extruder ripples in outer wall

Posted by ekaggrat

|

extruder ripples in outer wall May 04, 2016 03:18AM |

Registered: 11 years ago Posts: 364 |

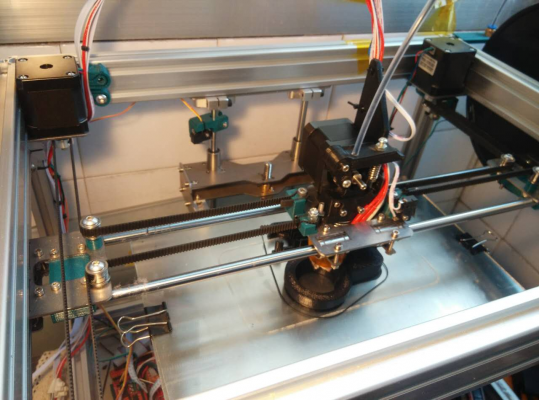

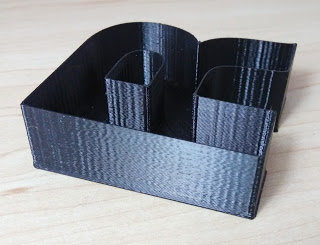

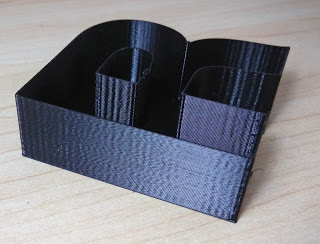

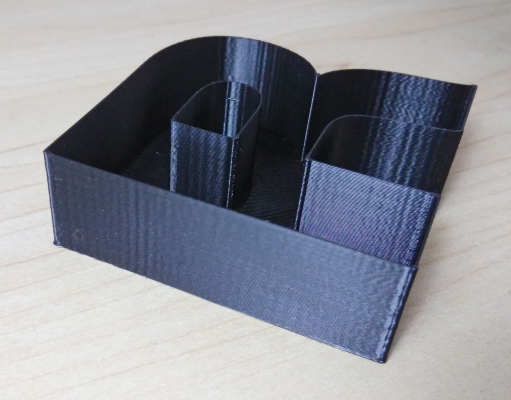

or my corexy i tried a direct drive extruder with a mk8 hobb . I am getting these wierd ripples in the prints. ( the rippples are visible in the plan like inconstant extrusion. The steps per mm for the motor are right, the hot end is new and not clogged. the nozzle is 0.5mm so the force needed to extrude is not so much ( u can easily push with 2 fingres ) . Up until now i have been using geared extruders and never had this problem

I tried 2 different motors and drivers ..

motor 1 :

12v

27 ohm

40mm nema 17

dont have any more details

motor 2

6 v

7.5 ohm

7.5 mh

0.8 amp

drivers :

1 drv 8825 in 1/16 mode

2 a 4988 in 1/16 mode

motor 1 works better with drv 8825 but has the ripples like in the pics, with the a4988 the ripples are double the amplitude( deeper and higher )

motor 2 works better with a4988 but again with the same ripples as the pics . With the drv 8825 the ripples are doubled

controller :

ramps 1.4

drivers for x and y sd 6128 in 1/32 mode

hot end e3d v6 with 0.5 mm nozzle

print z resolution 0.25

firmware repetier ( downloaded from online configuration wizard )

steps per mm for x, y : 160

steps per mm z : 400

steps per mm e : 140

any idea why this is happening ?

i did the following tests

printed with ALL DIRECT DRIVE MK8 ).4 nozzle e3d

a4988 stepper drivers at 0.8A ... ripples exist

drv 8825 1/32 0.3A-0.8A

sd 6128 1/32 0.8A

Then I did tests with a 1:3 geared extruder with mk8 hobb 0.4 e3d nozzle

Last i printed with twisting the belts so that the back side of the belt goes over the pulleys

I even tried two separate hot ends and two separate power supplyies . One a 6 Amp and the other a 30 AMp

the ripples exist in all prints..

they are least with the belt reversed and the print with a flow ratio of 150%

It looks like a under extrusion issue ( like on other forums ) but the measured extrution with is coming to 0.44 mm and the specified width is 0.4mm (auto in slic3r)

a4988

sd 6128 at 1/32 and 0.8 A

geared extruder with belt revered on pulley and sd 6128

[lh3.googleusercontent.com]

detail

I am stumped that the frequency of the pulsing is same for the direct and the geared extruder.. If it was the extruder creating the problem the frequency would vary with the gearing of the motor. Reversing the belts and increasing the flow helps but doent remove it completely

firmware : repetier

slicr : slic3r 1.1.7

Any guesses whats going on?

thanks

I tried 2 different motors and drivers ..

motor 1 :

12v

27 ohm

40mm nema 17

dont have any more details

motor 2

6 v

7.5 ohm

7.5 mh

0.8 amp

drivers :

1 drv 8825 in 1/16 mode

2 a 4988 in 1/16 mode

motor 1 works better with drv 8825 but has the ripples like in the pics, with the a4988 the ripples are double the amplitude( deeper and higher )

motor 2 works better with a4988 but again with the same ripples as the pics . With the drv 8825 the ripples are doubled

controller :

ramps 1.4

drivers for x and y sd 6128 in 1/32 mode

hot end e3d v6 with 0.5 mm nozzle

print z resolution 0.25

firmware repetier ( downloaded from online configuration wizard )

steps per mm for x, y : 160

steps per mm z : 400

steps per mm e : 140

any idea why this is happening ?

i did the following tests

printed with ALL DIRECT DRIVE MK8 ).4 nozzle e3d

a4988 stepper drivers at 0.8A ... ripples exist

drv 8825 1/32 0.3A-0.8A

sd 6128 1/32 0.8A

Then I did tests with a 1:3 geared extruder with mk8 hobb 0.4 e3d nozzle

Last i printed with twisting the belts so that the back side of the belt goes over the pulleys

I even tried two separate hot ends and two separate power supplyies . One a 6 Amp and the other a 30 AMp

the ripples exist in all prints..

they are least with the belt reversed and the print with a flow ratio of 150%

It looks like a under extrusion issue ( like on other forums ) but the measured extrution with is coming to 0.44 mm and the specified width is 0.4mm (auto in slic3r)

a4988

sd 6128 at 1/32 and 0.8 A

geared extruder with belt revered on pulley and sd 6128

[lh3.googleusercontent.com]

detail

I am stumped that the frequency of the pulsing is same for the direct and the geared extruder.. If it was the extruder creating the problem the frequency would vary with the gearing of the motor. Reversing the belts and increasing the flow helps but doent remove it completely

firmware : repetier

slicr : slic3r 1.1.7

Any guesses whats going on?

thanks

|

Re: extruder ripples in outer wall May 05, 2016 07:12AM |

Registered: 9 years ago Posts: 1,873 |

Hi Ekaggrat,

I followed the link from the "what causes..." thread. I don't think this is the drv missing steps problem that the diodes can help with. The lines in your photos always seem to be vertical, where as the missing steps problem produces diagonal lines. The slope of the lines changes with extrusion volume because it's tied to the rotation of the extruder. The fact that your lines always seem to be vertical suggest it's something to do with the XY motion mechanics.

I followed the link from the "what causes..." thread. I don't think this is the drv missing steps problem that the diodes can help with. The lines in your photos always seem to be vertical, where as the missing steps problem produces diagonal lines. The slope of the lines changes with extrusion volume because it's tied to the rotation of the extruder. The fact that your lines always seem to be vertical suggest it's something to do with the XY motion mechanics.

|

Re: extruder ripples in outer wall May 05, 2016 08:48AM |

Registered: 13 years ago Posts: 268 |

|

Re: extruder ripples in outer wall May 05, 2016 08:55AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: extruder ripples in outer wall May 05, 2016 10:44PM |

Registered: 8 years ago Posts: 916 |

Deltas have this problem all the time. My small delta has this problem a lot more than my large one. I don't think that it's extruder related, it's more likely positioning error, more specifically, the frame resonating at certain speeds of X/Y positioning.

You can:

1) Use 0.9 degree steppers instead of 1.8 degree steppers

2) Use 32 bit microstepping instead of 16

3) Slow down print speeds

4) Ensure that as little of the frame resonates as possible

5) Add the 'diode hack' to your stepper drivers

Good luck.

You can:

1) Use 0.9 degree steppers instead of 1.8 degree steppers

2) Use 32 bit microstepping instead of 16

3) Slow down print speeds

4) Ensure that as little of the frame resonates as possible

5) Add the 'diode hack' to your stepper drivers

Good luck.

|

Re: extruder ripples in outer wall May 06, 2016 03:51AM |

Registered: 11 years ago Posts: 364 |

|

Re: extruder ripples in outer wall May 06, 2016 04:32AM |

Registered: 8 years ago Posts: 916 |

|

Re: extruder ripples in outer wall May 06, 2016 08:10AM |

Registered: 11 years ago Posts: 5,780 |

Try tweaking the extruder motor current.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: extruder ripples in outer wall August 11, 2016 02:11AM |

Registered: 8 years ago Posts: 11 |

|

Re: extruder ripples in outer wall August 11, 2016 02:22PM |

Registered: 8 years ago Posts: 3,525 |

The only time I've seen this is with very low extruder steps per mm (80-100) and is a pulsing extruder but its odd that it still happens with gearing. I get very small ripples on the kossel mini with e3d titan using 3:1 gearing, 290 steps/mm but I always assumed this was frame resonance maybe it's still pulsing. Maybe try 5:1. I got this on my corexy with mk8 extruder but not anymore with flex3drive it's using 1500 steps/mm at 40:1 gearing and 1/8th microstepping.

Edited 1 time(s). Last edit at 08/11/2016 02:23PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Edited 1 time(s). Last edit at 08/11/2016 02:23PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: extruder ripples in outer wall August 12, 2016 03:11AM |

Registered: 7 years ago Posts: 168 |

|

Re: extruder ripples in outer wall August 12, 2016 05:32AM |

Registered: 11 years ago Posts: 364 |

i tried changing the current but nothing helped. I finally found a sweet spot at 40mm/s perimeter speed which shows minimal ripples. what i figured was that the ripples showup in models with more segments like in curved surfaces. I think it has to do something with the acceleration and de acceleration of the motor when going though the segments. I have been using the printer since last 3 months and printing a lot.. I gave up fixing the problem as i can't seem to find the cause .Maybe it is a combination of mechanical issues and firmware issues doing wierd things. I will soon be upgrading the xy motion to linear rails and then see if the extra stiffness helps... My printer can print a lot faster if only the damn ripples wouldnt show up at higher speeds!!!..

|

Re: extruder ripples in outer wall August 12, 2016 06:35AM |

Registered: 8 years ago Posts: 346 |

I have some suggestion of a test you can do:

The idea of the test is to check if the problem is with the extruder or x, y motions.

print a 20/10 mm test cube with a 45 degree rotation, this will allow to print all the outside wall using only one motor.

if you still have ripples, them is probably extruder problems.

The idea of the test is to check if the problem is with the extruder or x, y motions.

print a 20/10 mm test cube with a 45 degree rotation, this will allow to print all the outside wall using only one motor.

if you still have ripples, them is probably extruder problems.

|

Re: extruder ripples in outer wall August 12, 2016 11:33AM |

Registered: 10 years ago Posts: 236 |

Sorry, only registered users may post in this forum.