Corexy issues advice needed

Posted by rastaman46

|

Corexy issues advice needed June 13, 2016 04:36AM |

Registered: 9 years ago Posts: 93 |

Hi all again

im finished my corexy build. But suffering from quality issues don't know what to do.

Can print perfect cube!!! But cant print Big gear no matter what I do.

Is there any procedure for calibrating XY ???

See attached for comparison My prusa i3 performed much better then my Corexy

I have gone From Direct drive (Motor mounted on cartage) to Geared Bowden made no different in printing Gear

Thanks for any ones time

Regards

im finished my corexy build. But suffering from quality issues don't know what to do.

Can print perfect cube!!! But cant print Big gear no matter what I do.

Is there any procedure for calibrating XY ???

See attached for comparison My prusa i3 performed much better then my Corexy

I have gone From Direct drive (Motor mounted on cartage) to Geared Bowden made no different in printing Gear

Thanks for any ones time

Regards

|

Re: Corexy issues advice needed June 13, 2016 06:46AM |

Registered: 8 years ago Posts: 346 |

|

Re: Corexy issues advice needed June 13, 2016 07:29AM |

Registered: 9 years ago Posts: 93 |

Quote

filipeCampos

The problem you have is not a problem of the extruder. From the image i can see layers put with lack of precision, the cause can be many things...

You need to check the obvious: possible rigidity problem of the bed, carriage and main structure. Check the belt tension too.

Hi thanks for reply

My frame is welded strong as rock

Cartage looks and feels really tight

Belts are tight (Tried more tighter made no difference ) Same output but more noise from belts.

Reduced print speed to 40 still same

Using auto bed levelling

Regards

|

Re: Corexy issues advice needed June 13, 2016 08:03AM |

Registered: 9 years ago Posts: 346 |

Can you show a photo of the cube you said printed OK?

If the quality is dependent of the many changes in direction which are done for the gear, then that, for me, is an indication that it is not bed but the CoreXY system.

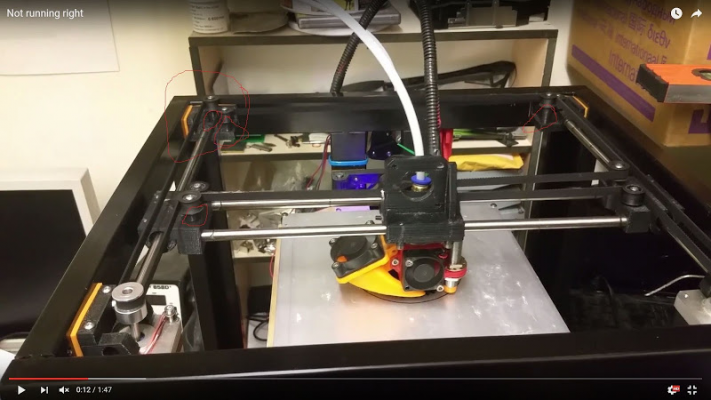

For me two things comes to mind when looking at the photo of your printer;

1) The post holding your belts are tall. Maybe the idlers can flex slightly inwards when loaded.

2) The nozzle is much below the smooth rods. Can you try to touch the nozzle (while cold) with your finger and try to see if it can move back and forth easily? I am talking about if the way you secured the hot-end allows it to move a little.

A better picture of your belt paths would be helpful.

If the quality is dependent of the many changes in direction which are done for the gear, then that, for me, is an indication that it is not bed but the CoreXY system.

For me two things comes to mind when looking at the photo of your printer;

1) The post holding your belts are tall. Maybe the idlers can flex slightly inwards when loaded.

2) The nozzle is much below the smooth rods. Can you try to touch the nozzle (while cold) with your finger and try to see if it can move back and forth easily? I am talking about if the way you secured the hot-end allows it to move a little.

A better picture of your belt paths would be helpful.

|

Re: Corexy issues advice needed June 13, 2016 08:10AM |

Registered: 8 years ago Posts: 346 |

the printer looks like to have a very strong main frame.

I only have some information and the photos, is pretty difficult to pinpoint the problem. I will suggest some action you can do, but not sure if it will help you.

Some of my conclusions:

From the image of the print is easy to see the hotend do not have the same position on all the layers. but is not a missing steps problems.

I think the problem was nothing to do with software or configuration, like the print speed.

It appears to be some type of problem related with the lack of rigidity or something not correctly installed that provoke this lack of precision of the hotend.

I will suggest to check the next items:

-check if the hotend is well secure in the carriage.

-check if the carriage move freely and not allow sides movements.

-The mk2 bed looks to be at a very high point in relation to the wood plate, I will suggest to screw more the bed, Try to put the metal mk2 at half the distant is actually is know.

My bet is the problem is related with the bed. The bed structure appears to be the weak point of the printer, you are using a heavy wood plate, small printed arms and 2 small rods. Is a bad combination.

-check if the bed arms was a good rigidity and lot allow side movements. From the image it appears you are using two printed arms, this can be the cause.

Edited 1 time(s). Last edit at 06/13/2016 08:21AM by filipeCampos.

I only have some information and the photos, is pretty difficult to pinpoint the problem. I will suggest some action you can do, but not sure if it will help you.

Some of my conclusions:

From the image of the print is easy to see the hotend do not have the same position on all the layers. but is not a missing steps problems.

I think the problem was nothing to do with software or configuration, like the print speed.

It appears to be some type of problem related with the lack of rigidity or something not correctly installed that provoke this lack of precision of the hotend.

I will suggest to check the next items:

-check if the hotend is well secure in the carriage.

-check if the carriage move freely and not allow sides movements.

-The mk2 bed looks to be at a very high point in relation to the wood plate, I will suggest to screw more the bed, Try to put the metal mk2 at half the distant is actually is know.

My bet is the problem is related with the bed. The bed structure appears to be the weak point of the printer, you are using a heavy wood plate, small printed arms and 2 small rods. Is a bad combination.

-check if the bed arms was a good rigidity and lot allow side movements. From the image it appears you are using two printed arms, this can be the cause.

Edited 1 time(s). Last edit at 06/13/2016 08:21AM by filipeCampos.

|

Re: Corexy issues advice needed June 13, 2016 08:17AM |

Registered: 9 years ago Posts: 93 |

Quote

filipeCampos

the printer looks like to have a very strong main frame.

I only have some information and the photos, is pretty difficult to pinpoint the problem. I will suggest some action you can do, but not sure if it will help you.

Some of my conclusions:

From the image of the print is easy to see the hotend do not have the same position on all the layers. but is not a missing steps problems.

I think the problem was nothing to do with software or configuration, like the print speed.

It appears to be some type of problem related with the lack of rigidity or something not correctly installed that provoke this lack of precision of the hotend.

I will suggest to check the next items:

-check if the hotend is well secure in the carriage.

-check if the carriage move freely and not allow sides movements.

-The mk2 bed looks to be at a very high point in relation to the wood plate, I will suggest to screw more the bed, Try to put the metal mk2 at half the distant is actually is know.

My bet is the problem is related with the bed structure.

-check if the bed arms was a good rigidity and lot allow side movements. From the image it appears you are using two printed arms, this can be the cause.

Thanks for your reply

Ill check all this

Image is quiet old I have upgraded to MK3 and probe for auto level

Ill check bed tonight

xy moves freely and there no play in movement

ill check hot end for movement aswell

Ill back once checked

Thanks again

Regards

|

Re: Corexy issues advice needed June 13, 2016 11:09AM |

Registered: 9 years ago Posts: 346 |

|

Re: Corexy issues advice needed June 13, 2016 11:49AM |

Registered: 9 years ago Posts: 93 |

|

Re: Corexy issues advice needed June 13, 2016 02:49PM |

Registered: 9 years ago Posts: 93 |

|

Re: Corexy issues advice needed June 13, 2016 04:25PM |

Registered: 10 years ago Posts: 12 |

|

Re: Corexy issues advice needed June 13, 2016 05:29PM |

Registered: 9 years ago Posts: 93 |

|

Re: Corexy issues advice needed June 13, 2016 05:39PM |

Registered: 10 years ago Posts: 12 |

|

Re: Corexy issues advice needed June 13, 2016 05:44PM |

Registered: 9 years ago Posts: 346 |

It seems when the printer is making the same movement all the time it returns to the same position.

I still say either the hotend can move or the idlers are flexing.

For further diagnostic I think you will need to make a video of it running while printing something difficult. The video should show all the idlers where the belts passes and the hotend itself.

I still say either the hotend can move or the idlers are flexing.

For further diagnostic I think you will need to make a video of it running while printing something difficult. The video should show all the idlers where the belts passes and the hotend itself.

|

Re: Corexy issues advice needed June 13, 2016 06:43PM |

Registered: 9 years ago Posts: 93 |

|

Re: Corexy issues advice needed June 13, 2016 07:14PM |

Registered: 11 years ago Posts: 5,780 |

The belt on the left side deflects laterally each time the motor reverses direction, and the belt on the right does the same to a lesser extent. That indicates an alignment problem. The belts should not deflect at all.

Edited 1 time(s). Last edit at 06/13/2016 07:16PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 06/13/2016 07:16PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Corexy issues advice needed June 14, 2016 07:54AM |

Registered: 9 years ago Posts: 93 |

Quote

the_digital_dentist

The belt on the left side deflects laterally each time the motor reverses direction, and the belt on the right does the same to a lesser extent. That indicates an alignment problem. The belts should not deflect at all.

Thanks for reply

Can you point me out please how to address this???

Regards

|

Re: Corexy issues advice needed June 14, 2016 08:03AM |

Registered: 9 years ago Posts: 346 |

I agree with The Digital Dentist that your belts are flexing - But I don't think it is belt tension.

I think it is the idler posts. When the printer changes direction the load on the idlers (marked with read below) changes and the idler posts flexes slightly. If this is true it should be visible if you feel with your finger on the screw that secures the idler while it is running

To fix this is not entirely trivial as you will need to redesign the support for the idlers to be stronger.

Edited 1 time(s). Last edit at 06/14/2016 08:05AM by LarsK.

I think it is the idler posts. When the printer changes direction the load on the idlers (marked with read below) changes and the idler posts flexes slightly. If this is true it should be visible if you feel with your finger on the screw that secures the idler while it is running

To fix this is not entirely trivial as you will need to redesign the support for the idlers to be stronger.

Edited 1 time(s). Last edit at 06/14/2016 08:05AM by LarsK.

|

Re: Corexy issues advice needed June 14, 2016 08:05AM |

Registered: 11 years ago Posts: 5,780 |

Measure the height of the pulley edges relative to the printer's frame. For each belt the pulleys should be at the same height. The belt should not be rubbing hard on the flanges of the pulleys. If the motor and pulleys' axes are not parallel it will cause the belt to ride against the flanges on the pulleys.

Doh! LarsK beat me to it.

That's the problem with cantilevered bearing posts, and especially if they are screwed to printed plastic mounts. Under belt tension the mounts will flex. If you're going to use printed plastic mounts for the pulleys, they should support the bearing axle at the top and the bottom. Likewise, plastic motor mounts. The left motor pulley looks like it is pulled up on the shaft away from the motor body. That makes a long lever with which to flex the motor mount. Keep the pulleys close to the motor body to minimize flex in the mount.

Edited 2 time(s). Last edit at 06/14/2016 08:15AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Doh! LarsK beat me to it.

That's the problem with cantilevered bearing posts, and especially if they are screwed to printed plastic mounts. Under belt tension the mounts will flex. If you're going to use printed plastic mounts for the pulleys, they should support the bearing axle at the top and the bottom. Likewise, plastic motor mounts. The left motor pulley looks like it is pulled up on the shaft away from the motor body. That makes a long lever with which to flex the motor mount. Keep the pulleys close to the motor body to minimize flex in the mount.

Edited 2 time(s). Last edit at 06/14/2016 08:15AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Corexy issues advice needed June 14, 2016 08:51AM |

Registered: 9 years ago Posts: 93 |

Thanks for reply

ok ill get this checked of any movement on this and report back once home

And how to make idler mount stronger on 3D printed parts ?

Thanks for your repply

I will get all measured and visually checked once home

The left motor pulley need to be that high cant just drop it flip it maybe?

Ill try to design new mount for that motor to drop pulley

Its printed small gear fine (9 teeth) come out perfect it gives perfect cycles aswell

[drive.google.com]

Edited 1 time(s). Last edit at 06/14/2016 08:56AM by rastaman46.

ok ill get this checked of any movement on this and report back once home

And how to make idler mount stronger on 3D printed parts ?

Quote

LarsK

I agree with The Digital Dentist that your belts are flexing - But I don't think it is belt tension.

I think it is the idler posts. When the printer changes direction the load on the idlers (marked with read below) changes and the idler posts flexes slightly. If this is true it should be visible if you feel with your finger on the screw that secures the idler while it is running

To fix this is not entirely trivial as you will need to redesign the support for the idlers to be stronger.

Thanks for your repply

I will get all measured and visually checked once home

The left motor pulley need to be that high cant just drop it flip it maybe?

Ill try to design new mount for that motor to drop pulley

Its printed small gear fine (9 teeth) come out perfect it gives perfect cycles aswell

[drive.google.com]

Quote

the_digital_dentist

Measure the height of the pulley edges relative to the printer's frame. For each belt the pulleys should be at the same height. The belt should not be rubbing hard on the flanges of the pulleys. If the motor and pulleys' axes are not parallel it will cause the belt to ride against the flanges on the pulleys.

Doh! LarsK beat me to it.

That's the problem with cantilevered bearing posts, and especially if they are screwed to printed plastic mounts. Under belt tension the mounts will flex. If you're going to use printed plastic mounts for the pulleys, they should support the bearing axle at the top and the bottom. Likewise, plastic motor mounts. The left motor pulley looks like it is pulled up on the shaft away from the motor body. That makes a long lever with which to flex the motor mount. Keep the pulleys close to the motor body to minimize flex in the mount.

Edited 1 time(s). Last edit at 06/14/2016 08:56AM by rastaman46.

|

Re: Corexy issues advice needed June 14, 2016 09:31AM |

Registered: 11 years ago Posts: 5,780 |

Are the black pulleys 3D printed? I would not trust 3D printed pulleys to be perfectly round. If they are out of round at all the belt tension and extruder carriage position will keep changing because the belt path length will be changing as the pulleys rotate. You'll never get two print layers to match up...

Edited 1 time(s). Last edit at 06/14/2016 09:32AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 06/14/2016 09:32AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Corexy issues advice needed June 14, 2016 10:19AM |

Registered: 9 years ago Posts: 93 |

Quote

the_digital_dentist

Are the black pulleys 3D printed? I would not trust 3D printed pulleys to be perfectly round. If they are out of round at all the belt tension and extruder carriage position will keep changing because the belt path length will be changing as the pulleys rotate. You'll never get two print layers to match up...

Yes they are 3d printed

What would be the best option to replace them with?

Regards

|

Re: Corexy issues advice needed June 14, 2016 10:33AM |

Registered: 11 years ago Posts: 5,780 |

Use flanged ball bearings (F608zz, F625zz, or similar), or use properly made, flanged, toothed pulleys (http://www.ebay.com/itm/5pcs-GT2-20-16-Tooth-Gear-3mm-5mm-Idler-Pulley-Aluminum-2GT-for-3D-Printer-/201584674855?var=&hash=item2eef620827:m:mIY9J8L1M_sWNwPpl2DToNw)

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Corexy issues advice needed June 14, 2016 10:46AM |

Registered: 9 years ago Posts: 93 |

Quote

the_digital_dentist

Use flanged ball bearings (F608zz, F625zz, or similar), or use properly made, flanged, toothed pulleys (http://www.ebay.com/itm/5pcs-GT2-20-16-Tooth-Gear-3mm-5mm-Idler-Pulley-Aluminum-2GT-for-3D-Printer-/201584674855?var=&hash=item2eef620827:m:mIY9J8L1M_sWNwPpl2DToNw)

Thanks for reply

Ill get all checked tonight and then I may put some more money in it again

Regards

|

Re: Corexy issues advice needed June 14, 2016 01:47PM |

Registered: 9 years ago Posts: 93 |

|

Re: Corexy issues advice needed June 15, 2016 06:05AM |

Registered: 9 years ago Posts: 93 |

Hi thanks for help all I think I sorted now

I have played with idlers yesterday

All idlers had no play at all

Then like you said I have checked roundness and have replaced couple and got gear printed nicely (Well its still not perfect but much better.

So I have ordered aluminium idlers to replace 3d printed once.

So thanks all again

Regards

I have played with idlers yesterday

All idlers had no play at all

Then like you said I have checked roundness and have replaced couple and got gear printed nicely (Well its still not perfect but much better.

So I have ordered aluminium idlers to replace 3d printed once.

So thanks all again

Regards

|

Re: Corexy issues advice needed June 15, 2016 07:46AM |

Registered: 9 years ago Posts: 346 |

Just for clarification, it is not play we are looking for. Play means when the idlers can move because a hole is too big or something like that. What I was looking for, was if the belt under load forces the idlers to bend in a direction. Maybe that is what you did, but just to clarify in case.

Nobody seemed to want to post a belt video, so here is one I shot from the printer I am currently working on: [goo.gl]

You see how the belt moves up and down the pulley? That is not supposed to happen - But you also see how my belt does not "relax" when going in the opposite direction, this is the important thing.

- But you also see how my belt does not "relax" when going in the opposite direction, this is the important thing.

And here is the 3d benchy I was printing yesterday: [goo.gl]

I recommend you do test printing of the 3dBenchy ( [www.thingiverse.com] & [www.3dbenchy.com] ). Benchy is really a good "standardized" challenge with many dimensions to check and pictures on the internet to compare.

Last night I was test printing the Benchy before I move on to replacing the bed on the printer, this way I can do before and after comparison.

Nobody seemed to want to post a belt video, so here is one I shot from the printer I am currently working on: [goo.gl]

You see how the belt moves up and down the pulley? That is not supposed to happen

- But you also see how my belt does not "relax" when going in the opposite direction, this is the important thing.

- But you also see how my belt does not "relax" when going in the opposite direction, this is the important thing. And here is the 3d benchy I was printing yesterday: [goo.gl]

I recommend you do test printing of the 3dBenchy ( [www.thingiverse.com] & [www.3dbenchy.com] ). Benchy is really a good "standardized" challenge with many dimensions to check and pictures on the internet to compare.

Last night I was test printing the Benchy before I move on to replacing the bed on the printer, this way I can do before and after comparison.

|

Re: Corexy issues advice needed June 15, 2016 08:14AM |

Registered: 11 years ago Posts: 5,780 |

Try not to cantilever the pulleys- support them at top and bottom of the pulley's axle. If you support from one side only the mounts will flex/distort. This sort of thing is why I try to minimize use of printed components in my printers.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Corexy issues advice needed June 15, 2016 08:19AM |

Registered: 9 years ago Posts: 93 |

Quote

LarsK

Just for clarification, it is not play we are looking for. Play means when the idlers can move because a hole is too big or something like that. What I was looking for, was if the belt under load forces the idlers to bend in a direction. Maybe that is what you did, but just to clarify in case.

Nobody seemed to want to post a belt video, so here is one I shot from the printer I am currently working on: [goo.gl]

You see how the belt moves up and down the pulley? That is not supposed to happen- But you also see how my belt does not "relax" when going in the opposite direction, this is the important thing.

And here is the 3d benchy I was printing yesterday: [goo.gl]

I recommend you do test printing of the 3dBenchy ( [www.thingiverse.com] & [www.3dbenchy.com] ). Benchy is really a good "standardized" challenge with many dimensions to check and pictures on the internet to compare.

Last night I was test printing the Benchy before I move on to replacing the bed on the printer, this way I can do before and after comparison.

Thanks for your reply

And yes idlers do not move when direction changes (Rock solid )

I cant watch 1st video keep getting error but will try at home maybe internet not good at work.

And my belts don't seam to go up and down they always in same position

I will try to print Benchy to se how good I get it.

and ill take about 2 to 3 weeks to get idlers coz they coming from china

Regards

|

Re: Corexy issues advice needed June 27, 2016 03:50AM |

Registered: 9 years ago Posts: 93 |

Sorry, only registered users may post in this forum.