What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys?

Posted by realthor

|

What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 05, 2016 03:12AM |

Registered: 9 years ago Posts: 1,035 |

Hi guys, I have a question about endstops. IMHO X and Y endstops don't need that angstrom accuracy whereas the Z endstop needs a bit more consideration (for repeatability, etc) but all in all they are there just to prevent the printhead and bed from hitting sides and if one doesn't provide switches on all sides of the axes it is used for calculating the maximum perimeter the printhead is allowed to move.

Having these said I see mechanical switches a still valid option as simplicity/cost is the lowest while providing enough at least for the X and Y.

For Z most likely a probe can be used for a very precise and repeatable Z endstop (also used in bed leveling) so is another endstop still needed?

Regarding the placement of the endstops, what is your experience? What areas of the corexy are best to position the endstops?

Thanks.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Having these said I see mechanical switches a still valid option as simplicity/cost is the lowest while providing enough at least for the X and Y.

For Z most likely a probe can be used for a very precise and repeatable Z endstop (also used in bed leveling) so is another endstop still needed?

Regarding the placement of the endstops, what is your experience? What areas of the corexy are best to position the endstops?

Thanks.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 05, 2016 04:59AM |

Registered: 8 years ago Posts: 346 |

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 05, 2016 06:38AM |

Registered: 9 years ago Posts: 1,035 |

Ok, for Z and Y you can do that. What about X? Most likely the endstop will be on te X Carriage itself with cables coming together with the other cables coming to the heater/etc.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 05, 2016 07:03AM |

Registered: 8 years ago Posts: 346 |

The obvious place for the x endstop is the carriage, but is not the best place.

In case of my printed i would remove the x endstops from the carriage and put both or only the min endstop one of the printed x or y motor support.

The zero positions will change with this setup. Orther place is to fix the x endstop to one of the front 2020 bar.

the other x and z are stationary and do not give trouble.

result: a little less weight on the carriage, less 4 cables moving with the carriage and remove problem of breaking the electric cables over time. The cable breaking happens pretty frequently, already need to solder 2 times...

Edited 1 time(s). Last edit at 05/05/2016 07:05AM by filipeCampos.

In case of my printed i would remove the x endstops from the carriage and put both or only the min endstop one of the printed x or y motor support.

The zero positions will change with this setup. Orther place is to fix the x endstop to one of the front 2020 bar.

the other x and z are stationary and do not give trouble.

result: a little less weight on the carriage, less 4 cables moving with the carriage and remove problem of breaking the electric cables over time. The cable breaking happens pretty frequently, already need to solder 2 times...

Edited 1 time(s). Last edit at 05/05/2016 07:05AM by filipeCampos.

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 05, 2016 07:38AM |

Registered: 9 years ago Posts: 1,035 |

Fixed end stops can be achieved if you manage to have a homing routine that does home first Z, then Y and then X, X being, like you suggest, somewhere on the frame so that the X carriage touches it instead of touching the Y carriage. And all other values to be inferred by software based on constants for bed size/etc.

THis way all 3 endstops can be placed in the same area (one corner of the frame), having all cables easily routed to the controlbox.

But it introduces the risk that in case that something goes wrong during normal operations, there are no endstops for the X carriage to trigger if steps have been slipped so you'll end up with the X carriage locking itself into the Y carriage and the motor skipping steps until you intervene.

Edited 1 time(s). Last edit at 05/05/2016 07:40AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

THis way all 3 endstops can be placed in the same area (one corner of the frame), having all cables easily routed to the controlbox.

But it introduces the risk that in case that something goes wrong during normal operations, there are no endstops for the X carriage to trigger if steps have been slipped so you'll end up with the X carriage locking itself into the Y carriage and the motor skipping steps until you intervene.

Edited 1 time(s). Last edit at 05/05/2016 07:40AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 05, 2016 09:05AM |

Registered: 10 years ago Posts: 14,672 |

Worth noting that on a Cartesian printer, an IR or similar head-mounted probe can be used not only for bed level compensation (if desired) and Z homing, but also for homing one of the other axis. This is done by having a sensor tab just off the edge of the printable area. The Ormerod printer does this, so it has a homing switch for the Y axis only.

On a CoreXY design, I think it may be possible to come up with a scheme whereby the probe is used for homing all 3 axes, so no endstop switches are needed at all.

Another trick that has been used on a delta printer with no endstop switches at all is to reduce the motor current during homing, and then let them stall against mechanical stops. This results in a possible error of up to 1 full step. but running auto calibration using the Z probe compensates for that.

Edited 1 time(s). Last edit at 05/05/2016 09:08AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

On a CoreXY design, I think it may be possible to come up with a scheme whereby the probe is used for homing all 3 axes, so no endstop switches are needed at all.

Another trick that has been used on a delta printer with no endstop switches at all is to reduce the motor current during homing, and then let them stall against mechanical stops. This results in a possible error of up to 1 full step. but running auto calibration using the Z probe compensates for that.

Edited 1 time(s). Last edit at 05/05/2016 09:08AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 05, 2016 10:07AM |

Registered: 9 years ago Posts: 1,035 |

The third option is software-only and it'll have to be implemented in firmware so there is not much we can do (other than coding).

The other two sound interesting, I'd like to hear (see) more about it if you (@dc42) or anybody else has some more details.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

The other two sound interesting, I'd like to hear (see) more about it if you (@dc42) or anybody else has some more details.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 06, 2016 04:58PM |

Registered: 10 years ago Posts: 651 |

What about something like a set of IR Break Beam Sensors? Kind of like the sensors on a Garage Door, if your Cat (carriage) runs under the garage door, the beam is broken and ends top is triggered. Have both them mounted static on the frame.

Edit: Maybe something like this?

https://www.adafruit.com/product/2168

Edited 2 time(s). Last edit at 05/06/2016 05:07PM by FA-MAS.

Edit: Maybe something like this?

https://www.adafruit.com/product/2168

Edited 2 time(s). Last edit at 05/06/2016 05:07PM by FA-MAS.

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 07, 2016 06:21AM |

Registered: 9 years ago Posts: 1,035 |

The question is about precision and repeatability. Following the same train of thought I am thinking about an analog-ish way to achieve the same. A similar example would have a wire that the cat pushes when trying to get out the door and that wire pulls a switch. It would be a high rigidity wire (maybe spectra) that goes around the XY stage and which is pushed by both the Y carriages when they get to the end of the rod and by the X carriage when it gets to the end of the X rods. By slightly pushing the wire (which will be under tension), a renishaw probe-like device, having the wire attached to the end of the probe, will register even the smallest over-tension when the wire is pushed by the carriages. Sounds pretty complicated but in fact is quite easy to do and can mostly be printed. Again same question. Can it achieve the desired repeatability/precision?

Now I wait for some in this forums to counterattack, but this would be a more "rep-rap"-ish way of doing it.

Now I wait for some in this forums to counterattack, but this would be a more "rep-rap"-ish way of doing it.

Edited 1 time(s). Last edit at 05/07/2016 08:09AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Now I wait for some in this forums to counterattack, but this would be a more "rep-rap"-ish way of doing it.

Now I wait for some in this forums to counterattack, but this would be a more "rep-rap"-ish way of doing it.Edited 1 time(s). Last edit at 05/07/2016 08:09AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 07, 2016 09:49AM |

Registered: 10 years ago Posts: 14,672 |

In a Cartesian or CoreXY printer, you don't need the X and Y endstop switches to be highly repeatable - unless you plan to implement pause/power down/power up/restart functionality, or something similar that means you need to home the X and Y axes in the middle of a print. So it really doesn't matter what sort of switch you use. The Z axis is a different matter.

A head-mounted Z probe can be used to home the Z axis, and can also be used for bed level compensation if desired (and possibly for homing the other axes too).

Edited 1 time(s). Last edit at 05/07/2016 09:49AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

A head-mounted Z probe can be used to home the Z axis, and can also be used for bed level compensation if desired (and possibly for homing the other axes too).

Edited 1 time(s). Last edit at 05/07/2016 09:49AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 07, 2016 09:55AM |

Registered: 8 years ago Posts: 776 |

if you are using RepRapFirmware, you do not need to do any coding, nor will you ever need to recompile the firmware. you can write it entirely as g-code. replace homeall.g, homex.g, homey.g and homez.g - very very straightforward.Quote

realthor

The third option is software-only and it'll have to be implemented in firmware so there is not much we can do (other than coding).

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 07, 2016 12:16PM |

Registered: 9 years ago Posts: 1,035 |

Quote

dc42

In a Cartesian or CoreXY printer, you don't need the X and Y endstop switches to be highly repeatable - unless you plan to implement pause/power down/power up/restart functionality, or something similar that means you need to home the X and Y axes in the middle of a print. So it really doesn't matter what sort of switch you use. The Z axis is a different matter.

A head-mounted Z probe can be used to home the Z axis, and can also be used for bed level compensation if desired (and possibly for homing the other axes too).

Most people want to have some sort of bed leveling probe and if that's one thing that will be there then not using it to home all axes seems like a waste. But again, most people look for an Induction probe which makes the X carriage quite heavy so if that can be made detachable and used for all axes homing then for less than 10moneys one could solve all wire moving issues and the bad looks of microswitches/etc hung all over the printer.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 07, 2016 03:37PM |

Registered: 10 years ago Posts: 14,672 |

Quote

realthor

Most people want to have some sort of bed leveling probe and if that's one thing that will be there then not using it to home all axes seems like a waste. But again, most people look for an Induction probe which makes the X carriage quite heavy so if that can be made detachable and used for all axes homing then for less than 10moneys one could solve all wire moving issues and the bad looks of microswitches/etc hung all over the printer.

If one of the advantages of CoreXY is supposed to be high speed, then making the print head heavier by adding an inductive probe seems like a rather daft thing to do, given that alternative low-mass probes are available.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 07, 2016 04:04PM |

Registered: 9 years ago Posts: 1,035 |

Unless there will be a competing (in price) option most people will go the sub 10moneys route of a heavier induction probe. And because I am also interested in the technology to change toolheads, having it as a detachable toolhead could be an improvement for many printers out there.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Anonymous User

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 10, 2016 02:41PM |

Real machines have their end stops just where the end stops ! In fact, three, one sometimes more sophisticated than a microswitch, to tell the computer, stop !, the second, a real switch, that cuts the motor power in case the computer was deaf, then a mechanical buffer to really prevent the slide from crashing real bad when all else failed !

As for the bed leveling probe, when you really need it and that is the first question to ask yourself, DC42 is right, the lighter the better. I am amazed when I see how heavy and unnecessarily complex the extruder are ! Some even "decorates" them I started with a bulky direct extruder of about 650g and trim it down to 270g carriage included.

Edited 1 time(s). Last edit at 05/10/2016 02:44PM by MKSA.

As for the bed leveling probe, when you really need it and that is the first question to ask yourself, DC42 is right, the lighter the better. I am amazed when I see how heavy and unnecessarily complex the extruder are ! Some even "decorates" them I started with a bulky direct extruder of about 650g and trim it down to 270g carriage included.

Edited 1 time(s). Last edit at 05/10/2016 02:44PM by MKSA.

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 10, 2016 05:03PM |

Registered: 11 years ago Posts: 5,780 |

If you really want to keep the extruder carriage light, build the machine so the bed stays level. Then you won't need a leveling probe, the wiring, the firmware options, or the debugging time you are going to have to spend on getting it to work. The reason the bed needs releveling all the time is because the machine is poorly built. If you build it better, so it doesn't need frequent releveling, you'll get better print quality out of it.

I think speed is grossly over-rated. I have seen a lot of videos of machines printing really fast, but I have never seen a really high quality print that was printed really fast. We build 3D printers because we want to make stuff that might otherwise be a PITA to make. After I print something that has taken a while, I sometimes think about how I would have made the object if I didn't use a 3D printer, and how long that would have taken. Then I think it's OK that the printer took 14 hours to make something that I could not have made otherwise in less than a month or not at all. A 3D printer will work for many hours without a break, even while you sleep, and will produce a very high quality output, if you give it time to do its job. If you print so much and you're in such a rush to start the next print that you have to accept poor print quality, maybe you need a second printer.

Edited 1 time(s). Last edit at 05/10/2016 05:09PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I think speed is grossly over-rated. I have seen a lot of videos of machines printing really fast, but I have never seen a really high quality print that was printed really fast. We build 3D printers because we want to make stuff that might otherwise be a PITA to make. After I print something that has taken a while, I sometimes think about how I would have made the object if I didn't use a 3D printer, and how long that would have taken. Then I think it's OK that the printer took 14 hours to make something that I could not have made otherwise in less than a month or not at all. A 3D printer will work for many hours without a break, even while you sleep, and will produce a very high quality output, if you give it time to do its job. If you print so much and you're in such a rush to start the next print that you have to accept poor print quality, maybe you need a second printer.

Edited 1 time(s). Last edit at 05/10/2016 05:09PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 10, 2016 05:08PM |

Registered: 9 years ago Posts: 1,035 |

Quote

the_digital_dentist

If you really want to keep the extruder carriage light, build the machine so the bed stays level. Then you won't need a leveling probe, the wiring, the firmware options, or the debugging time you are going to have to spend on getting it to work.

I think speed is grossly over-rated. I have seen a lot of videos of machines printing really fast, but I have never seen a really high quality print that was printed really fast. We build 3D printers because we want to make stuff that might otherwise be a PITA to make. After I print something that has taken a while, I sometimes think about how I would have made the object if I didn't use a 3D printer, and how long that would have taken. Then I think it's OK that the printer took 14 hours to make something that I could not have made otherwise in less than a month or not at all. A 3D printer will work for many hours without a break, even while you sleep, and will produce a very high quality output, if you give it time to do its job. If you print so much and you're in such a rush to start the next print that you have to accept poor print quality, maybe you need a second printer.

I completely agree. We're all trying to get our printers as rigid as we can/afford but truth is that most printers lack in the rigidity department. Those need, depending on the state they are in, a leveling once in a while and that's why I believe a detachable probe is desirable. I've kind of given up on the on-carriage probe.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 10, 2016 05:30PM |

Registered: 10 years ago Posts: 14,672 |

Even if you don't need to do bed levelling because your bed is flat and the gantry rigid enough not to sag by more than 0.05mm as the head moves, a Z probe is still useful to establish the Z=0 point just before starting the print.

Making the probe removable adds more complication, and IMO is pointless when the on-carriage probe weighs only 2g.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Making the probe removable adds more complication, and IMO is pointless when the on-carriage probe weighs only 2g.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 10, 2016 10:34PM |

Registered: 9 years ago Posts: 1,035 |

Quote

dc42

Even if you don't need to do bed levelling because your bed is flat and the gantry rigid enough not to sag by more than 0.05mm as the head moves, a Z probe is still useful to establish the Z=0 point just before starting the print.

Making the probe removable adds more complication, and IMO is pointless when the on-carriage probe weighs only 2g.

There is even a weightless probe, if you have ALU bed and are willing to wire the hotend and the bed in an open loop that gets closed when the two touch. And it's about free yet not many out there seem to like it and there are no "recipes" so enthusiasts can follow.

More complication will be added anyway when interchangeable heads will become more mainstream and thei will, if FDM is going to survive. The probe will be just another head.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Anonymous User

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 10, 2016 10:57PM |

Quote

dc42

Even if you don't need to do bed levelling because your bed is flat and the gantry rigid enough not to sag by more than 0.05mm as the head moves, a Z probe is still useful to establish the Z=0 point just before starting the print.

Making the probe removable adds more complication, and IMO is pointless when the on-carriage probe weighs only 2g.

And the simplest, accurate, no messing around, light, immune to normal t° change, magnetic field ... is to have a leaf switch NC. Same principle as probe used on machine tools.

As they are quite expensive, I made one using berylium copper gold plated Berg connectors. Just for my Z axis indeed.

As for a removable probe, the best, would be try to make one. It is a good occasion to learn what a micron really is, how to design, make accurate mechanical parts, etc.... Of course, the conclusion would be, not useful here but the skills gained are worth it.

Edited 1 time(s). Last edit at 05/10/2016 11:00PM by MKSA.

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 11, 2016 01:06AM |

Registered: 9 years ago Posts: 1,035 |

Quote

MKSA

And the simplest, accurate, no messing around, light, immune to normal t° change, magnetic field ... is to have a leaf switch NC. Same principle as probe used on machine tools.

As they are quite expensive, I made one using berylium copper gold plated Berg connectors. Just for my Z axis indeed..

... besides the nozzle2bed-direct-contact?

.That would fall under the NO category though...

.That would fall under the NO category though...any link to your DIY probe?

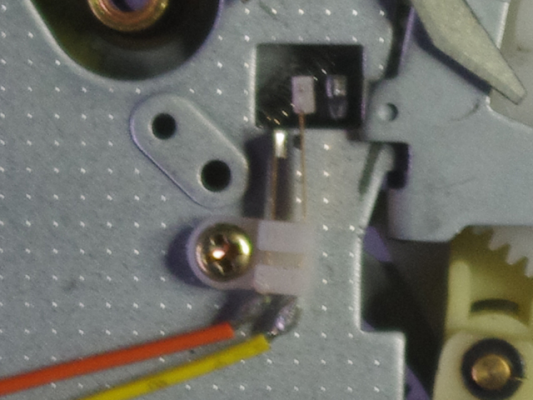

Edit: like this one:

Edited 3 time(s). Last edit at 05/11/2016 01:26AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Anonymous User

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 11, 2016 05:38AM |

What you show is indeed fine although I doubt the contacts are gold plated, no hysteresis.

I discussed the matter here. Geetech Prusa mod

I just reuse the housing of the microswitch. BTW, the guts of these cheap microswitches are disgusting.

I like gold, I even use it for the battery contacts of various devices. Left overs from an other time.

Edited 1 time(s). Last edit at 05/11/2016 05:45AM by MKSA.

I discussed the matter here. Geetech Prusa mod

I just reuse the housing of the microswitch. BTW, the guts of these cheap microswitches are disgusting.

I like gold, I even use it for the battery contacts of various devices. Left overs from an other time.

Edited 1 time(s). Last edit at 05/11/2016 05:45AM by MKSA.

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 11, 2016 06:13AM |

Registered: 9 years ago Posts: 1,035 |

Hmm, I think I missed something because all I saw in your link is the mention of it and two pictures where I couldn't get a clear idea of the way you modified the microswitch.

Any intention of making a tutorial?

Is the springiness of the assembly its differentiating feature compared to a direct-contact nozzle-bed? As I really see that one as a really good alternative, minus the fact that it's an NO system, which some say it's riskier in case the circuit gets somehow damaged and there will be no closed contact even when nozzle touches the bed.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Any intention of making a tutorial?

Is the springiness of the assembly its differentiating feature compared to a direct-contact nozzle-bed? As I really see that one as a really good alternative, minus the fact that it's an NO system, which some say it's riskier in case the circuit gets somehow damaged and there will be no closed contact even when nozzle touches the bed.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 11, 2016 06:33AM |

Registered: 9 years ago Posts: 1,035 |

Quote

MKSA

As for a removable probe, the best, would be try to make one. It is a good occasion to learn what a micron really is, how to design, make accurate mechanical parts, etc.... Of course, the conclusion would be, not useful here but the skills gained are worth it.

I have designed one that doesn't have the issues you are telling about. I've been posted about it here: [forums.reprap.org]

It's a derivative of the direct nozzle-to-metal-bed approach but works also for non-metal beds as the wiring is all contained in itself. It has been designed to be detachable and it really doesn't care if the printhead catches it at the right micron in height ... all that is accommodated by the ribbon between the nozzle and the bed (ideally a feller gauge "leaf").

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Anonymous User

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 11, 2016 10:09AM |

Quote

realthor

Quote

MKSA

As for a removable probe, the best, would be try to make one. It is a good occasion to learn what a micron really is, how to design, make accurate mechanical parts, etc.... Of course, the conclusion would be, not useful here but the skills gained are worth it.

I have designed one that doesn't have the issues you are telling about. I've been posted about it here: [forums.reprap.org]

It's a derivative of the direct nozzle-to-metal-bed approach but works also for non-metal beds as the wiring is all contained in itself. It has been designed to be detachable and it really doesn't care if the printhead catches it at the right micron in height ... all that is accommodated by the ribbon between the nozzle and the bed (ideally a feller gauge "leaf").

The discussion above was about an inductance proximity sensor that could be installed and removed to save weight.

As for what your present, yes, generally speaking the idea is OK. It is the same principle as one use on machine tools although I see different proposals.

Did you make it, did you use it, did you measure its accuracy and repeatability ? Do you work on the closing of the circuit or opening ?

How about the plastic residues on the nozzle, how about damaging the nozzle ?

And again, what advantage compared to a good Z switch ?

Are the knowledgeable people here having issues with properly built cartesian machines ?

Now, is your approach fit for machines really needing an automatic levelling (eg. Delta) ?

The picture I showed are self explanatory, just the principle is important. The moving part is just a leaf spring made out a beryllium copper gold plated square pin used in high end old equipment, one side wire wrap, the other for a Berg connector.

I could have used contact leaf spring from an old hard disk etc... You could even modify a good quality microswitch to remove the toggle mechanism.

ANd it is a normally ON.

I don't do tutorial and I don't like these lengthy boring youtube when a few pictures, a real schematic, formula and a few words can do in less time.

I prefer to do thing, define, search, compute, design, make, try, measure, test, then repeat the process eventually then talk about it..

Edited 3 time(s). Last edit at 05/11/2016 10:18AM by MKSA.

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 11, 2016 10:30AM |

Registered: 9 years ago Posts: 1,035 |

Well, I don't understand all you say so I can't imagine just by reading. And from the pictures I couldn't tell.

About my probe: I have printed it but haven't tested it on a printer. It's pretty simple actually and providing the nozzle is clean it should be repeatable. I haven't used it as I haven't yet designed a proper snapping mechanism (a way for the printhead to take it from a parked position). I could use magnets but I avoid it. It could easily be used by Deltas, actually those have a lot of room to park toolheads compared to a corexy. But I have left it aside for a while, being caught in other projects.

I designed it as a reprap option, not to replace the expensive or even the cheap yet still vitamins ones.

It works in an NO circuit so I have to find a way to make it normally closed. I don't have studies in electronics so it has been slow for me until I had to put it aside for another time.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

About my probe: I have printed it but haven't tested it on a printer. It's pretty simple actually and providing the nozzle is clean it should be repeatable. I haven't used it as I haven't yet designed a proper snapping mechanism (a way for the printhead to take it from a parked position). I could use magnets but I avoid it. It could easily be used by Deltas, actually those have a lot of room to park toolheads compared to a corexy. But I have left it aside for a while, being caught in other projects.

I designed it as a reprap option, not to replace the expensive or even the cheap yet still vitamins ones.

It works in an NO circuit so I have to find a way to make it normally closed. I don't have studies in electronics so it has been slow for me until I had to put it aside for another time.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Anonymous User

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 11, 2016 02:24PM |

Quote

realthor

Well, I don't understand all you say so I can't imagine just by reading. And from the pictures I couldn't tell.

About my probe: I have printed it but haven't tested it on a printer. It's pretty simple actually and providing the nozzle is clean it should be repeatable. I haven't used it as I haven't yet designed a proper snapping mechanism (a way for the printhead to take it from a parked position). I could use magnets but I avoid it. It could easily be used by Deltas, actually those have a lot of room to park toolheads compared to a corexy. But I have left it aside for a while, being caught in other projects.

I designed it as a reprap option, not to replace the expensive or even the cheap yet still vitamins ones.

It works in an NO circuit so I have to find a way to make it normally closed. I don't have studies in electronics so it has been slow for me until I had to put it aside for another time.

OK, so you built it, you use it for a while then you present the results. No electronic here, just mechanic, electricity, common sense, experience that can be gained by making it and using it. Oh hell, I am repeating myself.

To replace an expensive one is in fact a good way to do thing, do more with less. If it does less than a cheaper one, back to the drawing board or the bin.

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 11, 2016 11:01PM |

Registered: 9 years ago Posts: 1,035 |

Will do that as time and life and location permits  .

.

But the discussion sidestepped from the original question which was about each axis endstops location and the endstops people use. Are you guys using something else than mechanical endstops?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

.

.But the discussion sidestepped from the original question which was about each axis endstops location and the endstops people use. Are you guys using something else than mechanical endstops?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 12, 2016 03:44AM |

Registered: 8 years ago Posts: 622 |

Quote

dc42

Even if you don't need to do bed levelling because your bed is flat and the gantry rigid enough not to sag by more than 0.05mm as the head moves, a Z probe is still useful to establish the Z=0 point just before starting the print.

Making the probe removable adds more complication, and IMO is pointless when the on-carriage probe weighs only 2g.

I agree. Also, even if your bed is level and the guides are all tram, things can still go wrong after a few hundred hours of use. Having a probe is the quickest way I know of checking that the bed is still level and nothing has moved or broken. I don't use bed compensation but I always run the bed levelling check as part of my pre-print routine. It's also very useful during commissioning when you first adjust the levelling mechanism - mush easier than taking physical measurements or messing about rolling drill bits, or bits of paper under the nozzle etc.

|

Re: What's the best placement of EndStops in a CoreXY and are mechanical ones still used by you guys? May 13, 2016 02:25AM |

Registered: 9 years ago Posts: 1,035 |

Do you guys see a major problem/concern with Normally Open circuits? I think I remember seeing a circuit that makes a NO circuit a NC one by adding some electronics wizardry (nothing too complicated, but for me everything electronics is complicated).

Regarding NO:

- what about running wires in series through the 4 Y receiver parts so that when the bearing comes and touches it, the current closes circuit through the bearing thus registering for endstop touched. This would act like there are 4 endstops.

-it's much more difficult for X to offload the endstops from the X carriage, still thinking about it, but am a bit wary about NO.

Edited 1 time(s). Last edit at 05/13/2016 02:29AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Regarding NO:

- what about running wires in series through the 4 Y receiver parts so that when the bearing comes and touches it, the current closes circuit through the bearing thus registering for endstop touched. This would act like there are 4 endstops.

-it's much more difficult for X to offload the endstops from the X carriage, still thinking about it, but am a bit wary about NO.

Edited 1 time(s). Last edit at 05/13/2016 02:29AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Sorry, only registered users may post in this forum.