Yet another CoreXY printer

Posted by Mikk36

|

Yet another CoreXY printer August 17, 2016 11:01AM |

Registered: 9 years ago Posts: 125 |

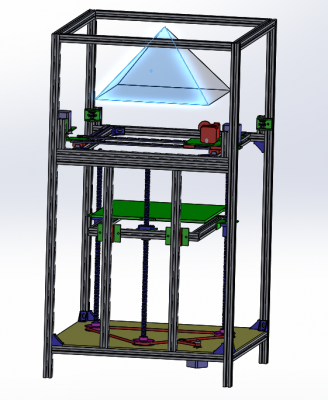

So, here I am in the middle of designing myself a new printer.

Currently I have a large-ish kossel-style delta printer, but I'm not that happy with it because I can reliably print only PLA, because it's, well, open.

It does have a heated bed, but anything larger than tiny things in ABS tend to warp really easily, so the plan is to make myself a new printer, that is to be enclosed and a CoreXY seems the best solution for that.

I also don't fancy bowden tubes because of the pressure issues and inability to print most soft stuff (especially with 1,75 mm filaments) and I want to go dual-extrusion this time around.

The bed is planned to be a 340 x 340 x 8 mm alu block (hopefully from that German guy that someone linked in another thread), heated by a 300 x 300 mm 230 V silicone heater.

All the various plate pieces are currently planned to be from 3 mm aluminium stock, which I can have cut on a big machine. So far I haven't had to put in a single plastic piece into the design, although the first piece from plastic is propably going to be the belt mounts on the effector platform, next up will be extruder mounts (if necessary, if course, maybe I can fab them also from some L profile or whatever).

In its current state I haven't yet touched the hotend and extruder mounts, so that's still lacking from the model, but here's a PDF showing the current state.

I'd be glad to get some comments as to what's good and what's bad about the design and how it could be improved.

Got 2 formats for the design:

A pdf (with 3D): [owncloud.lakrito.ee]

And an eDrawings assembly (measurable): [owncloud.lakrito.ee]

Some renders for just quick peek at it:

[dl.dropboxusercontent.com]

[dl.dropboxusercontent.com]

Edited 2 time(s). Last edit at 08/17/2016 04:39PM by Mikk36.

Currently I have a large-ish kossel-style delta printer, but I'm not that happy with it because I can reliably print only PLA, because it's, well, open.

It does have a heated bed, but anything larger than tiny things in ABS tend to warp really easily, so the plan is to make myself a new printer, that is to be enclosed and a CoreXY seems the best solution for that.

I also don't fancy bowden tubes because of the pressure issues and inability to print most soft stuff (especially with 1,75 mm filaments) and I want to go dual-extrusion this time around.

The bed is planned to be a 340 x 340 x 8 mm alu block (hopefully from that German guy that someone linked in another thread), heated by a 300 x 300 mm 230 V silicone heater.

All the various plate pieces are currently planned to be from 3 mm aluminium stock, which I can have cut on a big machine. So far I haven't had to put in a single plastic piece into the design, although the first piece from plastic is propably going to be the belt mounts on the effector platform, next up will be extruder mounts (if necessary, if course, maybe I can fab them also from some L profile or whatever).

In its current state I haven't yet touched the hotend and extruder mounts, so that's still lacking from the model, but here's a PDF showing the current state.

I'd be glad to get some comments as to what's good and what's bad about the design and how it could be improved.

Got 2 formats for the design:

A pdf (with 3D): [owncloud.lakrito.ee]

And an eDrawings assembly (measurable): [owncloud.lakrito.ee]

Some renders for just quick peek at it:

[dl.dropboxusercontent.com]

[dl.dropboxusercontent.com]

Edited 2 time(s). Last edit at 08/17/2016 04:39PM by Mikk36.

|

Re: Yet another CoreXY printer August 17, 2016 12:16PM |

Registered: 8 years ago Posts: 346 |

checked your design and overall is great.

In my opinion the x and y axis is over-engineered for the printer size. You could use only one long carriage instead of two on each rails and use only one bigger rail on the X: less expensive, more easy to install, less friction and less weight.

But if have the money or already the rails, them why not..

My remarks:

1) In case you are using small rails 9mm or even 12mm, is can be difficult to have a prefect aliment of both y rails because there are put directly on the aluminum profile. You are already using a metal plate from the z motor structure, why not use other one for the Y axis? the second plate will add a lot of rigidity, more easy to have y rails parallels and can be used to secure the top of the 3 z screws.

2) What type of teeth wheel pulleys you will use for the belts? i already ordered and receive at home one similar to this: [www.ebay.com]

They are pretty bad quality, they can not be well secure because they stop spinning and the spinning if far do be perfect. i have redesigned my printer to use big flagged bearings instead. If you will better one, can you share the link?

In my opinion the x and y axis is over-engineered for the printer size. You could use only one long carriage instead of two on each rails and use only one bigger rail on the X: less expensive, more easy to install, less friction and less weight.

But if have the money or already the rails, them why not..

My remarks:

1) In case you are using small rails 9mm or even 12mm, is can be difficult to have a prefect aliment of both y rails because there are put directly on the aluminum profile. You are already using a metal plate from the z motor structure, why not use other one for the Y axis? the second plate will add a lot of rigidity, more easy to have y rails parallels and can be used to secure the top of the 3 z screws.

2) What type of teeth wheel pulleys you will use for the belts? i already ordered and receive at home one similar to this: [www.ebay.com]

They are pretty bad quality, they can not be well secure because they stop spinning and the spinning if far do be perfect. i have redesigned my printer to use big flagged bearings instead. If you will better one, can you share the link?

|

Re: Yet another CoreXY printer August 17, 2016 04:31PM |

Registered: 9 years ago Posts: 125 |

Already have 6 rails available, so no point making it any weaker, they're MGN12-series. I also did not want to have any big mass swinging on just a single rail (think of 2 direct extruders, for example).

I left the top of the ballscrews open intentionally to leave all the alignment to the two vertical linear guides running on the front extrusions and have the ballscrews only deal with Z axis.

I haven't picked out the specific pulleys, but right now I'm looking at the ones from Robotdigg: [www.robotdigg.com] / [www.robotdigg.com]

I was wondering if the bed support is enough with the 3 mm aluminium pieces holding up the ~2.5 kg of the bed.

I left the top of the ballscrews open intentionally to leave all the alignment to the two vertical linear guides running on the front extrusions and have the ballscrews only deal with Z axis.

I haven't picked out the specific pulleys, but right now I'm looking at the ones from Robotdigg: [www.robotdigg.com] / [www.robotdigg.com]

I was wondering if the bed support is enough with the 3 mm aluminium pieces holding up the ~2.5 kg of the bed.

|

Re: Yet another CoreXY printer August 17, 2016 05:23PM |

Registered: 10 years ago Posts: 221 |

|

Re: Yet another CoreXY printer August 17, 2016 05:46PM |

Registered: 9 years ago Posts: 125 |

What do you mean by headroom for filament feed?

Anyway, since I haven't ordered any extrusions yet and I haven't designed the extruders/hotends into it yet, I haven't also set the height of the printer in stone.

I'm currently leaning towards 2x E3D v6 + Titan combos.

As for general design: it's been a hard goal to keep everything inside the frame while not wasting too much space.

Looking at digital dentsists XY assembly, for example, it's quite evident that it's massive compared to mine (total footprint vs usable space).

Another part where I'm not sure if I should brace it better are the idler pulley brackets at the ends of the X axis. Right now they're just 30x30 mm U profile with a thickness of 3 mm.

I'll still likely add some tube around the M5 bolt to hold the pulleys in place and have the nyloc nut pull it tight. Hopefully this will make the U-profile stiffer and less likely to cave in. Haven't yet decided where to source a nice tube for that, not quite happy with the smallest size of OD 8 mm and ID of 6 mm tube that's commonly available. Would prefer it to have an ID of 5 mm. I haven't checked eBay or whatever yet though, only local suppliers.

Edited 3 time(s). Last edit at 08/17/2016 05:54PM by Mikk36.

Anyway, since I haven't ordered any extrusions yet and I haven't designed the extruders/hotends into it yet, I haven't also set the height of the printer in stone.

I'm currently leaning towards 2x E3D v6 + Titan combos.

As for general design: it's been a hard goal to keep everything inside the frame while not wasting too much space.

Looking at digital dentsists XY assembly, for example, it's quite evident that it's massive compared to mine (total footprint vs usable space).

Another part where I'm not sure if I should brace it better are the idler pulley brackets at the ends of the X axis. Right now they're just 30x30 mm U profile with a thickness of 3 mm.

I'll still likely add some tube around the M5 bolt to hold the pulleys in place and have the nyloc nut pull it tight. Hopefully this will make the U-profile stiffer and less likely to cave in. Haven't yet decided where to source a nice tube for that, not quite happy with the smallest size of OD 8 mm and ID of 6 mm tube that's commonly available. Would prefer it to have an ID of 5 mm. I haven't checked eBay or whatever yet though, only local suppliers.

Edited 3 time(s). Last edit at 08/17/2016 05:54PM by Mikk36.

|

Re: Yet another CoreXY printer August 17, 2016 08:44PM |

Registered: 10 years ago Posts: 221 |

Quote

Mikk36

What do you mean by headroom for filament feed?

You are going to enclose your printer so you will want a couple of small holes in the top to feed filament to the extruders. The holes in the top will need a certain height above the top of the extruders so there is not too acute an angle for the path of the filament when the extruder carriage is at a full extremity. The pyramid sitting above the extruder in this screen shot is giving me an idea of the distance required.

|

Re: Yet another CoreXY printer August 17, 2016 08:47PM |

Registered: 11 years ago Posts: 5,780 |

You may be able to reduce that height by allowing the filament spool to swivel to follow the extruder. OTOH, doing so may lead to filament tangles on the spool. I plan to find out.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Yet another CoreXY printer August 17, 2016 09:48PM |

Registered: 10 years ago Posts: 221 |

I'm sure that would work but only if the spool is inside the enclosure or there is a large enough opening in the top.Quote

the_digital_dentist

You may be able to reduce that height by allowing the filament spool to swivel to follow the extruder. OTOH, doing so may lead to filament tangles on the spool. I plan to find out.

|

Re: Yet another CoreXY printer August 19, 2016 05:37PM |

Registered: 9 years ago Posts: 125 |

Can I flip this ball screw nut or are there any complications/downsides with this?

I'm aware that I need something to hold the balls to the ballscrew while I'm flipping it in order to prevent them from falling away. That's no issue, I can just print a placeholder plastic ball screw or whatever to roll the nut onto for flipping it.

I'm aware that I need something to hold the balls to the ballscrew while I'm flipping it in order to prevent them from falling away. That's no issue, I can just print a placeholder plastic ball screw or whatever to roll the nut onto for flipping it.

|

Re: Yet another CoreXY printer August 27, 2016 08:48PM |

Registered: 9 years ago Posts: 125 |

|

Re: Yet another CoreXY printer August 29, 2016 02:01PM |

Registered: 8 years ago Posts: 153 |

|

Re: Yet another CoreXY printer August 29, 2016 09:53PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Yet another CoreXY printer August 30, 2016 08:29AM |

Registered: 9 years ago Posts: 125 |

Just el-cheapo MGN12 rails with MGN12C blocks.Quote

n8bot

Very cool. Are those misumi high-temp miniature linear guides I spot?

Noted, will reevaluate amount of screws on assembly and tuning.Quote

cozmicray

Six bolts holding ballscrew nut.

Please allow this to float,

at least until all rails and ball screws are lined up.

If locked down, it will bind X, Y

All it has to be --- is accurate mover for Z

Latest render:

Edited 1 time(s). Last edit at 08/30/2016 08:31AM by Mikk36.

|

Re: Yet another CoreXY printer August 30, 2016 08:34AM |

Registered: 9 years ago Posts: 125 |

|

Re: Yet another CoreXY printer August 30, 2016 07:09PM |

Registered: 10 years ago Posts: 221 |

That will work and it is a nice look. However you do loose the slight adjust-ability of oversize holes and button or cap head screws and washers. With my machine I need that due to the relatively inaccurate method of constructionQuote

Mikk36

Also am pondering a bit on using countersunk screws on the effector platform to attach the plate to the blocks to get a flush finish.

The screw spec says 1.9 mm length for the countersunk head, plate itself is 3 mm.

I am wondering about your bed, is it going to have silicone heater underneath? If so do you have enough clearance for the mounting screws? I would have liked to mount mine like yours so I should have got Kenovo to clip the corners of the silicone heater.

|

Re: Yet another CoreXY printer August 31, 2016 05:10AM |

Registered: 9 years ago Posts: 125 |

|

Re: Yet another CoreXY printer August 31, 2016 09:38AM |

Registered: 11 years ago Posts: 5,780 |

The unheated 20 mm margin around the edge of the bed is going to create a temperature drop so your usable print area will likely be a bit less than the 300 mm square that is directly above the heater. I think you'll be better off trimming away the margin and leaving tabs for the leveling screws. OTOH, if you insulate the underside (and maybe the edges, too), you may be able to print over the entire surface.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Yet another CoreXY printer August 31, 2016 12:49PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Mikk36

The bed is 340x340 and will have a 300x300 silicone heater. I'm assuming that that 20 mm gap won't be an issue thanks to the bed being 8 mm thick.

Quote

the_digital_dentist

The unheated 20 mm margin around the edge of the bed is going to create a temperature drop so your usable print area will likely be a bit less than the 300 mm square that is directly above the heater.

You can't both be right, so let's do the maths. I'll approximate your bed margin as being 1280mm long, and it's 20mm deep and 8mm thick. The thermal conductivity of aluminium is around 210 W/(mK) according to [www.engineeringtoolbox.com]. So for each 1C temperature drop between the core and the periphery, there has to be 210 * 1.28 * 0.008/0.02 = 108W of power passing outwards through the margin.

In the steady state maintaining a bed temperature of 100C, I estimate that the heating power needed for a bed of that size will be about 280W. Your total bed area is 0.1156m^2 and the heated part is 0.09m^2. So the margin comprises 22% of the area of the bed. To a first approximation, the margin will lose 22% of the total heating power. In practice it may be a little more because of greater air currents at the edge, so call it 30%. As 30% of 280W is 84W, which is still less than 108W, I conclude that the temperature drop across the margin will be below 1C, and therefore not a problem.

Unless of course my calculation is wrong - please check it for yourself.

Putting thermal insulation underneath the margin will help reduce convection currents.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.