|

IDEX for CoreXY October 17, 2016 07:10AM |

Registered: 10 years ago Posts: 14,672 |

Is there any way to extend the CoreXY architecture so as to have 3 stationary motors controlling the XY positions of 2 print heads, where the Y positions are constrained to be the same?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: IDEX for CoreXY October 17, 2016 07:51AM |

Registered: 8 years ago Posts: 120 |

|

Re: IDEX for CoreXY October 18, 2016 07:09PM |

Registered: 10 years ago Posts: 651 |

I think stationary would be the hard part. I've seen a few machines out there that do it but the motor moves with the Y axis. I would think for a stationary setup, the motor could be in a 3rd corner, a pulley in the opposite corner, and with a belt forming a T across the X Axis rail with another pulley at the bottom of the T being on one of your bearing blocks. The hard part would be the software, plain Cartesian coordinates wouldn't work, It'd have to compensate knowing the Y axis is moving and move that second X Axis to keep position/move where it needs.

Edited 3 time(s). Last edit at 10/18/2016 07:19PM by FA-MAS.

Edited 3 time(s). Last edit at 10/18/2016 07:19PM by FA-MAS.

|

Re: IDEX for CoreXY October 19, 2016 01:06AM |

Registered: 10 years ago Posts: 14,672 |

Quote

FA-MAS

I think stationary would be the hard part. I've seen a few machines out there that do it but the motor moves with the Y axis. I would think for a stationary setup, the motor could be in a 3rd corner, a pulley in the opposite corner, and with a belt forming a T across the X Axis rail with another pulley at the bottom of the T being on one of your bearing blocks. The hard part would be the software, plain Cartesian coordinates wouldn't work, It'd have to compensate knowing the Y axis is moving and move that second X Axis to keep position/move where it needs.

Thanks for that suggestion. It sounds viable to me. The firmware isn't a problem, it's what I do for a living.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: IDEX for CoreXY October 19, 2016 03:12PM |

Registered: 10 years ago Posts: 651 |

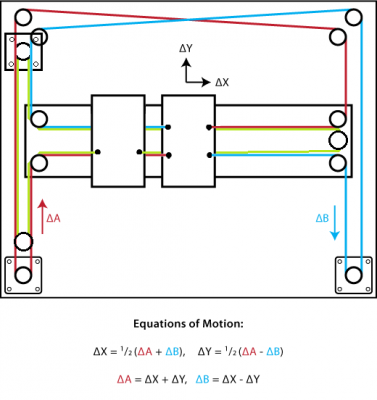

Drew it up like this. I'd put extra motor on whatever side is designated the X motor. Imagine the motor, green belt, and pulleys are on a different plane.

Now I have to build it.

Edited 1 time(s). Last edit at 10/19/2016 03:17PM by FA-MAS.

Now I have to build it.

Edited 1 time(s). Last edit at 10/19/2016 03:17PM by FA-MAS.

|

Re: IDEX for CoreXY October 19, 2016 08:53PM |

Registered: 8 years ago Posts: 120 |

|

Re: IDEX for CoreXY October 19, 2016 11:01PM |

Registered: 11 years ago Posts: 5,780 |

What would be the advantage of this over using two extruders mounted on a single carriage? Would that advantage be worth the extra trouble, expense, and reduced print area?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: IDEX for CoreXY October 20, 2016 04:09AM |

Registered: 10 years ago Posts: 14,672 |

Quote

the_digital_dentist

What would be the advantage of this over using two extruders mounted on a single carriage? Would that advantage be worth the extra trouble, expense, and reduced print area?

A problem with two extruders mounted on the same carriage is that even if you get the nozzle heights exactly equal (which needs careful design to make the height adjustment easy), the non-printing nozzle tends to leave a mark when it passes over filament that has been freshly laid by the printing nozzle.

Some people also complain about ooze from the non-printing nozzle, but with the correct retraction settings and standby temperature, I don't find that a problem.

Edited 1 time(s). Last edit at 10/20/2016 04:10AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: IDEX for CoreXY October 20, 2016 04:29AM |

Registered: 8 years ago Posts: 346 |

I done in the past a dual extruder setup and it was very difficult to get good prints, main problems you will get are:

- First you need to get the second hotend in the exact same Z level. if not, the lower nozzle will bump on the print making marks or even can remove the print from the bed.

- The second hotend not used will give oozing that will mark all the print. you can reduce the temperature of the not used hotend or use oozing shield, but still will not prevent a 100% color infection of the second nozzle.

- oozing shield will consume a lot of filament and slow down the print.

- droping temperature is not solution when you have a print that on each layer need to print with the two nozzle, it will take forever to drop down the temperature of one nozzle and increase the temp of the other.

- every-time you change of nozzle you need to take a lot of time to adjust both perfectly on the Z and sometime you need to alter the x or y position in the firmware of the second nozzle.

There are better and easy solutions to achieve multiple extrusion, the best is to go with a e3d cylope extruder or even a diamond for RGB. This will not remove printing space, no need to adjust a second hotend, no oozing problem, less electricity cost and cleaner setup.

- First you need to get the second hotend in the exact same Z level. if not, the lower nozzle will bump on the print making marks or even can remove the print from the bed.

- The second hotend not used will give oozing that will mark all the print. you can reduce the temperature of the not used hotend or use oozing shield, but still will not prevent a 100% color infection of the second nozzle.

- oozing shield will consume a lot of filament and slow down the print.

- droping temperature is not solution when you have a print that on each layer need to print with the two nozzle, it will take forever to drop down the temperature of one nozzle and increase the temp of the other.

- every-time you change of nozzle you need to take a lot of time to adjust both perfectly on the Z and sometime you need to alter the x or y position in the firmware of the second nozzle.

There are better and easy solutions to achieve multiple extrusion, the best is to go with a e3d cylope extruder or even a diamond for RGB. This will not remove printing space, no need to adjust a second hotend, no oozing problem, less electricity cost and cleaner setup.

|

Re: IDEX for CoreXY October 20, 2016 07:37AM |

Registered: 11 years ago Posts: 5,780 |

Wouldn't it be simpler/cheaper to just put the two extruders on a "see-saw" mechanism that lifts one and lowers the other as needed? Stratasys was doing that back in the 90s....

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: IDEX for CoreXY October 20, 2016 08:44AM |

Registered: 8 years ago Posts: 346 |

"see-saw" mechanism is a very good option, the new version of the ultimaker 3 use this mechanism too.

But is not so easy to implements this type of mechanism and i never see any option on firmware to support this.

I still think the use of only one hotend with saveral extruders is the best option, already see several new 3d printer using this with pretty good results. The only downside i can see is necessary to wast some filament and some time each time you need to change of color.

Edited 1 time(s). Last edit at 10/20/2016 08:46AM by filipeCampos.

But is not so easy to implements this type of mechanism and i never see any option on firmware to support this.

I still think the use of only one hotend with saveral extruders is the best option, already see several new 3d printer using this with pretty good results. The only downside i can see is necessary to wast some filament and some time each time you need to change of color.

Edited 1 time(s). Last edit at 10/20/2016 08:46AM by filipeCampos.

|

Re: IDEX for CoreXY October 20, 2016 09:14AM |

Registered: 10 years ago Posts: 14,672 |

Quote

filipeCampos

I done in the past a dual extruder setup and it was very difficult to get good prints, main problems you will get are:

- First you need to get the second hotend in the exact same Z level. if not, the lower nozzle will bump on the print making marks or even can remove the print from the bed.

I agree, however this is a matter of good design so that it is easy to get the nozzles at the same height. I heat them both up, drop them on to a sheet of paper on top of the bed, then adjust the levelling screws so that they grip the paper equally.

Quote

filipeCampos

- The second hotend not used will give oozing that will mark all the print. you can reduce the temperature of the not used hotend or use oozing shield, but still will not prevent a 100% color infection of the second nozzle.

I have zero colour infection from the second nozzle.

Quote

- oozing shield will consume a lot of filament and slow down the print.

- droping temperature is not solution when you have a print that on each layer need to print with the two nozzle, it will take forever to drop down the temperature of one nozzle and increase the temp of the other.

To speed this up, my printer waits for the new nozzle to reach printing temperature, but not for the old one to cool to standby temperature - which takes longer. The heating time does still slow down the print, but not too much if you use 40W heaters..

Quote

- every-time you change of nozzle you need to take a lot of time to adjust both perfectly on the Z and sometime you need to alter the x or y position in the firmware of the second nozzle.

Yes, this is a problem if you change nozzles. I haven't changed nozzles on that printer for over a year. They are RepRapPro hot ends with a PTFE liner. I only print PLA on that machine and they never jam.

Quote

There are better and easy solutions to achieve multiple extrusion, the best is to go with a e3d cylope extruder or even a diamond for RGB. This will not remove printing space, no need to adjust a second hotend, no oozing problem, less electricity cost and cleaner setup.

I agree this this sounds in principle a better solution. The problem that users report is that if you don't use one of the filaments for a while, molten filament oozes back up that heat break and jams it. Retracting all the filaments by the full amount every time you do a retraction helps, but I'm not sure it is a complete solution.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: IDEX for CoreXY October 20, 2016 09:17AM |

Registered: 10 years ago Posts: 14,672 |

Quote

the_digital_dentist

Wouldn't it be simpler/cheaper to just put the two extruders on a "see-saw" mechanism that lifts one and lowers the other as needed? Stratasys was doing that back in the 90s....

Yes and they patented it, so a system using that mechanism can't be sold commercially until the patent expires.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: IDEX for CoreXY June 06, 2018 12:35PM |

Registered: 6 years ago Posts: 4 |

Quote

dc42

Quote

FA-MAS

I think stationary would be the hard part. I've seen a few machines out there that do it but the motor moves with the Y axis. I would think for a stationary setup, the motor could be in a 3rd corner, a pulley in the opposite corner, and with a belt forming a T across the X Axis rail with another pulley at the bottom of the T being on one of your bearing blocks. The hard part would be the software, plain Cartesian coordinates wouldn't work, It'd have to compensate knowing the Y axis is moving and move that second X Axis to keep position/move where it needs.

Thanks for that suggestion. It sounds viable to me. The firmware isn't a problem, it's what I do for a living.

Is there any firmware that is able to support this setup as the printer design I currently have can easily be modified to use this system. I am just not very sure on how to configure the software to do this.

|

Re: IDEX for CoreXY June 07, 2018 04:20PM |

Registered: 10 years ago Posts: 14,672 |

RepRapFirmware has supported dual head CoreXY machines for over a year but with a different motor configuration. Search for CoreXYU and CoreXYUV.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: IDEX for CoreXY June 13, 2018 05:02AM |

Registered: 6 years ago Posts: 4 |

Quote

dc42

RepRapFirmware has supported dual head CoreXY machines for over a year but with a different motor configuration. Search for CoreXYU and CoreXYUV.

Yep I did some research and came across that. but I was just wondering if something similar to the above would be technically possible as I wanted to try it.

|

Re: IDEX for CoreXY June 13, 2018 07:30AM |

Registered: 10 years ago Posts: 14,672 |

Quote

rikesh942014

Quote

dc42

RepRapFirmware has supported dual head CoreXY machines for over a year but with a different motor configuration. Search for CoreXYU and CoreXYUV.

Yep I did some research and came across that. but I was just wondering if something similar to the above would be technically possible as I wanted to try it.

I think that's the same as the existing CoreXYU kinematics with the V motor removed. If so then the existing firmware could be used as-is if you use the M584 command to map the V motor to a non-existent driver such as 11 or 12.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: IDEX for CoreXY June 13, 2018 08:19AM |

Registered: 6 years ago Posts: 4 |

Quote

dc42

Quote

rikesh942014

Quote

dc42

RepRapFirmware has supported dual head CoreXY machines for over a year but with a different motor configuration. Search for CoreXYU and CoreXYUV.

Yep I did some research and came across that. but I was just wondering if something similar to the above would be technically possible as I wanted to try it.

I think that's the same as the existing CoreXYU kinematics with the V motor removed. If so then the existing firmware could be used as-is if you use the M584 command to map the V motor to a non-existent driver such as 11 or 12.

Awesome! Im gonna try building it and try this. will see how it goes.

|

Re: IDEX for CoreXY May 13, 2019 03:35PM |

Registered: 5 years ago Posts: 3 |

Even if this thread is older, I think its something to consider from time to time.

One very interesting design of a corexy ist the Tranform3r. Its moving the complete xy-gantry in z, so the bed is not moved at all. So to make an IDEX - build two Transform3r and mount the bed on rails. So "toolchange" means actualy to move the bed to the other printer. Calibration would of course be a challenge.

Same of course should work on deltas as they also have a fixed bed which can be put on rails. If you only want single coulor, simply add second bed and let booth printers work independend, for dual colour remove second bed and use two printers as one...

The oozing problem can be solved mostly by using a driect extruder. As CoreXY and Delta use leight extruders, best way to use direct extruder is the Nimble.

One very interesting design of a corexy ist the Tranform3r. Its moving the complete xy-gantry in z, so the bed is not moved at all. So to make an IDEX - build two Transform3r and mount the bed on rails. So "toolchange" means actualy to move the bed to the other printer. Calibration would of course be a challenge.

Same of course should work on deltas as they also have a fixed bed which can be put on rails. If you only want single coulor, simply add second bed and let booth printers work independend, for dual colour remove second bed and use two printers as one...

The oozing problem can be solved mostly by using a driect extruder. As CoreXY and Delta use leight extruders, best way to use direct extruder is the Nimble.

|

Re: IDEX for CoreXY May 14, 2019 03:20AM |

Registered: 10 years ago Posts: 14,672 |

I revamped the support for CoreXY and related architectures in RepRapFirmware at the end of last year. The standard firmware binary now supports any architecture with up to 9 axes for which the movement of each axis is a linear combination of movements of the stepper motors. So if you come up with a new Core-based architecture with up to 7 independent print heads, RepRapFirmware will be able to drive it.

The most complex machine of this type that I am aware of has two X gantries running independently along the Y axis, and each X gantry has two IDEX-style heads on it. But there is no reason why you couldn't have more than two print heads on each axis. You would just need to set up the tool change files to shift print heads to the correct end of the X axis to get at the one you want.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The most complex machine of this type that I am aware of has two X gantries running independently along the Y axis, and each X gantry has two IDEX-style heads on it. But there is no reason why you couldn't have more than two print heads on each axis. You would just need to set up the tool change files to shift print heads to the correct end of the X axis to get at the one you want.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: IDEX for CoreXY October 14, 2020 09:14AM |

Registered: 7 years ago Posts: 24 |

Quote

dc42

I revamped the support for CoreXY and related architectures in RepRapFirmware at the end of last year. The standard firmware binary now supports any architecture with up to 9 axes for which the movement of each axis is a linear combination of movements of the stepper motors. So if you come up with a new Core-based architecture with up to 7 independent print heads, RepRapFirmware will be able to drive it.

The most complex machine of this type that I am aware of has two X gantries running independently along the Y axis, and each X gantry has two IDEX-style heads on it. But there is no reason why you couldn't have more than two print heads on each axis. You would just need to set up the tool change files to shift print heads to the correct end of the X axis to get at the one you want.

Hey dc42,

As luck would have it, I'm looking to add a second extruder to my CoreXY printer which currently uses, a closed loop stepper driver for the X and Y motors, and 4 independent Z Motors. I'm looking to add this extra extruder as another head on the X axis, but the way I would connect it, using only one motor, is the same way I would connect the belts for the X axis as in a dual wire gantry setup [reprap.org]).

As part of my change, I'll have to loose my great direct drive setup (hemera) and go to a bowden setup, but this suits me fine. But does marlin support adding an extra driver in this fashion when using the second extruder.

Regards

Celcius1

|

Re: IDEX for CoreXY October 14, 2020 09:40AM |

Registered: 7 years ago Posts: 24 |

Quote

blt3dp

Drew it up like this. I'd put extra motor on whatever side is designated the X motor. Imagine the motor, green belt, and pulleys are on a different plane.

[attachment 85104 reference.png]

Now I have to build it.

Actually its simpler than you think if you use the Dual Wire Gantry method of driving, its on own belt and will only move when commanded [reprap.org])

|

Re: IDEX for CoreXY March 24, 2022 01:13PM |

Registered: 2 years ago Posts: 1 |

I just included a short presentation of what I call "CoreIDX" on the Duet3d forum. It is my conversion of a CoreXY to an IDEX.

[forum.duet3d.com]

It is similar to the Markforge style implementation of an IDEX system but my 2 lower belts/pulleys maintain their original positions as in a CoreXY. I just separate the X carriage into two and tie one of the belts to each new carriage, along with a Y drive motor and belt system similar to a standard cartesian arrangement. I designed this system at the end of 2019 and after some trial and error I built my machine in 2020 and have successfully operated it commercially for about 2 years.

[forum.duet3d.com]

It is similar to the Markforge style implementation of an IDEX system but my 2 lower belts/pulleys maintain their original positions as in a CoreXY. I just separate the X carriage into two and tie one of the belts to each new carriage, along with a Y drive motor and belt system similar to a standard cartesian arrangement. I designed this system at the end of 2019 and after some trial and error I built my machine in 2020 and have successfully operated it commercially for about 2 years.

|

Re: IDEX for CoreXY March 25, 2022 01:04AM |

Registered: 3 years ago Posts: 92 |

Couldn't you use a belt path like this for the second X carriage? Y movement would be controlled by the first carriage's CoreXY belts (not shown), and then this one moves independently in the X direction while riding on the same Y gantry.

Sorry, only registered users may post in this forum.

. I just ordered some OpenRail though to use for a rock solid cantelievered Z axis; last step on the CoreXY project!

. I just ordered some OpenRail though to use for a rock solid cantelievered Z axis; last step on the CoreXY project!