What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys?

Posted by realthor

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 04:30AM |

Registered: 10 years ago Posts: 14,672 |

Quote

realthor

Do you guys see a major problem/concern with Normally Open circuits? I think I remember seeing a circuit that makes a NO circuit a NC one by adding some electronics wizardry (nothing too complicated, but for me everything electronics is complicated).

Two reasons to prefer normally closed endstop switches:

1. The wiring from NO endstop switches is prone to capacitive pickup from other cables (e.g. stepper motor cables), causing false endstop detection, especially when using electronics with high impedance endstop inputs and no filtering (e.g. RAMPS). With NC endstops you would need inductive puckup to cause false triggering, but that is much easier to control.

2. If a connection goes bad, NO endstops will fail to trigger, so during homing the carriage or bed will not stop at the end, possibly causing damage in some designs unless the motor current is reduced during homing.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Anonymous User

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 05:00AM |

Quote

dc42

Quote

realthor

Do you guys see a major problem/concern with Normally Open circuits? I think I remember seeing a circuit that makes a NO circuit a NC one by adding some electronics wizardry (nothing too complicated, but for me everything electronics is complicated).

Two reasons to prefer normally closed endstop switches:

1. The wiring from NO endstop switches is prone to capacitive pickup from other cables (e.g. stepper motor cables), causing false endstop detection, especially when using electronics with high impedance endstop inputs and no filtering (e.g. RAMPS). With NC endstops you would need inductive puckup to cause false triggering, but that is much easier to control.

2. If a connection goes bad, NO endstops will fail to trigger, so during homing the carriage or bed will not stop at the end, possibly causing damage in some designs unless the motor current is reduced during homing.

Common sens and the rule since way way back

One thing that makes me uneasy on these printers is there is not much separation between power and signal, no shielding, same power rail, no well thought of ground etc... OK we don't deal with microV and microA close by, yet these chips runs at a low 3.3 V !

Even the connectors are not fit to carry the currents mainly of the hotbed.

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 05:13AM |

Registered: 10 years ago Posts: 14,672 |

Quote

MKSA

One thing that makes me uneasy on these printers is there is not much separation between power and signal, no shielding, same power rail, no well thought of ground etc... OK we don't deal with microV and microA close by, yet these chips runs at a low 3.3 V !

Even the connectors are not fit to carry the currents mainly of the hotbed.

That's certainly true for some boards, especially Arduino-based boards and boards built to a very low price. Arduinos break one of the fundamental rules of mixed signal design i.e. provide separate analog and digital grounds.

OTOH the Duet does use a separate analog ground connection (Vssa), which avoids issues with ground noise and ground offset on the analog inputs. The Duet 0.8.5 uses a heated bed terminal block rated at 32A, so hardly inadequate for a 12A bed heater.

Edited 1 time(s). Last edit at 05/13/2016 05:13AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 05:42AM |

Registered: 9 years ago Posts: 1,035 |

Quote

dc42

2. If a connection goes bad, NO endstops will fail to trigger, so during homing the carriage or bed will not stop at the end, possibly causing damage in some designs unless the motor current is reduced during homing.

With static cables and connectors it is quite unlikely for that to happen. And with 3D printers the motors will skip steps before damaging anything in the XY plane (not Z, that can damage the printhead, nozzle, etc). So with this regard it's quite safe to have NO systems. Can the false triggering be somehow avoided (cables in a corexy can be routed pretty much one by one through the various tubes and channels).

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 07:07AM |

Registered: 10 years ago Posts: 14,672 |

Using shielded endstop switch cables would avoid most of the risk of capacitive pickup with NO switches. But what is your objection to NC switches?

Edited 1 time(s). Last edit at 05/13/2016 07:07AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 05/13/2016 07:07AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 07:26AM |

Registered: 9 years ago Posts: 1,035 |

No objection really, maybe a bit more complexity and the fact that the simple low tech devices aren't that good (mechanical microswitches for ex). It's no secret that I like the low-tech approach of the instant direct-contact of the nozzle2bed approach for Z.

So I am in pursuit of similar versions of X and Y. Y is quite simple, like I said before, bearing closes the circuit when it touches two contacts on the Y Rod's clamp. X Endstop are not that easy to offload from the X carriage. All this can be done with NO mentality in mind but that increases a bit the complexity although it's more elegant (the way I imagine doing it - some sort of 2D renishaw-stule contact breaking)

Edited 1 time(s). Last edit at 05/13/2016 08:02AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

So I am in pursuit of similar versions of X and Y. Y is quite simple, like I said before, bearing closes the circuit when it touches two contacts on the Y Rod's clamp. X Endstop are not that easy to offload from the X carriage. All this can be done with NO mentality in mind but that increases a bit the complexity although it's more elegant (the way I imagine doing it - some sort of 2D renishaw-stule contact breaking)

Edited 1 time(s). Last edit at 05/13/2016 08:02AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Anonymous User

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 09:47AM |

Quote

realthor

No objection really, maybe a bit more complexity and the fact that the simple low tech devices aren't that good (mechanical microswitches for ex). It's no secret that I like the low-tech approach of the instant direct-contact of the nozzle2bed approach for Z.

So I am in pursuit of similar versions of X and Y. Y is quite simple, like I said before, bearing closes the circuit when it touches two contacts on the Y Rod's clamp. X Endstop are not that easy to offload from the X carriage. All this can be done with NO mentality in mind but that increases a bit the complexity although it's more elegant (the way I imagine doing it - some sort of 2D renishaw-stule contact breaking)

Different thing here. Talking about ENDSTOPs, which are BETTER to be NO.

The Z endstop is most of the time used to provide an accurate Z 0 (X 0 and Y 0 are not that important here) in addition to its role to set the limit to prevent a crash.

If you want an other mean to determine the Z 0 with for example a probe on the print head to provide ABL, indeed but you better make sure not to sacrifice reliability..

As a matter of fact this has been discussed in an other thread and I advised you to really BUILD, TEST and give the results. Without that, there is nothing.

Flashy 3D prototypes and animations are interesting, a fantastic tool for real life designers but prove NOTHING otherwise. Plenty of example on this forum of apparently jaw dropping "designs" hailed by a whole crowd of admirers which are in fact worthless.

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 09:59AM |

Registered: 9 years ago Posts: 83 |

The general consensus seems to be that while noise can impersonate a switch closing, it can't impersonate a switch opening.

So NC is in theory better than NO. Unless your wiring is clean, twisted, and relatively noise free (and doesn't run parallel to stepper wires).

Also, if you wire in series with NO -> NO -> NO -> NO, then closing any particular switch will not complete your circuit. Conversely, using all NC, any switch opening will break the circuit, causing the entire circuit to go "open".

Most mechanical endstops have three wires-- NO, NC and ground-- pick two.

So NC is in theory better than NO. Unless your wiring is clean, twisted, and relatively noise free (and doesn't run parallel to stepper wires).

Also, if you wire in series with NO -> NO -> NO -> NO, then closing any particular switch will not complete your circuit. Conversely, using all NC, any switch opening will break the circuit, causing the entire circuit to go "open".

Most mechanical endstops have three wires-- NO, NC and ground-- pick two.

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 10:01AM |

Registered: 9 years ago Posts: 1,035 |

Quote

MKSA

Different thing here. Talking about ENDSTOPs, which are BETTER to be NO.

Why is that? It is really the first time I hear that. Crashes can happen in XY as well...

Quote

MKSA

If you want an other mean to determine the Z 0 with for example a probe on the print head to provide ABL, indeed but you better make sure not to sacrifice reliability..

ABL=?

Quote

MKSA

As a matter of fact this has been discussed in an other thread and I advised you to really BUILD, TEST and give the results. Without that, there is nothing.

Yeah, it's a bit tiring

...as I've been patient and explained at least as many times why I can't for the time being. But well...

...as I've been patient and explained at least as many times why I can't for the time being. But well...RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 10:21AM |

Registered: 9 years ago Posts: 1,035 |

Quote

grat

Also, if you wire in series with NO -> NO -> NO -> NO, then closing any particular switch will not complete your circuit. Conversely, using all NC, any switch opening will break the circuit, causing the entire circuit to go "open".

You're completely right. I mixed them up in my previous post.

Actually I would build them in parallel for the NO and in series for NC, exactly as you say.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 11:04AM |

Registered: 9 years ago Posts: 1,035 |

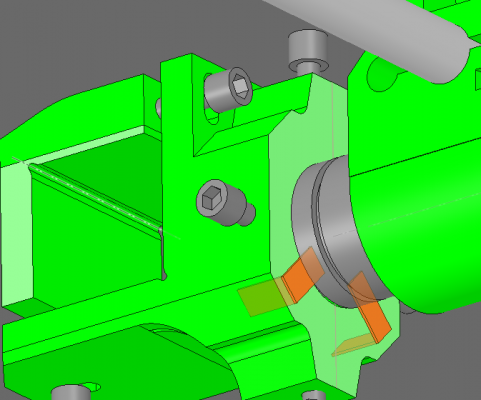

This is a NO circuit. A Contact-Tabs pair on each Y Rods Clamp as in this picture. Bearing touches, contact made => endstop triggered. Same for the other Y on this side. Either of them touches first (hopefully both at the same time but pretty unlikely) the endstop triggers. If this was done in series then both should touch to close the loop, which is not that bad either as the motors will pull until both bearings are in contact with the tabs on their side. Then some shielded twisted pair wires will run through the aluminum tubes frame.

Edited 1 time(s). Last edit at 05/13/2016 11:05AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 11:19AM |

Registered: 10 years ago Posts: 14,672 |

Building and testing is necessary and all very well, but the best designs also consider "what will be the effect if XXX happens?". For example:

- What will happen if there is a bad crimp connection in the endstop switch circuit?

- If you use exposed contacts instead of a microswitch, what will happen if the contacts pick up dirt?

Examples in electronics abound:

- What will happen if you wire the endstop switches to the wrong pins of the endstop switch connector? [Answer: With RAMPS, the answer is typically a blown voltage regulator on the Arduino.]

- What will happen if you use the same header pin strip to carry both hot end heater and thermistor wires, and a user offsets the connector by one pin? [That was a possibility on the Duet 0.6 before RepRapPro switched from header pin strips to Molex connectors.]

- What will happen if you plug the cable on to the 3-pin connector on one of my IR sensor boards the wrong way round? [Answer: Nothing nasty, because I went through the "what if?" exercise and I designed it to be tolerant of connector reversal.]

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

- What will happen if there is a bad crimp connection in the endstop switch circuit?

- If you use exposed contacts instead of a microswitch, what will happen if the contacts pick up dirt?

Examples in electronics abound:

- What will happen if you wire the endstop switches to the wrong pins of the endstop switch connector? [Answer: With RAMPS, the answer is typically a blown voltage regulator on the Arduino.]

- What will happen if you use the same header pin strip to carry both hot end heater and thermistor wires, and a user offsets the connector by one pin? [That was a possibility on the Duet 0.6 before RepRapPro switched from header pin strips to Molex connectors.]

- What will happen if you plug the cable on to the 3-pin connector on one of my IR sensor boards the wrong way round? [Answer: Nothing nasty, because I went through the "what if?" exercise and I designed it to be tolerant of connector reversal.]

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 11:48AM |

Registered: 9 years ago Posts: 1,035 |

Quote

dc42

Building and testing is necessary and all very well, but the best designs also consider "what will be the effect if XXX happens?". For example:

- What will happen if there is a bad crimp connection in the endstop switch circuit?

I'm not very technical but with normal microswitches you still have to do the wiring right? That would be the same situation.

- If you use exposed contacts instead of a microswitch, what will happen if the contacts pick up dirt?

That's a tough one... didn't think of that. Pointy/rounded instead of flat would be better in that case. Also running both Y Clamps Contacts in parallel ensures that at least one makes contact should dirt build up on one of them to a point that it doesn't let current pass.

Examples in electronics abound:

- What will happen if you wire the endstop switches to the wrong pins of the endstop switch connector? [Answer: With RAMPS, the answer is typically a blown voltage regulator on the Arduino.]

Like above, that is not a property of the switch but the board.

- What will happen if you use the same header pin strip to carry both hot end heater and thermistor wires, and a user offsets the connector by one pin? [That was a possibility on the Duet 0.6 before RepRapPro switched from header pin strips to Molex connectors.]

Now that i know ...

So what is about Molex connectors that prevents offsetting?

- What will happen if you plug the cable on to the 3-pin connector on one of my IR sensor boards the wrong way round? [Answer: Nothing nasty, because I went through the "what if?" exercise and I designed it to be tolerant of connector reversal.]

Well, you are a master of your stuff, I on the other hand...

Edited 4 time(s). Last edit at 05/13/2016 01:38PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Anonymous User

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 01:28PM |

Quote

realthor

Quote

MKSA

Different thing here. Talking about ENDSTOPs, which are BETTER to be NO.

Why is that? It is really the first time I hear that. Crashes can happen in XY as well...

Quote

MKSA

If you want an other mean to determine the Z 0 with for example a probe on the print head to provide ABL, indeed but you better make sure not to sacrifice reliability..

ABL=?

Quote

MKSA

As a matter of fact this has been discussed in an other thread and I advised you to really BUILD, TEST and give the results. Without that, there is nothing.

Yeah, it's a bit tiring...as I've been patient and explained at least as many times why I can't for the time being. But well...

Gee, you don't understand why when DC42 explained it just a few posts above. (OK, I press the wrong letter. NC, I had Normally On in my head and anyway, all I make is correct,)

BTW, don't you think you would make a better use of your time making and testing instead of drawing "nice" 3D models based on which concept, experience BTW ? Because, frankly, I had look at them !

Remember, "wow it looks fine" is NOT a proof of concept. And it is NOT to the community to prove it is good or wrong, the burden is yours.

DC42 gave you a good example of how it works in real life.

OK, I am done.

Edited 2 time(s). Last edit at 05/13/2016 01:49PM by MKSA.

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 03:47PM |

Registered: 9 years ago Posts: 1,035 |

I am not after fights here MKSA, the first one was a genuine question. Also the second, what is ABL? See, I accept people have different views and I really wanted NO to be better, because that's why I was after. Some people here in the forums have a hard time to understand that others can be very different and tend to put everybody in the same pot. I spend a lot of time out of my home/town/country so I am left with mostly designing, asking, educating myself, reading, etc.

So rather then proving such a short temper please try to understand that. I don't expect you to design as much as I do because you are different, have access to tools and like tinkering more than designing. I simply accept that.

Edit: about the community, as much as I love the community concept, it's not quite like that. When someone asked that I do some design to fit their situation I did it from scratch. Because I enjoyed it. It wasn't his burden, it was OUR burden. Now that's community

Edited 2 time(s). Last edit at 05/13/2016 05:17PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

So rather then proving such a short temper please try to understand that. I don't expect you to design as much as I do because you are different, have access to tools and like tinkering more than designing. I simply accept that.

Edit: about the community, as much as I love the community concept, it's not quite like that. When someone asked that I do some design to fit their situation I did it from scratch. Because I enjoyed it. It wasn't his burden, it was OUR burden. Now that's community

Edited 2 time(s). Last edit at 05/13/2016 05:17PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 04:57PM |

Registered: 11 years ago Posts: 5,780 |

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 05:00PM |

Registered: 9 years ago Posts: 1,035 |

Quote

the_digital_dentist

ABL = auto bed leveling

yeah... it didn't click.

[www.acronymfinder.com]

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 14, 2016 12:31AM |

Registered: 9 years ago Posts: 31 |

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 14, 2016 02:09AM |

Registered: 9 years ago Posts: 1,035 |

Quote

os3dp

I somehow had an old page. I posted but didn't see ALL the other posts before.

-os3dp

Funny, cause I got the mail with your post yet I don't see it here...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 14, 2016 02:36AM |

Registered: 9 years ago Posts: 1,035 |

As with most things a software solution is the best. Not only that software reducing the current while homing would prevent any damage if something was broken, but a software solution alone can replace the X and Y endstops alone. It would work like this:

- current is reduced by such amount that when the Y carriages hit the end points they "keep going", skipping steps easily (just as a torque adjustable cordless drill, when you set the dial so it skips at the right amount of force to prevent damaging the screw head)

- software knows the size of your bed (hard coded)

- printer goes for that amount of steps and then double it (what if it really was at the other side and it didn't know it). So in the ideal case it will go twice as far as it should but, by having a low current in the motors, it will hit the end and spend the other half of the distance skipping steps. In the worst case scenario it would start from the end and skip the steps for the whole "virtual" distance.

- printer comes back to the Home position for that axis by the distance that is hardcoded in your settings. basically homing. This can be done for all axes, but for Z it wouldn't matter much as you will have some sort of probe anyway to do the ABL .

.

How difficult would be in software such a setup?

Anyway for an NO circuit, reducing the current during homing would be enough to prevent catastrophic damages. That or sizing your parts so that the motors will skip steps if they hit an end even at full power (not that difficult with 3D printers torque needs, but as the desired speed of the printhead increases, so is the needed torque and so the above should be implemented - also needs digitally adjustable stepper motors).

I've found the digital current settings in Marlin & Repetier:

Marlin: Configuration_adv.h setting called DIGIPOT_MOTOR_CURRENT

Repetier: Configuration.h setting called MOTOR_CURRENT

Now if these are hard-coded values, how can they be altered during homing? This might not be as difficult of a task as I think.

Edited 2 time(s). Last edit at 05/14/2016 03:12AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

- current is reduced by such amount that when the Y carriages hit the end points they "keep going", skipping steps easily (just as a torque adjustable cordless drill, when you set the dial so it skips at the right amount of force to prevent damaging the screw head)

- software knows the size of your bed (hard coded)

- printer goes for that amount of steps and then double it (what if it really was at the other side and it didn't know it). So in the ideal case it will go twice as far as it should but, by having a low current in the motors, it will hit the end and spend the other half of the distance skipping steps. In the worst case scenario it would start from the end and skip the steps for the whole "virtual" distance.

- printer comes back to the Home position for that axis by the distance that is hardcoded in your settings. basically homing. This can be done for all axes, but for Z it wouldn't matter much as you will have some sort of probe anyway to do the ABL

.

. How difficult would be in software such a setup?

Anyway for an NO circuit, reducing the current during homing would be enough to prevent catastrophic damages. That or sizing your parts so that the motors will skip steps if they hit an end even at full power (not that difficult with 3D printers torque needs, but as the desired speed of the printhead increases, so is the needed torque and so the above should be implemented - also needs digitally adjustable stepper motors).

I've found the digital current settings in Marlin & Repetier:

Marlin: Configuration_adv.h setting called DIGIPOT_MOTOR_CURRENT

Repetier: Configuration.h setting called MOTOR_CURRENT

Now if these are hard-coded values, how can they be altered during homing? This might not be as difficult of a task as I think.

Edited 2 time(s). Last edit at 05/14/2016 03:12AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 14, 2016 01:40PM |

Registered: 9 years ago Posts: 31 |

Quote

realthor

I've found the digital current settings in Marlin & Repetier:

Marlin: Configuration_adv.h setting called DIGIPOT_MOTOR_CURRENT

Repetier: Configuration.h setting called MOTOR_CURRENT

Now if these are hard-coded values, how can they be altered during homing? This might not be as difficult of a task as I think.

Those settings will work if you have a controller board that is capable of making use of it.

RAMPS - Not a chance

Duet - I really think so

Others - not sure

-os3dp

P.S. My other post talked about NC circuits and why you would use them and why I would ONLY use them (IE. Broken wires) which was already discussed.

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 14, 2016 04:24PM |

Registered: 9 years ago Posts: 1,035 |

Boards with digital current control:

Rambo

Azteeg X3 Mini

Duet (most likely)

Boards with manual current control:

RAMPS

Brainwave Pro

Azteeg X5 (optional)

(http://matterhackers.dozuki.com/Guide/Tuning+Motor+Current/37)

Personal opinion: for static cables/switches wires breaking is very unlikely + with reduced current during homing (the way I explained above) even so the risk would be minimal.

Edited 1 time(s). Last edit at 05/14/2016 04:25PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Rambo

Azteeg X3 Mini

Duet (most likely)

Boards with manual current control:

RAMPS

Brainwave Pro

Azteeg X5 (optional)

(http://matterhackers.dozuki.com/Guide/Tuning+Motor+Current/37)

Personal opinion: for static cables/switches wires breaking is very unlikely + with reduced current during homing (the way I explained above) even so the risk would be minimal.

Edited 1 time(s). Last edit at 05/14/2016 04:25PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Anonymous User

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 15, 2016 04:08AM |

Quote

realthor

I am not after fights here MKSA, the first one was a genuine question. Also the second, what is ABL? See, I accept people have different views and I really wanted NO to be better, because that's why I was after. Some people here in the forums have a hard time to understand that others can be very different and tend to put everybody in the same pot. I spend a lot of time out of my home/town/country so I am left with mostly designing, asking, educating myself, reading, etc.

So rather then proving such a short temper please try to understand that. I don't expect you to design as much as I do because you are different, have access to tools and like tinkering more than designing. I simply accept that.

Edit: about the community, as much as I love the community concept, it's not quite like that. When someone asked that I do some design to fit their situation I did it from scratch. Because I enjoyed it. It wasn't his burden, it was OUR burden. Now that's community

Sorry, you don't "design" in the engineering sense, you design as a artist, a fashion designer, someone who does animation for movies. It is all fine as long as it stays in the computer but it would mostly fail in the real world.

You don't learn like that, in fact, it is even worse, you learn bad habits and false concepts.

You don't learn to drive a car by playing on a computer.

To design involves theory AND practice. A "design" starts in your head, on a sheet of paper, computation, CAD .... all together.

If you don't have the possibility to do things, then read, you will learn more in books than "designing" as you do.

As for your question above: "How difficult would be in software such a setup?" , my answer is simple DO IT then propose your software for someone to try it. You only need a computer and you have one !

DO THINGs, THEN talk about them.

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 15, 2016 04:53AM |

Registered: 9 years ago Posts: 1,035 |

noted.

noted.RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 15, 2016 04:59AM |

Registered: 10 years ago Posts: 14,672 |

Quote

realthor

As with most things a software solution is the best. Not only that software reducing the current while homing would prevent any damage if something was broken, but a software solution alone can replace the X and Y endstops alone. It would work like this:

- current is reduced by such amount that when the Y carriages hit the end points they "keep going", skipping steps easily (just as a torque adjustable cordless drill, when you set the dial so it skips at the right amount of force to prevent damaging the screw head)

- software knows the size of your bed (hard coded)

- printer goes for that amount of steps and then double it (what if it really was at the other side and it didn't know it). So in the ideal case it will go twice as far as it should but, by having a low current in the motors, it will hit the end and spend the other half of the distance skipping steps. In the worst case scenario it would start from the end and skip the steps for the whole "virtual" distance.

- printer comes back to the Home position for that axis by the distance that is hardcoded in your settings. basically homing. This can be done for all axes, but for Z it wouldn't matter much as you will have some sort of probe anyway to do the ABLwinking smiley.

How difficult would be in software such a setup?

Anyway for an NO circuit, reducing the current during homing would be enough to prevent catastrophic damages. That or sizing your parts so that the motors will skip steps if they hit an end even at full power (not that difficult with 3D printers torque needs, but as the desired speed of the printhead increases, so is the needed torque and so the above should be implemented - also needs digitally adjustable stepper motors).

I've found the digital current settings in Marlin & Repetier:

Marlin: Configuration_adv.h setting called DIGIPOT_MOTOR_CURRENT

Repetier: Configuration.h setting called MOTOR_CURRENT

Now if these are hard-coded values, how can they be altered during homing? This might not be as difficult of a task as I think.

Reducing motor current during homing is easy using a Duet, you just need to put appropriate M906 commands in the homing files on the SD card. The only tricky thing is that you need to know what currents to restore when homing is completed. If there is sufficient demand, I will change the firmware to allow motor current to be reduced to a percentage of normal, then it can easily be restored to 100% without knowing the actual motor current.

I tried this once on my delta printer. I use a Z probe to autocalibrate after homing, so the homing only needed to be accurate to about half a millimetre. It worked, but it was still noisy when driving the carriages against the stops, and of course homing took the same length of time as the worst-case even if the printer was almost at the home position already. My conclusion was that it is an option for making a very low cost printer, but you wouldn't want to use it otherwise.

Some motor drivers have built-in stall detection. Using such drivers, this scheme would be more practical.

Edited 2 time(s). Last edit at 05/15/2016 05:03AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 15, 2016 06:44AM |

Registered: 9 years ago Posts: 1,035 |

Quote

dc42

I tried this once on my delta printer. I use a Z probe to autocalibrate after homing, so the homing only needed to be accurate to about half a millimetre. It worked, but it was still noisy when driving the carriages against the stops, and of course homing took the same length of time as the worst-case even if the printer was almost at the home position already. My conclusion was that it is an option for making a very low cost printer, but you wouldn't want to use it otherwise.

Did you do it only for noise reduction purposes?

I am thinking no endstops at all besides the Z probe, so that it will be come simples, less wires, less vitamins, less visual clutter, all by doing the homing the way I explained before: reduce current so that hitting the wall will not bend anything, then don't stop immediately the motors until the "perceived" traveled distance is twice the length of the real distance, then start counting the steps on the way back, until the hardcoded distance is achieved.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 15, 2016 06:16PM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

No objection really, maybe a bit more complexity and the fact that the simple low tech devices aren't that good (mechanical microswitches for ex). It's no secret that I like the low-tech approach of the instant direct-contact of the nozzle2bed approach for Z.

rthor - listen to dc42's advice (and os3dp's - just spotted his reply about using NC switches, too). on the other hand, i do notice you're questioning things so that you get to learn more, which is great to see. most microswitches have both NC and NO on them: the switch is spring-loaded to flip between them both. i've never actually seen a single-pole, single-throw microswitch - they're pretty much all double-throw. please don't assume that everything will go perfectly! copper could even just break inside a wire if it's bent back and forwards enough times (such as being mounted on a moving object... such as a carriage or a printhead or a carriage end). do you _really_ want that one piece of wire being broken to cause a cascade of extra damage? baaaaad....

Edited 1 time(s). Last edit at 05/15/2016 06:21PM by lkcl.

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 15, 2016 06:19PM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

Bearing touches, contact made => endstop triggered.

bleughh. except if you have grease or dirt on the outside of the bearing(s). you should see how insanely quickly dirt builds up on rods and surfaces here in the apartment i live in for the next 2 weeks anyway. it's by the sea, and the sheer amount of grit and dirt covers everything in only a few days. so the design you came up with assumes perfect environmental conditions everywhere that *you* believe the printer will be operated. assumptions are the mother of all f***-ups....

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 16, 2016 12:38AM |

Registered: 9 years ago Posts: 1,035 |

Nono, i've kind of given up that idea -I understood about the NO shortcomings and the exposed contacts risks- ... was focusing on switchless homing by reducing the motor current so it hits the wall, skipping steps as it thinks it's still moving, until enough coverage has been traversed to be sure it's there at the end of the rods, then coming back and counting the steps on its way.

Edited 1 time(s). Last edit at 05/16/2016 12:39AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Edited 1 time(s). Last edit at 05/16/2016 12:39AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 16, 2016 05:12AM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

Nono, i've kind of given up that idea -I understood about the NO shortcomings and the exposed contacts risks- ... was focusing on switchless homing by reducing the motor current so it hits the wall, skipping steps as it thinks it's still moving, until enough coverage has been traversed to be sure it's there at the end of the rods, then coming back and counting the steps on its way.

.... blerrgh! ingenious idea but one that has me kinda shuddering at the calibration you'd need to perform, and the testing - how many printers are you planning to get through during the testing phase?

hey i know - how about, instead of changing the current (which you can do with RepRapFirmware anyway) you change the microstepping rate to something mad like 1/256? my main objection to the "bang it against the wall" idea is that it's not very accurate, you'd get juddering down the belt, you'd be relying on the elastic properties of the belt as well and it really might not like the large steps when subjected to tension. i know they survive wall-banging but it's not a nice sound. buuut if you're using silly-ridiculously-accurate microstepping, not only would the torque be reduced but the accuracy would go up, and, also, you'd be forced to run at a much slower speed.

hey i know - how about, instead of changing the current (which you can do with RepRapFirmware anyway) you change the microstepping rate to something mad like 1/256? my main objection to the "bang it against the wall" idea is that it's not very accurate, you'd get juddering down the belt, you'd be relying on the elastic properties of the belt as well and it really might not like the large steps when subjected to tension. i know they survive wall-banging but it's not a nice sound. buuut if you're using silly-ridiculously-accurate microstepping, not only would the torque be reduced but the accuracy would go up, and, also, you'd be forced to run at a much slower speed.for the z-axis... the thought of banging the z-bed into things... you'd better have a good bed design! or have just a z-probe.

Sorry, only registered users may post in this forum.