and your hot end runs parallel to the bed. A little bit of glue stick will even compensate for some uneveness there, too, but there's no reason you can't get a decently calibrated printer to print PLA straight to glass.

Quote

And why plan for eventualities like enclosing the machine? Planning is too much work. It's much less trouble to just rewire the whole machine later when you decide to enclose the machine. Besides, you may not like 3D printing enough to bother with enclosing the machine later.

Maybe the struggle to get prints to stick to the bed and all the other problems you're going to have to solve will convince you that 3D printing isn't for you and you'll be glad you didn't waste more than $300 on the machine.

Probably because enclosing the print volume in any useful form requires advanced planning, which I wouldn't expect a 3D printing novice to have-- Not to mention which, you can print PLA and PETG all day long without an enclosed printer-- but, if you like the smell of ABS in the morning, I suppose that's OK too.

I agree that building too cheap a printer (sub $500, you're asking for trouble) is a bad idea and likely to leave a bad taste for 3D printing (one reason why I despise the chinese cheapo deltas with the shower door rollers), but expecting a novice to lay out a couple grand for a well-built "perfect" printer (according to you) is also a bit excessive.

Yeah, the smartrapcore is a cheap printer-- the power supply is wimpy, the electronics are crap, and the motors are questionable. On the other hand, it's pretty easy to upgrade, it's a full kit that won't require you to make accurate 90 degree cuts through aluminum extrusions and tapping threads (not difficult per se, but may require tools / experience the average novice doesn't have).

Oh, and from all accounts, the MDF based smartcores are incredibly noisy. Something to do with the entire box vibrating.

As for stepper boards, there's no reason to not use them-- but go with A4988 or THB6128 based ones. Avoid the DRV8825, because chances are, they won't work with your stepper drivers (Find Ryan Carlyle's stepper sim spreadsheet to find out why). If you blow one up (another novice trick) by yanking your stepper motor plug while the system's powered, you don't have to replace the entire controller, just that particular driver.

I don't like RAMPS because it's turned into a race-to-the-bottom, and most of them will melt if you have an LCD and a heated bed. Due+RADDS is pretty solid, and the Duet setup is good as well. Due+RADDS is also a good upgrade path from RAMPS, since Repetier firmware will run on both.

|

Re: What CoreXY design to choose? April 28, 2016 12:28PM |

Registered: 7 years ago Posts: 33 |

Quote

the_digital_dentist

I suppose you're right. Why spend $40 on a cast bed plate that's flat, rigid, heats evenly, and prints stick, when you can spend $30 on a thin, flexible piece of aluminum and a piece of glass to try to flatten it? You saved $10! So what if you're going to be messing around for many hours over the life of the printer, trying to get prints to stick. Life is long, you have nothing better to do, and that $10 you saved is worth at least a couple cups of coffee you can sip while you're struggling with your 3D printer.

And why plan for eventualities like enclosing the machine? Planning is too much work. It's much less trouble to just rewire the whole machine later when you decide to enclose the machine. Besides, you may not like 3D printing enough to bother with enclosing the machine later.

Maybe the struggle to get prints to stick to the bed and all the other problems you're going to have to solve will convince you that 3D printing isn't for you and you'll be glad you didn't waste more than $300 on the machine.

We'll I understand that my novice and probably stupid comments and questions is probably borderline insulting to you guys with years of experience with most likely multiple builds in your repertoire.

For every choice there's a better more expensive alternative... and the increase in price as far as I've found is not in 10 bucks increments, it's more in double the price.

Why build a 3D printer when the company in the same house sells their Arcam A2X metal 3D printer for just around $ 250,000??

What I'm here trying to understand and learn is were to best put the eggs, given the budget is limited.

|

Re: What CoreXY design to choose? April 28, 2016 12:33PM |

Registered: 8 years ago Posts: 346 |

Amoniak created this tread to have some help about selecting a good printer and not more of 400€. I still think for the money the SmartRapCore is the best option. Is clear to build a good printed you can not go cheap on some parts of the printer. I have the same opinion of the_digital_dentist, in the 3d printing word going cheap most of the time will cost more in the long run.

I my point of view you have the next options:

1- buy/build a cheap 300€ printer. You have a good probability to get problems and wast lots of time to solve it. but you learn in the process. Most of this cheap printers will print just fine most of the time, but not with a fine quality, speed and reliability. Some of this printers can be really difficult to put/setup correctly and most of the person will build a better one or simply quit.

2- build a medium printer: 500 to 800 €. you will have less problem, a lot easy to get god result.If you do not like 3d printing, then you can sell it and pretty sure you will recover almost the cost of the hardware.

3- build a printer a la "the_digital_dentist". it will be 1000€ or more: But, if you build correctly you get a top end printer. This type of printers are expensive in the market, if you do not like 3d printing, simply sell it and in the process you will probably gain money.

If you want a good 3d printer, wait a little more to have more money and chose a better design. but if you like building thing, them there is nothing wrong to go with a cheap printer, is the best option to learn. You need to try with the bad hardware to understand the difference between the god and bad. Myself i have chose the first path, build a prusa i3, now i have the "medium" printer (g&c), next will be something the_digital_dentist approves..

this thread was already lot of line of text but not mutch that help Amoniak..

So.. for 400€ or less someone think there are a better of the SmartRapCore? if so, why?

Edited 3 time(s). Last edit at 04/28/2016 12:45PM by filipeCampos.

I my point of view you have the next options:

1- buy/build a cheap 300€ printer. You have a good probability to get problems and wast lots of time to solve it. but you learn in the process. Most of this cheap printers will print just fine most of the time, but not with a fine quality, speed and reliability. Some of this printers can be really difficult to put/setup correctly and most of the person will build a better one or simply quit.

2- build a medium printer: 500 to 800 €. you will have less problem, a lot easy to get god result.If you do not like 3d printing, then you can sell it and pretty sure you will recover almost the cost of the hardware.

3- build a printer a la "the_digital_dentist". it will be 1000€ or more: But, if you build correctly you get a top end printer. This type of printers are expensive in the market, if you do not like 3d printing, simply sell it and in the process you will probably gain money.

If you want a good 3d printer, wait a little more to have more money and chose a better design. but if you like building thing, them there is nothing wrong to go with a cheap printer, is the best option to learn. You need to try with the bad hardware to understand the difference between the god and bad. Myself i have chose the first path, build a prusa i3, now i have the "medium" printer (g&c), next will be something the_digital_dentist approves..

this thread was already lot of line of text but not mutch that help Amoniak..

So.. for 400€ or less someone think there are a better of the SmartRapCore? if so, why?

Edited 3 time(s). Last edit at 04/28/2016 12:45PM by filipeCampos.

|

Re: What CoreXY design to choose? April 28, 2016 01:43PM |

Registered: 9 years ago Posts: 893 |

When I said a 'kit' for the SmartRapCore - I meant a kit of the plastic parts. These are the bits you can't make for yourself, or just buy off the shelf. These kits of plastic parts are reasonably cheap, e.g. smartfriendz. All the rest can be bought here and there, as needed. So - a bag of plastic parts, 5 MDF panels that you can make yourself from stuff bought from your local DIY store, 4 stepper motors, a control board, power supply, wire, a few bits and pieces and a hot end of your choice. Add a heap of skills that you may have already, or are willing to pick up as you go along, and you're away.

A basic printer like this will help a beginner get over those problems that beset just about every novice (check out the help requests in these forums almost every day):

It's also worth remembering that the next wonderful printer can use many of the major components from this first printer.

Edited 1 time(s). Last edit at 04/28/2016 01:48PM by David J.

A basic printer like this will help a beginner get over those problems that beset just about every novice (check out the help requests in these forums almost every day):

- Communicating with the computer.

- Getting the various motors to work properly.

- Working out how to stop the filament from jamming up the hot end, or tangling in the extruder.

- Getting the print to stick on the build surface.

- Probably most important: deciding whether 3D printing is really as interesting as people make out.

It's also worth remembering that the next wonderful printer can use many of the major components from this first printer.

Edited 1 time(s). Last edit at 04/28/2016 01:48PM by David J.

|

Re: What CoreXY design to choose? April 28, 2016 01:44PM |

Registered: 8 years ago Posts: 12 |

Quote

filipeCampos

this thread was already lot of line of text but not mutch that help Amoniak..

So.. for 400€ or less someone think there are a better of the SmartRapCore? if so, why?

Yes, for example your printer, it has much better parts, design from that SmartRapCore kit

Your basic BOM is 467€, but you really overspent on some parts:

21.42€ on 100 t-nuts - $5 on aliexpress

almost 65+€ on brackets, inner brackets, connector plates... - i don't think that you need so many of them with some tapping/drilling.

Edited 1 time(s). Last edit at 04/28/2016 06:42PM by ivo95.

|

Re: What CoreXY design to choose? April 28, 2016 05:12PM |

Registered: 8 years ago Posts: 622 |

@ Amoniak,

Don't be put off by some of the comments you've received. It's the same with any hobby, there will always be those who say you need to spend at least 10 times what you had budgeted and anything less will be a complete waste of time and money. If you are into photography, you can take great pictures with a £250 Canon EOS 1200 D camera or you can spend $50,000 on a Leica M9 P Hermes edition. You can get very reasonably sounding Hi-Fi for £ a few hundred or you can spend tens of thousands on just a pair of speakers.

I only got into 3d printing about a year ago (I'm a 60 something carpenter). I built a RepRapPro (no longer in business) Mendel 3 from a kit. It's just a bunch of 3d printed parts and lots of threaded rod for the frame. It looks bloody awful but I'm amazed at the accuracy and quality of the printed parts it can produce. Also, the reliability has been excellent. The heated bed consists of a piece of 3mm thick mdf as an insulator, then the pcb heater with a 1.5mm thick sheet of aluminium as a heat spreader and then 3mm thick glass which I cover with Kapton tape. I don't have any problem with things sticking to the bed, in fact getting them off the bed is the problem, usually resolved with a small chisel and a tap with a hammer. Is the mdf flat? No. Is the aluminium flat? No. Does it matter? No. Why? Because the glass is flat and the bed is level and I have the z axis homing set correctly. I have 3 pieces of prepared glass so as soon as one print is finished, I simply replace the glass give a quick wipe over with acetone, and start printing again, without waiting for the bed to cool. So cheap does not always mean inferior.

It doesn't really matter what printer you start with although it's generally noted that beginners should avoid delta designs for their first printer. Other than that, the basic requirements are that the the x, y and z axes run smoothly, parallel and at right angles to each other. That generally means you need to use some sort of metal guides and a support structure to hold it all together.

I note from your OP that you describe yourself as a tinkerer. That's good. You'll find that most of the expensive items are things like the electronics, stepper motors, hot end, extruder, etc. Note that all these items are common to a large number of kits and designs. So, if you cobble something together and it doesn't work, then it's no big deal. You can carry the expensive parts over and design/build something else. All you'll have lost is the cost of the framing materials (metal work or wood) and some time. But you won't have wasted the time because you'll have learned a lot along the way and this knowledge will stand you in good stead for the next version.

Don't be put off by some of the comments you've received. It's the same with any hobby, there will always be those who say you need to spend at least 10 times what you had budgeted and anything less will be a complete waste of time and money. If you are into photography, you can take great pictures with a £250 Canon EOS 1200 D camera or you can spend $50,000 on a Leica M9 P Hermes edition. You can get very reasonably sounding Hi-Fi for £ a few hundred or you can spend tens of thousands on just a pair of speakers.

I only got into 3d printing about a year ago (I'm a 60 something carpenter). I built a RepRapPro (no longer in business) Mendel 3 from a kit. It's just a bunch of 3d printed parts and lots of threaded rod for the frame. It looks bloody awful but I'm amazed at the accuracy and quality of the printed parts it can produce. Also, the reliability has been excellent. The heated bed consists of a piece of 3mm thick mdf as an insulator, then the pcb heater with a 1.5mm thick sheet of aluminium as a heat spreader and then 3mm thick glass which I cover with Kapton tape. I don't have any problem with things sticking to the bed, in fact getting them off the bed is the problem, usually resolved with a small chisel and a tap with a hammer. Is the mdf flat? No. Is the aluminium flat? No. Does it matter? No. Why? Because the glass is flat and the bed is level and I have the z axis homing set correctly. I have 3 pieces of prepared glass so as soon as one print is finished, I simply replace the glass give a quick wipe over with acetone, and start printing again, without waiting for the bed to cool. So cheap does not always mean inferior.

It doesn't really matter what printer you start with although it's generally noted that beginners should avoid delta designs for their first printer. Other than that, the basic requirements are that the the x, y and z axes run smoothly, parallel and at right angles to each other. That generally means you need to use some sort of metal guides and a support structure to hold it all together.

I note from your OP that you describe yourself as a tinkerer. That's good. You'll find that most of the expensive items are things like the electronics, stepper motors, hot end, extruder, etc. Note that all these items are common to a large number of kits and designs. So, if you cobble something together and it doesn't work, then it's no big deal. You can carry the expensive parts over and design/build something else. All you'll have lost is the cost of the framing materials (metal work or wood) and some time. But you won't have wasted the time because you'll have learned a lot along the way and this knowledge will stand you in good stead for the next version.

|

Re: What CoreXY design to choose? April 28, 2016 05:17PM |

Registered: 8 years ago Posts: 776 |

Quote

Amoniak

Would a RAMBO controller board be an option?

NO. the RAMBO is just as s**t as all the other "let's use test equipment parts on a production board" designs. the RAMBO - again - uses those tiny 16x16mm PCBs to house a 2 to 2.5A IC, leaving absolutely no way for the heat to escape.

i know people think it's a great idea to have modularity but when you blatantly ignore datasheets and the laws of physics and basic thermodynamics, s**t's gonna happen fairly quickly. you might still be able to get hold of a Melzi if you're lucky (you'll need to find a dual 12+5V PSU if you're going with one of those, though. an AT PSU from a PC will do - or an ATX if you're prepared to add a couple of large high-wattage resistors across a couple of wires, look up how it's done on the mendel90). but the rambo v1.2g you can have (for next to nothing) is about the lowest offer you'll get, and it's a decent-enough board (look it up) - i got it on a refund as i helped the shop evaluate why the voltage-divider circuits were not up to spec.

|

Re: What CoreXY design to choose? April 28, 2016 05:22PM |

Registered: 9 years ago Posts: 893 |

Amoniak - are you thoroughly confused yet?

I think deckingman is saying the same as me - pick a simple design, have a go at building it, make some mistakes and try again (and again), and gain experience as you go. Go 'advanced' later on.

Note: Like him I'm a '60-something' tinkerer who loves building things: I knew nothing about 3D printing 2 years ago, and since then I've had a lot of fun by progressing through the hobby. I did have some prior skills - I've done some model engineering, up to including a large-scale steam engine, and I've played with electronics for many years, but they're all skills I've picked up as I've gone along.

Edited 1 time(s). Last edit at 04/28/2016 05:27PM by David J.

I think deckingman is saying the same as me - pick a simple design, have a go at building it, make some mistakes and try again (and again), and gain experience as you go. Go 'advanced' later on.

Note: Like him I'm a '60-something' tinkerer who loves building things: I knew nothing about 3D printing 2 years ago, and since then I've had a lot of fun by progressing through the hobby. I did have some prior skills - I've done some model engineering, up to including a large-scale steam engine, and I've played with electronics for many years, but they're all skills I've picked up as I've gone along.

Edited 1 time(s). Last edit at 04/28/2016 05:27PM by David J.

|

Re: What CoreXY design to choose? April 28, 2016 05:36PM |

Registered: 8 years ago Posts: 622 |

Quote

David J

Amoniak - are you thoroughly confused yet?

I think deckingman is saying the same as me - pick a simple design, have a go at building it, make some mistakes and try again (and again), and gain experience as you go. Go 'advanced' later on.

Note: Like him I'm a '60-something' tinkerer who loves building things: I knew nothing about 3D printing 2 years ago, and since then I've had a lot of fun by progressing through the hobby. I did have some prior skills - I've done some model engineering, up to including a large-scale steam engine, and I've played with electronics for many years, but they're all skills I've picked up as I've gone along.

Yes we are on the same wavelength. Also, it sounds like we have much in common. I've played around with PICs in the past and Arduino UNOs more recently. I'm more of a woodworker than model engineer and have built a wooden Mississippi paddle boat (non working).

|

Re: What CoreXY design to choose? April 28, 2016 06:07PM |

Registered: 11 years ago Posts: 1,049 |

Hey lets hear it for the 3D printing Geriatrics (an aged person)

We can print our own walker and wheelchair parts!

Grasshoppas -- listen to the sage --- unless they haven't taken their medication

We can print our own walker and wheelchair parts!

Quote

DavidJ

Note: Like him I'm a '60-something' tinkerer who loves building things:

Quote

deckingman

I only got into 3d printing about a year ago (I'm a 60 something carpenter)

Grasshoppas -- listen to the sage --- unless they haven't taken their medication

|

Re: What CoreXY design to choose? April 28, 2016 06:25PM |

Registered: 11 years ago Posts: 1,049 |

Guide rails

3pcs/set 3D Printer, MGN12 ,12mm miniature linear rail slide for XYZ Axies

400mm long $61.00usd

[www.ebay.com]

See the other items this seller has

Probably will mount on MDF

or maybe an aluminum frame holding the CoreXY atop the MDF

NO WOOD SCREWS --- Furniture connectors/bolts made to hold MDF together

IKEA a master at using them

Like these (just example -- may be able to find them elsewhere)

[www.eurofitdirect.co.uk]

3pcs/set 3D Printer, MGN12 ,12mm miniature linear rail slide for XYZ Axies

400mm long $61.00usd

[www.ebay.com]

See the other items this seller has

Probably will mount on MDF

or maybe an aluminum frame holding the CoreXY atop the MDF

NO WOOD SCREWS --- Furniture connectors/bolts made to hold MDF together

IKEA a master at using them

Like these (just example -- may be able to find them elsewhere)

[www.eurofitdirect.co.uk]

|

Re: What CoreXY design to choose? April 28, 2016 06:46PM |

Registered: 7 years ago Posts: 33 |

Again, I appreciate all of your responses (even the negative ones, they at least give some perspective  )

)

@filipeCampos

Thanks!

Your right! I suppose everyone starts somewhere, only time and experience will tell if this is something for me.

I know my budget is low and cheapish, my intention coming here was simpel, make a choice for a existing design knowing it's limitation but being confident that for the budget it's a good choice.

And BTW I really like your G&C design, I'm so tempted stretching the budget going for it...

@David J

Yes, even more so now, but it's good . I learn and search for information based on the comments, to hopefully get a little bit wiser.

. I learn and search for information based on the comments, to hopefully get a little bit wiser.

But I think you and deckingman are on to something, thanks

@lkcl

So the rambo v1.2g is a decent low end board? it's what I meant with RAMBO but I probably need to learn the correct lingo.

)

)@filipeCampos

Thanks!

Your right! I suppose everyone starts somewhere, only time and experience will tell if this is something for me.

I know my budget is low and cheapish, my intention coming here was simpel, make a choice for a existing design knowing it's limitation but being confident that for the budget it's a good choice.

And BTW I really like your G&C design, I'm so tempted stretching the budget going for it...

@David J

Yes, even more so now, but it's good

. I learn and search for information based on the comments, to hopefully get a little bit wiser.

. I learn and search for information based on the comments, to hopefully get a little bit wiser.But I think you and deckingman are on to something, thanks

@lkcl

So the rambo v1.2g is a decent low end board? it's what I meant with RAMBO but I probably need to learn the correct lingo.

Sorry, only registered users may post in this forum.