How can I fix belt shifting?

Posted by MatthewHall

|

How can I fix belt shifting? January 20, 2017 08:53PM |

Registered: 8 years ago Posts: 120 |

So I built a printer and am trying to fix the remaining issues I have. I am surprised by the excellent quality of the printer - when it works. The only problem I still have is that the belt skips while doing diagonals, curves, or corners (sometimes). Basically the belt shifts whenever there is a fast speed change. The belts slip on the GT2 pulleys, the rest of the printer is rock solid.

I attempted to fix this issue in two ways:

1. Changing the acceleration values in Marlin to a lower value. This worked a little bit: now it shifts less often, but is still unpredictable.

2. Tightening or loosening the belts. I thought that maybe the slack in the belts was causing them to skip, but that is not the case. When I make the belts rather tight, the pulleys skip even more. If I make them really loose, it does better for constant speed movements but not for accelerate/decelerate moves.

Part of me feels that the printer should be able to accelerate at standard Reprap speeds, but who knows...

Thanks!

I attempted to fix this issue in two ways:

1. Changing the acceleration values in Marlin to a lower value. This worked a little bit: now it shifts less often, but is still unpredictable.

2. Tightening or loosening the belts. I thought that maybe the slack in the belts was causing them to skip, but that is not the case. When I make the belts rather tight, the pulleys skip even more. If I make them really loose, it does better for constant speed movements but not for accelerate/decelerate moves.

Part of me feels that the printer should be able to accelerate at standard Reprap speeds, but who knows...

Thanks!

|

Re: How can I fix belt shifting? January 20, 2017 09:44PM |

Registered: 9 years ago Posts: 238 |

|

Re: How can I fix belt shifting? January 20, 2017 09:53PM |

Registered: 11 years ago Posts: 5,780 |

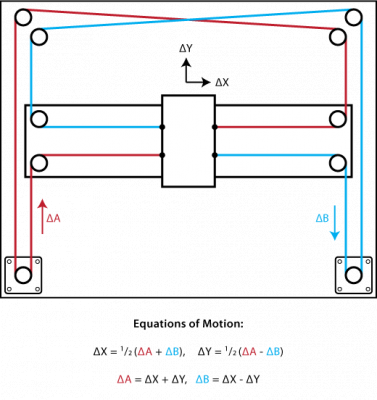

Assuming you've inspected and found no physical problems (binding, loose pulley grub screws, etc.), try printing slower or reduce acceleration and jerk. CoreXY machines can run really fast when printing the perimeters of test cubes because both motors are contributing torque to create movements that are parallel to the X and Y axes. As soon as it switches to infill at 45 or 135 degrees, only one motor has to move the entire mass of the X and Y axes. The available torque is instantly cut in half and it can't run at the same speed.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: How can I fix belt shifting? January 20, 2017 10:47PM |

Registered: 7 years ago Posts: 249 |

Drive pulley may be too small.

Recommended minimum pulley size for GT2 belts is 40 teeth, and a minimum engagement of 9 teeth.

About the only way round this is use wider belts, or create more wrap on the drive pulley by adding an idler so the belt wraps the drive pulley by more than 180 degrees.

Guessing you have a CoreXY, as this is the CoreXY sub forum.

DD is right about the 45/135 move. Only one motor will be active, while the mass will be the Y (Y gantry+X-Carriage) plus the mass of the X-Carriage. 2 degrees of freedom, two contributing masses.

Recommended minimum pulley size for GT2 belts is 40 teeth, and a minimum engagement of 9 teeth.

About the only way round this is use wider belts, or create more wrap on the drive pulley by adding an idler so the belt wraps the drive pulley by more than 180 degrees.

Guessing you have a CoreXY, as this is the CoreXY sub forum.

DD is right about the 45/135 move. Only one motor will be active, while the mass will be the Y (Y gantry+X-Carriage) plus the mass of the X-Carriage. 2 degrees of freedom, two contributing masses.

|

Re: How can I fix belt shifting? January 21, 2017 07:17AM |

Registered: 11 years ago Posts: 5,780 |

To the OP: if the belt is physically slipping it is not tight enough and the cure is obvious. It is far more likely that the motor is slipping due to a combo of excessively high acceleration/jerk/speed and/or too high or too low current. What are the settings you're using? Photos of the machine might help.

Prot0typ1cal: 40 teeth is the recommended (by SDP/SI) minimum equivalent diameter (about 25 mm) for a smooth pulley with belt teeth riding against it, not the drive pulley diameter. 16 and 20 tooth drive pulleys are common and fine with GT2 belt assuming the typical 180 degree wrap in a CoreXY printer. Using larger drive pulleys increases drive speed, reduces resolution, and reduces available force to move the mechanism. The width of the belt doesn't change the pulley diameter recommendation.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Prot0typ1cal: 40 teeth is the recommended (by SDP/SI) minimum equivalent diameter (about 25 mm) for a smooth pulley with belt teeth riding against it, not the drive pulley diameter. 16 and 20 tooth drive pulleys are common and fine with GT2 belt assuming the typical 180 degree wrap in a CoreXY printer. Using larger drive pulleys increases drive speed, reduces resolution, and reduces available force to move the mechanism. The width of the belt doesn't change the pulley diameter recommendation.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: How can I fix belt shifting? January 21, 2017 08:43AM |

Registered: 8 years ago Posts: 120 |

Quote

the_digital_dentist

To the OP: if the belt is physically slipping it is not tight enough and the cure is obvious. It is far more likely that the motor is slipping due to a combo of excessively high acceleration/jerk/speed and/or too high or too low current. What are the settings you're using? Photos of the machine might help.

Prot0typ1cal: 40 teeth is the recommended (by SDP/SI) minimum equivalent diameter (about 25 mm) for a smooth pulley with belt teeth riding against it, not the drive pulley diameter. 16 and 20 tooth drive pulleys are common and fine with GT2 belt assuming the typical 180 degree wrap in a CoreXY printer. Using larger drive pulleys increases drive speed, reduces resolution, and reduces available force to move the mechanism. The width of the belt doesn't change the pulley diameter recommendation.

You spoke of jerk. I changed the acceleration settings but never changed the jerk. Could you explain jerk to me?

|

Re: How can I fix belt shifting? January 21, 2017 10:35AM |

Registered: 11 years ago Posts: 5,780 |

Jerk is the allowable speed for "instantaneous" direction change. When the extruder is coming into a corner, the speed is decelerating. It will decelerate to the "jerk" speed and then try to change direction without coming to a complete stop. It's relying on the springiness of the belt and the motor torque to slam the extruder carriage around the corner. That is when layer shifting occurs if the jerk is set too high.

If you set jerk to zero, the extruder will come to a complete stop at every direction change and that will slow down printing. Curves are made up up short, straight segments and the extruder will crawl around curves. Jerk helps keep things moving along smoothly and quickly. You know it's is set too high when the motors start to skip steps which causes layer shifting.

Setting acceleration too high can cause layer shifting, as can setting speed too high. If the motor current is set too low or too high you can also have layer shifting.

See: [github.com]

Edited 1 time(s). Last edit at 01/21/2017 11:16AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you set jerk to zero, the extruder will come to a complete stop at every direction change and that will slow down printing. Curves are made up up short, straight segments and the extruder will crawl around curves. Jerk helps keep things moving along smoothly and quickly. You know it's is set too high when the motors start to skip steps which causes layer shifting.

Setting acceleration too high can cause layer shifting, as can setting speed too high. If the motor current is set too low or too high you can also have layer shifting.

See: [github.com]

Edited 1 time(s). Last edit at 01/21/2017 11:16AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: How can I fix belt shifting? January 22, 2017 12:12AM |

Registered: 7 years ago Posts: 249 |

|

Re: How can I fix belt shifting? January 22, 2017 01:42PM |

Registered: 8 years ago Posts: 120 |

Quote

the_digital_dentist

Jerk is the allowable speed for "instantaneous" direction change. When the extruder is coming into a corner, the speed is decelerating. It will decelerate to the "jerk" speed and then try to change direction without coming to a complete stop. It's relying on the springiness of the belt and the motor torque to slam the extruder carriage around the corner. That is when layer shifting occurs if the jerk is set too high.

If you set jerk to zero, the extruder will come to a complete stop at every direction change and that will slow down printing. Curves are made up up short, straight segments and the extruder will crawl around curves. Jerk helps keep things moving along smoothly and quickly. You know it's is set too high when the motors start to skip steps which causes layer shifting.

Setting acceleration too high can cause layer shifting, as can setting speed too high. If the motor current is set too low or too high you can also have layer shifting.

See: [github.com]

So I see two options to fix this: get pulleys with more teeth/larger radius or lower the jerk settings to near 0 and work my way faster from there.

Edit: print speeds are slow during debug phase, 30-60 mm/s

Edited 1 time(s). Last edit at 01/22/2017 07:22PM by MatthewHall.

|

Re: How can I fix belt shifting? January 22, 2017 02:02PM |

Registered: 11 years ago Posts: 5,780 |

No, larger diameter pulleys will make the problem worse. torque=force x distance Torque is fixed by the motor current. If you increase the distance from the edge of the belt to the center of the shaft (i..e use a larger pulley), the force gets smaller.

I don't believe you ever said what speed you're trying to print. Forget about going 300 mm/sec. Start at a reasonable 50mm/sec and work up from there. Try starting with jerk set to 5 mm/sec^3 and work up from there. Start with acceleration set to 500 and work up from there.

It takes longer to type these messages than it does to tweak the settings. Start tweaking!

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I don't believe you ever said what speed you're trying to print. Forget about going 300 mm/sec. Start at a reasonable 50mm/sec and work up from there. Try starting with jerk set to 5 mm/sec^3 and work up from there. Start with acceleration set to 500 and work up from there.

It takes longer to type these messages than it does to tweak the settings. Start tweaking!

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: How can I fix belt shifting? January 22, 2017 07:12PM |

Registered: 8 years ago Posts: 120 |

|

Re: How can I fix belt shifting? January 22, 2017 10:16PM |

Registered: 8 years ago Posts: 120 |

|

Re: How can I fix belt shifting? January 22, 2017 11:41PM |

Registered: 7 years ago Posts: 249 |

|

Re: How can I fix belt shifting? January 23, 2017 06:41AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: How can I fix belt shifting? January 24, 2017 08:09AM |

Registered: 8 years ago Posts: 120 |

|

Re: How can I fix belt shifting? January 25, 2017 01:06PM |

Registered: 8 years ago Posts: 120 |

|

Re: How can I fix belt shifting? January 25, 2017 03:40PM |

Registered: 10 years ago Posts: 14,672 |

Edited 2 time(s). Last edit at 01/25/2017 04:12PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: How can I fix belt shifting? January 25, 2017 04:04PM |

Registered: 11 years ago Posts: 5,780 |

In the second and third images, the belt does not appear to be parallel to the X axis. That is going to cause distorted prints.

In the fourth image, the motor looks much too small to be driving any but a tiny coreXY mechanism. That is probably why your motors are slipping.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

In the fourth image, the motor looks much too small to be driving any but a tiny coreXY mechanism. That is probably why your motors are slipping.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: How can I fix belt shifting? January 25, 2017 04:49PM |

Registered: 7 years ago Posts: 249 |

Those smooth idlers look kinda small.

Not that it matters much, but the offset idlers on you're Y carriage will torque the linear guide blocks. If they're cheap Chinese blocks they'll ratchet some.

Regarding your belt path to the X-carriage:

Since the back lengths are at an angle, this will cause the belt to stretch/slacken during X moves. Basic trigonometry, or simpler, Pythagorean theorem. Twisting them makes it even worse.

Only one end of each belt is angled, that length is the hypotenuese. Add that to the other end of the other belt (which is straight) from the Y carriage idler to the X-carriage, the sum needs to be the same at all X positions.

One principle of the CoreXY is the belts stay a constant length in all XY coordinates where the X-carriage is moved, as referenced by this image from CoreXY.com:

Edited 2 time(s). Last edit at 01/25/2017 04:53PM by prot0typ1cal.

Not that it matters much, but the offset idlers on you're Y carriage will torque the linear guide blocks. If they're cheap Chinese blocks they'll ratchet some.

Regarding your belt path to the X-carriage:

Since the back lengths are at an angle, this will cause the belt to stretch/slacken during X moves. Basic trigonometry, or simpler, Pythagorean theorem. Twisting them makes it even worse.

Only one end of each belt is angled, that length is the hypotenuese. Add that to the other end of the other belt (which is straight) from the Y carriage idler to the X-carriage, the sum needs to be the same at all X positions.

One principle of the CoreXY is the belts stay a constant length in all XY coordinates where the X-carriage is moved, as referenced by this image from CoreXY.com:

Edited 2 time(s). Last edit at 01/25/2017 04:53PM by prot0typ1cal.

|

Re: How can I fix belt shifting? January 25, 2017 06:55PM |

Registered: 8 years ago Posts: 120 |

So should I get new motors?Quote

the_digital_dentist

In the second and third images, the belt does not appear to be parallel to the X axis. That is going to cause distorted prints.

In the fourth image, the motor looks much too small to be driving any but a tiny coreXY mechanism. That is probably why your motors are slipping.

|

Re: How can I fix belt shifting? January 25, 2017 07:18PM |

Registered: 11 years ago Posts: 5,780 |

You should probably invest in higher torque motors. How big is the printer? What are the moving masses of the X and Y axes?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: How can I fix belt shifting? January 25, 2017 08:35PM |

Registered: 8 years ago Posts: 120 |

The printer is rather large (bed 10x11 inches theoretically) but the only part I've used is the middle few inches. The mass of the axes is pretty light, just a few 3d printed components, the rails (12mm versions) and a bowden E3D.

Don't know if that helps. Back to debugging in a day or two once I get time away from education...

Edit: so if my motors aren't weak enough then it won't have enough to move in diagonal moves! (that is where it struggles - straights seem OK). Can I fix this without buying new motors?

Edited 1 time(s). Last edit at 01/26/2017 07:37AM by MatthewHall.

Don't know if that helps. Back to debugging in a day or two once I get time away from education...

Edit: so if my motors aren't weak enough then it won't have enough to move in diagonal moves! (that is where it struggles - straights seem OK). Can I fix this without buying new motors?

Edited 1 time(s). Last edit at 01/26/2017 07:37AM by MatthewHall.

|

Re: How can I fix belt shifting? January 27, 2017 04:08PM |

Registered: 10 years ago Posts: 14,672 |

Those motors don't look ideal, but may have enough torque to run your printer if you give them enough current and use only modest values of acceleration and jerk, assuming you don't have too much friction in the axes. When you want to increase acceleration and jerk, you may need longer motors to provide higher torque.

What is the rated current and torque of those motors, and what current are you running them at?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

What is the rated current and torque of those motors, and what current are you running them at?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: How can I fix belt shifting? January 27, 2017 05:32PM |

Registered: 8 years ago Posts: 120 |

|

Re: How can I fix belt shifting? January 28, 2017 04:48AM |

Registered: 10 years ago Posts: 14,672 |

If you bought the 12V 0.4A motor, that's the problem. You need to use stepper motors with a voltage @ rated current well below the supply voltage you are using.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: How can I fix belt shifting? January 29, 2017 11:11AM |

Registered: 8 years ago Posts: 120 |

|

Re: How can I fix belt shifting? January 29, 2017 12:03PM |

Registered: 11 years ago Posts: 5,780 |

Stepper motor torque comes from current, that is why torque ratings are at a specified current. Motors have coils of wire that create magnetic fields. The greater the current, the stronger the field, the higher the torque. Coils of wire have two properties- resistance and inductance. current = voltage/resistance or voltage = current x resistance. That is the voltage spec you see on a motor and has nothing to do with driving the motor except that it provides an indication of the inductance. Stepper drivers operate by setting current to drive the motor. A low voltage motor has less inductance than a high voltage motor and behaves in a more ideal way than a high voltage motor for a given supply voltage. It is normal to operate steppers from supplies that are 10-20x the rated voltage of the motor. A 3V rated motor will maintain torque at higher speeds when operated from a 12V supply than a 12V motor rated for the same current/torque.

TLDR: you want low voltage motors for a 3D printer. 2-4V rated motors are typical. Currents of 1-2.5A are also typical for NEMA-17 size motors. Don't buy 12V or higher voltage motors unless you're going to drive them with high voltage drivers and power supplies.

For a given motor size (say NEMA-17 which specifies the width/height of the motor as 1.7 inches) and current rating, say 1.8A for example, the length of the motor is proportional to the torque.

The normal way to design a motor into any device is to match the motor's torque/speed curve to the required performance. In hobbyist 3D printing that's rarely done- people tend to buy whatever motors they see, and are cheap, and hope they'll work, like you did, or copy what someone else has demonstrated working in their similar printer.

In my relatively high moving mass XY stage, I used this motor: [www.omc-stepperonline.com] and it seems to be capable of driving the mechanism at more than 150mm/sec (though not fully tested yet). There are many similarly spec'd motors available from different vendors. Note that they do not specify motor voltage, but they do specify current and resistance. From those numbers the voltage rating for this motor would be 2.8V. I will be running it from a 24V power supply, about 8X the rated voltage. That's OK, it's normal, it's desireable. The motor driver will deliver the current the motor needs and not let it burn up.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

TLDR: you want low voltage motors for a 3D printer. 2-4V rated motors are typical. Currents of 1-2.5A are also typical for NEMA-17 size motors. Don't buy 12V or higher voltage motors unless you're going to drive them with high voltage drivers and power supplies.

For a given motor size (say NEMA-17 which specifies the width/height of the motor as 1.7 inches) and current rating, say 1.8A for example, the length of the motor is proportional to the torque.

The normal way to design a motor into any device is to match the motor's torque/speed curve to the required performance. In hobbyist 3D printing that's rarely done- people tend to buy whatever motors they see, and are cheap, and hope they'll work, like you did, or copy what someone else has demonstrated working in their similar printer.

In my relatively high moving mass XY stage, I used this motor: [www.omc-stepperonline.com] and it seems to be capable of driving the mechanism at more than 150mm/sec (though not fully tested yet). There are many similarly spec'd motors available from different vendors. Note that they do not specify motor voltage, but they do specify current and resistance. From those numbers the voltage rating for this motor would be 2.8V. I will be running it from a 24V power supply, about 8X the rated voltage. That's OK, it's normal, it's desireable. The motor driver will deliver the current the motor needs and not let it burn up.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: How can I fix belt shifting? January 29, 2017 01:12PM |

Registered: 8 years ago Posts: 120 |

|

Re: How can I fix belt shifting? January 29, 2017 10:02PM |

Registered: 7 years ago Posts: 249 |

I'd fix your belt routing first. Go ahead and rapid through your XY limits. Let us know how that works.

Regarding bigger steppers,

Smaller steppers won't effect overall print speed by lowering the accel/decel rates, as much as having to limit print speeds because the belts are out of plane and twisted. Wacked belt routing is also going to limit your available/reliable print volume.

Let me explain. If you can accelerate slowly to 60-100mm/sec normal print speeds, your total print time will still be less than trying to accelerate fast to only 20-30mm/sec for the entire print.

Yea, it'd be nice to accelerate quickly, and print super fast. However, until you make a new carriage that clamps your belts so they are in plane, and straight out, don't spend money on larger steppers just yet.

Just my 2 cents.

Regarding bigger steppers,

Smaller steppers won't effect overall print speed by lowering the accel/decel rates, as much as having to limit print speeds because the belts are out of plane and twisted. Wacked belt routing is also going to limit your available/reliable print volume.

Let me explain. If you can accelerate slowly to 60-100mm/sec normal print speeds, your total print time will still be less than trying to accelerate fast to only 20-30mm/sec for the entire print.

Yea, it'd be nice to accelerate quickly, and print super fast. However, until you make a new carriage that clamps your belts so they are in plane, and straight out, don't spend money on larger steppers just yet.

Just my 2 cents.

|

Re: How can I fix belt shifting? January 30, 2017 01:13PM |

Registered: 8 years ago Posts: 120 |

Quote

prot0typ1cal

I'd fix your belt routing first. Go ahead and rapid through your XY limits. Let us know how that works.

Regarding bigger steppers,

Smaller steppers won't effect overall print speed by lowering the accel/decel rates, as much as having to limit print speeds because the belts are out of plane and twisted. Wacked belt routing is also going to limit your available/reliable print volume.

Let me explain. If you can accelerate slowly to 60-100mm/sec normal print speeds, your total print time will still be less than trying to accelerate fast to only 20-30mm/sec for the entire print.

Yea, it'd be nice to accelerate quickly, and print super fast. However, until you make a new carriage that clamps your belts so they are in plane, and straight out, don't spend money on larger steppers just yet.

Just my 2 cents.

So I should rout the belts to where they are parallel on their way to the x carriage: you say that may fix the skipping problem? So bigger motors won't keep the thing from skipping...

Sorry, only registered users may post in this forum.