|

belts path on the same plane using a belt twist July 19, 2016 06:30AM |

Registered: 8 years ago Posts: 346 |

Found on youtube a german guy that is building a corexy printer with a belt path different of the usual ones, check the video:

[www.youtube.com]

This setup allow to simplify a lot the pulley locations and both belt are in the same plane.

I really liked this setup and i was planning to use it, but i not sure if the twist of the belt can give or not troubles.

I would like to listen yours opinions about this setup..

[www.youtube.com]

This setup allow to simplify a lot the pulley locations and both belt are in the same plane.

I really liked this setup and i was planning to use it, but i not sure if the twist of the belt can give or not troubles.

I would like to listen yours opinions about this setup..

|

Re: belts path on the same plane using a belt twist July 19, 2016 07:56AM |

Registered: 11 years ago Posts: 5,780 |

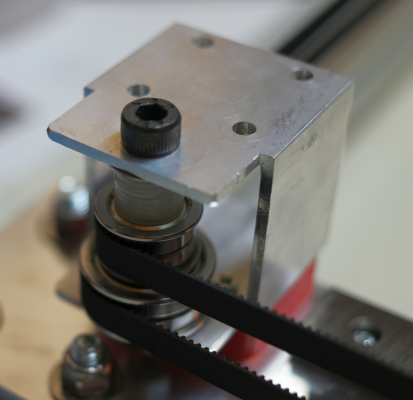

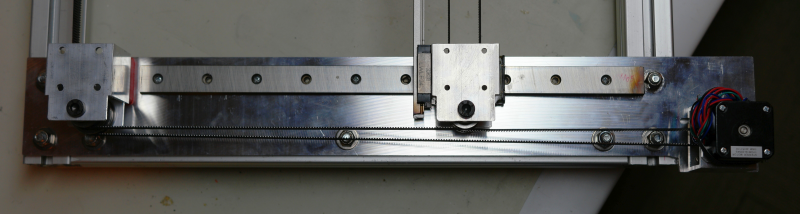

If you put the belts on one level vertically, you have to put the twist in. Notice that each pulley has its own axle, and they are spread out next to each other increasing the area required by the belt system. If you put the belts on two vertical levels, you avoid the twist and can use one axle for both belts at each "corner". In theory it could be made a little more compact. Using the one level bet/pulley design, the motor mounts are identical. Using two levels may require nonidentical motor mounts. Using one level belts/pulleys, the posts that support the pulleys are shorter and less likely to flex under belt tension.

The pulleys used in the video look pretty small and I can't tell if they have teeth or not. If you're going to use small pulleys with belt teeth contacting the pulley, they should have teeth. Small, smooth pulleys with few belt teeth contacting the smooth pulley surface will cause variations in belt tension as each tooth meets and leaves the pulley surface which may cause artifacts in the print surface. According to SDP/SI, smooth pulleys should at least have equivalent diameter of 40 tooth pulley (roughly, for 2 mm pitch belt, that's 80 mm circumference, therefore 25.5 mm diameter). I used not quite ideal F608ZZ bearings, 22 mm in diameter and F6903ZZ bearings, 30 mm in diameter for my dual level belt design. Some people put one twist in each belt for two level belt/pulley systems in order to keep the smooth side of the belt against smooth pulley surfaces.

Twisting the belt and using small pulleys may reduce the life of the belt. It has been my experience that it is hard to keep twisted belts centered on their pulleys, but it looks like the machine in the video has things under control.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The pulleys used in the video look pretty small and I can't tell if they have teeth or not. If you're going to use small pulleys with belt teeth contacting the pulley, they should have teeth. Small, smooth pulleys with few belt teeth contacting the smooth pulley surface will cause variations in belt tension as each tooth meets and leaves the pulley surface which may cause artifacts in the print surface. According to SDP/SI, smooth pulleys should at least have equivalent diameter of 40 tooth pulley (roughly, for 2 mm pitch belt, that's 80 mm circumference, therefore 25.5 mm diameter). I used not quite ideal F608ZZ bearings, 22 mm in diameter and F6903ZZ bearings, 30 mm in diameter for my dual level belt design. Some people put one twist in each belt for two level belt/pulley systems in order to keep the smooth side of the belt against smooth pulley surfaces.

Twisting the belt and using small pulleys may reduce the life of the belt. It has been my experience that it is hard to keep twisted belts centered on their pulleys, but it looks like the machine in the video has things under control.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: belts path on the same plane using a belt twist July 19, 2016 09:51AM |

Registered: 7 years ago Posts: 558 |

Stacking the pulleys on top of each other reduces the amount you can travel very so slightly as the closer you get to the pulleys, the belt teeth begin to line up and eventually interlock before you reach the complete end of travel. On smaller machines, its not as noticeable, but I ran into this with my 300x300 coreXY build and redesigned my rear parts. Thingiverse.com

|

Re: belts path on the same plane using a belt twist July 19, 2016 10:01AM |

Registered: 9 years ago Posts: 346 |

The idea was discussed in here some time ago. I thought it was in the Zeologic thread but can't seem to find it now. I tried the same on my printer but at my build size with some 450 mm it seemed to me I wouldn't be able to get it working so nicely so I abandoned it. When doing this the belts does still have a width of almost 2 mm and they both want to pass in the absolute center so they will have contact with each other or force them self up/down on the idler post. I remember the the user who had done it said the contact seemed very light and he did not believe it would matter. I think it is wrong to have two belts that can move in opposite directions rubbing against each other but I agree that the impact should be small - Again considering the printer liftetime is maybe 2 magnitudes smaller then the belt life in optimal conditions. And as he said - If the belts fail he just puts new belts... Not that big of a deal.

At the end of the day I do not think one way or the other prohibits the printer from working but I think the two plane concept is superior to this. Aka., you must have some third restraining reason why you want to do this, because otherwise the two plane method is better.

About twisting belts; We discussed the belt twisting here some time back.

My point of view in short: The GT2 belts can have an angular misalignment of 5.22 mm per m or 1/4 deg. That is from Gates them-self (p 199)

After that forum discussion I have come to doubt how to actually read the specification, but even using the most conservative 1/4 deg you still get that the belt can be stretched some 0.026 mm which is roughly the same stretch you get when twisting the belts on a 0.5m length.

Gates are however very clear that any angular misalignment will impact lifetime. In my experience printers fail for a lot of things before belts fail.

On the Delta forums there has been a lot of discussion if the belts running on plain side idlers impacts lifetime, this is because it is inherent to the Delta with belts that this will happen - The overall consensus (I think) is that it does not impact print quality. It only makes more noise.

In the specification for the belts it is given how big an idler you must use if you run the toothed side on the plain idler.

At the end of the day I do not think one way or the other prohibits the printer from working but I think the two plane concept is superior to this. Aka., you must have some third restraining reason why you want to do this, because otherwise the two plane method is better.

About twisting belts; We discussed the belt twisting here some time back.

My point of view in short: The GT2 belts can have an angular misalignment of 5.22 mm per m or 1/4 deg. That is from Gates them-self (p 199)

After that forum discussion I have come to doubt how to actually read the specification, but even using the most conservative 1/4 deg you still get that the belt can be stretched some 0.026 mm which is roughly the same stretch you get when twisting the belts on a 0.5m length.

Gates are however very clear that any angular misalignment will impact lifetime. In my experience printers fail for a lot of things before belts fail.

On the Delta forums there has been a lot of discussion if the belts running on plain side idlers impacts lifetime, this is because it is inherent to the Delta with belts that this will happen - The overall consensus (I think) is that it does not impact print quality. It only makes more noise.

In the specification for the belts it is given how big an idler you must use if you run the toothed side on the plain idler.

|

Re: belts path on the same plane using a belt twist July 19, 2016 01:36PM |

Registered: 11 years ago Posts: 5,780 |

Quote

PDBeal

Stacking the pulleys on top of each other reduces the amount you can travel very so slightly as the closer you get to the pulleys, the belt teeth begin to line up and eventually interlock before you reach the complete end of travel. On smaller machines, its not as noticeable, but I ran into this with my 300x300 coreXY build and redesigned my rear parts. Thingiverse.com

I think you missed the easy fix. Just use a larger pulley for each belt at the corner opposite the motor. I used 22 mm pulleys and 30 mm pulleys. It guarantees at least 4mm of spacing..

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.