slight bulge at corners

Posted by appjaws1

|

slight bulge at corners October 10, 2016 05:20AM |

Registered: 10 years ago Posts: 780 |

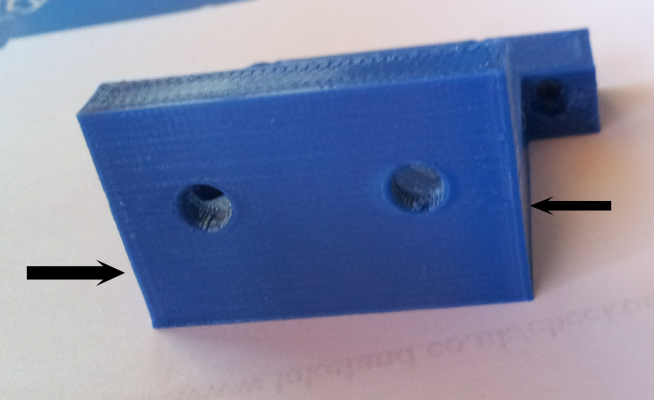

If I print a square profile, each corner has a slight bulge due to too much filament being extruded. I think this happens at the instant of change direction when the nozzle is at a standstill.

I have tried various tweaks in simplify3d but have been unable to eradicate this anomaly

I wonder if a firmware tweak could solve this.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I have tried various tweaks in simplify3d but have been unable to eradicate this anomaly

I wonder if a firmware tweak could solve this.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: slight bulge at corners October 10, 2016 08:38AM |

Registered: 10 years ago Posts: 14,672 |

Have you tried enabling pressure advance?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: slight bulge at corners October 10, 2016 10:22AM |

Registered: 10 years ago Posts: 780 |

No, I haven't tried pressure advance.

This must have passed me by.

Where can I find information on it's use and set up details?

Thanks for your help

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

This must have passed me by.

Where can I find information on it's use and set up details?

Thanks for your help

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: slight bulge at corners October 10, 2016 12:56PM |

Registered: 10 years ago Posts: 14,672 |

See [reprap.org]. It could also be that you are over-extruding.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: slight bulge at corners October 14, 2016 05:37AM |

Registered: 10 years ago Posts: 780 |

Thank you for the response dc42.

I have tried pressure advance with settings ranging from 0.09 to 0.15 and I could not see any difference in the bulge problem on external corners.

On my core xy machine the bowden tubing is 800 mm long, so I wonder if I need to try larger settings, maybe 0.2, what do you think?

I have also tried reducing the extrusion multiplier from 0.98 to 0.93, but again no real difference.

Is there any setting in config that would speed up the change of direction so that the nozzle is not stopping on a corner?

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I have tried pressure advance with settings ranging from 0.09 to 0.15 and I could not see any difference in the bulge problem on external corners.

On my core xy machine the bowden tubing is 800 mm long, so I wonder if I need to try larger settings, maybe 0.2, what do you think?

I have also tried reducing the extrusion multiplier from 0.98 to 0.93, but again no real difference.

Is there any setting in config that would speed up the change of direction so that the nozzle is not stopping on a corner?

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: slight bulge at corners October 14, 2016 05:59AM |

Registered: 8 years ago Posts: 346 |

|

Re: slight bulge at corners October 14, 2016 12:46PM |

Registered: 10 years ago Posts: 780 |

Quote

filipeCampos

Hi,

This problem is because you over extruding on the corner, tacking to much time to change direction. Simply increase the value of Jerk XY moves to speed up the direction change, but not too much or your printer can start shack big time or even missing step

Have increased X and Y jerk speed to 700 from 600 and looking at the object I am printing at the moment, I can see no improvement.

What do you think is the maximum jerk speed I should have?

I have another thought, I wonder if I have enough tension on my belts, I suppose low tension could cause similar problems e.g. delay in changing direction.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: slight bulge at corners October 14, 2016 03:08PM |

Registered: 10 years ago Posts: 14,672 |

Quote

appjaws1

Thank you for the response dc42.

I have tried pressure advance with settings ranging from 0.09 to 0.15 and I could not see any difference in the bulge problem on external corners.

On my core xy machine the bowden tubing is 800 mm long, so I wonder if I need to try larger settings, maybe 0.2, what do you think?

I have also tried reducing the extrusion multiplier from 0.98 to 0.93, but again no real difference.

Is there any setting in config that would speed up the change of direction so that the nozzle is not stopping on a corner?

Yes you may need 0.2 or even more with a Bowden tube hat long. Higher acceleration and maybe jerk will reduce the time spent at the corners.

Are you printing external perimeters first, or not?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: slight bulge at corners October 15, 2016 08:58AM |

Registered: 8 years ago Posts: 346 |

Quote

appjaws1

Quote

filipeCampos

Hi,

This problem is because you over extruding on the corner, tacking to much time to change direction. Simply increase the value of Jerk XY moves to speed up the direction change, but not too much or your printer can start shack big time or even missing step

Have increased X and Y jerk speed to 700 from 600 and looking at the object I am printing at the moment, I can see no improvement.

What do you think is the maximum jerk speed I should have?

I have another thought, I wonder if I have enough tension on my belts, I suppose low tension could cause similar problems e.g. delay in changing direction.

600 is a very high jerk speed, i have only 30mm/s. your printer run ok with this jerk value? I think the default is 20mm/s, normally is 20 to 30% of the printing speed of the outside walls. With a good printer you can increase the value to up 50%, but never 600mm/s...

check the belt tension if is not too low or if there are some electricity on the belt because maybe you are using printed parts, motor dampers, etc.. in this case you can try the opposite and decrease the jerk value to reduce the impact of the deceleration.

have you tested if your extruder is not over extruding all the time? is easy to test, send a gcode to extrude 100mm of filament and check if the extruder was really pushed 100mm.

|

Re: slight bulge at corners October 15, 2016 12:58PM |

Registered: 10 years ago Posts: 14,672 |

In RepRapFirmware the jerk is given in mm/min, same as for all other speeds. So 600 in the M566 command is 10mm/sec.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: slight bulge at corners October 16, 2016 08:43AM |

Registered: 8 years ago Posts: 622 |

@appjaws1. IMO your surface finish is not good either and I think if you get that right, the corners will come good. It looks like over extrusion to me and/or too high acceleration. Ignore that fact that you may have calibrated your extruders to push the right amount of filament. It could be your nozzle isn't exactly the size you think it is (I've had the same problem). Try printing a simple large cube, say 100mm square by a few mm high. Keep reducing extrusion until the finish looks good. Don't mess around with 1% increments - start with 5% increments and keep going until you see gaps between the lines, then increase. If you get long moves smooth but as the print head gets close to the corners (short axis movements) it gets rough, reduce the acceleration. This will have the effect of slowing down short print moves. Filament extrusion doesn't accelerate the way that the machine axes do. All extrusion acceleration does is cause rapid pressure changes in the nozzle but that doesn't translate to rapid changes in filament extrusion as it is effectively damped and takes time to respond. HTH

|

Re: slight bulge at corners October 18, 2016 12:18PM |

Registered: 10 years ago Posts: 780 |

Thanks to all,

I was over extruding so getting that correct plus tweaks of acceleration etc has solved the problem

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I was over extruding so getting that correct plus tweaks of acceleration etc has solved the problem

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: slight bulge at corners October 18, 2016 02:55PM |

Registered: 8 years ago Posts: 622 |

Glad to hear it. Is you surface finish better too?

Edit. Also, just out of curiosity, how much did you have to reduce extrusion? The reason I ask is that I calibrated my extruders by the normal method of extruding an amount of filament then measuring what was actually extruded and adjusting the steps accordingly. The number I ended up with were very close to the starting point that E3D recommend for their Titans. I've checked them a few times, both with the hot end heated and with the Bowden tubes disconnected from the hot end. All good. Yet, when started to run some commissioning prints, I had to reduce extrusion by an alarming amount (like set the extrusion multiplier to 70%). I have to go down to around 60% or less before I see signs of under extruding. Trying to get my head around why this should be. Can't see anything in Slc3R that would account for it.

Edited 1 time(s). Last edit at 10/19/2016 05:59AM by deckingman.

Edit. Also, just out of curiosity, how much did you have to reduce extrusion? The reason I ask is that I calibrated my extruders by the normal method of extruding an amount of filament then measuring what was actually extruded and adjusting the steps accordingly. The number I ended up with were very close to the starting point that E3D recommend for their Titans. I've checked them a few times, both with the hot end heated and with the Bowden tubes disconnected from the hot end. All good. Yet, when started to run some commissioning prints, I had to reduce extrusion by an alarming amount (like set the extrusion multiplier to 70%). I have to go down to around 60% or less before I see signs of under extruding. Trying to get my head around why this should be. Can't see anything in Slc3R that would account for it.

Edited 1 time(s). Last edit at 10/19/2016 05:59AM by deckingman.

|

Re: slight bulge at corners October 19, 2016 10:32AM |

Registered: 10 years ago Posts: 780 |

Sorry, only registered users may post in this forum.