What is the best option for heated bed 300x200

Posted by filipeCampos

|

What is the best option for heated bed 300x200 July 25, 2016 05:13AM |

Registered: 8 years ago Posts: 346 |

Hi,

Planning to build a heated bed with 300mm x 200mm. It will be supported with two rods of 16mm, 2 linear bearing of 60mm long, threaded screw 8mm with 1.5 pitch and a big nema17 2.5A.

I know two posible options:

1) using a 300x200 mk3 bed, with a 3mm glass on top. (total cost: 39€)

2) Aluminum plate with 320 x 200 x 6mm, 200x200 silicone heater and a 3mm glass on top. (total cost 50€)

Only have experience with the first solution, it work ok on my 200x200 bed, but not sure if is a good option with a bigger bed. the mk3 bed is very slim (2mm)

About the second option, i only found aluminum plate with 6mm thick, the plate only will have 1kg. Not sure if is not to heavy for the setup.

What will be the best option between the two?

there is other better solution i do not know?

Planning to build a heated bed with 300mm x 200mm. It will be supported with two rods of 16mm, 2 linear bearing of 60mm long, threaded screw 8mm with 1.5 pitch and a big nema17 2.5A.

I know two posible options:

1) using a 300x200 mk3 bed, with a 3mm glass on top. (total cost: 39€)

2) Aluminum plate with 320 x 200 x 6mm, 200x200 silicone heater and a 3mm glass on top. (total cost 50€)

Only have experience with the first solution, it work ok on my 200x200 bed, but not sure if is a good option with a bigger bed. the mk3 bed is very slim (2mm)

About the second option, i only found aluminum plate with 6mm thick, the plate only will have 1kg. Not sure if is not to heavy for the setup.

What will be the best option between the two?

there is other better solution i do not know?

|

Re: What is the best option for heated bed 300x200 July 25, 2016 07:53AM |

Registered: 11 years ago Posts: 5,780 |

The MK3 is a PCB based heater- those are always under powered. You should be able to find a 300 x 200 silicone heater without too much trouble. Some of the Chinese suppliers will even do custom jobs for a single piece. You need at least 0.4 W/ cm^2 or you'll be waiting for the thing to heat up all day. You've got 600 cm^2, so look for at least 240 W. I'd go for 300W or so just to be sure. If the bed takes a long time to heat up because of an under powered heater, the controller will have trouble maintaining a constant temperature.

Glass is unnecessary. 1/4" plain aluminum sheet is very rigid, so clamping a piece of thin glass to it will not flatten it. 1/4" cast aluminum tooling plate will be flat enough to print on without glass.

Do you need a heated bed at all? I have found that PLA sticks almost too well to blue painter's tape at room temperature. ABS requires a heated bed, but it also requires the printer to be enclosed (if you print anything but small parts) with an internal temperature of 45-50C. Are you going to enclose the machine?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Glass is unnecessary. 1/4" plain aluminum sheet is very rigid, so clamping a piece of thin glass to it will not flatten it. 1/4" cast aluminum tooling plate will be flat enough to print on without glass.

Do you need a heated bed at all? I have found that PLA sticks almost too well to blue painter's tape at room temperature. ABS requires a heated bed, but it also requires the printer to be enclosed (if you print anything but small parts) with an internal temperature of 45-50C. Are you going to enclose the machine?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: What is the best option for heated bed 300x200 July 25, 2016 08:47AM |

Registered: 8 years ago Posts: 346 |

The printer is only for pla and it will not be temperature enclosed. So a good solution will be only use the 6mm stick aluminum plate and blue painter tape?

planning to buy the plate where:

[www.motedis.com]

In the description say it was a tolerance of thickness of -0.1 to + 0.18, i think is pretty good..

This tape allow to print many times on the same tape?

The pla will not give wrap´s problems printing at room temperature?

planning to buy the plate where:

[www.motedis.com]

In the description say it was a tolerance of thickness of -0.1 to + 0.18, i think is pretty good..

This tape allow to print many times on the same tape?

The pla will not give wrap´s problems printing at room temperature?

|

Re: What is the best option for heated bed 300x200 July 25, 2016 10:24AM |

Registered: 11 years ago Posts: 5,780 |

When you heat a bed for PLA you typically only take it up to 80C and most heaters, including PCB type will handle that just fine. You still need flatness... If you're not going to heat it, you can use almost anything that's flat for the bed. Unfortunately, few things besides cast tooling plate, come with any sort of flatness spec, and you need flatness within 0.1 mm (or better) over the entire surface.

I can't understand much of the Motedis description- it says it is laminated- but with what? If they are applying some sort of plastic to the surface it could be a problem if a hot extruder nozzle contacts it. It also says it is machined, but does that mean the large surfaces or just the sawn (sawed?) edges? Thickness isn't as important as flatness, and I don't see any spec on flatness.

Blue painter's tape is a consumable, but it's very cheap. You use as much as needed for the print - no need to cover the whole bed if the print is small. It leaves the bottom surface with a similar roughness as the top surface of the print, not the shiny smoothness that glass or kapton would leave on the bottom of the print. You can print directly on glass or Kapton with heat. My limited experience with printing PLA on heated kapton is that it doesn't stick any better than blue painter's tape at room temp, but it releases from the bed more easily. I've never printed PLA on glass.

If you search these forums you'll find about 30 different methods of getting PLA prints to stick to the bed. The simplest is blue painter's tape at room temp. Next up is to wipe the blue tape with IPA (alcohol, not beer) before printing. From there people do all sort of weird stuff like hairspray, glue stick, with and without heat, etc. Keep in mind a lot of people's printers don't have flat or level bed surfaces, so a lot of the crazy stuff people do to get prints to stick is due to those problems, whether they realize it or not.

How did you decide on the size of the bed? There are a lot of square heaters readily available, but many fewer rectangular.

I think the safest option is to get unlaminated, cast aluminum tooling plate. You know it will be flat enough to print on whether you put tape or glass on it. It is thermally conductive so if you decide to add a heater it will heat very evenly. You can easily drill holes in it for leveling screws. If the rest of the printer isn't yet built, you might consider going with a square bed plate. There are many more heaters available off the shelf from many sources at very low prices without having to resort to custom parts that will take time and cost a bit more.

Edited 1 time(s). Last edit at 07/25/2016 10:26AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I can't understand much of the Motedis description- it says it is laminated- but with what? If they are applying some sort of plastic to the surface it could be a problem if a hot extruder nozzle contacts it. It also says it is machined, but does that mean the large surfaces or just the sawn (sawed?) edges? Thickness isn't as important as flatness, and I don't see any spec on flatness.

Blue painter's tape is a consumable, but it's very cheap. You use as much as needed for the print - no need to cover the whole bed if the print is small. It leaves the bottom surface with a similar roughness as the top surface of the print, not the shiny smoothness that glass or kapton would leave on the bottom of the print. You can print directly on glass or Kapton with heat. My limited experience with printing PLA on heated kapton is that it doesn't stick any better than blue painter's tape at room temp, but it releases from the bed more easily. I've never printed PLA on glass.

If you search these forums you'll find about 30 different methods of getting PLA prints to stick to the bed. The simplest is blue painter's tape at room temp. Next up is to wipe the blue tape with IPA (alcohol, not beer) before printing. From there people do all sort of weird stuff like hairspray, glue stick, with and without heat, etc. Keep in mind a lot of people's printers don't have flat or level bed surfaces, so a lot of the crazy stuff people do to get prints to stick is due to those problems, whether they realize it or not.

How did you decide on the size of the bed? There are a lot of square heaters readily available, but many fewer rectangular.

I think the safest option is to get unlaminated, cast aluminum tooling plate. You know it will be flat enough to print on whether you put tape or glass on it. It is thermally conductive so if you decide to add a heater it will heat very evenly. You can easily drill holes in it for leveling screws. If the rest of the printer isn't yet built, you might consider going with a square bed plate. There are many more heaters available off the shelf from many sources at very low prices without having to resort to custom parts that will take time and cost a bit more.

Edited 1 time(s). Last edit at 07/25/2016 10:26AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: What is the best option for heated bed 300x200 July 25, 2016 10:55AM |

Registered: 8 years ago Posts: 346 |

Hi,

I decided to go with a 300x200 bed because i need to have a bigger print volume on one axis and i trying to upgrade my actual printer (200x200). if i go with a 300x300 i need to replace all the 2020 extrusions bars of my actual printer and redesign a new bed Z axis (2 x 16mm will not work). And most important factor: i do not have space on my desk for a 300x300 printer...

The printer will be only for pla, so my first chose was to go with a small 200x200 heater to heat the build plate at maximum 70ºC.

I never try blue painter's tape, i will buy some and make some testing to check if i do not get warping problems with pla. If it work then i will go with a simple aluminum plate, the reduction of electricity consummation will justify the price of the blue tape.

motedis sell unlaminated and laminated, i do not know what is the difference..

[www.motedis.com]

from the very short description it was appear to me the laminated version was more precise and without cuting edges.

I decided to go with a 300x200 bed because i need to have a bigger print volume on one axis and i trying to upgrade my actual printer (200x200). if i go with a 300x300 i need to replace all the 2020 extrusions bars of my actual printer and redesign a new bed Z axis (2 x 16mm will not work). And most important factor: i do not have space on my desk for a 300x300 printer...

The printer will be only for pla, so my first chose was to go with a small 200x200 heater to heat the build plate at maximum 70ºC.

I never try blue painter's tape, i will buy some and make some testing to check if i do not get warping problems with pla. If it work then i will go with a simple aluminum plate, the reduction of electricity consummation will justify the price of the blue tape.

motedis sell unlaminated and laminated, i do not know what is the difference..

[www.motedis.com]

from the very short description it was appear to me the laminated version was more precise and without cuting edges.

|

Re: What is the best option for heated bed 300x200 July 25, 2016 02:03PM |

Registered: 7 years ago Posts: 558 |

I went with the E3D Varipower Heated Bed. It was a bit pricey, but it was worth it in the end. I have a comfortable seeling based on the design I have even heating across the whole bed area, and the clips they provide for the glass are invaluable. There is almost 0 chance of them getting caught in the hotend unless your trying to print outside the 300x200 area. Only downside was 24V, but I remedied that by just going 24V on the entire machine. Heatup time is next to nothing.

Just like the E3D hotends, I would highly recommend the E3D Varipower heatbed.

Just like the E3D hotends, I would highly recommend the E3D Varipower heatbed.

|

Re: What is the best option for heated bed 300x200 July 25, 2016 05:40PM |

Registered: 8 years ago Posts: 346 |

the e3d looks great but i can not go with 24v, already too many hardware invested that works on 12v.

i tested a print with the blue tape (was gray color) and it worked just fine, the pla adession was good and easy to remove at the end.

decided to go with a aluminum plate without heater and start to use the blue tape. this reduce my cost a little, remove height from the bed and reduce eletricity consumation.

thank you the_digital_dentist and PDBeal for your help.

i tested a print with the blue tape (was gray color) and it worked just fine, the pla adession was good and easy to remove at the end.

decided to go with a aluminum plate without heater and start to use the blue tape. this reduce my cost a little, remove height from the bed and reduce eletricity consumation.

thank you the_digital_dentist and PDBeal for your help.

|

Re: What is the best option for heated bed 300x200 July 25, 2016 08:23PM |

Registered: 10 years ago Posts: 221 |

Here is a 220v 200x300 heater for a good price you will just need a solid state relay to drive it.

[www.aliexpress.com]

They do a 12v version too but only half the wattage.

[www.aliexpress.com]

I have a 12v heater from them on my current machine and it takes ages to heat up to 100C. I also have to run a separate power supply and a relay as it draws over 20 amps! I'm about to replace it with a 220v version.

Edited 1 time(s). Last edit at 07/25/2016 08:59PM by RodF.

[www.aliexpress.com]

They do a 12v version too but only half the wattage.

[www.aliexpress.com]

I have a 12v heater from them on my current machine and it takes ages to heat up to 100C. I also have to run a separate power supply and a relay as it draws over 20 amps! I'm about to replace it with a 220v version.

Edited 1 time(s). Last edit at 07/25/2016 08:59PM by RodF.

|

Re: What is the best option for heated bed 300x200 July 26, 2016 08:32AM |

Registered: 7 years ago Posts: 109 |

|

Re: What is the best option for heated bed 300x200 July 26, 2016 08:40AM |

Registered: 8 years ago Posts: 346 |

|

Re: What is the best option for heated bed 300x200 July 26, 2016 08:47AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: What is the best option for heated bed 300x200 July 26, 2016 10:15AM |

Registered: 8 years ago Posts: 346 |

|

Re: What is the best option for heated bed 300x200 July 26, 2016 11:25AM |

Registered: 7 years ago Posts: 109 |

Quote

filipeCampos

from portugal, post the ebay link of this seller.

Here it is : [www.ebay.de]

I just checked... they seem to only ship inside germany.

There are other sellers that ship within EU, but you have to search for the right plate on their stock:

[www.ebay.de]

[stores.ebay.de],

[stores.ebay.de]

Hope this helps

|

Re: What is the best option for heated bed 300x200 July 26, 2016 01:38PM |

Registered: 11 years ago Posts: 5,780 |

If you've ever had a geometry class, you learned that it takes 2 points to define a line and 3 points to define a plane. With 3 screws you can actually level the bed. With 4 you'll be bending the bed and or undercarriage, not leveling it. A bent surface isn't flat by definition and getting prints to stick can be a problem.

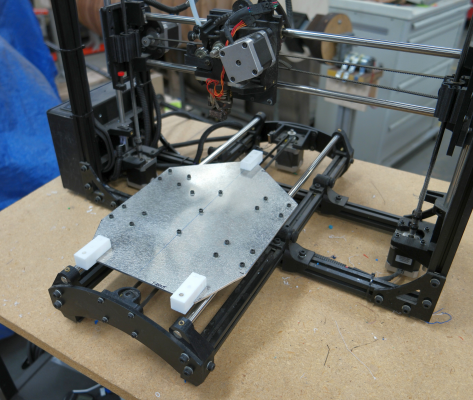

3 point leveling is set up with two screws parallel to one axis and a third screw on the opposite end of the bed. Here's an example of a recent conversion I did from 4 point to 3 point leveling on a Taz printer after its glass bed broke. This is the undercarriage with three teflon blocks that will support the leveling screws:

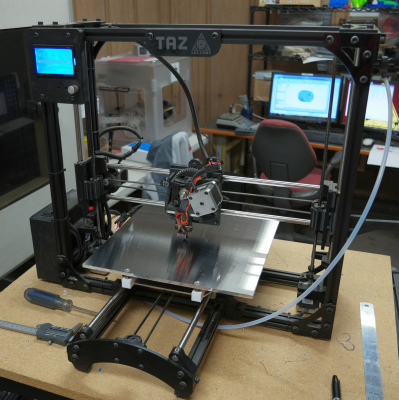

Here's it is with the bed in place (you can't see the back screw):

That printer went from requiring releveling every few prints to not having to be touched in months since the conversion was done. I have been using 3 point leveling on my printer for 3+ years and I don't have to adjust it at all unless I do some work on the printer's undercarriage or bed. I haven't adjusted it in months, even after hauling it back and forth between home and the makerspace laying on its side in my car. It has been at the makerspace for 5 months, used by many people with varying degrees of competency, and it still hasn't had to be adjusted.

Leveling with a three point system is very fast and easy. Using the Taz as an example, you move the nozzle to the left side of the bed near the front edge, adjust the leveling screw until the nozzle grabs a piece of paper, then move the nozzle to the right side near the front edge and adjust that screw the same way. You have just adjusted the pitch in the X axis to zero. Now you move the nozzle to the back edge of the bed and adjust that screw until the nozzle just grabs paper. Now the roll about the X axis is adjusted to 0 and the bed is parallel to the printer's XY plane as it should be. The roll adjustment has no effect on the pitch adjustment that you made previously. It takes longer to describe the leveling process than it does to perform it.

It doesn't matter where you put the screws, just as long as two of them are in line in one axis and the other is on the opposite end of the bed.

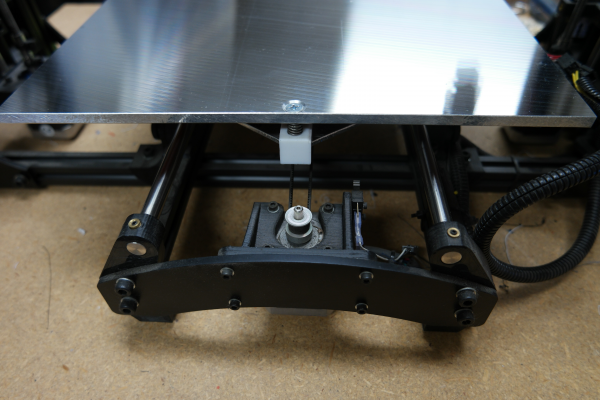

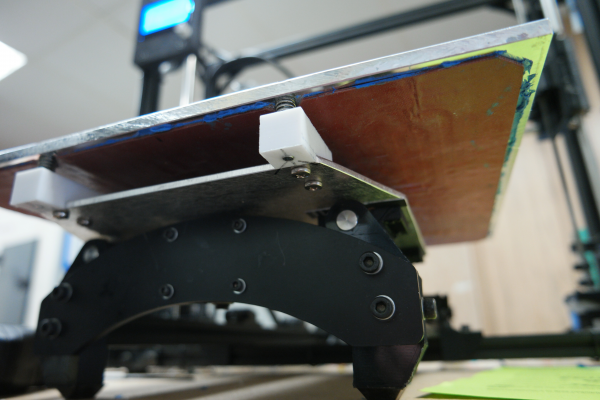

Here's a closeup of one of the Taz leveling screws. All the leveling screws are identical. :

The leveling screw has a very stiff spring that pushes the bed plate hard up against the screw head. The screw head is countersunk so that nothing stands above the bed surface to crash into the hot-end. The screw hole in the bed plate is about 1-1.5 mm oversized so that the plate can easily pivot on the screw head as you adjust the leveling screws. The teflon blocks, screwed to the undercarriage with two screws each, hold the leveling screws firmly and don't allow any wobble. The teflon blocks don't mind the heat from the bed heater.

I replaced the broken glass bed on that printer with a piece of cast aluminum tooling plate and it works much better than it ever did with the glass bed. We have almost no problem getting prints to stick. It's amazing what a flat, level, evenly heated bed surface does for the ease of operation of a 3D printer. I put a layer of PET tape and/or blue painter's tape on the aluminum and print- no glass and no clips needed or wanted.

Edited 1 time(s). Last edit at 07/26/2016 01:39PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

3 point leveling is set up with two screws parallel to one axis and a third screw on the opposite end of the bed. Here's an example of a recent conversion I did from 4 point to 3 point leveling on a Taz printer after its glass bed broke. This is the undercarriage with three teflon blocks that will support the leveling screws:

Here's it is with the bed in place (you can't see the back screw):

That printer went from requiring releveling every few prints to not having to be touched in months since the conversion was done. I have been using 3 point leveling on my printer for 3+ years and I don't have to adjust it at all unless I do some work on the printer's undercarriage or bed. I haven't adjusted it in months, even after hauling it back and forth between home and the makerspace laying on its side in my car. It has been at the makerspace for 5 months, used by many people with varying degrees of competency, and it still hasn't had to be adjusted.

Leveling with a three point system is very fast and easy. Using the Taz as an example, you move the nozzle to the left side of the bed near the front edge, adjust the leveling screw until the nozzle grabs a piece of paper, then move the nozzle to the right side near the front edge and adjust that screw the same way. You have just adjusted the pitch in the X axis to zero. Now you move the nozzle to the back edge of the bed and adjust that screw until the nozzle just grabs paper. Now the roll about the X axis is adjusted to 0 and the bed is parallel to the printer's XY plane as it should be. The roll adjustment has no effect on the pitch adjustment that you made previously. It takes longer to describe the leveling process than it does to perform it.

It doesn't matter where you put the screws, just as long as two of them are in line in one axis and the other is on the opposite end of the bed.

Here's a closeup of one of the Taz leveling screws. All the leveling screws are identical. :

The leveling screw has a very stiff spring that pushes the bed plate hard up against the screw head. The screw head is countersunk so that nothing stands above the bed surface to crash into the hot-end. The screw hole in the bed plate is about 1-1.5 mm oversized so that the plate can easily pivot on the screw head as you adjust the leveling screws. The teflon blocks, screwed to the undercarriage with two screws each, hold the leveling screws firmly and don't allow any wobble. The teflon blocks don't mind the heat from the bed heater.

I replaced the broken glass bed on that printer with a piece of cast aluminum tooling plate and it works much better than it ever did with the glass bed. We have almost no problem getting prints to stick. It's amazing what a flat, level, evenly heated bed surface does for the ease of operation of a 3D printer. I put a layer of PET tape and/or blue painter's tape on the aluminum and print- no glass and no clips needed or wanted.

Edited 1 time(s). Last edit at 07/26/2016 01:39PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: What is the best option for heated bed 300x200 July 26, 2016 05:27PM |

Registered: 8 years ago Posts: 346 |

My first printer was a prusa i3 with a 3 point leveling system, i already knew most parts you have explained.

I using the 4 point solution in my printer from the beginning and i do not remember the last time it was leveled, but i think it was only leveled and them made some little adjustments only in the firsts prints. When i change the hotend or service it, i only make some adjustments on the minimum Z endstop. I not building a new printer, i upgrading my printer on the parts that need to be improved. the bed leveling was never in my list. if it works, them why change it?

But assuming i will modify the bed to use 3 points leveling. I quickly remember one possible problem:

I have a cantilever bed, if i go with a 3 points leveling system, them i only use one arm (2020 profile) in the middle instead of my actual 2 arms. Was result of using only one bed arms is probable to have vibrations during a print because of the heavy 6mm plate (1 kilograms).

One possible solution is to buy a 20X60 to use was the middle arm, but again it will be necessary to spend more money and i will lose 4cm of print volume on the z.

When i was designing the g&c printer, i remember to spend some time on a solution to secure the bed on 3 points. but i never found a easy way to implement this using only 2020 profile.

Is know 3 point is more easy and quick to setup, but the solution i using was never give me trouble. I do not see any reason to spend money and time on something that works.

Edited 1 time(s). Last edit at 07/26/2016 05:56PM by filipeCampos.

I using the 4 point solution in my printer from the beginning and i do not remember the last time it was leveled, but i think it was only leveled and them made some little adjustments only in the firsts prints. When i change the hotend or service it, i only make some adjustments on the minimum Z endstop. I not building a new printer, i upgrading my printer on the parts that need to be improved. the bed leveling was never in my list. if it works, them why change it?

But assuming i will modify the bed to use 3 points leveling. I quickly remember one possible problem:

I have a cantilever bed, if i go with a 3 points leveling system, them i only use one arm (2020 profile) in the middle instead of my actual 2 arms. Was result of using only one bed arms is probable to have vibrations during a print because of the heavy 6mm plate (1 kilograms).

One possible solution is to buy a 20X60 to use was the middle arm, but again it will be necessary to spend more money and i will lose 4cm of print volume on the z.

When i was designing the g&c printer, i remember to spend some time on a solution to secure the bed on 3 points. but i never found a easy way to implement this using only 2020 profile.

Is know 3 point is more easy and quick to setup, but the solution i using was never give me trouble. I do not see any reason to spend money and time on something that works.

Edited 1 time(s). Last edit at 07/26/2016 05:56PM by filipeCampos.

Sorry, only registered users may post in this forum.