To twist or not to twist

Posted by appjaws1

|

To twist or not to twist May 18, 2016 06:56AM |

Registered: 10 years ago Posts: 780 |

Did we ever get a definitive answer as to twist the drive belts so that they run against the smooth side of the belt or not to twist, so that the teeth of the belt run against the idler bearings.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: To twist or not to twist May 18, 2016 11:57AM |

Registered: 10 years ago Posts: 651 |

|

Re: To twist or not to twist May 18, 2016 03:25PM |

Registered: 9 years ago Posts: 83 |

I think it goes with other questions such as "How much wood can a woodchuck chuck", "What is the sound of one hand clapping", and "which is better, Delta or CoreXY".

I can point to designs that run teeth against smooth idlers, and designs that run teeth against teethed idlers-- both seem to be equally effective at printing. It is possible (although anecdotal) that the toothed pulleys produce more noise as the air gets squooshed out of the grooves, but as I say, that's anecdotal.

Some people have claimed that the teeth against the smooth pulley causes irregular offsets in their printing, but that implies stretching / relaxing due to force, which in theory, the fibreglass / steel reinforced GT2 shouldn't be doing-- just a bit of stretching when initially run in.

Other theories include using a larger smooth pulley than you would for a toothed, but that's (as far as I know) just a theory.

On the other hand, getting off my duff and doing actual research, I find the following from [sdp-si.com]:

I can point to designs that run teeth against smooth idlers, and designs that run teeth against teethed idlers-- both seem to be equally effective at printing. It is possible (although anecdotal) that the toothed pulleys produce more noise as the air gets squooshed out of the grooves, but as I say, that's anecdotal.

Some people have claimed that the teeth against the smooth pulley causes irregular offsets in their printing, but that implies stretching / relaxing due to force, which in theory, the fibreglass / steel reinforced GT2 shouldn't be doing-- just a bit of stretching when initially run in.

Other theories include using a larger smooth pulley than you would for a toothed, but that's (as far as I know) just a theory.

On the other hand, getting off my duff and doing actual research, I find the following from [sdp-si.com]:

Quote

Idlers, either of the inside or outside type, are not recommended and should not be used except for power takeoff or functional use. When an idler is necessary, it should be on the slack side of the belt. Inside idlers must be grooved, unless their diameters are greater than an equivalent 40-groove pulley. Flat idlers must not be crowned (use edge flanges). Idler diameters must exceed the smallest diameter drive pulley. Idler arc of contact should be held to a minimum.

|

Re: To twist or not to twist May 18, 2016 05:33PM |

Registered: 11 years ago Posts: 5,780 |

My experience with twisted belts is that it becomes very hard to keep the belt centered on the pulley and has no effect on print quality. I think a lot of people mistakenly attribute print quality defects to belt teeth on smooth pulleys when the problem is actually something else such as motor current or acceleration settings.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: To twist or not to twist May 18, 2016 10:01PM |

Registered: 11 years ago Posts: 1,049 |

Please use

[www.sdp-si.com]

I know your going to go out and get cheap Chinese belts and pulleys

because US designed and manufactured belts / pulleys price will take your breath away.

Is it really that critical?

Twist belts -- kill the belts --- crappy way to use them

use the guidelines for pulley contact and idlers --- or NOT

just have fun --- watch the belts jump around and fray

or run smoothly as a swiss watch ---- let us know how it works

after 1000 hours of use

[www.sdp-si.com]

I know your going to go out and get cheap Chinese belts and pulleys

because US designed and manufactured belts / pulleys price will take your breath away.

Is it really that critical?

Twist belts -- kill the belts --- crappy way to use them

use the guidelines for pulley contact and idlers --- or NOT

just have fun --- watch the belts jump around and fray

or run smoothly as a swiss watch ---- let us know how it works

after 1000 hours of use

|

Re: To twist or not to twist May 19, 2016 12:10PM |

Registered: 10 years ago Posts: 780 |

Thanks to all who replied.

I think I will go without a twist so that the belt runs with the teeth against the flanged idler bearings.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I think I will go without a twist so that the belt runs with the teeth against the flanged idler bearings.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: To twist or not to twist May 19, 2016 12:49PM |

Registered: 10 years ago Posts: 14,672 |

Quote

appjaws1

Thanks to all who replied.

I think I will go without a twist so that the belt runs with the teeth against the flanged idler bearings.

My personal opinion is that it is better to put a twist in the belt, provided that the run with the twist is long and of constant length. My delta printer has a toothed belt running over smooth flanged idler bearings, and I can hear the noise it makes. It must also be causing the belt to vibrate. My Ormerod has twists in the X and Y belts, and they have never caused me any problems.

Alternatively, use a toothed idler wheel.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: To twist or not to twist May 20, 2016 04:34AM |

Registered: 8 years ago Posts: 776 |

Quote

the_digital_dentist

My experience with twisted belts is that it becomes very hard to keep the belt centered on the pulley and has no effect on print quality.

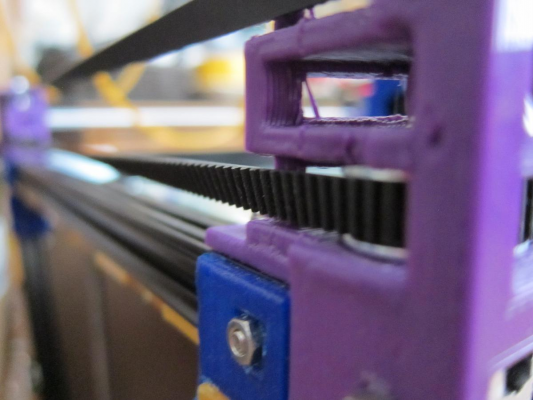

strangely i am having no such difficulties, but then i have ensured that the twists are placed where the belts are longest on all sides of the bearings where the twist is located. so this is at the front:

this is unlike what i described here [forums.reprap.org] where i was going to put the twist in the side because it is longest: that would have had the belt rubbing against the return path, so i compromised and put it in the front instead, so i have only the one idler which is tooth-to-smooth.

from the photo you can see that, like nophead does in the mendel90 i am using 20mm M5 washers around all the bearings, and the belts are not rubbing against plastic.

currently i am sorting out a replacement design, the existing (vertically-stacked) corexy rods are a 100% total design failure, i am currently seeing the printhead "stick" and then vibrate, causing juddering that makes the belts vibrate by a good 2-3mm each time.

now, if running at high speed i could envisage a scenario where the belts, if they are tooth-to-bearing, would end up significantly vibrating in a similar way, end-result that would affect the print quality in unpredictable ways. but at low speeds? naah.

dc42: you're running at higher speeds, aren't you? i seem to recall you mentioning that you go up to 500mm/sec or so, don't you?

the_digital_dentist: i seem to recall you saying that the SonOfMegaMax was specifically designed for accuracy, and that you don't go over 50mm/sec, is that right?

so it would appear that there is indeed, based on this small sample size, an empirical correlation between "speed" and "problem".

Edited 1 time(s). Last edit at 05/20/2016 04:35AM by lkcl.

|

Re: To twist or not to twist May 20, 2016 08:26AM |

Registered: 11 years ago Posts: 5,780 |

Yes. I generally print at 50 mm/sec or less. I recently modified the y axis and took out almost 1kg of moving mass from the original design. The change has resulted in a slight reduction of print quality. At some point in the immediate future I'm going to try some speed tests and see how fast I can move it. It would be nice to print faster if I don't have to give up to much print quality mostly because at low speeds I get a lot of resonance and the machine is pretty loud. Running faster might reduce the noise level. The machine is at the makerspace now in part because my wife was complaining about the noise!

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: To twist or not to twist March 05, 2018 04:04AM |

Registered: 11 years ago Posts: 1,277 |

On a laser machine this was tested but remember a laser engraver is way finer in resolution than a 3d printer but with a toothed belt running on a smooth idler it results in a pattern that we call the curtain effect. Toothed belt into a toothed pulley was the same end result but when you flip the belt over where the smooth side of the belt comes in contact with the smooth idler pulley the curtain effect is gone. Since it has an effect that is easily shown in the laser engraving world the answer is to use smooth on smooth for the best results BUT can you get away with using toothed on smooth at the resolution 3d printers can achieve? I personally try my hardest to do smooth on smooth everywhere just in case.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: To twist or not to twist March 06, 2018 02:56AM |

Registered: 8 years ago Posts: 5,232 |

The thread is a bit older, so I want to share my new? solution to twist the belt without twisting it.

The printer is running a continous torture test for several weeks now and none of the belts failed. It's glued with CA and the carrier movement is blocked such, that the glued part never bends.

Edited 1 time(s). Last edit at 03/06/2018 02:59AM by o_lampe.

The printer is running a continous torture test for several weeks now and none of the belts failed. It's glued with CA and the carrier movement is blocked such, that the glued part never bends.

Edited 1 time(s). Last edit at 03/06/2018 02:59AM by o_lampe.

|

Re: To twist or not to twist March 07, 2018 03:05AM |

Registered: 6 years ago Posts: 1,007 |

Quote

Dark Alchemist

On a laser machine this was tested but remember a laser engraver is way finer in resolution than a 3d printer but with a toothed belt running on a smooth idler it results in a pattern that we call the curtain effect. Toothed belt into a toothed pulley was the same end result but when you flip the belt over where the smooth side of the belt comes in contact with the smooth idler pulley the curtain effect is gone. Since it has an effect that is easily shown in the laser engraving world the answer is to use smooth on smooth for the best results BUT can you get away with using toothed on smooth at the resolution 3d printers can achieve? I personally try my hardest to do smooth on smooth everywhere just in case.

What about the motor pulley ? If the idler gives that effect, the motor pulley should too ? The curtain effect should be halved isn't ? Are you using brand names components ?

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: To twist or not to twist March 07, 2018 09:25AM |

Registered: 11 years ago Posts: 5,780 |

Quote

o_lampe

The thread is a bit older, so I want to share my new? solution to twist the belt without twisting it.

The printer is running a continous torture test for several weeks now and none of the belts failed. It's glued with CA and the carrier movement is blocked such, that the glued part never bends.

CA isn't flexible and not very strong in shear. As you tension the belt, the belt tries to stretch a little and produces shear force on the glue bond. I would not trust it. I think that contact cement, which remains flexible when cured, would be a better choice when gluing flexible parts, especially when they are subjected to tension.

Toothed vs smooth pulleys has been discussed ad nauseum. I think the issue that people run into with smooth pulleys is that in many cheap printers, they use too small diameter bearings as smooth pulleys. As long as smooth pulley diameter is "adequate", letting belt teeth hit a smooth pulley surface doesn't matter. Gates recommends that the smooth pulley diameter should be equivalent to the diameter of a 40 tooth pulley of whatever belt pitch you're using, which translates to about 25 mm diameter for a 2mm pitch belt. 608 bearings are 22 mm diameter and I've been using them with great results in UMMD. Using two F608zz bearings stacked makes a great, flanged pulley for 9-10 mm wide belt.

Edited 2 time(s). Last edit at 03/07/2018 10:11AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: To twist or not to twist March 07, 2018 11:08AM |

Registered: 6 years ago Posts: 1,007 |

Quote

the_digital_dentist

...

CA isn't flexible and not very strong in shear. As you tension the belt, the belt tries to stretch a little and produces shear force on the glue bond. I would not trust it. I think that contact cement, which remains flexible when cured, would be a better choice when gluing flexible parts, especially when they are subjected to tension.

...]

Loctite sells a CA that is somewhat flexible and used to make O rings. I used it to make a close loop GT2 belt that has been in use for about 2 years.

[www.na.henkel-adhesives.com]

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: To twist or not to twist March 07, 2018 11:52AM |

Registered: 11 years ago Posts: 5,780 |

Interesting, but is that the stuff o_lampe used?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: To twist or not to twist March 07, 2018 12:38PM |

Registered: 11 years ago Posts: 1,277 |

All I know is that the driver can be toothed but the follower (idler) needs to be smooth on smooth and if you make the idler smooth on smooth the effect isn't halved it is completely gone.Quote

MKSA

Quote

Dark Alchemist

On a laser machine this was tested but remember a laser engraver is way finer in resolution than a 3d printer but with a toothed belt running on a smooth idler it results in a pattern that we call the curtain effect. Toothed belt into a toothed pulley was the same end result but when you flip the belt over where the smooth side of the belt comes in contact with the smooth idler pulley the curtain effect is gone. Since it has an effect that is easily shown in the laser engraving world the answer is to use smooth on smooth for the best results BUT can you get away with using toothed on smooth at the resolution 3d printers can achieve? I personally try my hardest to do smooth on smooth everywhere just in case.

What about the motor pulley ? If the idler gives that effect, the motor pulley should too ? The curtain effect should be halved isn't ? Are you using brand names components ?

[www.youtube.com]

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: To twist or not to twist March 08, 2018 02:34AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: To twist or not to twist March 08, 2018 03:23AM |

Registered: 6 years ago Posts: 1,007 |

Quote

Dark Alchemist

All I know is that the driver can be toothed but the follower (idler) needs to be smooth on smooth and if you make the idler smooth on smooth the effect isn't halved it is completely gone.

[www.youtube.com]

On the video, he changed both sides. Looks like standard timing belt, not GT2

GT2 profile is supposed to be better according to their doc .

An other thing, bad pulleys tooth profile but also bad alignment between motor and idler pulleys could make the teeth engage impropermy and cause this ripple (curtain) ? Just wondering.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: To twist or not to twist March 08, 2018 09:45AM |

Registered: 11 years ago Posts: 1,277 |

I talk to him a lot and only one side was changed and he did try, off camera, a toothed pully on the far side and the effect was still there. Having quality parts isn't going to help you because if you just think about it it is akin to driving over railroad ties or the drunk shoulder assist on major highways. Bumpty bumpity bump. Quality parts isn't going to change that.Quote

MKSA

Quote

Dark Alchemist

All I know is that the driver can be toothed but the follower (idler) needs to be smooth on smooth and if you make the idler smooth on smooth the effect isn't halved it is completely gone.

[www.youtube.com]

On the video, he changed both sides. Looks like standard timing belt, not GT2

GT2 profile is supposed to be better according to their doc .

An other thing, bad pulleys tooth profile but also bad alignment between motor and idler pulleys could make the teeth engage impropermy and cause this ripple (curtain) ? Just wondering.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: To twist or not to twist March 08, 2018 10:43AM |

Registered: 11 years ago Posts: 5,780 |

Toothed belts are simply floppy gears. In order to drive them you need a toothed drive pulley. The guy in the video may have fixed one problem, but he probably created others. For one thing, he's now driving the belt using just a couple teeth because of the goofy arrangement of the bearings that are pushing the belt against the drive pulley.

Quality parts may indeed make a difference. Unlike like your drunk-bumps analogy in which a big tire is rolling over a bunch of small closely spaced bumps, the pulley teeth and the belt teeth are supposed to match up. The rounded tooth profile of the GT2 type belt is intended to eliminate bumpy contact with the pulley.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Quality parts may indeed make a difference. Unlike like your drunk-bumps analogy in which a big tire is rolling over a bunch of small closely spaced bumps, the pulley teeth and the belt teeth are supposed to match up. The rounded tooth profile of the GT2 type belt is intended to eliminate bumpy contact with the pulley.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: To twist or not to twist March 08, 2018 01:21PM |

Registered: 11 years ago Posts: 1,277 |

I disagree and he has no issues since he fixed it so anything you say will be anecdotal, at best, whereas he actually uses his fix on a daily basis. Now his belt, as my belt or any belt on a purchased laser machine that I have seen, uses GT3 belts.Quote

the_digital_dentist

Toothed belts are simply floppy gears. In order to drive them you need a toothed drive pulley. The guy in the video may have fixed one problem, but he probably created others. For one thing, he's now driving the belt using just a couple teeth because of the goofy arrangement of the bearings that are pushing the belt against the drive pulley.

Quality parts may indeed make a difference. Unlike like your drunk-bumps analogy in which a big tire is rolling over a bunch of small closely spaced bumps, the pulley teeth and the belt teeth are supposed to match up. The rounded tooth profile of the GT2 type belt is intended to eliminate bumpy contact with the pulley.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: To twist or not to twist March 08, 2018 04:02PM |

Registered: 6 years ago Posts: 1,007 |

Quote

Dark Alchemist

I disagree and he has no issues since he fixed it so anything you say will be anecdotal, at best, whereas he actually uses his fix on a daily basis. Now his belt, as my belt or any belt on a purchased laser machine that I have seen, uses GT3 belts.Quote

the_digital_dentist

Toothed belts are simply floppy gears. In order to drive them you need a toothed drive pulley. The guy in the video may have fixed one problem, but he probably created others. For one thing, he's now driving the belt using just a couple teeth because of the goofy arrangement of the bearings that are pushing the belt against the drive pulley.

Quality parts may indeed make a difference. Unlike like your drunk-bumps analogy in which a big tire is rolling over a bunch of small closely spaced bumps, the pulley teeth and the belt teeth are supposed to match up. The rounded tooth profile of the GT2 type belt is intended to eliminate bumpy contact with the pulley.

We know that a smooth belt surface on a smooth pulley will not generate "ripples" ! That doesn't imply it is the only way to solve the issue.

We are trying to understand exactly what happens.

From the video, the belt doesn't look like a GT but more like a regular timing belt (trapezoid profile) more prone to ratcheting (a bumpy ride). I wouldn't be surprised if these chinese belts, pulleys are not exact and well made copies and they may even mix belts and pulleys.

These GT profiles are designed to address this ratcheting effect. May be with the right elements and of good quality, it won't happen or eventually they are yet not good enough for these laser machines.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: To twist or not to twist March 08, 2018 05:25PM |

Registered: 11 years ago Posts: 1,277 |

Nope, it is a 15mm wide GT3 profile belt.[edit] For those who do not know his machine caught fire and the original belt melted (the only damage) so he had to buy a belt for it and what he paid for that GT3 belt was crazy but he wanted to be sure it was a quality GT3 belt. SDP or some expensive brand as I forget what he purchased now.Quote

MKSA

Quote

Dark Alchemist

I disagree and he has no issues since he fixed it so anything you say will be anecdotal, at best, whereas he actually uses his fix on a daily basis. Now his belt, as my belt or any belt on a purchased laser machine that I have seen, uses GT3 belts.Quote

the_digital_dentist

Toothed belts are simply floppy gears. In order to drive them you need a toothed drive pulley. The guy in the video may have fixed one problem, but he probably created others. For one thing, he's now driving the belt using just a couple teeth because of the goofy arrangement of the bearings that are pushing the belt against the drive pulley.

Quality parts may indeed make a difference. Unlike like your drunk-bumps analogy in which a big tire is rolling over a bunch of small closely spaced bumps, the pulley teeth and the belt teeth are supposed to match up. The rounded tooth profile of the GT2 type belt is intended to eliminate bumpy contact with the pulley.

We know that a smooth belt surface on a smooth pulley will not generate "ripples" ! That doesn't imply it is the only way to solve the issue.

We are trying to understand exactly what happens.

From the video, the belt doesn't look like a GT but more like a regular timing belt (trapezoid profile) more prone to ratcheting (a bumpy ride). I wouldn't be surprised if these chinese belts, pulleys are not exact and well made copies and they may even mix belts and pulleys.

These GT profiles are designed to address this ratcheting effect. May be with the right elements and of good quality, it won't happen or eventually they are yet not good enough for these laser machines.

Here is what he had to say about this -

That curtains exist is beyond doubt. Are they artifacts of the toothed drive belt? I believe so, but others may doubt it. I have no problem with doubters they can continue bitching and never move forward. I am looking to see what cost effective elements would go to make and ideal Chinese machine that would overcome the 10% design compromises that have been made to keep the current machines simple and low cost. There are no large CNC machine reliying on toothed belts and stepper motors. It will instead be using backlash compensated rack and pinion or precision recirculating ball-screw systems. Toothed belts were designed for non-slip power transmission in ONE direction. They were not designed for precision control of absolute positioning systems. For very light loads they have been hijacked because they 95% work. I have analyzed the maths of the geometry and there is acceleration and deceleration profile as each tooth engages. There is also the natural want for the the first engaging tooth to stick/jam part way up the wall of the pulley tooth. Rubber and aluminium do not naturally slip against each other. When you are scanning just watch the belt rising as it enters the pulley and falls as it exits the pulley. There are natural clearances in the design of the belt and pulley profiles and all these factors subtract from a perfect bi directional control system.

If you analyze my reverse belt solution you will find that what I am doing is effectively creating a flexible rack and pinion system. There are only one or two teeth acting at any one time and because of the way I have clamped the belt against the drive pulley, I have overcome the belt climb issue. By running the smooth side of the belt over smooth pulleys there is no acceleration and deceleration caused when you run a belt (toothed or not) over a roller with flats on it.. Whether you run a 3D printer or a laser head you have a constant feed of melt material or a constant beam power. In either case you ASSUME that the traverse speed is absolutely constant. If it slows slightly you get a material buildup with 3D material extrusion and a material deficit if the speed increases. With a laser head you get increased cut depth as it slows and less cut depth as it increases. If you follow this logical analysis you can see that your varying material deposition/varying laser cut depth is in fact a record of varying velocity.

I restate finally that you would never consider running a smooth belt over a roller with flats on it whether it be 4 flats or 40 flats. What changes just because you add teeth? Now make that belt run over two flatted rollers (as many propose) that just adds to the problem. In short toothed belts will NEVER give absolutely constant speed that can ONLY be achieved with a flat belt on smooth pulleys. I hope you can see the logic of this, however, I will have no issue if you continue to believe in a "flat earth"

Edited 1 time(s). Last edit at 03/08/2018 05:32PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: To twist or not to twist March 08, 2018 05:59PM |

Registered: 11 years ago Posts: 335 |

I also find it unlikely that toothed idlers degrade motion quality as the drive pulley must always be toothed. If toothed pulleys always cause a curtain effect then all timing belt systems must be doomed.

Running teeth on smooth idlers will of course introduce some degree of vibration. At some diameter this will become negligable, but I prefer to avoid the risk myself.

This is likely his problem. How does he know what tooth profile the Chinese pulleys came with? I'm pretty sure it ain't Gates Powergrip.

The naming conventions that surround timing belt profiles are absolute insanity. There is both an Asian and a Gates version of GT. Gates Powergrip belts are available in the original GT profile, second generation GT2, and third generation GT3 profile; all of which are available in 2, 3, and 5mm pitches.

Misumi sells both GT and Gates GT belts so they differentiate the part numbers more clearly than most: [blog.misumiusa.com]

You can see how Gates organizes their belts here: [gatesbeltsandapplications.blogspot.ca]

There is no MR3 part number for an open loop belt, so GT2 and GT3 probably only differ by how they handle closed-loop tension members.

Modern belts have infiltrated a ton of positioning applications and are designed for smooth bidirectional motion. In properly matched timing belt systems you absolutely do not see the belt rise and fall as its teeth enter and exit the pulley.

Edited 1 time(s). Last edit at 03/08/2018 06:01PM by 691175002.

Running teeth on smooth idlers will of course introduce some degree of vibration. At some diameter this will become negligable, but I prefer to avoid the risk myself.

Quote

Nope, it is a 15mm wide GT3 profile belt. For those who do not know his machine caught fire and the original belt melted (the only damage) so he had to buy a belt for it and what he paid for that GT3 belt was crazy but he wanted to be sure it was a quality GT3 belt. SDP or some expensive brand as I forget what he purchased now.

This is likely his problem. How does he know what tooth profile the Chinese pulleys came with? I'm pretty sure it ain't Gates Powergrip.

The naming conventions that surround timing belt profiles are absolute insanity. There is both an Asian and a Gates version of GT. Gates Powergrip belts are available in the original GT profile, second generation GT2, and third generation GT3 profile; all of which are available in 2, 3, and 5mm pitches.

Misumi sells both GT and Gates GT belts so they differentiate the part numbers more clearly than most: [blog.misumiusa.com]

You can see how Gates organizes their belts here: [gatesbeltsandapplications.blogspot.ca]

There is no MR3 part number for an open loop belt, so GT2 and GT3 probably only differ by how they handle closed-loop tension members.

Quote

Toothed belts were designed for non-slip power transmission in ONE direction.

[...]

When you are scanning just watch the belt rising as it enters the pulley and falls as it exits the pulley.

Modern belts have infiltrated a ton of positioning applications and are designed for smooth bidirectional motion. In properly matched timing belt systems you absolutely do not see the belt rise and fall as its teeth enter and exit the pulley.

Edited 1 time(s). Last edit at 03/08/2018 06:01PM by 691175002.

|

Re: To twist or not to twist March 08, 2018 06:24PM |

Registered: 11 years ago Posts: 1,277 |

I sent him an email with what you said and like him I want to know why it happens and how to properly solve it from happening. When I am dealing with a laser beam I see the curtain effect but I do also see an effect on my 3d prints that I have never been able to explain away or fix. I used to think that what I was seeing is just the plastic goo not smoothly leaving the nozzle but a laser has no goo or nozzle so that shot that theory out the window. Russ is in England so I never know when he is awake or asleep but await his response. Now I will say he has two machines and one was the one I have and the other is a Lightblade machine which was given to him for work done and it is a far superior machine (the burns into Acrylic are far sharper for instance) BUT it too has the curtain effect (has 20t pulleys) but not as severe. Heck, now that I know about the effect I have seen it in every single picture thrown up on the Facebook groups I am in and these are machines ranging from the lowly K40 all the way through the Lightblade up to Epilog machines and all brands inbetween. His pulleys are 16t whereas mine are 20t (most are 20t) and to compound the issue most of these blasted machines use press on gears (smh) so not easy to slap on your own like it is with Nema 17 GT2 systems on our 3d printers.Quote

691175002

I also find it unlikely that toothed idlers degrade motion quality as the drive pulley must always be toothed. If toothed pulleys always cause a curtain effect then all timing belt systems must be doomed.

Running teeth on smooth idlers will of course introduce some degree of vibration. At some diameter this will become negligable, but I prefer to avoid the risk myself.

Quote

Nope, it is a 15mm wide GT3 profile belt. For those who do not know his machine caught fire and the original belt melted (the only damage) so he had to buy a belt for it and what he paid for that GT3 belt was crazy but he wanted to be sure it was a quality GT3 belt. SDP or some expensive brand as I forget what he purchased now.

This is likely his problem. How does he know what tooth profile the Chinese pulleys came with? I'm pretty sure it ain't Gates Powergrip.

The naming conventions that surround timing belt profiles are absolute insanity. There is both an Asian and a Gates version of GT. Gates Powergrip belts are available in the original GT profile, second generation GT2, and third generation GT3 profile; all of which are available in 2, 3, and 5mm pitches.

Misumi sells both GT and Gates GT belts so they differentiate the part numbers more clearly than most: [blog.misumiusa.com]

You can see how Gates organizes their belts here: [gatesbeltsandapplications.blogspot.ca]

There is no MR3 part number for an open loop belt, so GT2 and GT3 probably only differ by how they handle closed-loop tension members.

Quote

Toothed belts were designed for non-slip power transmission in ONE direction.

[...]

When you are scanning just watch the belt rising as it enters the pulley and falls as it exits the pulley.

Modern belts have infiltrated a ton of positioning applications and are designed for smooth bidirectional motion. In properly matched timing belt systems you absolutely do not see the belt rise and fall as its teeth enter and exit the pulley.

Edited 1 time(s). Last edit at 03/08/2018 06:29PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: To twist or not to twist March 08, 2018 07:23PM |

Registered: 11 years ago Posts: 1,277 |

Here is your reply and I doubt he will comment anymore on the subject from what I gathered from his response.Quote

691175002

I also find it unlikely that toothed idlers degrade motion quality as the drive pulley must always be toothed. If toothed pulleys always cause a curtain effect then all timing belt systems must be doomed.

Running teeth on smooth idlers will of course introduce some degree of vibration. At some diameter this will become negligable, but I prefer to avoid the risk myself.

Quote

Nope, it is a 15mm wide GT3 profile belt. For those who do not know his machine caught fire and the original belt melted (the only damage) so he had to buy a belt for it and what he paid for that GT3 belt was crazy but he wanted to be sure it was a quality GT3 belt. SDP or some expensive brand as I forget what he purchased now.

This is likely his problem. How does he know what tooth profile the Chinese pulleys came with? I'm pretty sure it ain't Gates Powergrip.

The naming conventions that surround timing belt profiles are absolute insanity. There is both an Asian and a Gates version of GT. Gates Powergrip belts are available in the original GT profile, second generation GT2, and third generation GT3 profile; all of which are available in 2, 3, and 5mm pitches.

Misumi sells both GT and Gates GT belts so they differentiate the part numbers more clearly than most: [blog.misumiusa.com]

You can see how Gates organizes their belts here: [gatesbeltsandapplications.blogspot.ca]

There is no MR3 part number for an open loop belt, so GT2 and GT3 probably only differ by how they handle closed-loop tension members.

Quote

Toothed belts were designed for non-slip power transmission in ONE direction.

[...]

When you are scanning just watch the belt rising as it enters the pulley and falls as it exits the pulley.

Modern belts have infiltrated a ton of positioning applications and are designed for smooth bidirectional motion. In properly matched timing belt systems you absolutely do not see the belt rise and fall as its teeth enter and exit the pulley.

To sum all this up. My engineering background has taught me that understanding a problem (REALLY understanding it ) is 50% of the solution. Once I identify that a problem (or something I dont understand) exists, I research and analyse with as much logic and open mindedness as possible. I don't argue or discuss. I formulate a solution based on an understanding of the problem and test it. It either works or not. If black proves to be black and you cannot accept it...... what can I say? I have often got it wrong on video but admission and ultimately discovering the real truth is all part of the learning process that I hope others benefit from. I do not claim I am solving everyone's problems I am only showing what I am doing. It is MY learning journey with MY pretty standard Chinese machine. It MAY apply to your machine.

By the way I agree that a toothed belt running round a plain pulley is the same effect as passing a flat belt around a pulley with flats on it. The belt names usually confirm POWER is the key function for these belts The tooth design is all about reducing tooth stress whilst transmitting that power. That is why I say that these standard cheap industrial components have been hijacked for another unintended purpose..

I'm not discussing your last paragraph because I have no facts or evidence. My work can only be limited to the problems that I have in front of me and these machines use standard engineering components which is all I can assess.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: To twist or not to twist March 09, 2018 02:49AM |

Registered: 8 years ago Posts: 5,232 |

On which side of the idler will we see vibrations? On the entry side ( where it counts ) or on the rear side? I don't mind the belt humming on the back path to the drive gear unless there is a resonance with the printer.Quote

6911...

Running teeth on smooth idlers will of course introduce some degree of vibration.

|

Re: To twist or not to twist March 09, 2018 04:24AM |

Registered: 6 years ago Posts: 1,007 |

An other potential cause, the pulleys used rather small and PU reinforced belt not as flexible as rubber.

The Misumi doc rates the different belt regarding their char. Here we are interested in positioning accuracy and backlash: [blog.misumiusa.com]

Fact is, the mod works, nobody question this.

But fact is that it doens't prove these GT timing belts are intrinsically unsuitable because IF the cause are: poor belt/pulley quality, matching, improper mount (idler not // to motor) etc... this mod eliminates these.

It is an other way to mount/use a belt, smart indeed and achieves its goal considering the load is light as only one, two tooth are engaged.

Edited 2 time(s). Last edit at 03/09/2018 07:06AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

The Misumi doc rates the different belt regarding their char. Here we are interested in positioning accuracy and backlash: [blog.misumiusa.com]

Fact is, the mod works, nobody question this.

But fact is that it doens't prove these GT timing belts are intrinsically unsuitable because IF the cause are: poor belt/pulley quality, matching, improper mount (idler not // to motor) etc... this mod eliminates these.

It is an other way to mount/use a belt, smart indeed and achieves its goal considering the load is light as only one, two tooth are engaged.

Edited 2 time(s). Last edit at 03/09/2018 07:06AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Sorry, only registered users may post in this forum.