My coreXY design is progressing to the build stage

Posted by the_digital_dentist

|

Re: My coreXY design is progressing to the build stage August 10, 2018 07:00PM |

Registered: 6 years ago Posts: 134 |

|

Re: My coreXY design is progressing to the build stage August 11, 2018 06:36PM |

Registered: 5 years ago Posts: 155 |

Quote

the_digital_dentist

XCR3D (also Chinese made) hot-end

I was looking at the XCR3D, in the german ebay is a comment that the cartridge heater is ok for 350 °C, but the hotend shall be used only up to 240 °C, a high temperature version will be available in the future.

Seems to be the same version like on alixepress, as he advertises using a german imported cnc machine in both offers. Just wanted to let you know to be careful with the temperature.

|

Re: My coreXY design is progressing to the build stage August 11, 2018 09:41PM |

Registered: 11 years ago Posts: 5,780 |

Quote

piper3d

the_digital_dentist, you have some epic job documented in this thread. Multiple innovative solutions. People may read it as a book on how to design your own printer. Congratulations on a great job!

Thanks, it has been a long road...

Quote

JoergS5

Quote

the_digital_dentist

XCR3D (also Chinese made) hot-end

I was looking at the XCR3D, in the german ebay is a comment that the cartridge heater is ok for 350 °C, but the hotend shall be used only up to 240 °C, a high temperature version will be available in the future.

Seems to be the same version like on alixepress, as he advertises using a german imported cnc machine in both offers. Just wanted to let you know to be careful with the temperature.

I'm not sure what would limit the upper temperature except that it came with a thermistor to sense the temperature. The heatbreak is SS, and the teflon liner stops well above the narrow part of the heat break. The heater cartridge has glass/silicone insulation on the leads, though I suppose it may have a problem at very high temperatures. I have installed an E3D PT100 sensor that should be good to 350C or so. So far I mostly print ABS and it has been fine. I am planning to try some PC in the near future.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage August 16, 2018 01:08AM |

Registered: 11 years ago Posts: 5,780 |

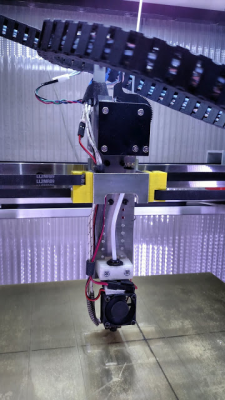

UMMD has a new extruder carriage. I didn't like the motor hanging so far below the X axis guide rail, like a big pendulum, so I put the motor immediately above the bearing block and put the hot-end and its fan down low. I had to add a Bowden tube about 100 mm long to make it work, but doing so allowed me to center the nozzle and then recenter the bed in the Z axis frame. The motor and hot-end are mounted on a 4.75mm thick aluminum plate, and the belts are anchored to a piece of 2" x 1.5" aluminum tubing with 1/8" thick walls. The hot-end is secured by a printed ABS clamp. There is a lot of room on the back side of the plate, near the hot-end to mount a print cooling fan and duct.

I'll be modifying it a little, but expect this to be the more-or-less final form for the extruder carriage.

I found some problems with the Aluminum Titan extruder when I took it apart so I could mount it on the new carriage. The lever for the pinch roller fits over the motor shaft just like the plastic part that E3D uses. The steel shaft of the motor was chewing up the aluminum and the inside of the extruder had a lot of fine black dust from it. Maybe that part needs a bronze bushing. Also, the seal on the pinch roller bearing came out of the bearing and was preventing it from turning properly.

Edited 1 time(s). Last edit at 08/16/2018 07:22AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I'll be modifying it a little, but expect this to be the more-or-less final form for the extruder carriage.

I found some problems with the Aluminum Titan extruder when I took it apart so I could mount it on the new carriage. The lever for the pinch roller fits over the motor shaft just like the plastic part that E3D uses. The steel shaft of the motor was chewing up the aluminum and the inside of the extruder had a lot of fine black dust from it. Maybe that part needs a bronze bushing. Also, the seal on the pinch roller bearing came out of the bearing and was preventing it from turning properly.

Edited 1 time(s). Last edit at 08/16/2018 07:22AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage August 16, 2018 08:31PM |

Registered: 8 years ago Posts: 338 |

|

Re: My coreXY design is progressing to the build stage August 22, 2018 04:24AM |

Registered: 6 years ago Posts: 13 |

Quote

piper3d

the_digital_dentist, you have some epic job documented in this thread. Multiple innovative solutions. People may read it as a book on how to design your own printer. Congratulations on a great job!

I basically used this thread along with his blog as an instruction book while I was designing and building my modified d-bot. I really do feel like a book would be a good idea. Having all the information and design methodology(?) from this thread organized in a more readable way would be epic. Mr. Rehorst does such a good job explaining engineering principles that even a flunkie chicken-plant mechanic like me was able to understand and implement them. Seriously, dd, write a book.

It's super easy with Amazon self-publishing. If nothing else, monetize your blog. I feel like I should compensate you somehow for all the ideas I stole from you while I was building my printer.

It's super easy with Amazon self-publishing. If nothing else, monetize your blog. I feel like I should compensate you somehow for all the ideas I stole from you while I was building my printer.[www.wildbot3d.com]

|

Re: My coreXY design is progressing to the build stage August 23, 2018 10:22AM |

Registered: 9 years ago Posts: 251 |

Quote

hayseed_byte

Quote

piper3d

the_digital_dentist, you have some epic job documented in this thread. Multiple innovative solutions. People may read it as a book on how to design your own printer. Congratulations on a great job!

I basically used this thread along with his blog as an instruction book while I was designing and building my modified d-bot. I really do feel like a book would be a good idea. Having all the information and design methodology(?) from this thread organized in a more readable way would be epic. Mr. Rehorst does such a good job explaining engineering principles that even a flunkie chicken-plant mechanic like me was able to understand and implement them. Seriously, dd, write a book.It's super easy with Amazon self-publishing. If nothing else, monetize your blog. I feel like I should compensate you somehow for all the ideas I stole from you while I was building my printer.

+1 from a long time lurker of this thread.

Edited 1 time(s). Last edit at 08/23/2018 10:22AM by widespreaddeadhead.

|

Re: My coreXY design is progressing to the build stage August 23, 2018 11:33PM |

Registered: 11 years ago Posts: 5,780 |

Thanks for the comments. I have been working on monetizing the blog a little by getting ads placed in it, but I have yet to see any money from it. The information I post is only of interest to a relative few people and will never get enough page views to generate any meaningful funds.

I wrote a blog post specifically on corexy layout that I think will prevent a lot of errors if people actually see it before they start building their printers. Maybe I should start a separate thread here and just put the same stuff in a post or two, since people are more likely to see it here than on my blog.

UMMD, the big sand table, and me will be at the Milwaukee MakerFaire on the last weekend of September. This will be the 5th year, and we typically get 30-40k people, so it's a pretty big deal. If you come, stop by the Milwaukee Makerspace booth and say hello. I might even let you buy me a beer...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I wrote a blog post specifically on corexy layout that I think will prevent a lot of errors if people actually see it before they start building their printers. Maybe I should start a separate thread here and just put the same stuff in a post or two, since people are more likely to see it here than on my blog.

UMMD, the big sand table, and me will be at the Milwaukee MakerFaire on the last weekend of September. This will be the 5th year, and we typically get 30-40k people, so it's a pretty big deal. If you come, stop by the Milwaukee Makerspace booth and say hello. I might even let you buy me a beer...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My coreXY design is progressing to the build stage August 27, 2018 03:24AM |

Registered: 6 years ago Posts: 13 |

I think a tip jar might be better suited than ads on your blog. Getting a few pennies per visit probably won't add up to much. However, most of your readers are probably a lot like me. Someone stumbling through building/upgrading a 3d printer with no formal training/education in engineering. Personally, I'd be happy to drop some cash into a digital tip jar whenever I learn something useful or when you solve a problem I've been facing but didn't know how to approach. If there had been an easy way to throw you $10 every time you helped me over a hurdle the last six months, you'd be $200 or so richer just from me. And I'm pretty sure I'm not alone in this.

[www.wildbot3d.com]

[www.wildbot3d.com]

|

Re: My coreXY design is progressing to the build stage August 27, 2018 10:32AM |

Registered: 8 years ago Posts: 338 |

|

Re: My coreXY design is progressing to the build stage August 27, 2018 05:27PM |

Registered: 6 years ago Posts: 13 |

|

Re: My coreXY design is progressing to the build stage September 17, 2018 08:29PM |

Registered: 5 years ago Posts: 71 |

Is the nozzle placed far from the linear rail on purpose (for counter-balancing the extruder)? I'm always fretting about reducing the lever arm/distance from the nozzle to the rail to try to reduce high acceleration artifacts, though your video of 200mm/s speed looks impressive for a large machine.

|

Re: My coreXY design is progressing to the build stage September 17, 2018 09:55PM |

Registered: 11 years ago Posts: 5,780 |

There are two reasons the extruder carriage is so long. I put the Z belt pulleys at the top of the X axis, and the XY stage mechanics are on top of the plates instead of under it, so the extruder carriage needs to be extended so the nozzle can reach the bed. I also don't like not being able to see what's going on at the nozzle when the printer runs (like my cubex machine). The original design had the entire extruder hanging below the X axis bearing block like a big, heavy pendulum. I recently redesigned it and now the extruder sits immediately above the X axis bearing block and the hot-end is mounted below on a 4.5 mm thick piece of aluminum- see the photo in the above post.

I see a lot of designs for extruder carriages that look really pretty and very professional compared to mine, but if I need to get at something to fix it, it's all right there and easy to work on. I do a lot of experimenting with extruders, hot-ends, and cooling fans, so it's easy to fit different parts on the extruder carriage.

If I put a few hours of work into it I can probably shorten the length of that extension by 20 or 30 mm, but it's performing quite well and I'm not currently inclined to attack it. There are other projects I want to work on like this

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I see a lot of designs for extruder carriages that look really pretty and very professional compared to mine, but if I need to get at something to fix it, it's all right there and easy to work on. I do a lot of experimenting with extruders, hot-ends, and cooling fans, so it's easy to fit different parts on the extruder carriage.

If I put a few hours of work into it I can probably shorten the length of that extension by 20 or 30 mm, but it's performing quite well and I'm not currently inclined to attack it. There are other projects I want to work on like this

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.