My coreXY design is progressing to the build stage

Posted by the_digital_dentist

|

Re: My coreXY design is progressing to the build stage January 22, 2018 03:25AM |

Registered: 8 years ago Posts: 5,232 |

Quote

SydneyDesigner

What about just using the enclosure heater to heat the entire enclosure and bed together - up to say 60-80C, as required to best suit the material being printed? In other words, not use a bed heater at all.

Do people think this would work for a good range of printed materials?...including TPU, PLA, ABS etc.?

How would you spread the heat evenly across the bed? A thick plate of aluminum spreads the heat pretty good, but with a single heat source in the center of the bed, you'd still see a difference.

|

Re: My coreXY design is progressing to the build stage January 22, 2018 08:30AM |

Registered: 11 years ago Posts: 5,780 |

I think there are several problems with that idea. First, ABS won't stick to the bed if the temperature is too low, and getting the enclosure up to 100C is going to create all sorts of other problems. Belts and motors aren't going to work well or last long, the hot end is going to need water cooling, etc.

You can do as stratasys used to do in older printers and print ABS on a sacrificial foam bed. We've tested PIR foam in Stratasys printers at the Milwaukee Makerspace and works, though it's a little softer than the foam stratasys normally uses for the purpose. Those printers heated the enclosure to 70C, and they pipe in and exhaust room air to cool the extruders.

In smaller printers with insulated enclosures, the bed heater alone (or with the addition of a lightbulb) is often adequate to heat the enclosure.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You can do as stratasys used to do in older printers and print ABS on a sacrificial foam bed. We've tested PIR foam in Stratasys printers at the Milwaukee Makerspace and works, though it's a little softer than the foam stratasys normally uses for the purpose. Those printers heated the enclosure to 70C, and they pipe in and exhaust room air to cool the extruders.

In smaller printers with insulated enclosures, the bed heater alone (or with the addition of a lightbulb) is often adequate to heat the enclosure.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage January 23, 2018 05:08AM |

Registered: 12 years ago Posts: 27 |

Thank you for your replies.

The heater heats the enclosure air (circulated by a fan) and the enclosure air heats the bed - top and bottom. So, the bed should be heated very evenly.

The limit is that the enclosure (and hence bed) can probably only go up to about 80C (motors and electronics are outside enclosure, extruders water cooled, belts are inside enclosure).

Other than ABS as above, what materials do you think I would be able to print like this at up to 80C enclosure/bed temp? I'm particularly interested in printing large, thin curvy parts (e.g. swim fins) without them warping - in flexible materials like TPUs.

Edited 2 time(s). Last edit at 01/23/2018 05:09AM by SydneyDesigner.

Quote

o_lampe

How would you spread the heat evenly across the bed? A thick plate of aluminum spreads the heat pretty good, but with a single heat source in the center of the bed, you'd still see a difference.

The heater heats the enclosure air (circulated by a fan) and the enclosure air heats the bed - top and bottom. So, the bed should be heated very evenly.

Quote

the_digital_dentist

I think there are several problems with that idea. First, ABS won't stick to the bed if the temperature is too low, and getting the enclosure up to 100C is going to create all sorts of other problems. Belts and motors aren't going to work well or last long, the hot end is going to need water cooling, etc.

You can do as stratasys used to do in older printers and print ABS on a sacrificial foam bed. We've tested PIR foam in Stratasys printers at the Milwaukee Makerspace and works, though it's a little softer than the foam stratasys normally uses for the purpose. Those printers heated the enclosure to 70C, and they pipe in and exhaust room air to cool the extruders.

In smaller printers with insulated enclosures, the bed heater alone (or with the addition of a lightbulb) is often adequate to heat the enclosure.

The limit is that the enclosure (and hence bed) can probably only go up to about 80C (motors and electronics are outside enclosure, extruders water cooled, belts are inside enclosure).

Other than ABS as above, what materials do you think I would be able to print like this at up to 80C enclosure/bed temp? I'm particularly interested in printing large, thin curvy parts (e.g. swim fins) without them warping - in flexible materials like TPUs.

Edited 2 time(s). Last edit at 01/23/2018 05:09AM by SydneyDesigner.

|

Re: My coreXY design is progressing to the build stage January 23, 2018 08:39AM |

Registered: 11 years ago Posts: 5,780 |

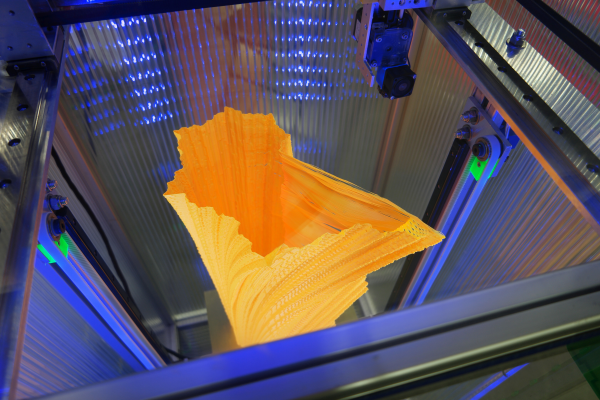

TPU sticks to a PEI bed at about 60C. I don't know if there would be any benefit to printing it inside a warm enclosure. The biggest problem with printing flexible materials like TPU is that sooner or later, depending on the geometry of the print, the print will flex due to its own weight and print quality will become very poor or fail outright. This can actually happen with ABS and PLA too, but the prints are usually bulky enough to support their own weight without flexing much. Here's an example of a 500mm tall single-walled ABS vase that got too tall/heavy to support itself. The wall was 0.4mm thick and the layers were 0.2 mm.

It might be better to print flexible materials inside a chilled enclosure.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

It might be better to print flexible materials inside a chilled enclosure.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage January 24, 2018 06:51AM |

Registered: 12 years ago Posts: 27 |

Thanks. Yes, I need to design self supporting part geometries especially for softer TPUs. Or add extra supports which can be cut off. Or possibly dual print supports in a second material.

Also need to keep the part warm enough so each new layer sticks to the previous layer.

A juggling act!

Also need to keep the part warm enough so each new layer sticks to the previous layer.

A juggling act!

|

Re: My coreXY design is progressing to the build stage January 28, 2018 06:28PM |

Registered: 11 years ago Posts: 5,780 |

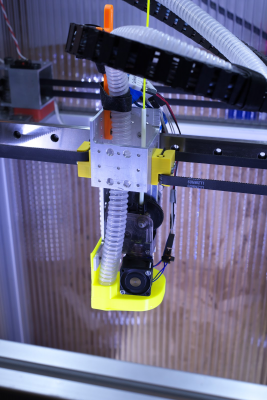

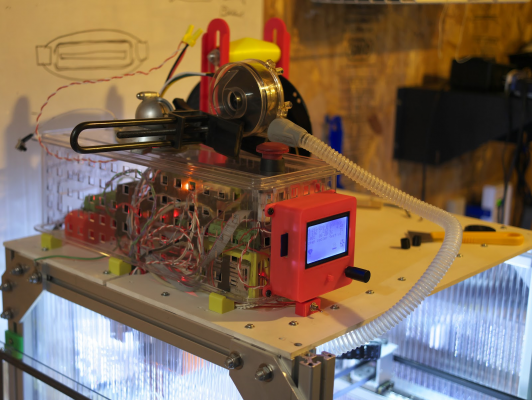

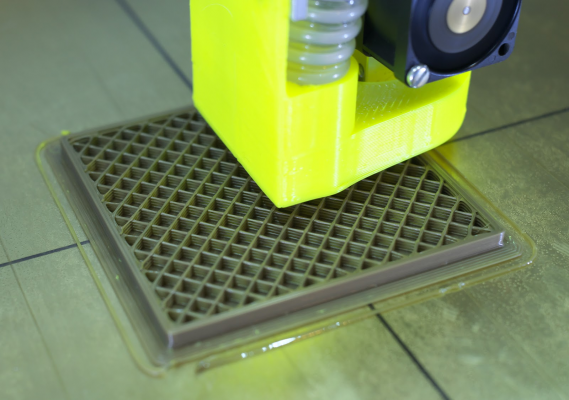

I now have remote print cooling working on UMMD. It uses a CPAP blower (a centrifugal air pump) to blow air through a hose that attaches to a nozzle on the extruder carriage. It appears to work well. All I have to do is get the settings for the volcano heater block and 0.8 mm nozzle tuned up, which has proven much more difficult than expected.

The big question: does it have any real advantages over using a blower and duct/nozzle mounted on the extruder carriage? Not sure... but it was fun to play with, and it can definitely move a LOT more air. That may be useful if you're using a large nozzle and laying down a lot of plastic.

Blog post with details here.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The big question: does it have any real advantages over using a blower and duct/nozzle mounted on the extruder carriage? Not sure... but it was fun to play with, and it can definitely move a LOT more air. That may be useful if you're using a large nozzle and laying down a lot of plastic.

Blog post with details here.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage January 29, 2018 02:54AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: My coreXY design is progressing to the build stage January 29, 2018 07:52AM |

Registered: 8 years ago Posts: 338 |

|

Re: My coreXY design is progressing to the build stage January 29, 2018 07:53AM |

Registered: 11 years ago Posts: 5,780 |

I wouldn't put a filter on an axial or radial fan that's doing the same job, so why put one on the CPAP blower? I can open the blower up and clean the impeller a lot easier than cleaning off an axial fan blade or squirrel cage...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage January 29, 2018 11:31AM |

Registered: 11 years ago Posts: 5,780 |

Quote

Qdeathstar

Does a cpap pump move the air at low pressure? That’s a really big hose... takes up quite a bit of real estate. One of the advantages of a air pump is that it blows cool air instead of hot air in the build chamber..

A pressure difference is what moves the air. In my tests it was running at less than 1/10 of its capacity. The hose is 18 mm OD, and is very light and very flexible and I used it because it was handy. It may work fine with a smaller hose or tube. The CPAP blower blows room temperature air.

It is quite a bit smaller than the squirrel cage blower I was using:

Edited 1 time(s). Last edit at 01/29/2018 03:56PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage January 29, 2018 03:53PM |

Registered: 8 years ago Posts: 5,232 |

Quote

the_digital_dentist

I wouldn't put a filter on an axial or radial fan that's doing the same job, so why put one on the CPAP blower? I can open the blower up and clean the impeller a lot easier than cleaning off an axial fan blade or squirrel cage...

I thought, it would pump so much more air, it might suck in cat's hair or dust and spread it across the print...

|

Re: My coreXY design is progressing to the build stage January 29, 2018 03:57PM |

Registered: 11 years ago Posts: 5,780 |

I suppose it's possible. We'll see. I can always add a piece of foam.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage February 02, 2018 08:37AM |

Registered: 11 years ago Posts: 5,780 |

If you want to try using one of these blowers and don't have access to a junked CPAP machine, you can get the blower (first link) for $23 or blower with driver (second link) for $35 from China.

[www.alibaba.com]

[www.alibaba.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

[www.alibaba.com]

[www.alibaba.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage February 03, 2018 07:46PM |

Registered: 8 years ago Posts: 338 |

|

Re: My coreXY design is progressing to the build stage February 04, 2018 09:17AM |

Registered: 11 years ago Posts: 5,780 |

(200 steps/ 1 motor rev) x (16 usteps/step) x (30 motor revs/1 pulley rev) x (1 pulley rev/36 pulley teeth) x (1 pulley tooth/3mm) = 888.888888... usteps/mm

It would have been better (more satisfying, anyway) to use 32 tooth pulleys (1000 usteps/mm), and that is what I thought I ordered, but when the pulleys arrived I discovered I had ordered the wrong ones. It wasn't a big enough problem to be worth spending another $30 to correct it.

Edited 3 time(s). Last edit at 02/04/2018 09:25AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

It would have been better (more satisfying, anyway) to use 32 tooth pulleys (1000 usteps/mm), and that is what I thought I ordered, but when the pulleys arrived I discovered I had ordered the wrong ones. It wasn't a big enough problem to be worth spending another $30 to correct it.

Edited 3 time(s). Last edit at 02/04/2018 09:25AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage February 04, 2018 04:45PM |

Registered: 8 years ago Posts: 338 |

|

Re: My coreXY design is progressing to the build stage February 04, 2018 06:35PM |

Registered: 11 years ago Posts: 5,780 |

I just did some calculations I should have done earlier...

Using a pulley that gives whole number steps and usteps per mm would be "nicer" than what I have now (4th column). Since nozzle sizes are typically in tenths of mm such as 0.4, 0.6, etc., layer thicknesses in multiples of 0.1 mm (and a lot of 0.05 mm multiples) end up in whole numbers for both usteps and full steps. I can either convert to GT2 belt (I have some steel core belt sitting unused) or get 40 tooth HTD_3M pulleys. Hmmmm. The pulley diameter changes will require redesigning and printing the belt clamps, not too much trouble...

Slight update: the 50 full steps/mm combos are an excellent way to go- every layer thickness that is a multiple of 20 um will be a Z motor full-step thickness. I couldn't find any 60 tooth 2mm pitch pulleys for 10 mm wide belt, so I ordered a couple 40 tooth HTD-3M pulleys and will update the Z axis when they arrive. Lunar new year is coming up so I don't expect to see them for a couple months...

What I have with 36 tooth pulleys- magic whole-step values at multiples of 0.09 mm:

What happens with a switch to 40 tooth pulleys- magic whole-step values every 0.02 um:

Edited 2 time(s). Last edit at 02/06/2018 08:14AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

motor steps/rev 200 200 200 200 200 ustepping 16 16 16 16 16 gear reduction 30 30 30 30 30 pulley teeth 60 50 48 36 40 belt pitch 2 2 2 3 3 usteps/mm 800 960 1000 888.89 800 full steps/mm 50 60 62.5 55.56 50

Using a pulley that gives whole number steps and usteps per mm would be "nicer" than what I have now (4th column). Since nozzle sizes are typically in tenths of mm such as 0.4, 0.6, etc., layer thicknesses in multiples of 0.1 mm (and a lot of 0.05 mm multiples) end up in whole numbers for both usteps and full steps. I can either convert to GT2 belt (I have some steel core belt sitting unused) or get 40 tooth HTD_3M pulleys. Hmmmm. The pulley diameter changes will require redesigning and printing the belt clamps, not too much trouble...

Slight update: the 50 full steps/mm combos are an excellent way to go- every layer thickness that is a multiple of 20 um will be a Z motor full-step thickness. I couldn't find any 60 tooth 2mm pitch pulleys for 10 mm wide belt, so I ordered a couple 40 tooth HTD-3M pulleys and will update the Z axis when they arrive. Lunar new year is coming up so I don't expect to see them for a couple months...

What I have with 36 tooth pulleys- magic whole-step values at multiples of 0.09 mm:

layer thickness full steps 0.01 0.556 0.02 1.111 0.03 1.667 0.04 2.222 0.05 2.778 0.06 3.333 0.07 3.889 0.08 4.444 0.09 5.000 0.1 5.556 0.11 6.111 0.12 6.667 0.13 7.222 0.14 7.778 0.15 8.333 0.16 8.889 0.17 9.444 0.18 10.000 0.19 10.556 0.2 11.111 0.21 11.667 0.22 12.222 0.23 12.778 0.24 13.333 0.25 13.889 0.26 14.444 0.27 15.000 0.28 15.556 0.29 16.111 0.3 16.667 0.31 17.222 0.32 17.778 0.33 18.333 0.34 18.889 0.35 19.444 0.36 20.000 0.37 20.556 0.38 21.111 0.39 21.667 0.4 22.222 0.41 22.778 0.42 23.333 0.43 23.889 0.44 24.444 0.45 25.000 0.46 25.556 0.47 26.111 0.48 26.667 0.49 27.222 0.5 27.778 0.51 28.333 0.52 28.889 0.53 29.444 0.54 30.000

What happens with a switch to 40 tooth pulleys- magic whole-step values every 0.02 um:

layer thickness full steps 0.01 0.500 0.02 1.000 0.03 1.500 0.04 2.000 0.05 2.500 0.06 3.000 0.07 3.500 0.08 4.000 0.09 4.500 0.1 5.000 0.11 5.500 0.12 6.000 0.13 6.500 0.14 7.000 0.15 7.500 0.16 8.000 0.17 8.500 0.18 9.000 0.19 9.500 0.2 10.000 0.21 10.500 0.22 11.000 0.23 11.500 0.24 12.000 0.25 12.500 0.26 13.000 0.27 13.500 0.28 14.000 0.29 14.500 0.3 15.000 0.31 15.500 0.32 16.000 0.33 16.500 0.34 17.000 0.35 17.500 0.36 18.000 0.37 18.500 0.38 19.000 0.39 19.500 0.4 20.000 0.41 20.500 0.42 21.000 0.43 21.500 0.44 22.000 0.45 22.500 0.46 23.000 0.47 23.500 0.48 24.000 0.49 24.500 0.5 25.000 0.51 25.500 0.52 26.000 0.53 26.500 0.54 27.000

Edited 2 time(s). Last edit at 02/06/2018 08:14AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage February 07, 2018 09:10AM |

Registered: 7 years ago Posts: 128 |

Obvious question for me is why the need for whole-step values does that add to accuracy?

How does this math work? I'm obviously missing something here....

200*16*30*1*1

ampapa,

Edited 1 time(s). Last edit at 02/07/2018 09:10AM by ampapa.

Quote

TDD

(200 steps/ 1 motor rev) x (16 usteps/step) x (30 motor revs/1 pulley rev) x (1 pulley rev/36 pulley teeth) x (1 pulley tooth/3mm) = 888.888888... usteps/mm

How does this math work? I'm obviously missing something here....

200*16*30*1*1

ampapa,

Edited 1 time(s). Last edit at 02/07/2018 09:10AM by ampapa.

|

Re: My coreXY design is progressing to the build stage February 07, 2018 12:55PM |

Registered: 11 years ago Posts: 5,780 |

You're missing the division by 36 teeth and 3 mm. If you check the units, they all cancel except for usteps and 1/mm

200 steps/motor rev x 16 usteps/step x 30 motor revs/ 1 pulley rev = 96000 ustep per pulley rev. 1 pulley rev moves the bed 36 teeth x 3 mm/tooth = 108 mm, so 96000/108 = 888.88888 usteps/mm

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

200 steps/motor rev x 16 usteps/step x 30 motor revs/ 1 pulley rev = 96000 ustep per pulley rev. 1 pulley rev moves the bed 36 teeth x 3 mm/tooth = 108 mm, so 96000/108 = 888.88888 usteps/mm

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage February 07, 2018 04:51PM |

Registered: 7 years ago Posts: 128 |

So wouldn't the formula be different if we have to divide?

(200 steps/ 1 motor rev) x (16 usteps/step) x (30 motor revs/1 pulley rev) / ((1 pulley rev/36 pulley teeth) x (1 pulley tooth/3mm)) = 888.888888... usteps/mm

... and what about the "whole" steps. I think you were trying to achieve whole steps ultimately...

Does that add to the accuracy of the print?

I guess I'm trying to figure out what it is that would be the ultimate setup. Does higher/lower steps improve the precision?

Edited 1 time(s). Last edit at 02/07/2018 05:02PM by ampapa.

(200 steps/ 1 motor rev) x (16 usteps/step) x (30 motor revs/1 pulley rev) / ((1 pulley rev/36 pulley teeth) x (1 pulley tooth/3mm)) = 888.888888... usteps/mm

... and what about the "whole" steps. I think you were trying to achieve whole steps ultimately...

Does that add to the accuracy of the print?

I guess I'm trying to figure out what it is that would be the ultimate setup. Does higher/lower steps improve the precision?

Edited 1 time(s). Last edit at 02/07/2018 05:02PM by ampapa.

|

Re: My coreXY design is progressing to the build stage February 07, 2018 10:30PM |

Registered: 11 years ago Posts: 5,780 |

My formula was all multiplication, but the last two terms were multiplication by fractions 1/36 and 1/3. Multiplication and division are "equivalent" order operators, so you go left to right.

If you look at it from a dimensional analysis point of view, the way I wrote the formula, all the units cancel except for usteps in the numerator and mm in the denominator, leaving a value expressed in usteps/mm

The point of using full step multiple layer thicknesses is that precision should be maximum, which minimizes Z banding due to imprecision potentially introduced by microstepping. Is it a real problem? I don't know for sure. I haven't noticed any issues when using ustepping, but the guys who use lead screws in the Z axis are always trying to use full step multiple layer thicknesses.

If you have microstepping turned on, if you use full steps layer thicknesses, there's no guarantee that the layer is going to start on a full step of the motor. In order to get the theoretically improved precision of using full step intervals, I think you have to actually drive the motor in full steps. That way when you zero the bed it gets zeroed on a full step position and then moves in those full steps. If you use microstepping, when you zero the bed, the motor may not be at a full step position, so even if you use full step multiple layer thickness, the layers may not be at full step positions. I think.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you look at it from a dimensional analysis point of view, the way I wrote the formula, all the units cancel except for usteps in the numerator and mm in the denominator, leaving a value expressed in usteps/mm

The point of using full step multiple layer thicknesses is that precision should be maximum, which minimizes Z banding due to imprecision potentially introduced by microstepping. Is it a real problem? I don't know for sure. I haven't noticed any issues when using ustepping, but the guys who use lead screws in the Z axis are always trying to use full step multiple layer thicknesses.

If you have microstepping turned on, if you use full steps layer thicknesses, there's no guarantee that the layer is going to start on a full step of the motor. In order to get the theoretically improved precision of using full step intervals, I think you have to actually drive the motor in full steps. That way when you zero the bed it gets zeroed on a full step position and then moves in those full steps. If you use microstepping, when you zero the bed, the motor may not be at a full step position, so even if you use full step multiple layer thickness, the layers may not be at full step positions. I think.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage February 08, 2018 07:59AM |

Registered: 7 years ago Posts: 128 |

|

Re: My coreXY design is progressing to the build stage February 08, 2018 10:32AM |

Registered: 11 years ago Posts: 5,780 |

1000 usteps/mm sounds nice, but that means there are 1000/16= 62.5 full steps per mm. That means full step layer thicknesses occur at 1mm/62.5= 16 um multiples. So for example, you can print in ... 0.064, 0.096,... 0.128, 0.144... 0.240 mm, etc.

800 usteps/mm results in 50 full steps per mm, with full step layer thicknesses at 20 um intervals. You can then print in ... 0.060, 0.080, 0.100, 0.120... 0.200 mm , ...

Both are more resolution in Z that you will ever need. Neither allows you to print at 0.150 mm, 0.250 mm, etc., in whole steps.

20 um intervals tend to land on nice, round, whole-step-multiple print layer thickness values. The smaller pulley will provide more torque (but at lower maximum speed) so it should be able to lift more weight on the bed, but with either pulley, the motor will be able to lift far more than it will ever have to (in my printer, anyway) as fast as it will ever need to, so it really doesn't matter.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

800 usteps/mm results in 50 full steps per mm, with full step layer thicknesses at 20 um intervals. You can then print in ... 0.060, 0.080, 0.100, 0.120... 0.200 mm , ...

Both are more resolution in Z that you will ever need. Neither allows you to print at 0.150 mm, 0.250 mm, etc., in whole steps.

20 um intervals tend to land on nice, round, whole-step-multiple print layer thickness values. The smaller pulley will provide more torque (but at lower maximum speed) so it should be able to lift more weight on the bed, but with either pulley, the motor will be able to lift far more than it will ever have to (in my printer, anyway) as fast as it will ever need to, so it really doesn't matter.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage February 10, 2018 05:12AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: My coreXY design is progressing to the build stage February 10, 2018 11:16AM |

Registered: 11 years ago Posts: 5,780 |

Mostly I have a lot of experience with them in 2 other machines. I like the ease of configuring them, and they provide adequate I/O. Reliability and documentation are good. I print from SD cards, so their limited networking performance doesn't mean much for me.

I may try a Duet at some point - I'd like to try quieter motor drivers.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I may try a Duet at some point - I'd like to try quieter motor drivers.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage February 14, 2018 08:25PM |

Registered: 7 years ago Posts: 51 |

Duet also prints from sdcard, the gcodes are not streamed from the PC. You need the fast networking speed to transfer the gcode from your pc to the local sdcard on the duet .

Having used smoothie and duet , I must say that duet is now further ahead in features than smoothieboard. And printing is so convenient now, no need to insert and remove the sdcard, just upload and print.

Having used smoothie and duet , I must say that duet is now further ahead in features than smoothieboard. And printing is so convenient now, no need to insert and remove the sdcard, just upload and print.

|

Re: My coreXY design is progressing to the build stage February 16, 2018 01:28AM |

Registered: 11 years ago Posts: 38 |

@digital_dentist I looked at Rino block and not sure how you mounted the shaft to that. Rino has 8mm hole diameter with a little groove on it. Did you cut a groove to the shaft and put there a bar or something to connect the shaft with the Rino block?

|

Re: My coreXY design is progressing to the build stage February 16, 2018 02:47AM |

Registered: 6 years ago Posts: 13 |

Quote

printman

@digital_dentist I looked at Rino block and not sure how you mounted the shaft to that. Rino has 8mm hole diameter with a little groove on it. Did you cut a groove to the shaft and put there a bar or something to connect the shaft with the Rino block?

That slot is for a keyed shaft. Basically a shaft with a matching slot then you slide a piece of keystock into the slot on the shaft, then slide the shaft into the gearbox with the key sitting in both slots. That's what locks the shaft in.

|

Re: My coreXY design is progressing to the build stage February 16, 2018 07:42AM |

Registered: 11 years ago Posts: 5,780 |

Yup, keyed shaft. I didn't have the tooling to do it, so I contacted a guy on ebay who sells short keyed shafts for Rinos and paid him about $20 (IRIC) to make a long one. The keyed shaft can still slide out of the gearbox, so I used lock rings on either side of it, though placement of the pulleys and pillow blocks at the ends of the shaft could also keep the shaft from sliding out. In my build there is space between the pillow blocks and the pulleys, so the lock rings help. There aren't any forces along the length of the shaft, so it probably wouldn't move anyway, but why take the chance? You can either print lock rings to fit at the gearbox or spacers to fit between the pulleys and pillow block bearings. Either way does the job.

When I made the heater for the enclosure I thought I might just move the gearbox toward the left side of the shaft, but then I realized the shaft key is centered so I can't move the gearbox more than about 1 cm.

Edited 1 time(s). Last edit at 02/16/2018 07:43AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

When I made the heater for the enclosure I thought I might just move the gearbox toward the left side of the shaft, but then I realized the shaft key is centered so I can't move the gearbox more than about 1 cm.

Edited 1 time(s). Last edit at 02/16/2018 07:43AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage February 16, 2018 01:01PM |

Registered: 11 years ago Posts: 5,780 |

I am now working on a worm gear reducer for a NEMA-17 motor and have ordered the parts and printed a couple different versions of the gearbox that holds it all together.

This design is for mounting on 40 mm square t-slot, but it's easily modified for any size t-slot extrusion.

It will use 8 mm output shaft, and a few, standard, cheap parts to essentially duplicate the function of the Rino ($108 shipped, from the guy who sells them on ebay) for about $30. The gear reduction will be 40:1 and the resolution will be 100 full steps per mm. The Rino in UMMD has a 164 oz-in NEMA-23 motor that I operate at a little over 1/2 its rated current. With 30:1 gear reduction it can lift at least 7.5 kg (3.5 kg bed assembly plus 4 kg of print mass), so I am confident that a NEMA-17 motor with 40:1 reduction will be able to do similar work. Very few printers would need to lift that much mass, so small NEMA-17 motors should be fine. I'll be testing it with a 36 mm motor that I have in hand.

As soon as the parts arrive I'll build one up and run some tests...

Edited 1 time(s). Last edit at 02/16/2018 02:52PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

This design is for mounting on 40 mm square t-slot, but it's easily modified for any size t-slot extrusion.

It will use 8 mm output shaft, and a few, standard, cheap parts to essentially duplicate the function of the Rino ($108 shipped, from the guy who sells them on ebay) for about $30. The gear reduction will be 40:1 and the resolution will be 100 full steps per mm. The Rino in UMMD has a 164 oz-in NEMA-23 motor that I operate at a little over 1/2 its rated current. With 30:1 gear reduction it can lift at least 7.5 kg (3.5 kg bed assembly plus 4 kg of print mass), so I am confident that a NEMA-17 motor with 40:1 reduction will be able to do similar work. Very few printers would need to lift that much mass, so small NEMA-17 motors should be fine. I'll be testing it with a 36 mm motor that I have in hand.

As soon as the parts arrive I'll build one up and run some tests...

Edited 1 time(s). Last edit at 02/16/2018 02:52PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.