My coreXY design is progressing to the build stage

Posted by the_digital_dentist

|

Re: My coreXY design is progressing to the build stage March 27, 2017 09:28AM |

Registered: 12 years ago Posts: 72 |

I guess you can still stick to high top-speeds and still benefit, especially with the size of your print-bed.

Were both the prints done after performing the extruder calibration ? I noticed that a test cube I printed ages ago was quite shiny, but a recent one that I did had a really dull surface - I can't remember changing anything of value, except the extruder calibration so maybe it's related to that ? I can't think why it would affect it though.

Visibility is a fair concern. I don't know if you've seen this cooler but maybe this is of help: [www.thingiverse.com] - It just about fits under a Titan Aero, as long as you use a thin (20mm / 13NM) stepper motor.

See the "X Axis Assembly V5" tab: [cad.onshape.com] (But please ignore my very crude Titan Aero model)

Were both the prints done after performing the extruder calibration ? I noticed that a test cube I printed ages ago was quite shiny, but a recent one that I did had a really dull surface - I can't remember changing anything of value, except the extruder calibration so maybe it's related to that ? I can't think why it would affect it though.

Visibility is a fair concern. I don't know if you've seen this cooler but maybe this is of help: [www.thingiverse.com] - It just about fits under a Titan Aero, as long as you use a thin (20mm / 13NM) stepper motor.

See the "X Axis Assembly V5" tab: [cad.onshape.com] (But please ignore my very crude Titan Aero model)

|

Re: My coreXY design is progressing to the build stage March 27, 2017 10:56AM |

Registered: 11 years ago Posts: 5,780 |

I have found that the print cooling fan and the hot-end temperature both affect the shininess of the surface with PLA prints. I didn't experiment with the extrusion temperature at all- just used the same settings I use on my other printer.

Both prints were done after extruder calibration.

I don't trust those pancake motors to deliver torque when it's needed. My BullDog XL with 5:1 gearing doesn't stop pushing the filament for anything. I rather print a little slower because I have a heavier extruder motor and know that the print is going to finish than push everything right to the limits of its performance and have to do a lot of babysitting and restarting prints.

Edited 1 time(s). Last edit at 03/27/2017 09:33PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Both prints were done after extruder calibration.

I don't trust those pancake motors to deliver torque when it's needed. My BullDog XL with 5:1 gearing doesn't stop pushing the filament for anything. I rather print a little slower because I have a heavier extruder motor and know that the print is going to finish than push everything right to the limits of its performance and have to do a lot of babysitting and restarting prints.

Edited 1 time(s). Last edit at 03/27/2017 09:33PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage March 31, 2017 10:47PM |

Registered: 11 years ago Posts: 5,780 |

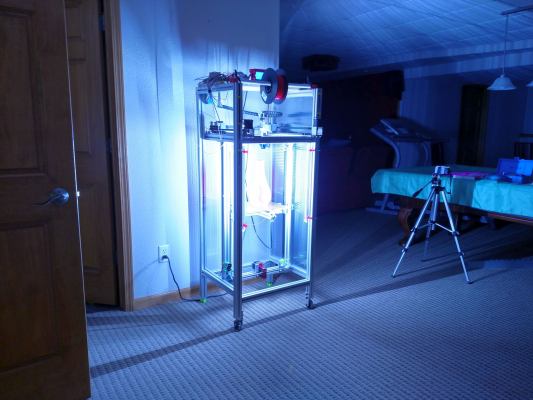

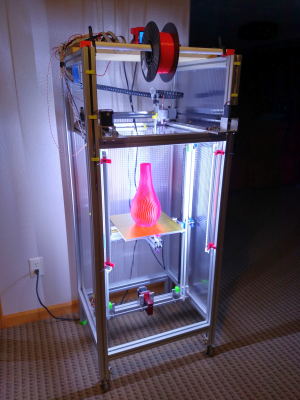

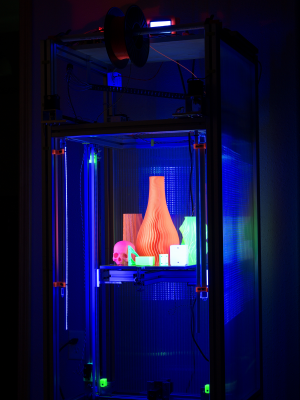

I got some dual layer polycarbonate material (via Craig's list) to use for the enclosure today and cut a piece to try the fit. The material is 8mm thick, same as the slot width in the t-slot frame. It is sort of transparent and sort of thermally insulating because of all the long air filled channels.

I'll haven't tried printing with it yet, so I don't know if it will rattle. If it does I'll jam something into the slots along with the PC.

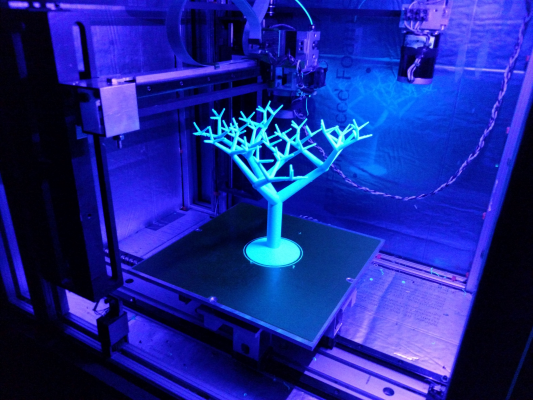

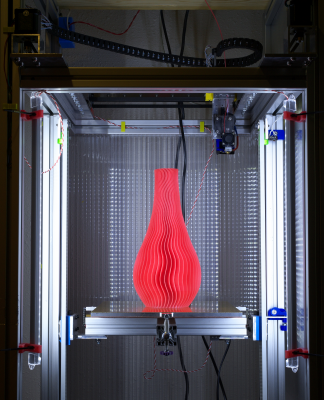

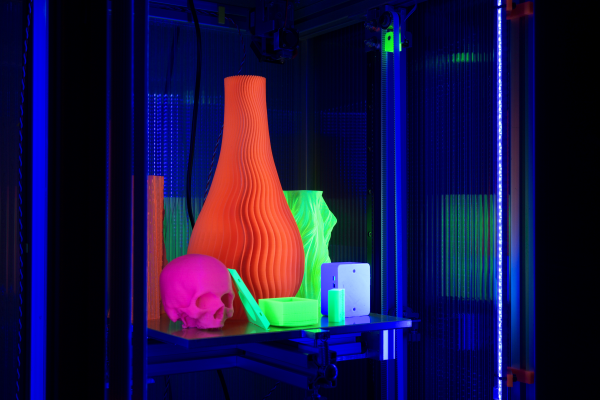

I'll be using this stuff for the left and right sides, the back, and maybe the bottom of the machine. The front of the machine will be clear, plain PC so I can see what's going on inside the printer. I plan to install white and UV LEDs to light up the print.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I'll haven't tried printing with it yet, so I don't know if it will rattle. If it does I'll jam something into the slots along with the PC.

I'll be using this stuff for the left and right sides, the back, and maybe the bottom of the machine. The front of the machine will be clear, plain PC so I can see what's going on inside the printer. I plan to install white and UV LEDs to light up the print.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage April 01, 2017 08:46AM |

Registered: 12 years ago Posts: 27 |

I'm planning to use the dual layer PC too for my large corexy too. But I plan to to bolt the PC on the outside of the entire aluminium frame (separated by a slight air gap too, using insulating washers). That way minimises heat lost from the frame and also ensures the entire frame heats uniformly to the enclosure temperature, and hence expands uniformly.

|

Re: My coreXY design is progressing to the build stage April 01, 2017 09:37AM |

Registered: 11 years ago Posts: 5,780 |

I ran a print and the PC panel didn't rattle or make any other noise that I could detect, though tapping on it with my fingers makes it rattle.

The dual layer PC isn't exactly structural stuff- it is easily deformed by the pressure of screws, etc. The plastic is very thin- I measure 0.6 mm. I think the corners of an external cover made from it would suffer a lot of damage pretty quickly. I move my printer around from time to time (laying on its back in my car) and having the PC locked inside the aluminum frame structure protects it. It also makes access to the machine a little more difficult- I have to lay the machine down and remove a top or bottom frame member to slide the PC out of the slots. I don't anticipate having to access the machine very often so right now I think I can live with the inconvenience. We'll see... The entire front side of this printer will be accessible.

Another minor inconvenience of putting the PC in the frame slots is not being able to run cables in those slots. The Z axis verticals are entirely inside the frame so I can still run cables in those slots.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The dual layer PC isn't exactly structural stuff- it is easily deformed by the pressure of screws, etc. The plastic is very thin- I measure 0.6 mm. I think the corners of an external cover made from it would suffer a lot of damage pretty quickly. I move my printer around from time to time (laying on its back in my car) and having the PC locked inside the aluminum frame structure protects it. It also makes access to the machine a little more difficult- I have to lay the machine down and remove a top or bottom frame member to slide the PC out of the slots. I don't anticipate having to access the machine very often so right now I think I can live with the inconvenience. We'll see... The entire front side of this printer will be accessible.

Another minor inconvenience of putting the PC in the frame slots is not being able to run cables in those slots. The Z axis verticals are entirely inside the frame so I can still run cables in those slots.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage April 01, 2017 05:45PM |

Registered: 8 years ago Posts: 338 |

Hi,

I am interested in using your xy carriage design in my printer due to the fact that i think i go "all metal" and still be accurate using 2" aluminum channel and a drill press. Do you have any dimensional drawings avaiable of the hole layout in the aluminum channel? Also what are the red things seen up top in this picture?

[mark.rehorst.com]

thanks!

I am interested in using your xy carriage design in my printer due to the fact that i think i go "all metal" and still be accurate using 2" aluminum channel and a drill press. Do you have any dimensional drawings avaiable of the hole layout in the aluminum channel? Also what are the red things seen up top in this picture?

[mark.rehorst.com]

thanks!

|

Re: My coreXY design is progressing to the build stage April 02, 2017 12:09AM |

Registered: 11 years ago Posts: 5,780 |

Those red things are printed ABS spacers to lift the rectangular tubing that holds the pulleys up to the same height as the other pieces of rectangular tubing. The screws that hold them down go all the way through the plastic and anchor in threaded holes in the aluminum base plates. The exact dimensions will depend on the linear guides and bearings you use for pulleys. The positions of the holes are critical for keeping the belts parallel to the X and Y axes.

When the whole thing is done, soon, I'll be posting the CAD models on my web site.

Edited 1 time(s). Last edit at 04/02/2017 11:16AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

When the whole thing is done, soon, I'll be posting the CAD models on my web site.

Edited 1 time(s). Last edit at 04/02/2017 11:16AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage April 07, 2017 12:29AM |

Registered: 11 years ago Posts: 5,780 |

I added an LCD panel to the controller and got it working, ordered some white and UV LED bars to fit into the enclosure to light everything up, and added a buck/boost converter to provide 12V at a few Amps for running things like fans and LEDs. Still trying to select the top and bottom panel materials. I haven't found one I like yet. I have a piece of 3/8" thick Corian type stuff but it's very heavy so I am reluctant to use it. Also trying to decide what to do about an enclosure for the electronics that will be mounted on top of the printer. I suppose I could print an enclosure, but it will have to be pretty big. Hmmmm. I probably should have devoted a little more time to planning that part of this design...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage April 07, 2017 03:58AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: My coreXY design is progressing to the build stage April 07, 2017 08:55PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: My coreXY design is progressing to the build stage April 07, 2017 09:56PM |

Registered: 11 years ago Posts: 5,780 |

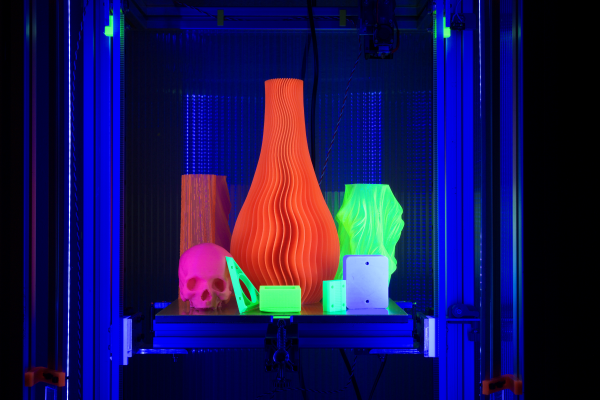

UV for use when printing fluorescent filament.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage April 08, 2017 12:00PM |

Registered: 8 years ago Posts: 338 |

|

Re: My coreXY design is progressing to the build stage April 08, 2017 12:08PM |

Registered: 11 years ago Posts: 5,780 |

Sure, it makes it print better!

Most UV LEDs, including the stuff I ordered, are actually just 400 nm blue, but high enough energy to cause fluorescence. You have to get down to 250 nm or so to sterilize anything. I think there are some LEDs that work at that wavelength but they're probably crazy expensive. Mercury vapor lights are the usual source for that wavelength.

Here's some crap being sold as an LED sterilizer: [www.ebay.com] They show the wavelength is 395-400 nm. That won't sterilize anything. It would probably be a great addition to a 3D printer though, to make fluorescent filament glow while you're printing.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Most UV LEDs, including the stuff I ordered, are actually just 400 nm blue, but high enough energy to cause fluorescence. You have to get down to 250 nm or so to sterilize anything. I think there are some LEDs that work at that wavelength but they're probably crazy expensive. Mercury vapor lights are the usual source for that wavelength.

Here's some crap being sold as an LED sterilizer: [www.ebay.com] They show the wavelength is 395-400 nm. That won't sterilize anything. It would probably be a great addition to a 3D printer though, to make fluorescent filament glow while you're printing.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage April 08, 2017 12:40PM |

Registered: 8 years ago Posts: 338 |

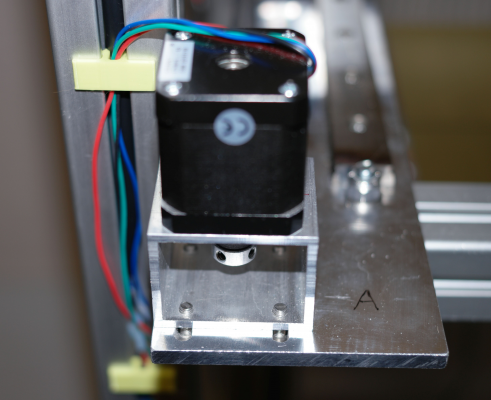

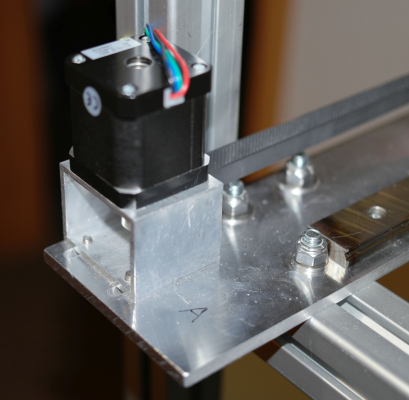

Could you take a picture of your belt tensioning method? I saw you were planning to cut slots on the motor mounts so you slide it back, is that you need up doing?

On my design, I plan to use the two inch aluminum extrusion like you are, but I'm going to mount that directly to t slot. Do you think two m5 t nuts is good enough to secure the motor? (X y axis)

On my design, I plan to use the two inch aluminum extrusion like you are, but I'm going to mount that directly to t slot. Do you think two m5 t nuts is good enough to secure the motor? (X y axis)

|

Re: My coreXY design is progressing to the build stage April 08, 2017 01:35PM |

Registered: 11 years ago Posts: 5,780 |

Here ya go. This one uses 1.5"x 2" x 1/8" aluminum tube. The beta motor uses 2" square tubing.

The slots are 14 mm long, IRIC. I used 8-32 mounting screws.

I don't know if two t-nuts will do the job to hold the motor mount, but it's easy enough to try.

Using aluminum tubing to mount the motors has several advantages. It transfers heat away from the motor, ensures that the motor axle is perpendicular to the base plate and parallel to the side plate, it's very rigid, and can be mounted to a flat surface on either side or the base. It's also pretty easy to fabricate with basic tools, and gives easy access to the drive pulley grub screws, and the material is very cheap. In my use, the mounting screw hole spacing matches the motor hole spacing and those holes serve as tool access holes for screwing the motor to the mount.

Edited 1 time(s). Last edit at 04/08/2017 01:37PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The slots are 14 mm long, IRIC. I used 8-32 mounting screws.

I don't know if two t-nuts will do the job to hold the motor mount, but it's easy enough to try.

Using aluminum tubing to mount the motors has several advantages. It transfers heat away from the motor, ensures that the motor axle is perpendicular to the base plate and parallel to the side plate, it's very rigid, and can be mounted to a flat surface on either side or the base. It's also pretty easy to fabricate with basic tools, and gives easy access to the drive pulley grub screws, and the material is very cheap. In my use, the mounting screw hole spacing matches the motor hole spacing and those holes serve as tool access holes for screwing the motor to the mount.

Edited 1 time(s). Last edit at 04/08/2017 01:37PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage April 08, 2017 03:23PM |

Registered: 8 years ago Posts: 338 |

Yes, I plan to use the 2" aluminum extrusion, like you did, then bolt that to the t slot using the t nuts.

I planned it out on inventor as much as I could suffer (mainly just to be frame size). I opted just to buy the t slot new, as I can get it cut to

Edited 1 time(s). Last edit at 04/08/2017 03:24PM by Qdeathstar.

I planned it out on inventor as much as I could suffer (mainly just to be frame size). I opted just to buy the t slot new, as I can get it cut to

Edited 1 time(s). Last edit at 04/08/2017 03:24PM by Qdeathstar.

|

Re: My coreXY design is progressing to the build stage April 16, 2017 07:11PM |

Registered: 11 years ago Posts: 5,780 |

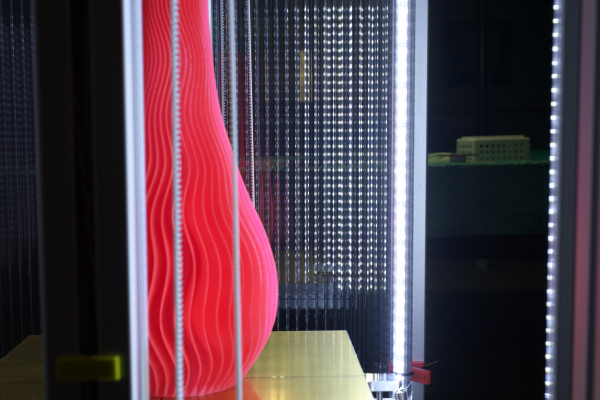

I added some white LED bars to light things up. I'm still waiting for delivery of the UV LED strips to mount along side the white LEDs for when it's printing with fluorescent filament.

I still have to finish the main enclosure and the electronics enclosure so I can button it up once and for all.

Edited 1 time(s). Last edit at 04/16/2017 07:13PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I still have to finish the main enclosure and the electronics enclosure so I can button it up once and for all.

Edited 1 time(s). Last edit at 04/16/2017 07:13PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage April 18, 2017 11:42AM |

Registered: 9 years ago Posts: 251 |

|

Re: My coreXY design is progressing to the build stage April 18, 2017 03:12PM |

Registered: 11 years ago Posts: 5,780 |

The UV LEDs arrived, but they are disappointingly unbright. The hunt continues...

I want something that floods it with light similar to the white LEDs:

Edited 1 time(s). Last edit at 04/18/2017 03:13PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I want something that floods it with light similar to the white LEDs:

Edited 1 time(s). Last edit at 04/18/2017 03:13PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage April 18, 2017 03:21PM |

Registered: 8 years ago Posts: 338 |

|

Re: My coreXY design is progressing to the build stage April 18, 2017 06:23PM |

Registered: 11 years ago Posts: 5,780 |

Yes, but most LEDs sold as UV LEDs aren't UV, they are blue to purple depending on the wavelength. I'm actually not so concerned about the lighting up the room, but I want the fluorescent print to glow really brightly.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage April 19, 2017 10:40PM |

Registered: 11 years ago Posts: 5,780 |

I mounted and hay-wired the UV LED strips to test anyway, and it's actually not too bad. Not quite as bright as I want, and I'll keep watching for something better, but for now I think it will do and I'm moving on...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage April 20, 2017 12:10AM |

Registered: 8 years ago Posts: 338 |

looks really good. I limped the way the 2 layer polycarbonate refracts the leds into a starlike pattern

If you want to go crazy hook up several of these bad boys and get blinded by science, litterally.

[www.mouser.com]

If you want to go crazy hook up several of these bad boys and get blinded by science, litterally.

[www.mouser.com]

|

Re: My coreXY design is progressing to the build stage April 20, 2017 07:14AM |

Registered: 11 years ago Posts: 5,780 |

That looks like the type of LED I want.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage May 04, 2017 01:46AM |

Registered: 10 years ago Posts: 38 |

I like the work that has been presented here and would like to build a machine this. When I have time. I have been keeping an eye out for miscellaneous parts that would go into the project. I did notice that someone on ebay is selling these linear guides.

[www.ebay.com]

They are 24mm x 430mm x 8mm. The seller wants $39.00 each. They are a little long but that is not a problem for me. A couple of things concern me. The life expectancy and stiffness? They are made of stainless steel. Also the author of the original project used a 28mm guide for the X axis. The stiffness would not be a problem as I could add a piece to increase the stiffness. And lastly what do you think about the price.

Any input is appreciated. Thank you.

[www.ebay.com]

They are 24mm x 430mm x 8mm. The seller wants $39.00 each. They are a little long but that is not a problem for me. A couple of things concern me. The life expectancy and stiffness? They are made of stainless steel. Also the author of the original project used a 28mm guide for the X axis. The stiffness would not be a problem as I could add a piece to increase the stiffness. And lastly what do you think about the price.

Any input is appreciated. Thank you.

|

Re: My coreXY design is progressing to the build stage May 04, 2017 02:20AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: My coreXY design is progressing to the build stage May 04, 2017 07:32AM |

Registered: 11 years ago Posts: 5,780 |

Good find! $60 each shipped for new old stock Japanese rails is a pretty good deal. If they are too long you can always cut them with a cut off wheel on a grinder. Don't take the bearing blocks off the rails or you may spend hours getting the balls back into the blocks.

I usd 24x8 mm rails for both the X and Y axes.

Edited 1 time(s). Last edit at 05/04/2017 07:33AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I usd 24x8 mm rails for both the X and Y axes.

Edited 1 time(s). Last edit at 05/04/2017 07:33AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage May 04, 2017 07:38AM |

Registered: 12 years ago Posts: 72 |

|

Re: My coreXY design is progressing to the build stage May 04, 2017 01:51PM |

Registered: 11 years ago Posts: 5,780 |

Their life expectancy is probably longer than yours in a 3D printer.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage May 04, 2017 07:29PM |

Registered: 8 years ago Posts: 338 |

Sorry, only registered users may post in this forum.