Is Nema17 1.2A too weak for 3d printing?

Posted by realthor

|

Is Nema17 1.2A too weak for 3d printing? May 16, 2016 08:51AM |

Registered: 9 years ago Posts: 1,035 |

What range of amperage should we look for when buying stepper motors? Nema 17 specifically, they seem to be the norm with 3d printers these days.

Thanks.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Thanks.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Is Nema17 1.2A too weak for 3d printing? May 16, 2016 09:16AM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

What range of amperage should we look for when buying stepper motors? Nema 17 specifically, they seem to be the norm with 3d printers these days.

Thanks.

it entirely depends on the design, the gearing, the target speed, and what micro-stepping rate used, and many other factors. let me do a few examples, i'm sure other people can contribute as well.

- if you have an original reprap, which didn't even have linear bearings, 1.2A is waaaay below what's needed because of massive amounts of friction. my friend's 1.68A NEMA17s that he donated to me are.... badly abused and noisy as a result.

- if you have a Flex3Drive, the 40:1 wormdrive is such a high gear ratio that a NEMA17 motor should be operating somewhere around... 0.5A or *less*, because you run them at 1/4 or 1/8th microstepping *NOT* 1/6th, and the steps/mm you set at 900 or 1800 respectively (which is still extremely high for an extruder).

- if you have gearing on the z-axis - i have a 50:16 belt drive on a 2mm pitch triple set of lead screws, and the steps/mm is 5,000 - again that's enormous. the current i've arbitrarily set to i think it's 700mA, i should try reducing that some time.

- if you have gearing on the X and Y. for example i'm planning to use GT2-16s and there is a pulley system that introduces an extra factor of 2:1 gearing. i should be able to reduce the current consumption accordingly, maybe even use 1/8th micro-stepping because of the 2.5:1 extra gear ratio.

this is in no way an exhaustive list, and it's already super-varied. so it's probably best to describe the specification - the requirements - and then people can help you assess what's appropriate for that. almost certainly, however, i would follow dc42's advice which is to use 0.9deg per step (400 steps / rev) motors for a new build, and combine that with 24v electronics. 0.9deg steppers are quieter, and they can run at up to 1000mm/sec on a CoreXY design without breaking things.

|

Re: Is Nema17 1.2A too weak for 3d printing? May 16, 2016 09:33AM |

Registered: 9 years ago Posts: 1,035 |

This motor is being sold by someone in the area i've noticed it on a local sale website so I was wondering if it's worth it.

My reprap is as simple as it gets, belt everywhere (Z included - that should have some gearing or 0.9 at least) and linear rods, so nothing spectacular or fancy.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

My reprap is as simple as it gets, belt everywhere (Z included - that should have some gearing or 0.9 at least) and linear rods, so nothing spectacular or fancy.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Is Nema17 1.2A too weak for 3d printing? May 16, 2016 09:56AM |

Registered: 10 years ago Posts: 14,672 |

Quote

realthor

What range of amperage should we look for when buying stepper motors? Nema 17 specifically, they seem to be the norm with 3d printers these days.

Thanks.

That depends on the electronics and drivers you will be using, the supply voltage, and the full specification of the motor - as well as the design of the machine. Can you provide that information? A 1.2A motor would be suitable for some designs, especially as it's quite common to run motors at only 0.8A.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Is Nema17 1.2A too weak for 3d printing? May 16, 2016 11:47AM |

Registered: 9 years ago Posts: 1,035 |

I am barely decided on the mechanical aspect of my printer, electronics is quite in the air.

I have more questions than answers...

Initial plan (for a couple of months) would be ramps/arduino so I can blow it up without breaking the bank, no heated bed, ATX power supply, DRV8825 drivers, 0.9deg motors (no gearing), mechanical switches, what else ...

In the meantime I want a proper 32bit controller, web interface, maybe wifi, SD, no LCD, same motors, reuse if possible the drivers...

It's such a mess in my head right now. I don't quite know what is about 24V vs 12V and many many more, I don't want to ask questions that I'd find answers by reading a bit more ... which I'll do of course.

Anyway I will want to eventually have dual hotend, heated bed, 32bit controller (possibly Duet 0.85 even if not open source it's the one I would buy under 60Eur/$).

Perhaps the more sensible approach is to be guided by a series of questions from the guys that know

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I have more questions than answers...

Initial plan (for a couple of months) would be ramps/arduino so I can blow it up without breaking the bank, no heated bed, ATX power supply, DRV8825 drivers, 0.9deg motors (no gearing), mechanical switches, what else ...

In the meantime I want a proper 32bit controller, web interface, maybe wifi, SD, no LCD, same motors, reuse if possible the drivers...

It's such a mess in my head right now. I don't quite know what is about 24V vs 12V and many many more, I don't want to ask questions that I'd find answers by reading a bit more ... which I'll do of course.

Anyway I will want to eventually have dual hotend, heated bed, 32bit controller (possibly Duet 0.85 even if not open source it's the one I would buy under 60Eur/$).

Perhaps the more sensible approach is to be guided by a series of questions from the guys that know

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Is Nema17 1.2A too weak for 3d printing? May 16, 2016 02:53PM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

This motor is being sold by someone in the area i've noticed it on a local sale website so I was wondering if it's worth it.

My reprap is as simple as it gets, belt everywhere (Z included - that should have some gearing or 0.9 at least) and linear rods, so nothing spectacular or fancy.

ok sooo, are you going with GT2 20 teeth on X and Y? and a bowden tube? if so the carriage *should* be reasonably light, so 1.2A motors would get you a speed of mmm..... 200mm/sec maximum or so.

Z typically doesn't need high current, if it does you're doing something reaaallly wrong. belt-drive try to make yourself some GT2 40 or 50 tooth gears, i made one you can grab here which is suited for GT2 6mm belt mmm let me find it... [hands.com] that's from a libre-licensed random scad file i found on the internet, you may have to adjust it. with that you could arrange a GT2 16t around it, a closed loop belt, that would give you a huge gear-ratio drop, loads of accuracy, and i feel you would definitely get away with 1.2A motors on Z.

if however you are thinking of not using lead screws / threaded-bar, instead to support the entire weight of the bed on a closed loop belt, where the loop is on a direct-drive round say a GT2-16 or GT2-20, *don't*. if on the other hand you put in some gearing (say 2.5 to 5 to 1) then yes, i think you might get away with that.

extruder is where you'll struggle. even a 4:1 gear ratio where it's considered "normal" in the non-professional 3d printing community to run the motor red-hot, you'd run into problems. i'm currently running at 1.2A and 1/16th microstepping on the Flex3Drive i have here (with a whopping 3600 steps / mm), the reason why i'm doing that is because i haven't yet cut the tracks on the Duet 0.8.5 PCB to enable 1/4 microstepping, at which point i can ramp the current right down to below 0.5A.

you *MIGHT* get away with 1.2A on that new E3Dv6 "Titan" extruder. it's using a quite large gear ratio, and i believe it has one of those MK8 drive gears at the centre. if you *really* want to experiment with a 1.2A motor, but don't want to get a Flex3Drive, then at the very least do it this way:

- find a "hobbed bolt" design (8mm or even 5mm)

- only use 1.75mm filament

- make sure that there's a huuuuge gearing ratio on it. minimum 4:1, preferably a lot more than that.

- for preference make sure it's got herringbone gears.

the compact geared extruder i designed could easily be adapted to take a 5mm hobbed bolt, it's designed to be minimal BOM and adaptable with minimal replacement parts.

so can you see what both i and dc42 meant, you need to make some decisions, then it becomes possible to assess from there. be clear, be decisive!

-- sandwich200: compact portable folding corexy printer [reprap.org]

|

Re: Is Nema17 1.2A too weak for 3d printing? May 16, 2016 03:40PM |

Registered: 10 years ago Posts: 14,672 |

Quote

realthor

Anyway I will want to eventually have dual hotend, heated bed, 32bit controller (possibly Duet 0.85 even if not open source it's the one I would buy under 60Eur/$).

The Duet 0.8.5 IS open source (CERN OHW license). But you won't find it for 60Eur/$ because it's made in the UK, not China, to good quality standards, and completed Duets are tested properly before they are shipped.

Edited 1 time(s). Last edit at 05/16/2016 03:43PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Is Nema17 1.2A too weak for 3d printing? May 16, 2016 03:52PM |

Registered: 9 years ago Posts: 1,035 |

For XY I plan on using 16 tooth GT2 pulleys.

For Z I was planning the same before I get some good no-backlash gearing and I was not very concerned (smartrapcore alu still uses this solution so it's doable -yes, it'll go bang on a power-cut but there are solutions out there)

For extruder I plan bowden as you observed and i will not use 1.2A but was planning to use a bigger motor as I wanted to go direct drive. E3D Titan is soo appealing though.

I have a big questionmark for the power source (12V / 24V?), hotends heaters (*V?).

Edited 1 time(s). Last edit at 05/16/2016 04:08PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

For Z I was planning the same before I get some good no-backlash gearing and I was not very concerned (smartrapcore alu still uses this solution so it's doable -yes, it'll go bang on a power-cut but there are solutions out there)

For extruder I plan bowden as you observed and i will not use 1.2A but was planning to use a bigger motor as I wanted to go direct drive. E3D Titan is soo appealing though.

I have a big questionmark for the power source (12V / 24V?), hotends heaters (*V?).

Edited 1 time(s). Last edit at 05/16/2016 04:08PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Is Nema17 1.2A too weak for 3d printing? May 16, 2016 03:57PM |

Registered: 10 years ago Posts: 14,672 |

Quote

lkcl

extruder is where you'll struggle. even a 4:1 gear ratio where it's considered "normal" in the non-professional 3d printing community to run the motor red-hot, you'd run into problems.

What matters is the holding torque of the motor at the current you run it at, which should normally be no more than about 85% of the rated current. If high speed is important, then the motor resistance and inductance are important too, along with the power supply voltage. Both my printers use extruders with approx. 3:1 gear ration, 420 steps/mm, using motors rated at 1.33A and 0.24Nm, driven at 0.8A to 1.0A.

[/quote]Quote

lkcl

i'm currently running at 1.2A and 1/16th microstepping on the Flex3Drive i have here (with a whopping 3600 steps / mm), the reason why i'm doing that is because i haven't yet cut the tracks on the Duet 0.8.5 PCB to enable 1/4 microstepping, at which point i can ramp the current right down to below 0.5A.

You'll be sadly disappointed if you think that reducing microstepping by a factor of 4 will allow you to reduce the current. The only reason to reduce the microstepping is if the electronics can't generate the step pulses fast enough to achieve the speed you want. The Duet can generate step pulses at more than 100k steps/sec, so with 3600 steps/mm you should be able to achieve a retraction speed of around 30mm/sec. If you want faster retraction speed, then reducing microstepping will be worthwhile.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Is Nema17 1.2A too weak for 3d printing? May 16, 2016 03:58PM |

Registered: 9 years ago Posts: 1,035 |

Quote

dc42

Quote

realthor

Anyway I will want to eventually have dual hotend, heated bed, 32bit controller (possibly Duet 0.85 even if not open source it's the one I would buy under 60Eur/$).

The Duet 0.8.5 IS open source (CERN OHW license). But you won't find it for 60Eur/$ because it's made in the UK, not China, to good quality standards, and completed Duets are tested properly before they are shipped.

Yes, I should have known that. If I buy Duet 0.8.5 I'll buy from Replikeo, have followed the threads lately they seem to have solved their quality issues. It's around $60 there. If not I would really want to try the Gen7 32bits ... I know the friction that goes here in the forums but yeah...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Is Nema17 1.2A too weak for 3d printing? May 16, 2016 04:02PM |

Registered: 10 years ago Posts: 14,672 |

Quote

realthor

Quote

dc42

Quote

realthor

Anyway I will want to eventually have dual hotend, heated bed, 32bit controller (possibly Duet 0.85 even if not open source it's the one I would buy under 60Eur/$).

The Duet 0.8.5 IS open source (CERN OHW license). But you won't find it for 60Eur/$ because it's made in the UK, not China, to good quality standards, and completed Duets are tested properly before they are shipped.

Yes, I should have known that. If I buy Duet 0.8.5 I'll buy from Replikeo, have followed the threads lately they seem to have solved their quality issues. It's around $60 there. If not I would really want to try the Gen7 32bits ... I know the friction that goes here in the forums but yeah...

AFAIK Replikeo only sells the older Duet 0.6 version, which was a good board but lacks some of the features added in the 0.8.5, e.g. dual extrusion and the second controlled fan. I've had no feedback on whether they have solved their QA problems or not.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Is Nema17 1.2A too weak for 3d printing? May 16, 2016 04:06PM |

Registered: 9 years ago Posts: 1,035 |

Quote

dc42

Quote

realthor

Quote

dc42

Quote

realthor

Anyway I will want to eventually have dual hotend, heated bed, 32bit controller (possibly Duet 0.85 even if not open source it's the one I would buy under 60Eur/$).

The Duet 0.8.5 IS open source (CERN OHW license). But you won't find it for 60Eur/$ because it's made in the UK, not China, to good quality standards, and completed Duets are tested properly before they are shipped.

Yes, I should have known that. If I buy Duet 0.8.5 I'll buy from Replikeo, have followed the threads lately they seem to have solved their quality issues. It's around $60 there. If not I would really want to try the Gen7 32bits ... I know the friction that goes here in the forums but yeah...

AFAIK Replikeo only sells the older Duet 0.6 version, which was a good board but lacks some of the features added in the 0.8.5, e.g. dual extrusion and the second controlled fan. I've had no feedback on whether they have solved their QA problems or not.

Maan, I am on an error spree here, yes I meant the 0.6 ....pfff

Yes I know the downsides but 50-60 is all I allow myself to pay for a board... I wish about 2 extruders at that price but that means MKS Sbase, which I don't trust.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Is Nema17 1.2A too weak for 3d printing? May 16, 2016 05:39PM |

Registered: 8 years ago Posts: 776 |

Quote

dc42

Quote

lkcl

extruder is where you'll struggle. even a 4:1 gear ratio where it's considered "normal" in the non-professional 3d printing community to run the motor red-hot, you'd run into problems.

What matters is the holding torque of the motor at the current you run it at, which should normally be no more than about 85% of the rated current. If high speed is important, then the motor resistance and inductance are important too, along with the power supply voltage. Both my printers use extruders with approx. 3:1 gear ration, 420 steps/mm, using motors rated at 1.33A and 0.24Nm, driven at 0.8A to 1.0A.

great. i thought you might know a bit more about this. realthor i made the mistake of going for the biggest-rated motors i could find (2.5A, 60N.cm) which are *not* properly matched to the drivers on the duet 0.8.5 (which do 2A max). listen to dc42

Quote

lkcl

i'm currently running at 1.2A and 1/16th microstepping on the Flex3Drive i have here (with a whopping 3600 steps / mm), the reason why i'm doing that is because i haven't yet cut the tracks on the Duet 0.8.5 PCB to enable 1/4 microstepping, at which point i can ramp the current right down to below 0.5A.

You'll be sadly disappointed if you think that reducing microstepping by a factor of 4 will allow you to reduce the current. The only reason to reduce the microstepping is if the electronics can't generate the step pulses fast enough to achieve the speed you want. The Duet can generate step pulses at more than 100k steps/sec, so with 3600 steps/mm you should be able to achieve a retraction speed of around 30mm/sec. If you want faster retraction speed, then reducing microstepping will be worthwhile.[/quote]

if you recall, we discussed this before, where someone ... ahh can't remember who ... kindly posted an article about how the two phases counteract (fight) each other at the smaller micro-stepping rates, but also how the dynamic and static friction significantly contribute to drastically reduce available torque in a non-linear fashion. but yes, also, i am looking to run at 40mm/sec retract speeds - waiting around at 20mm/sec on prints with a lot of retracts.... zzzz

|

Re: Is Nema17 1.2A too weak for 3d printing? May 16, 2016 05:47PM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

For XY I plan on using 16 tooth GT2 pulleys.

watch out for that, though: *don't* wrap the corexy belt through 180 degrees round GT2-16t's. put an idler bearing in (or two) so that the belt loops back on itself through 90 degrees instead.

Quote

For Z I was planning the same before I get some good no-backlash gearing and I was not very concerned (smartrapcore alu still uses this solution so it's doable -yes, it'll go bang on a power-cut but there are solutions out there)

you should ask around before committing to this design - ask around what current people use (and what rating motor). you *need* to know the specs on that motor. find out its exact part number from the supplier, you should be able to track down the datasheet.

the last thing you want to find is that even with a GT2-16 those 1.2A motors can't even hold the printbed up even at max current.

Quote

For extruder I plan bowden as you observed and i will not use 1.2A but was planning to use a bigger motor as I wanted to go direct drive.

don't do it. don't do direct-drive. you'll regret it, i promise you. if you absolutely must do it, make absolutely sure you get a MK8 drive gear (or something else with a similarly tiny inner diameter - i think the hob goblin has just as small an inner diameter) and on no account go with 3mm filament on direct-drive.

Quote

E3D Titan is soo appealing though.

Quote

I have a big questionmark for the power source (12V / 24V?), hotends heaters (*V?).

24V definitely. E3Dv6 definitely. heater up to you, i like the Alu MK3 because it's rock-solid and rigid, but has a high specific heat capacity so takes a while to warm up.

Edited 1 time(s). Last edit at 05/16/2016 05:49PM by lkcl.

|

Re: Is Nema17 1.2A too weak for 3d printing? May 16, 2016 06:25PM |

Registered: 13 years ago Posts: 268 |

"watch out for that, though: *don't* wrap the corexy belt through 180 degrees round GT2-16t's. put an idler bearing in (or two) so that the belt loops back on itself through 90 degrees instead."

Complete and total nonsense. I have >180 wrap on 15t GT2's Worked just fine for many hundreds of hours so far.

Complete and total nonsense. I have >180 wrap on 15t GT2's Worked just fine for many hundreds of hours so far.

|

Re: Is Nema17 1.2A too weak for 3d printing? May 17, 2016 02:35AM |

Registered: 9 years ago Posts: 1,035 |

I was only planning to use 1.2A for XY stage. I plan for Z to have 1.8+A and for the extruder I never gave it enough thought by now but direct drive with MK7 worked for so many... although I think I got some MK8s even if I ordered MK7 on aliexpress. But I still have those abroad, at my previous location. It's not difficult to print a herringbone-geared ensemble if it doesn't perform well enough.

One question about gears, I am in Europe, where can I get some gears module for Z motor if I didn't want to buy a stepper motor with gears built-in? Preferably Germany would be best...

The question about the power source remains... what power (considering I will want to have a heated bed eventually, +2 extruders) and what is with this 12V vs 24V debate and what is with the relay and all that stuff...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

One question about gears, I am in Europe, where can I get some gears module for Z motor if I didn't want to buy a stepper motor with gears built-in? Preferably Germany would be best...

The question about the power source remains... what power (considering I will want to have a heated bed eventually, +2 extruders) and what is with this 12V vs 24V debate and what is with the relay and all that stuff...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Is Nema17 1.2A too weak for 3d printing? May 17, 2016 04:16AM |

Registered: 8 years ago Posts: 776 |

Quote

Koko76

"watch out for that, though: *don't* wrap the corexy belt through 180 degrees round GT2-16t's. put an idler bearing in (or two) so that the belt loops back on itself through 90 degrees instead."

Complete and total nonsense.

i believe i warned you before a couple of days ago, koko76, but let me be more clear: your words here are hurtful and cause me distress that you should use them in relation to some advice that i received and am merely relaying to another member of this community.

do you think that it is appropriate to be offensive and hurtful to other members of this community, and if so, why?

Quote

I have >180 wrap on 15t GT2's Worked just fine for many hundreds of hours so far.

that's fine koko76 - if it works for you. i'm relaying realthor someone else's advice (from cozmicray) who is an extremely experienced engineer who reads up on manufacturer's advice and engineering datasheets. the advice specifically advises that belt angles should be minimised and that if they are absolutely necessary that a larger diameter should be used.

if you specifically choose to ignore manufacturer's recommendations that is entirely your choice but do NOT insult me or anyone else in this community by going around telling me or anyone else on this forum that following manufacturer's recommendations is "complete and utter nonsense".

have i made myself ABSOLUTELY clear?

|

Re: Is Nema17 1.2A too weak for 3d printing? May 17, 2016 04:35AM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

I was only planning to use 1.2A for XY stage. I plan for Z to have 1.8+A and for the extruder I never gave it enough thought by now but direct drive with MK7 worked for so many... although I think I got some MK8s even if I ordered MK7 on aliexpress. But I still have those abroad, at my previous location. It's not difficult to print a herringbone-geared ensemble if it doesn't perform well enough.

ehh, sounds like you're getting some clarity, and a plan's forming, which is great.

Quote

One question about gears, I am in Europe, where can I get some gears module for Z motor if I didn't want to buy a stepper motor with gears built-in?

see above: i printed my own pulleys, i provided a link where you can grab either pre-made STL files or get the scad source and alter one line to set a different number of teeth. i'm ordering stuff from alfa-tech3d.com, he delivers to europe, but like many of these 3D printing companies he will have a specific set of parts common across a wide range of 3D printers,

Quote

Preferably Germany would be best...

The question about the power source remains... what power (considering I will want to have a heated bed eventually, +2 extruders) and what is with this 12V vs 24V debate and what is with the relay and all that stuff...

heated beds take a *lot* of current. power dissipation is a square law based on voltage (W = V^2 / R). so if you need say 300 watts to heat up a printed bed, the wires leading to them have to have FOUR TIMES the amount of copper in them (double the diameter) to cope with the current at 12V than you would at 24V. it's why even on a 350W ATX PSU you have something mad like 8 wires dedicated to GND and 8 to 12V, i can't remember the exact numbers.

if you're doing a 200x200 printbed and don't plan to upgrade it to a larger size later then a 300 or 350W PSU would do you fine. i ordered a Mean Well (love the literal translations from taiwanese company names...) 350W 24V PSU from Mouser, but you can also get the same one from a UK supplier.... P/N is LRS-350-24 and it's a low-profile one that's actually really reasonably priced.

basically the people who have a lot of experience here in electronics and 3d printing, such as dc42 and many others, are *not* recommending to go with 12V for new designs, but it does mean that you need to pick parts accordingly... *including* the controller, which must, of course, be able to cope with a 24V supply. if you've got some other over-riding factor (such as low-cost availability of a specific part) then of course go with that.

there's also a whole stack of other options, some heated beds you can get now are mains-powered, and to switch that safely using an EC you'd need a mechanical electrically-isolated switch.... known in the trade as a "relay"... so that's probably why you heard about relays being used in relation to heated beds. the nice thing about those is, you can retro-fit them afterwards, and if you happened to have picked an EC which limited to 12v and can't do 24v it wouldn't matter, because the relay would [probably?] be operated off the 3.3v GPIO from the EC - just guessing here, i don't really know. it's not something i've looked at.

anyway - this is supposed to be motors discussion!

|

Re: Is Nema17 1.2A too weak for 3d printing? May 17, 2016 04:52AM |

Registered: 9 years ago Posts: 1,035 |

well, it's my thread  ... and we are talking about what PSU to be able to give all that power to the motors considering all the above: heated bed, hotend(s) heater(s), etc.

... and we are talking about what PSU to be able to give all that power to the motors considering all the above: heated bed, hotend(s) heater(s), etc.

Ok, related to motors, I am talking about the Z here and I wouldn't want to let some printed gears to take care of the Z resolution. For extruder I get it, it's easy to retrofit a direct drive with a 3d printed part.

For Z ideally I would have a motor with a worm reduction and I haven't seen those on stepper motors nor do I know of a worm reduction add-on for a stepper motor. It should have minimal backlash though (it's Z we're talking about).

I also want to make some things clear here that's why I am talking about many things. Sorry if I hijack my own thread, I feel ok about doing it. So for XY I can do 1.2A/16t-GT2. For Z it's not yet decided... if some sort of gearing is also involved I can get away with 1.2A right? But if not, should I must opt for higher amperage right?

For the extruder I believe that dhat direct drive with more powerful motor is doable but geared(3d printed) with 1.2A would be even better. This is an bowden so size/weight is not that critical.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

... and we are talking about what PSU to be able to give all that power to the motors considering all the above: heated bed, hotend(s) heater(s), etc.

... and we are talking about what PSU to be able to give all that power to the motors considering all the above: heated bed, hotend(s) heater(s), etc.Ok, related to motors, I am talking about the Z here and I wouldn't want to let some printed gears to take care of the Z resolution. For extruder I get it, it's easy to retrofit a direct drive with a 3d printed part.

For Z ideally I would have a motor with a worm reduction and I haven't seen those on stepper motors nor do I know of a worm reduction add-on for a stepper motor. It should have minimal backlash though (it's Z we're talking about).

I also want to make some things clear here that's why I am talking about many things. Sorry if I hijack my own thread, I feel ok about doing it. So for XY I can do 1.2A/16t-GT2. For Z it's not yet decided... if some sort of gearing is also involved I can get away with 1.2A right? But if not, should I must opt for higher amperage right?

For the extruder I believe that dhat direct drive with more powerful motor is doable but geared(3d printed) with 1.2A would be even better. This is an bowden so size/weight is not that critical.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Is Nema17 1.2A too weak for 3d printing? May 17, 2016 05:02AM |

Admin Registered: 16 years ago Posts: 13,886 |

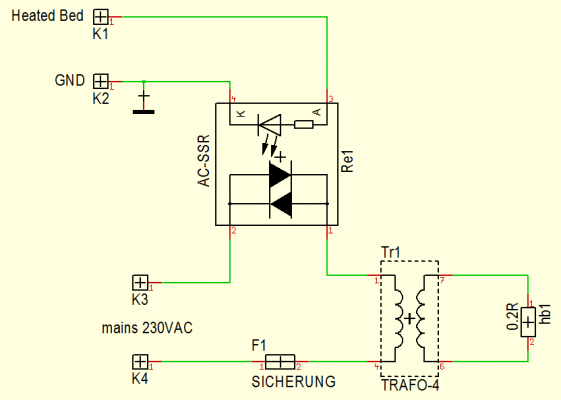

... I've powered my first heated bed simply with a bare 12VAC@8A transformator (which gives roughly 16 to 14 Volts AC depending on load) and switched the current with an AC-SSR.

This can be done with any available transformator (found several from 5VAC@60A to 14000VAC@1mA in my scrapery), but for heated beds I'll avoid output powers above 50 Volts and currents greater than 20 Amps for safety reasons (and it's hard to find proper connectors).

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

This can be done with any available transformator (found several from 5VAC@60A to 14000VAC@1mA in my scrapery), but for heated beds I'll avoid output powers above 50 Volts and currents greater than 20 Amps for safety reasons (and it's hard to find proper connectors).

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Is Nema17 1.2A too weak for 3d printing? May 17, 2016 05:23AM |

Registered: 9 years ago Posts: 1,035 |

Quote

VDX

... I've powered my first heated bed simply with a bare 12VAC@8A transformator (which gives roughly 16 to 14 Volts AC depending on load) and switched the current with an AC-SSR.

This can be done with any available transformator (found several from 5VAC@60A to 14000VAC@1mA in my scrapery), but for heated beds I'll avoid output powers above 50 Volts and currents greater than 20 Amps for safety reasons (and it's hard to find proper connectors).

You know what you're talking about, I couldn't understand half of it

. I would venture in electronics but I don't know if it's smart to do that as a beginner. I think I'm going with an ATX power source (I have one around) and see from there. I believe there are good tutorials around the web how to use that (i've seen a good one but I can't seem to find it).

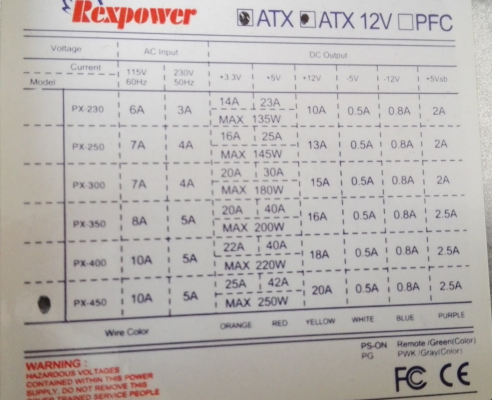

. I would venture in electronics but I don't know if it's smart to do that as a beginner. I think I'm going with an ATX power source (I have one around) and see from there. I believe there are good tutorials around the web how to use that (i've seen a good one but I can't seem to find it).Here's the ATX one I can use:

Edited 1 time(s). Last edit at 05/17/2016 05:34AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Is Nema17 1.2A too weak for 3d printing? May 17, 2016 06:11AM |

Registered: 13 years ago Posts: 268 |

Quote

lkcl

Quote

Koko76

"watch out for that, though: *don't* wrap the corexy belt through 180 degrees round GT2-16t's. put an idler bearing in (or two) so that the belt loops back on itself through 90 degrees instead."

Complete and total nonsense.

i believe i warned you before a couple of days ago, koko76, but let me be more clear: your words here are hurtful and cause me distress that you should use them in relation to some advice that i received and am merely relaying to another member of this community.

do you think that it is appropriate to be offensive and hurtful to other members of this community, and if so, why?

Quote

I have >180 wrap on 15t GT2's Worked just fine for many hundreds of hours so far.

that's fine koko76 - if it works for you. i'm relaying realthor someone else's advice (from cozmicray) who is an extremely experienced engineer who reads up on manufacturer's advice and engineering datasheets. the advice specifically advises that belt angles should be minimised and that if they are absolutely necessary that a larger diameter should be used.

if you specifically choose to ignore manufacturer's recommendations that is entirely your choice but do NOT insult me or anyone else in this community by going around telling me or anyone else on this forum that following manufacturer's recommendations is "complete and utter nonsense".

have i made myself ABSOLUTELY clear?

You are not in the position to warn me about anything. There is not anything in a manufacturers recommendation matching what you say, you misunderstood the advice you are given, and ignorantly keep repeating it. The SDP-SI manual is more than passingly familiar to me.

As a matter of practical example I'd invite you to go take a look at how more than a few Delta printers function and utilize timing belts.

I build things professionally, and I make a fair living doing so. Companies pay me to make purpose built machines (among other things), to do something right the first time. I don't get 6 iterations of the floppy sandwich cart to get it right, mine has to work the first time, every time on workpieces that cost more than the average house. If that's not something you feel you can learn from, then find the ignore button.

|

Re: Is Nema17 1.2A too weak for 3d printing? May 17, 2016 06:19AM |

Registered: 9 years ago Posts: 1,035 |

guys, I appreciate any piece of advice you give here for free and I take notes of everything but please try keep it cool  ... This faceless communication does more harm than good in these types of argumentative discussions.

... This faceless communication does more harm than good in these types of argumentative discussions.

I myself don't want to hurt anybody's feelings but my ultimate choice will make someone feel betrayed/etc in his advice if this behavior isn't kept under control.

I don't exactly understood what @lkcl tried to explain but I think I going with @Koko76's advice just because I planned it that way and I am happy everyone is not against it -like most are with other things I say/propose/explore here in the forums

-like most are with other things I say/propose/explore here in the forums  .

.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

... This faceless communication does more harm than good in these types of argumentative discussions.

... This faceless communication does more harm than good in these types of argumentative discussions.I myself don't want to hurt anybody's feelings but my ultimate choice will make someone feel betrayed/etc in his advice if this behavior isn't kept under control.

I don't exactly understood what @lkcl tried to explain but I think I going with @Koko76's advice just because I planned it that way and I am happy everyone is not against it

-like most are with other things I say/propose/explore here in the forums

-like most are with other things I say/propose/explore here in the forums  .

.RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Anonymous User

Re: Is Nema17 1.2A too weak for 3d printing? May 17, 2016 06:34AM |

Quote

Koko76

You are not in the position to warn me about anything. There is not anything in a manufacturers recommendation matching what you say, you misunderstood the advice you are given, and ignorantly keep repeating it. The SDP-SI manual is more than passingly familiar to me.

As a matter of practical example I'd invite you to go take a look at how more than a few Delta printers function and utilize timing belts.

I build things professionally, and I make a fair living doing so. Companies pay me to make purpose built machines (among other things), to do something right the first time. I don't get 6 iterations of the floppy sandwich cart to get it right, mine has to work the first time, every time on workpieces that cost more than the average house. If that's not something you feel you can learn from, then find the ignore button.

Don't upset him, he won't be able to complete his cardboard IATA compliant foldable mouse trap mimicking a 3D printer

Just relax, have fun reading.

|

Re: Is Nema17 1.2A too weak for 3d printing? May 17, 2016 06:36AM |

Registered: 9 years ago Posts: 1,035 |

@MKSA you're not helping and this type of attitude is only perpetuating a tensed environment. What about some common sense in these forums ...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Anonymous User

Re: Is Nema17 1.2A too weak for 3d printing? May 17, 2016 06:48AM |

Quote

realthor

@MKSA you're not helping and this type of attitude is only perpetuating a tensed environment. What about some common sense in these forums ...

Tensed ? No, just funny ! Common sense ? Not very common, reading your non sense !

I am just wondering, do you know nothing about everything or everything about nothing ?

|

Re: Is Nema17 1.2A too weak for 3d printing? May 17, 2016 06:51AM |

Admin Registered: 16 years ago Posts: 13,886 |

Quote

realthor

Quote

VDX

... I've powered my first heated bed simply with a bare 12VAC@8A transformator (which gives roughly 16 to 14 Volts AC depending on load) and switched the current with an AC-SSR.

This can be done with any available transformator (found several from 5VAC@60A to 14000VAC@1mA in my scrapery), but for heated beds I'll avoid output powers above 50 Volts and currents greater than 20 Amps for safety reasons (and it's hard to find proper connectors).

You know what you're talking about, I couldn't understand half of it. I would venture in electronics but I don't know if it's smart to do that as a beginner. I think I'm going with an ATX power source (I have one around) and see from there. I believe there are good tutorials around the web how to use that (i've seen a good one but I can't seem to find it).

Here's the ATX one I can use:

[attachment 78241 IMG_20160517_122534.jpg]

... here's a sketch to show the driving of a heated bed with a transformer and switching it with an AC-SSR (solid-state-relay):

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Is Nema17 1.2A too weak for 3d printing? May 17, 2016 07:56AM |

Registered: 9 years ago Posts: 1,035 |

Quote

VDX

... here's a sketch to show the driving of a heated bed with a transformer and switching it with an AC-SSR (solid-state-relay):

[attachment 78242 HB-Test.png]

This can be useful since my ATX power supply might not be up to the task of providing the heated bed and dual hotend with enough power so an additional provider for current for the heatbed/hotends might be needed. ATX can only provide 12V anyway. I don't understand it much but I can do some homework.

Edited 1 time(s). Last edit at 05/17/2016 07:57AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Is Nema17 1.2A too weak for 3d printing? May 17, 2016 02:09PM |

Registered: 11 years ago Posts: 1,049 |

ikcl There you go again

turning up manure spreader to high

It is only "offensive and hurtful " if the reader allows it to be

None of us here know if the comments are by experts, experienced users or just smoke blowers

What are timing belt issues doing in a topic about NEMA 17 current draw?

BTW the more contact (wrap) of a belt on a pulley is better for power transmission

keeping in mind that the belt has to be able to withstand a sharp bend by a small diameter pulley.

turning up manure spreader to high

It is only "offensive and hurtful " if the reader allows it to be

None of us here know if the comments are by experts, experienced users or just smoke blowers

What are timing belt issues doing in a topic about NEMA 17 current draw?

BTW the more contact (wrap) of a belt on a pulley is better for power transmission

keeping in mind that the belt has to be able to withstand a sharp bend by a small diameter pulley.

Quote

lkcl

Quote

Koko76

"watch out for that, though: *don't* wrap the corexy belt through 180 degrees round GT2-16t's. put an idler bearing in (or two) so that the belt loops back on itself through 90 degrees instead."

Complete and total nonsense.

i believe i warned you before a couple of days ago, koko76, but let me be more clear: your words here are hurtful and cause me distress that you should use them in relation to some advice that i received and am merely relaying to another member of this community.

do you think that it is appropriate to be offensive and hurtful to other members of this community, and if so, why?

Quote

I have >180 wrap on 15t GT2's Worked just fine for many hundreds of hours so far.

that's fine koko76 - if it works for you. i'm relaying realthor someone else's advice (from cozmicray) who is an extremely experienced engineer who reads up on manufacturer's advice and engineering datasheets. the advice specifically advises that belt angles should be minimised and that if they are absolutely necessary that a larger diameter should be used.

if you specifically choose to ignore manufacturer's recommendations that is entirely your choice but do NOT insult me or anyone else in this community by going around telling me or anyone else on this forum that following manufacturer's recommendations is "complete and utter nonsense".

have i made myself ABSOLUTELY clear?

|

Anonymous User

Re: Is Nema17 1.2A too weak for 3d printing? May 17, 2016 02:34PM |

Quote

cozmicray

ikcl There you go again

turning up manure spreader to high

It is only "offensive and hurtful " if the reader allows it to be

None of us here know if the comments are by experts, experienced users or just smoke blowers

....

I know who is who !

I worked in a nut case asylum and I can identify the real Washingtons from the fake ones !

Sorry, only registered users may post in this forum.