My coreXY design is progressing to the build stage

Posted by the_digital_dentist

|

Re: My coreXY design is progressing to the build stage May 11, 2016 06:20AM |

Registered: 8 years ago Posts: 622 |

Quote

the_digital_dentist

Yes, two-level belts. Attempting to set approximately equal tension on both belts at the same time might require me to grow and extra arm or two. It's OK- the screws will attach the belt clamps to the inside of a rectangular aluminum tube and prevent it from going anywhere. I'll countersink the holes to force the screws to center themselves in the holes.

May I ask what bearings you are using? From the picture it looks like two bearings for each belt, each bearing having a flange on one side. Is that correct? Also, I'm assuming there are some sort of spacers between the bearings and the holder and also between the two bearings. Are they just simple washers?

|

Re: My coreXY design is progressing to the build stage May 11, 2016 07:57AM |

Registered: 11 years ago Posts: 5,780 |

F608ZZ bearings with washers for spacers. F608ZZ bearings are 22 mm in diameter and 7 mm wide. Stacking two gives a flat belt surface between the flanges of 11 mm. I'll be using 9 mm wide belt.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage May 11, 2016 02:08PM |

Registered: 11 years ago Posts: 1,049 |

Will you be using smooth or toothed/grooved pulleys

where toothed side of belt runs over the pulley?

I suppose if bearing has a large diameter the belt teeth won't vibrate to bad.

TIMING BELT DESIGN AND INSTALLATION SUGGESTIONS: GENERAL GUIDE LINES

When an idler is necessary, it should be on the slack side of the belt. Inside idlers must be grooved, unless their diameters are greater than an equivalent 40-groove pulley. Flat idlers must not be crowned (use edge flanges). Idler diameters must exceed the smallest diameter drive pulley. Idler arc of contact should be held to a minimum.

where toothed side of belt runs over the pulley?

I suppose if bearing has a large diameter the belt teeth won't vibrate to bad.

TIMING BELT DESIGN AND INSTALLATION SUGGESTIONS: GENERAL GUIDE LINES

When an idler is necessary, it should be on the slack side of the belt. Inside idlers must be grooved, unless their diameters are greater than an equivalent 40-groove pulley. Flat idlers must not be crowned (use edge flanges). Idler diameters must exceed the smallest diameter drive pulley. Idler arc of contact should be held to a minimum.

|

Re: My coreXY design is progressing to the build stage May 11, 2016 02:39PM |

Registered: 11 years ago Posts: 5,780 |

I'll be using smooth pulleys made from F608ZZ bearings. A 40 tooth pulley is about 25 mm diameter. F608ZZs are 22 mm diameter.

That stuff from SDP/SI is a little tricky to interpret. When they say "idler" pulley they seem to be talking about things like pulleys used to adjust belt tension- idler arc of contact should be minimum? Hmmm.

I've seen other info (can't find the link) that said there should be a minimum of 6 teeth in contact with a smooth pulley. In this application, we have 90 degree contact, and since the pulleys are equivalent diameter of about a 34 tooth pulley, there will be at least 8 teeth of the belt in contact with the pulley. I think it will be OK.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

That stuff from SDP/SI is a little tricky to interpret. When they say "idler" pulley they seem to be talking about things like pulleys used to adjust belt tension- idler arc of contact should be minimum? Hmmm.

I've seen other info (can't find the link) that said there should be a minimum of 6 teeth in contact with a smooth pulley. In this application, we have 90 degree contact, and since the pulleys are equivalent diameter of about a 34 tooth pulley, there will be at least 8 teeth of the belt in contact with the pulley. I think it will be OK.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage May 12, 2016 03:26AM |

Registered: 8 years ago Posts: 622 |

Quote

the_digital_dentist

I'll be using smooth pulleys made from F608ZZ bearings. A 40 tooth pulley is about 25 mm diameter. F608ZZs are 22 mm diameter.

That stuff from SDP/SI is a little tricky to interpret. When they say "idler" pulley they seem to be talking about things like pulleys used to adjust belt tension- idler arc of contact should be minimum? Hmmm.

I've seen other info (can't find the link) that said there should be a minimum of 6 teeth in contact with a smooth pulley. In this application, we have 90 degree contact, and since the pulleys are equivalent diameter of about a 34 tooth pulley, there will be at least 8 teeth of the belt in contact with the pulley. I think it will be OK.

My RRP Mendel 3 which I bought as kit, uses 18T pulleys with 623 idlers and MXL belt with the teeth facing the bearings. In theory it doesn't "feel right" but in practice, I've never had a problem after many hundreds of hours of use even with these tiny bearings, so I'd say you'll be fine. Based on my experience with the Mendel, I'll be doing the same as you, if and when I every get around to building a new printer.

|

Re: My coreXY design is progressing to the build stage May 12, 2016 09:46AM |

Registered: 8 years ago Posts: 776 |

Quote

the_digital_dentist

That stuff from SDP/SI is a little tricky to interpret. When they say "idler" pulley they seem to be talking about things like pulleys used to adjust belt tension- idler arc of contact should be minimum? Hmmm.

it's quite straightforward. they've left out personal pronouns and other words. "contact" refers to the belt in contact with the "idler". "arc" is a part of a circle. i assume you're using circular bearings...

so "idler arc of contact" refers to how far the belt goes round the idler bearing. if it's over 180 degrees you've got a serious problem, for example

so "idler arc of contact" refers to how far the belt goes round the idler bearing. if it's over 180 degrees you've got a serious problem, for example

basically you can tell there's a problem if when you have the belt slightly slack, move the belt in one direction, you can see clearly it will be taut leading up to the idler, and even looser on the other side, it will even bow outwards. tighten the belt up, this problem *partly* goes away, but the faster you move the belt, the more weight (yes, of the belt) is thrown round the corner...

... and, also, the larger the angle you try to turn the belt round, the more resistance you end up with, the more inertia, and so on.

so, they're saying: don't make the belt bend round corners any more than you absolutely have to. design the entire system around minimising that bend. 90 degrees is kinda ok, 180 degrees really isn't. if you really have to do 180 degrees, use a bigger idler.

|

Anonymous User

Re: My coreXY design is progressing to the build stage May 12, 2016 11:48AM |

6 teeth min is for driving pulleys. Idler usage is as per above coMicray post. Just common sense.

GT2 tooth are round, just rubber, the less tooth on a smooth pulley, the more they will get crushed like in a small diam pulley whith the belt covering 180°. The force depends on the angle formed by the belt around the idler.

If it is true that 3D printers requirements are not excessive (see all the clunkers around nevertheless able to spit marvin blobs) smooth idler pulleys even just a naked ball bearing are OK but considering the low price of toothed idler pulleys why not use them ?

Edited 3 time(s). Last edit at 05/12/2016 02:17PM by MKSA.

GT2 tooth are round, just rubber, the less tooth on a smooth pulley, the more they will get crushed like in a small diam pulley whith the belt covering 180°. The force depends on the angle formed by the belt around the idler.

If it is true that 3D printers requirements are not excessive (see all the clunkers around nevertheless able to spit marvin blobs) smooth idler pulleys even just a naked ball bearing are OK but considering the low price of toothed idler pulleys why not use them ?

Edited 3 time(s). Last edit at 05/12/2016 02:17PM by MKSA.

|

Re: My coreXY design is progressing to the build stage May 12, 2016 12:04PM |

Registered: 11 years ago Posts: 5,780 |

I ordered the F608ZZ bearings for $8 for 10 pieces. Where do you get cheap toothed pulleys?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage May 12, 2016 12:55PM |

Registered: 10 years ago Posts: 344 |

|

Anonymous User

Re: My coreXY design is progressing to the build stage May 12, 2016 01:37PM |

Quote

the_digital_dentist

I ordered the F608ZZ bearings for $8 for 10 pieces. Where do you get cheap toothed pulleys?

Aliexpress, Banggood. OK, its chinese so not the best but the ball bearings you ordered are chinese too so ?. I used them for my Prusa, and they are OK.

I cry when I compare these to SKF, Timken and the like but hell, once all is set, we can always replace by the real stuff. A good source for small high quality ball bearing are hard disk. Almost all are standard metric fit for these pulleys, extruder ....

|

Re: My coreXY design is progressing to the build stage May 12, 2016 02:53PM |

Registered: 11 years ago Posts: 1,049 |

So ickl

Your now a timing belt engineer?

I wish my father was still around to comment on this

He was the inventor of the timing belt (positive drive belt) while working

at US Rubber company.

I was six at the time but the patent with a one dollar bill on it

hanging in our basement was cool

[pdfpiw.uspto.gov]

The IBM selectronic typewriter drive, dragster blower belts,

Fiat spyder (first to use timing belt in engine),

polaris snow mobile track just a small example of his expertise.

I don't ever he imagined a timing belt going every direction at once but he could design

it to maximize timing belt design.

DD is a sage in this area --- he is using a large enough diameter in

direction change pulley to be acceptable.

Twisting belt kills the belt and the drive design.

Design with sharp arc or pulley diameter may have to use a belt with out

kevlar or steel cord inside

to keep it from jumping around drive pulley and destroying cord inside

a belt with a special cover would be necessary .

What is a flanged pulley --- a flanged doughnut with bearing inside

Non-spherical bearings (bearings that have flat outer race) are fine

The washers that spin independently of bearing may chew up

edge of belt if belt rides up/down on them.

Many bearings have spherical outer race surface to be self aligning to axis

DD if your 608s are crowned --- I would order up some flat ones.

ickl ---So Please just stop spewing your bad knowledge,

from 12 minutes of experience, of timing belts

what he declares is almost opposite of good timing belt drive design

Your now a timing belt engineer?

I wish my father was still around to comment on this

He was the inventor of the timing belt (positive drive belt) while working

at US Rubber company.

I was six at the time but the patent with a one dollar bill on it

hanging in our basement was cool

[pdfpiw.uspto.gov]

The IBM selectronic typewriter drive, dragster blower belts,

Fiat spyder (first to use timing belt in engine),

polaris snow mobile track just a small example of his expertise.

I don't ever he imagined a timing belt going every direction at once but he could design

it to maximize timing belt design.

DD is a sage in this area --- he is using a large enough diameter in

direction change pulley to be acceptable.

Twisting belt kills the belt and the drive design.

Design with sharp arc or pulley diameter may have to use a belt with out

kevlar or steel cord inside

to keep it from jumping around drive pulley and destroying cord inside

a belt with a special cover would be necessary .

What is a flanged pulley --- a flanged doughnut with bearing inside

Non-spherical bearings (bearings that have flat outer race) are fine

The washers that spin independently of bearing may chew up

edge of belt if belt rides up/down on them.

Many bearings have spherical outer race surface to be self aligning to axis

DD if your 608s are crowned --- I would order up some flat ones.

ickl ---So Please just stop spewing your bad knowledge,

from 12 minutes of experience, of timing belts

what he declares is almost opposite of good timing belt drive design

|

Re: My coreXY design is progressing to the build stage May 12, 2016 04:17PM |

Registered: 11 years ago Posts: 5,780 |

My current printer has one idler bearing for the X axis and it doesn't not produce any visible artifacts in the prints. It uses a smaller diameter bearing than the 608zz, but probably has a few more teeth in contact with the bearing surface because of the 180 degree wrap than I will have with these. If I notice any problems in the prints I can swap out the bearings for larger pulleys without too much trouble.

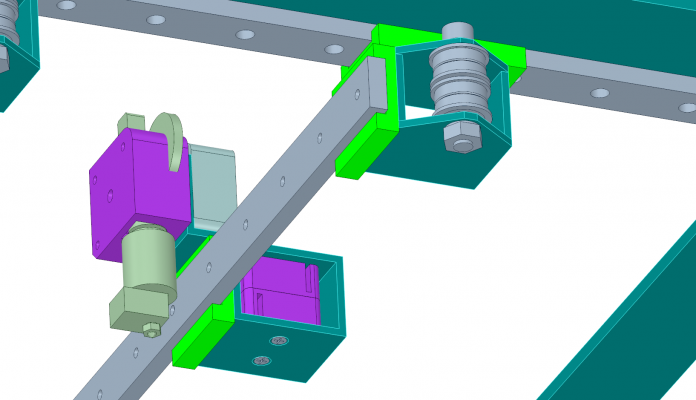

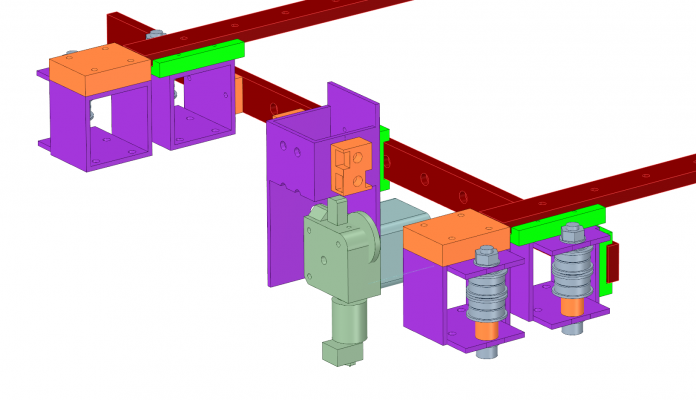

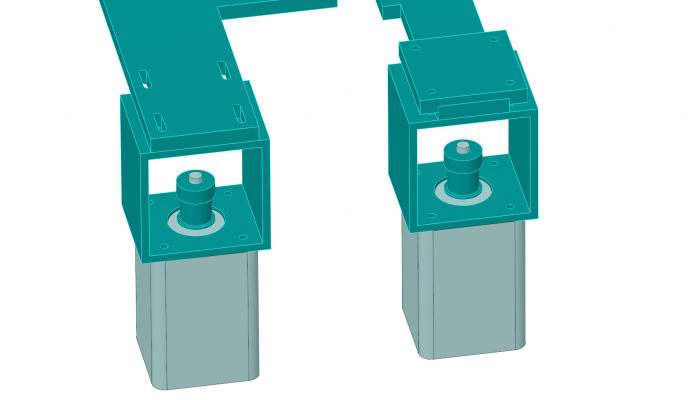

While I wait for parts I've been reworking the design. I am planning to use a Titan extruder with v6 hot-end. The Titan extruder doesn't really have much provision for mounting it- you have to print a bracket that has a spacer that fits between the motor and the body of the extruder. Printed brackets are far too flexible for my taste, so I figured out a scheme that solves multiple problems at once including the extruder mount:

The pulley brackets (purple) and extruder carriage are all made from 2" square aluminum tubing with 1/8" walls. The extruder will hang down from it's bearing block and the filament will feed to it through the big aluminum tube. I left a tab along the top edge of the tube as a convenient mounting point for cables that go to the extruder. I also left some of the aluminum on the left side of the extruder which will stiffen the mount and provide a convenient place to mount a circuit board and/or print cooling fan. There's plenty of room above the extruder to reach the pinch wheel tension release lever, and a hole in the left side of the tube to allow screw driver access for spring tension adjustment.

I ended up redesigning the belt clamps for the extruder carriage. Each side of the carriage has an identical clamp printed as a single piece. The width of the clamp and the spacing between the belt slots matches the pulleys. As long as I mount the clamp on the center line on the extruder carriage, the belts will be parallel to the X axis. The belts enter each clamp along its outer edges and pass all the way through the clamp then get folded back on themselves outside the clamps. The folded belt is then pulled back into the slot which is 2.2 mm wide, making it self-locking. I may tweak the clamp design a little more before I'm done.

Even though the clamps are mounted on the sides of the extruder carriage they do not impose any penalty on X-axis range of motion. When the extruder carriage moves all the way to the end of the axis, the clamps fit inside the pulley brackets with plenty of clearance. I'll probably mount the X axis limit switch(s) inside the the pulley bracket(s).

I know, all this aluminum adds to the moving mass so I probably won't be able to print at 200 mm/sec...

Edited 1 time(s). Last edit at 05/12/2016 04:24PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

While I wait for parts I've been reworking the design. I am planning to use a Titan extruder with v6 hot-end. The Titan extruder doesn't really have much provision for mounting it- you have to print a bracket that has a spacer that fits between the motor and the body of the extruder. Printed brackets are far too flexible for my taste, so I figured out a scheme that solves multiple problems at once including the extruder mount:

The pulley brackets (purple) and extruder carriage are all made from 2" square aluminum tubing with 1/8" walls. The extruder will hang down from it's bearing block and the filament will feed to it through the big aluminum tube. I left a tab along the top edge of the tube as a convenient mounting point for cables that go to the extruder. I also left some of the aluminum on the left side of the extruder which will stiffen the mount and provide a convenient place to mount a circuit board and/or print cooling fan. There's plenty of room above the extruder to reach the pinch wheel tension release lever, and a hole in the left side of the tube to allow screw driver access for spring tension adjustment.

I ended up redesigning the belt clamps for the extruder carriage. Each side of the carriage has an identical clamp printed as a single piece. The width of the clamp and the spacing between the belt slots matches the pulleys. As long as I mount the clamp on the center line on the extruder carriage, the belts will be parallel to the X axis. The belts enter each clamp along its outer edges and pass all the way through the clamp then get folded back on themselves outside the clamps. The folded belt is then pulled back into the slot which is 2.2 mm wide, making it self-locking. I may tweak the clamp design a little more before I'm done.

Even though the clamps are mounted on the sides of the extruder carriage they do not impose any penalty on X-axis range of motion. When the extruder carriage moves all the way to the end of the axis, the clamps fit inside the pulley brackets with plenty of clearance. I'll probably mount the X axis limit switch(s) inside the the pulley bracket(s).

I know, all this aluminum adds to the moving mass so I probably won't be able to print at 200 mm/sec...

Edited 1 time(s). Last edit at 05/12/2016 04:24PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage May 12, 2016 04:22PM |

Registered: 11 years ago Posts: 5,780 |

Quote

gforce1

@ DD Why don't you twist the belts that are running on the outside? Then they are running with the smooth side on the idlers.

I tried that before and found it difficult to keep the belt centered on the pulley, but maybe the distance between the pulleys was too small. I may try it again with this build, but there isn't much room on that side for the twist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Anonymous User

Re: My coreXY design is progressing to the build stage May 12, 2016 11:02PM |

Quote

the_digital_dentist

Quote

gforce1

@ DD Why don't you twist the belts that are running on the outside? Then they are running with the smooth side on the idlers.

I tried that before and found it difficult to keep the belt centered on the pulley, but maybe the distance between the pulleys was too small. I may try it again with this build, but there isn't much room on that side for the twist.

Argh, you really tried it ? Don't do that, it is a non sense.

I have these 608 bearing, yes, the radius is big enough and fits the bill but they are unnecessary big with a big hole requiring a bigger bracket and axle and gives an amateur look.

Edited 1 time(s). Last edit at 05/12/2016 11:14PM by MKSA.

|

Re: My coreXY design is progressing to the build stage May 13, 2016 12:21AM |

Registered: 11 years ago Posts: 5,780 |

I'm a lot less concerned about the appearance than the function. It's also quite easy to fabricate the brackets from aluminum tubing, requiring only a saw, drill, and a file or deburring tool for clean-up (though I'll probably mill the cuts just make it look more "professional").

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Anonymous User

Re: My coreXY design is progressing to the build stage May 13, 2016 02:19AM |

Quote

the_digital_dentist

I'm a lot less concerned about the appearance than the function. It's also quite easy to fabricate the brackets from aluminum tubing, requiring only a saw, drill, and a file or deburring tool for clean-up (though I'll probably mill the cuts just make it look more "professional").

How well a function is implemented makes the "appearance" for an engineer.

True, your set up is Ok but nevertheless, why not make it super OK ?.

To use proper idler pulleys requires even less work and is more compact for a few bucks more.

Depending on the set up, when the two belts sides have to stay // as in a Prusa, it is easy, just use driving pulleys and idler with the same tooth nbr.

Compare these cheap chinese ball bearing with a SKF, they do the same function but just looking at the "details" and thus the appearance, one can see which one is better.

|

Anonymous User

Re: My coreXY design is progressing to the build stage May 13, 2016 02:29AM |

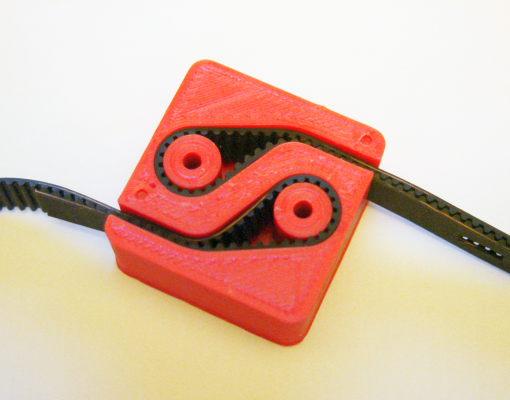

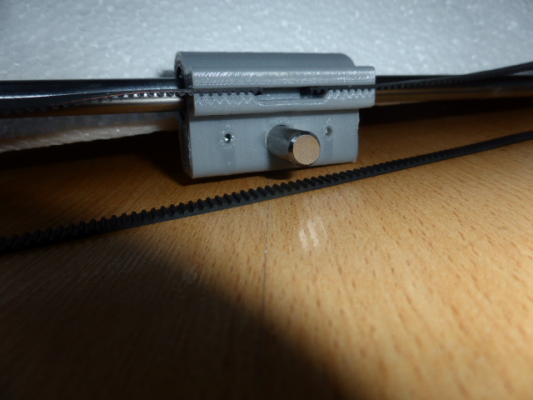

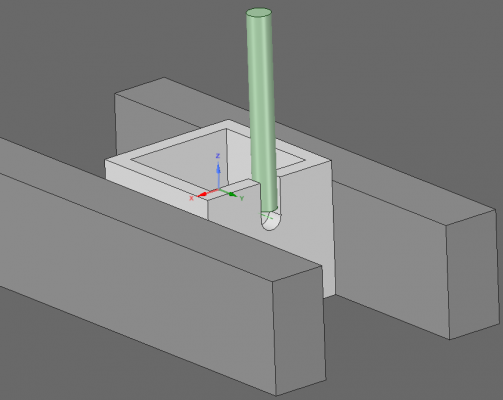

BTW, this is how I connect my belt to carriage (I use the principle on my new Prusa carriage but this is a prototype to use on a printer I have not yet defined, may be a Core XY ?)

PS: The flash makes the part looks worse than it is.

Edited 1 time(s). Last edit at 05/13/2016 02:38AM by MKSA.

|

Re: My coreXY design is progressing to the build stage May 13, 2016 07:50AM |

Registered: 11 years ago Posts: 5,780 |

Very nice, but it wouldn't work for what I'm doing.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Anonymous User

Re: My coreXY design is progressing to the build stage May 14, 2016 04:25AM |

Due to their ubiquitous use in the Reprap world, I got some of these cheap chinese 608 (8x22x7) bearings and dismounted one. It is HORRIBLE ! The poor external appearance is a pale hint of the horror inside. The race tracks are not only awful, with tooling marks but not even tempered ! Yup, the balls (at least, they are tempered) rides on regular steel. They are just fit for the least demanding applications and I wouldn't bet on a long life neither use them at their rated load.

These are the 608 at 8 bucks per ten. May be the more expensive one are better ? Anyway, better get the real stuff. This size is quite common and 8mm ID even more. Old power tools, office equipment for example, plenty of 8 mm shaft, bearings balls and sintered metal.

These are the 608 at 8 bucks per ten. May be the more expensive one are better ? Anyway, better get the real stuff. This size is quite common and 8mm ID even more. Old power tools, office equipment for example, plenty of 8 mm shaft, bearings balls and sintered metal.

|

Re: My coreXY design is progressing to the build stage May 14, 2016 07:18AM |

Registered: 11 years ago Posts: 5,780 |

How can you tell if the balls are but the races are not hardened with just a visual inspection?

And do the cheap, toothed pulleys you previously suggested come with "proper" bearings?

Edited 1 time(s). Last edit at 05/14/2016 07:19AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

And do the cheap, toothed pulleys you previously suggested come with "proper" bearings?

Edited 1 time(s). Last edit at 05/14/2016 07:19AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Anonymous User

Re: My coreXY design is progressing to the build stage May 14, 2016 08:57AM |

Quote

the_digital_dentist

How can you tell if the balls are but the races are not hardened with just a visual inspection?

And do the cheap, toothed pulleys you previously suggested come with "proper" bearings?

Easy, just a small file, even a sharp cutter scratches the surface ! No need for extensive metallurgy testing ! Take one apart, you will see.

Note that I have some chinese 10X22X7 not bought in bulk and pricier, a few buck a piece and they are OK. Not everything from China is junk, I hope so

Just more expensive.

Just more expensive.May be the really cheap junk, they got it from Pakistan ?

Check, may be yours are OK.

I had the same issues with the smooth rod. Got crap and got surprisingly fine ones.

About the idler ? Indeed, I started to be concerned too. Just checked and they seem ok.

Fortunately, just in case I have a few bearings on hand. These small bearings can be found in old hard disk drive for example. I used them already for my extruder.

|

Re: My coreXY design is progressing to the build stage May 14, 2016 10:18AM |

Registered: 11 years ago Posts: 5,780 |

I've used HDD bearings in extruder experiments, too. They are probably the best bearings made. A little too small for 3D printer idlers unless you press them into machined pulleys. The next problem with them is the tiny screw hole...

On another topic- the motor for one of the belts will be positioned perfectly if I use a piece of the 2" square tubing for the motor mount. The other motor mount can be made using a piece of 1.5" x 2" tubing. Very simple, and very cheap. Cutting grooves in the plate to allow adjustability will be a little tricky. If I cut the plate narrower I can just make clamps that fit and then I won't have to mill narrow slots in the plate.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

On another topic- the motor for one of the belts will be positioned perfectly if I use a piece of the 2" square tubing for the motor mount. The other motor mount can be made using a piece of 1.5" x 2" tubing. Very simple, and very cheap. Cutting grooves in the plate to allow adjustability will be a little tricky. If I cut the plate narrower I can just make clamps that fit and then I won't have to mill narrow slots in the plate.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Anonymous User

Re: My coreXY design is progressing to the build stage May 14, 2016 10:59AM |

Quote

the_digital_dentist

I've used HDD bearings in extruder experiments, too. They are probably the best bearings made. A little too small for 3D printer idlers unless you press them into machined pulleys. The next problem with them is the tiny screw hole...

On another topic- the motor for one of the belts will be positioned perfectly if I use a piece of the 2" square tubing for the motor mount. The other motor mount can be made using a piece of 1.5" x 2" tubing. Very simple, and very cheap. Cutting grooves in the plate to allow adjustability will be a little tricky. If I cut the plate narrower I can just make clamps that fit and then I won't have to mill narrow slots in the plate.

These small HDD bearing can fit the chinese idler pulley and indeed are not to be used as idler, they are too small. The axle (with the tiny screw) has to be removed. It is glued, a bit of heat (100°) will break the bond. ID is usually 4 or 5. Note, plenty of M2, M2.5 and M3 with Torx head in these. Comes handy.

The clamp to hold the motor if fine too. Two bigger screws, M5 or M6 are enough.

Note that you could use only two slots too if it is the narrow slot milling the issue.

|

Re: My coreXY design is progressing to the build stage May 14, 2016 05:26PM |

Registered: 11 years ago Posts: 5,780 |

I have a box full of the little screws from the HDDs. When you need a small screw or three it's hard to find them anywhere else.

I'll probably go with the clamp.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I'll probably go with the clamp.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage May 14, 2016 05:59PM |

Registered: 11 years ago Posts: 1,049 |

The 608, 608z, 606zz are common used skateboards

z -- designate shield on side. rs - designates sealed

Might look at ABEC rateing -- higher suppose to be better

but are not tested/ rated for reciprocating (back and forth) operation

Hey these are used for direction change, are they really loaded

Is the inner race pressed onto axle so the bearing is in proper use?

Mount it on a shaft, tight fit to shaft

spin it both directions

Does it continue to spin?

Is it noisy?

Might have to clean them out well. Kerosene, WD40.

If you clean them out well -- may have to lube them up with very light oil.

Select good ones.

Give the bad ones for the neighborhood skateboarder

but he probably has the top notch ceramic bearings?

z -- designate shield on side. rs - designates sealed

Might look at ABEC rateing -- higher suppose to be better

but are not tested/ rated for reciprocating (back and forth) operation

Hey these are used for direction change, are they really loaded

Is the inner race pressed onto axle so the bearing is in proper use?

Mount it on a shaft, tight fit to shaft

spin it both directions

Does it continue to spin?

Is it noisy?

Might have to clean them out well. Kerosene, WD40.

If you clean them out well -- may have to lube them up with very light oil.

Select good ones.

Give the bad ones for the neighborhood skateboarder

but he probably has the top notch ceramic bearings?

|

Anonymous User

Re: My coreXY design is progressing to the build stage May 14, 2016 09:50PM |

Quote

the_digital_dentist

I have a box full of the little screws from the HDDs. When you need a small screw or three it's hard to find them anywhere else.

I'll probably go with the clamp.

OK. No need to mill needed then.

Note that if you have access to a mill, the 2 slots can be milled in the piece of square tube, easy to hold in the mill vise instead of securing the plate (how big ?) to the mill table.

|

Anonymous User

Re: My coreXY design is progressing to the build stage May 14, 2016 10:09PM |

Quote

cozmicray

The 608, 608z, 606zz are common used skateboards

z -- designate shield on side. rs - designates sealed

Might look at ABEC rateing -- higher suppose to be better

but are not tested/ rated for reciprocating (back and forth) operation

Hey these are used for direction change, are they really loaded

Is the inner race pressed onto axle so the bearing is in proper use?

Mount it on a shaft, tight fit to shaft

spin it both directions

Does it continue to spin?

Is it noisy?

Might have to clean them out well. Kerosene, WD40.

If you clean them out well -- may have to lube them up with very light oil.

Select good ones.

Give the bad ones for the neighborhood skateboarder

but he probably has the top notch ceramic bearings?

Chinese ABEC rating ?Yup, like their UL and FCC approvals you mean ? BTW, the junk I have are ABEC 5 !

Give them to the neighborhood skateboarder and risk a lawsuit while you have here a designer craving for worn out bearings for his project ?

I like your sense of humor

|

Re: My coreXY design is progressing to the build stage May 15, 2016 06:03PM |

Registered: 8 years ago Posts: 776 |

Quote

cozmicray

Give the bad ones for the neighborhood skateboarder

but he probably has the top notch ceramic bearings?

i reaaally used to want ceramic bearings, but then i found out that eddie matzger uses Twincam ILQ9s bearings [www.inlineplanet.com] which have a special shaped s-channel that stops crap getting in them. eddie's hilarious - he's 48, and still wins professional skating marathons... and *really* pisses off all the rather aggressive competitors by smiling and taking videos on his phone whilst overtaking them.

anyway those Twincam bearings are some serious bits of engineering, so i thought i'd mention them.

|

Re: My coreXY design is progressing to the build stage May 20, 2016 01:59AM |

Registered: 9 years ago Posts: 1,035 |

Quote

the_digital_dentist

Cutting grooves in the plate to allow adjustability will be a little tricky. If I cut the plate narrower I can just make clamps that fit and then I won't have to mill narrow slots in the plate.

Would slots that are open to the sides work for this? They could potentially be done with a vertical drill:

I am not sure how the thin wall will react to the ripping forces of the spinning drill bit though. It might get torn out. Maybe clamp some shims on the sides.

Edited 1 time(s). Last edit at 05/20/2016 02:00AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: My coreXY design is progressing to the build stage May 20, 2016 05:59AM |

Registered: 13 years ago Posts: 268 |

Sorry, only registered users may post in this forum.