Optimum XYZ axis steps/mm in corexy setup

Posted by renatortb

|

Optimum XYZ axis steps/mm in corexy setup February 28, 2017 06:46PM |

Registered: 7 years ago Posts: 26 |

Hello folks, i need to say that i'm just started in the world of 3D printer. I'm sorry if this is a dumb question, but i couldn't find an answer until now.

Buying a 3D pinter here in Brazil is very expensive and the good models costs a kidney. So i decided to build my own 3D printer based on a corexy system.

But i'm struggling to understant what is the optimum XY and Z axis steps/mm in corexy setup.

I realised that most people uses a 1.8º (200 per revolution) stepper motor, 1/6 microsteps, with a 20 tooth pulley for XY and GT2 2mm belt. Using the Prusa Calculator, it gives me 80.0 steps/mm. Is this the optimum steps/mm for the XY? Why yes or not? We need less steps/mm in XY for speed, correct? What speed a 1.8º (200 per revolution) must handle?

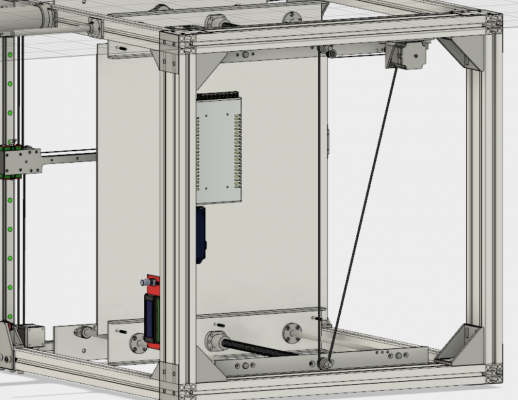

Also, i'm thinking in the Z axiswith pulley/belt system with two ball screws (on which side of the print bed) conected with a belt to the motor, as seen in the image below. For a 1.8º (200 per revolution) motor, 1/6 microsteps, M8 (1.25 mm per rotation) screw and GT2 2mm belt, what's the optimum steps/mm, gear ratio and pulleys thooth of the three pulleys used? Why? I realised (wrong or not) that in the Z axis we need more steps/mm for a better resolution, is that correct?

This is a bottom view

Already thankful for all help.

Edited 4 time(s). Last edit at 03/02/2017 01:55PM by renatortb.

Building a custom coreXY based on BigXY Large Format CoreXY Printer, Vulcanus V2, Vulcanus MAX... ++Brazil++

Buying a 3D pinter here in Brazil is very expensive and the good models costs a kidney. So i decided to build my own 3D printer based on a corexy system.

But i'm struggling to understant what is the optimum XY and Z axis steps/mm in corexy setup.

I realised that most people uses a 1.8º (200 per revolution) stepper motor, 1/6 microsteps, with a 20 tooth pulley for XY and GT2 2mm belt. Using the Prusa Calculator, it gives me 80.0 steps/mm. Is this the optimum steps/mm for the XY? Why yes or not? We need less steps/mm in XY for speed, correct? What speed a 1.8º (200 per revolution) must handle?

Also, i'm thinking in the Z axis

This is a bottom view

Already thankful for all help.

Edited 4 time(s). Last edit at 03/02/2017 01:55PM by renatortb.

Building a custom coreXY based on BigXY Large Format CoreXY Printer, Vulcanus V2, Vulcanus MAX... ++Brazil++

|

Re: Optimum XYZ axis steps/mm in corexy setup February 28, 2017 07:52PM |

Registered: 11 years ago Posts: 5,780 |

There isn't any optimum value, just different steps/mm values. If it can move fast enough for you it's fine.

If you use large pulleys on the XY motors, the machine will theoretically be capable of higher speeds than if you use smaller pulleys, but you'll have reduced torque, so if the moving mass is high, you won't be able to print that fast anyway. In the end, the commonly available 16 or 20 tooth pulleys work fine, with the 16 tooth pulleys providing slightly higher resolution at slightly lower maximum print speed (but probably more than fast enough anyway).

The ultimate print speed will depend on the controller pulse output as well as the pulley teeth, belt pitch, microstepping, and motor steps/rev, available motor torque, acceleration, and the moving mass.

For the Z axis, a high steps/mm value generally means more torque is available to lift a larger load. Speed isn't normally a concern- if the bed can move 10 mm/sec it's probably fast enough.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you use large pulleys on the XY motors, the machine will theoretically be capable of higher speeds than if you use smaller pulleys, but you'll have reduced torque, so if the moving mass is high, you won't be able to print that fast anyway. In the end, the commonly available 16 or 20 tooth pulleys work fine, with the 16 tooth pulleys providing slightly higher resolution at slightly lower maximum print speed (but probably more than fast enough anyway).

The ultimate print speed will depend on the controller pulse output as well as the pulley teeth, belt pitch, microstepping, and motor steps/rev, available motor torque, acceleration, and the moving mass.

For the Z axis, a high steps/mm value generally means more torque is available to lift a larger load. Speed isn't normally a concern- if the bed can move 10 mm/sec it's probably fast enough.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Optimum XYZ axis steps/mm in corexy setup March 01, 2017 07:10AM |

Registered: 7 years ago Posts: 26 |

Quote

the_digital_dentist

There isn't any optimum value, just different steps/mm values. If it can move fast enough for you it's fine.

If you use large pulleys on the XY motors, the machine will theoretically be capable of higher speeds than if you use smaller pulleys, but you'll have reduced torque, so if the moving mass is high, you won't be able to print that fast anyway. In the end, the commonly available 16 or 20 tooth pulleys work fine, with the 16 tooth pulleys providing slightly higher resolution at slightly lower maximum print speed (but probably more than fast enough anyway).

The ultimate print speed will depend on the controller pulse output as well as the pulley teeth, belt pitch, microstepping, and motor steps/rev, available motor torque, acceleration, and the moving mass.

For the Z axis, a high steps/mm value generally means more torque is available to lift a larger load. Speed isn't normally a concern- if the bed can move 10 mm/sec it's probably fast enough.

The 16 tooth pulley give me a 100 steps/mm. That may be better, I agree. I'm looking for better resolution, not speed.

For the Z axis, if I use a 1:1 gear ratio I will get much speed and low resolution, so I'm thinking in use a reduction. In the motor I can use a 20 tooth pulley and in the lead screw a 60 tooth pulley, giving me a 1:3 gear ratio and 1200 steps/mm using a 1.8º (200 per revolution) motor, 1/6 microsteps, M8 (1.25 mm per rotation) screw and GT2 2mm belt. Is that correct? In the prusa calculator in "lead screw pitch" I put 8 mm/revolution for M8 (1.25 mm per rotation), is that correct? Why?

About steps/mm and MHz of the processor, could you explain it to me? I really want to buy a Duetwifi, but importing it to Brazil is very expensive, so I'm thinking in buy a MKS Gen 1.4 for starting. How can I calculate if the processor will handle the load?

Already thankful for your help!!

|

Re: Optimum XYZ axis steps/mm in corexy setup March 01, 2017 09:47AM |

Registered: 8 years ago Posts: 88 |

|

Re: Optimum XYZ axis steps/mm in corexy setup March 01, 2017 11:59AM |

Registered: 11 years ago Posts: 5,780 |

200 steps/rev x 16 usteps/step = 3200 usteps/rev of the motor, 3:1 motor:screw, so 9600 usteps to turn the screw one rev which lifts the bed 1.25 mm. So 9600/1.25 = 7680 usteps per mm in Z. Moving the bed at 10 mm/sec will require 76800 pps- OK with 32 bit controllers, but probably not with 8 bit controllers.

I don't think you need the 3:1 step down with the pulleys. Without it you'd still have 2560 usteps per mm of bed lift. More than enough.

Lead screws have two specs- lead and pitch. Pitch is the distance between the ridges on the screw. Lead is the distance that the bed will move in one rotation of the screw. The lead = pitch x starts.

Starts is the number of paths on the screw- it is usually 1, 2, or 4. Check the number of starts or the lead of the screw when making calculations. The calcs above are valid for 1 start (pitch = lead).

Edited 1 time(s). Last edit at 03/01/2017 12:02PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I don't think you need the 3:1 step down with the pulleys. Without it you'd still have 2560 usteps per mm of bed lift. More than enough.

Lead screws have two specs- lead and pitch. Pitch is the distance between the ridges on the screw. Lead is the distance that the bed will move in one rotation of the screw. The lead = pitch x starts.

Starts is the number of paths on the screw- it is usually 1, 2, or 4. Check the number of starts or the lead of the screw when making calculations. The calcs above are valid for 1 start (pitch = lead).

Edited 1 time(s). Last edit at 03/01/2017 12:02PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Optimum XYZ axis steps/mm in corexy setup March 01, 2017 06:47PM |

Registered: 7 years ago Posts: 26 |

Quote

sigxcpu

On processor is easy: 8 bit - less step pulses per second => less speed. 32 bit more pps => more speed. Get a MKS SBASE, not a MKS GEN.

Revolution = rotation so the M8 has 1.25mm per rotation/revolution.

Thank you for your answer.

This i understand, what i don't understand is how to calculate how much step/mm the processor can do. Could you explain it to me?

The MKS SBASE v1.3 has 5x DRV8825 stepper driver buid-in. I read that this stepper driver is not very good (LINK), is it right? Until now i'm thinking in buying a MKS GEN 1.4 or a Arduino 2560 + RAMPS 1.4 and TMC2100 drivers. The last option alow me to buy in the future a RE-ARM if i feel that i need a 32-bit processor, what do you think?

Quote

the_digital_dentist

200 steps/rev x 16 usteps/step = 3200 usteps/rev of the motor, 3:1 motor:screw, so 9600 usteps to turn the screw one rev which lifts the bed 1.25 mm. So 9600/1.25 = 7680 usteps per mm in Z. Moving the bed at 10 mm/sec will require 76800 pps- OK with 32 bit controllers, but probably not with 8 bit controllers.

I don't think you need the 3:1 step down with the pulleys. Without it you'd still have 2560 usteps per mm of bed lift. More than enough.

Lead screws have two specs- lead and pitch. Pitch is the distance between the ridges on the screw. Lead is the distance that the bed will move in one rotation of the screw. The lead = pitch x starts.

Starts is the number of paths on the screw- it is usually 1, 2, or 4. Check the number of starts or the lead of the screw when making calculations. The calcs above are valid for 1 start (pitch = lead).

Thank you very much. I think i got it now.

So i will choose a 16 tooth pulley on the motor and the lead screw, using the same pulley of the XY system. That's ok, right?

Edited 1 time(s). Last edit at 03/01/2017 06:51PM by renatortb.

|

Re: Optimum XYZ axis steps/mm in corexy setup March 01, 2017 09:10PM |

Registered: 11 years ago Posts: 5,780 |

Expecting a stepper to have any torque left beyond about 6-10 revs per sec is probably wishful thinking.

Arduino/RAMPS running Marlin is limited to 40,000 pps to drive a motor. If you use 2560 usteps/mm your maximum Z axis speed will be just under 16 mm/sec, probably fast enough. But, 40,000 pps / 3200 usteps per rev = 12.5 rev/sec = 750 rpm, probably more than the motor can handle.

A 32 bit controller like the smoothieboard will be able to produce 100,000 pps. 100,000 pps / 3200 ustep/rev > 39 mm/sec, assuming your motor has enough torque to keep lifting the bed at that speed. 3200 usteps/rev @ 100,000 usteps/sec= 31 rev/sec= 1875 rpm which is probably much more than the motor can actually do.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Arduino/RAMPS running Marlin is limited to 40,000 pps to drive a motor. If you use 2560 usteps/mm your maximum Z axis speed will be just under 16 mm/sec, probably fast enough. But, 40,000 pps / 3200 usteps per rev = 12.5 rev/sec = 750 rpm, probably more than the motor can handle.

A 32 bit controller like the smoothieboard will be able to produce 100,000 pps. 100,000 pps / 3200 ustep/rev > 39 mm/sec, assuming your motor has enough torque to keep lifting the bed at that speed. 3200 usteps/rev @ 100,000 usteps/sec= 31 rev/sec= 1875 rpm which is probably much more than the motor can actually do.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Optimum XYZ axis steps/mm in corexy setup March 01, 2017 10:11PM |

Registered: 7 years ago Posts: 26 |

Quote

the_digital_dentist

Expecting a stepper to have any torque left beyond about 6-10 revs per sec is probably wishful thinking.

Arduino/RAMPS running Marlin is limited to 40,000 pps to drive a motor. If you use 2560 usteps/mm your maximum Z axis speed will be just under 16 mm/sec, probably fast enough. But, 40,000 pps / 3200 usteps per rev = 12.5 rev/sec = 750 rpm, probably more than the motor can handle.

A 32 bit controller like the smoothieboard will be able to produce 100,000 pps. 100,000 pps / 3200 ustep/rev > 39 mm/sec, assuming your motor has enough torque to keep lifting the bed at that speed. 3200 usteps/rev @ 100,000 usteps/sec= 31 rev/sec= 1875 rpm which is probably much more than the motor can actually do.

I must confess, i don't understand much of it. Sorry to bother you... If i'm been annoying, you could bring me some literature to read. I haven't found any about this subject.

"Expecting a stepper to have any torque left beyond about 6-10 revs per sec is probably wishful thinking." Could you explain why?

i'm trying to figure it out what's the best step/mm for the configuration of Z axis as seen in the following image.

This is a bottom view

My doubt is what size of pulley (tooths) i must use in this Z axis setup (motor and the two lead screws) with a Arduino + RAMPS setup and why. Also how can i calculate if the arduino processor will handle all processing (pps?) for all motors?

I need to understand it, is personal now... LOL

EDIT: found this: [softsolder.com]

I realised that 40.000 pps is for e each motor and not the total of motors.

Edited 1 time(s). Last edit at 03/01/2017 10:14PM by renatortb.

|

Re: Optimum XYZ axis steps/mm in corexy setup March 02, 2017 02:53AM |

Registered: 8 years ago Posts: 5,232 |

40.000 ppm is for all steppers, but it doesn't make a difference for the CPU if it is one stepper or 8 steppers, because the step pulses are all sent simultaneously by an 8bit register.

If you're in doubt what pulleys to use on the Z-axis: start with 16 tooth ( best torque ) and see, how fast you can move without skipping steps. ( two leadscrews and four linear rails are a challenge to align, so you will need all the torque you can get)

Edited 1 time(s). Last edit at 03/02/2017 02:57AM by o_lampe.

If you're in doubt what pulleys to use on the Z-axis: start with 16 tooth ( best torque ) and see, how fast you can move without skipping steps. ( two leadscrews and four linear rails are a challenge to align, so you will need all the torque you can get)

Edited 1 time(s). Last edit at 03/02/2017 02:57AM by o_lampe.

|

Re: Optimum XYZ axis steps/mm in corexy setup March 02, 2017 08:29AM |

Registered: 7 years ago Posts: 26 |

Quote

o_lampe

40.000 ppm is for all steppers, but it doesn't make a difference for the CPU if it is one stepper or 8 steppers, because the step pulses are all sent simultaneously by an 8bit register.

If you're in doubt what pulleys to use on the Z-axis: start with 16 tooth ( best torque ) and see, how fast you can move without skipping steps. ( two leadscrews and four linear rails are a challenge to align, so you will need all the torque you can get)

Found this: [nutz95.wordpress.com]

Very good to start understand more. I will try to think in terms of Z axis now. I will put my calculations after. Thanks!

PS: I'm still not understand how can I calculate if the processor will handle the step/mm of all motors.

Edited 1 time(s). Last edit at 03/02/2017 01:38PM by renatortb.

|

Re: Optimum XYZ axis steps/mm in corexy setup March 02, 2017 10:27AM |

Registered: 11 years ago Posts: 5,780 |

All you have to worry about is how many pulses per second the processor/firmware can handle. Each pulse represents one microstep. Marlin/Arduino/RAMPS (MAR) maxs out at 40,000 pps. Smoothieware defaults to 100,000 pps (though I think it can be tweaked upward a little).

The linear speed of the extruder carriage (or Y or Z axis) translates to revs per sec of the motor. revs per sec of the motor translates to usteps per sec which equals pps from the controller.

Almost everyone uses 200 step/rev motors with 16:1 ustepping. That requires 3200 usteps (pulses) per rev. With a common 20 tooth pulley and 2 mm pitch belt, 1 motor rev= 40 mm of linear displacement. You want to print at 200 mm/sec, the motor has to spin at 200 mm/sec / 40 mm/rev = 5 rev/sec. Since 1 rev requires 3200 usteps (pulses), the controller will have to be able to deliver 5 rev/sec x 3200 pulses/rev = 16,000 pulses per sec. So, you can see that the controller is almost never going to be the limiting factor in the speed.

The situation changes if you want to use some of the better drivers that can use finer ustepping- some as high as 256 usteps/step. In that case, the 200 step/rev motor will need 200 steps/rev X 256 pulses/step = 51200 pulses per rev. MAR can only produce 40,000 pps, so you'll be able to go 40,000 pps / 51,200 pprev = 0.78125 revs per sec. If one rev moves 40 mm, that means top print speed will be 0.78125 revs/sec x 40 mm = 31.25 mm/sec.

Smoothie can go faster- 100,000 pps / 51,200 pprev = 1.95 revs/sec which translates to 1.95 revs/sec x 40 mm/rev = 78.125 mm/sec.

Higher microstepping gives up a little torque but reduces vibration - i.e. motors run very quietly.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The linear speed of the extruder carriage (or Y or Z axis) translates to revs per sec of the motor. revs per sec of the motor translates to usteps per sec which equals pps from the controller.

Almost everyone uses 200 step/rev motors with 16:1 ustepping. That requires 3200 usteps (pulses) per rev. With a common 20 tooth pulley and 2 mm pitch belt, 1 motor rev= 40 mm of linear displacement. You want to print at 200 mm/sec, the motor has to spin at 200 mm/sec / 40 mm/rev = 5 rev/sec. Since 1 rev requires 3200 usteps (pulses), the controller will have to be able to deliver 5 rev/sec x 3200 pulses/rev = 16,000 pulses per sec. So, you can see that the controller is almost never going to be the limiting factor in the speed.

The situation changes if you want to use some of the better drivers that can use finer ustepping- some as high as 256 usteps/step. In that case, the 200 step/rev motor will need 200 steps/rev X 256 pulses/step = 51200 pulses per rev. MAR can only produce 40,000 pps, so you'll be able to go 40,000 pps / 51,200 pprev = 0.78125 revs per sec. If one rev moves 40 mm, that means top print speed will be 0.78125 revs/sec x 40 mm = 31.25 mm/sec.

Smoothie can go faster- 100,000 pps / 51,200 pprev = 1.95 revs/sec which translates to 1.95 revs/sec x 40 mm/rev = 78.125 mm/sec.

Higher microstepping gives up a little torque but reduces vibration - i.e. motors run very quietly.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Optimum XYZ axis steps/mm in corexy setup March 02, 2017 12:36PM |

Registered: 10 years ago Posts: 14,672 |

Quote

the_digital_dentist

Higher microstepping gives up a little torque but reduces vibration - i.e. motors run very quietly.

It's a myth that higher microstepping loses torque. The torque for a given lag angle is exactly the same whatever microstepping you use, with the exception that when going from full steps to half steps you lose about 30% of torque if you keep the current the same.Think of it this way: suppose you energise the motor and then clamp the shaft in its current position. If you then send either one 1/16 microstep or 16 1/256 microsteps, the current in the coils will be exactly the same.

What confuses people is that there are tables on the web that show how the torque per additional microstep of lag angle drops with increasing microstepping. That's hardly surprising, because the torque produced by a motor is approximately proportional to the sine of the lag angle - that's the difference between the actual position of the motor shaft and the equilibrium position.

Increasing microstepping from 16x to 256x does make them much quieter, to the extent that the motor noise is typically drowned by the fan noise.

Edited 2 time(s). Last edit at 03/02/2017 12:38PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Optimum XYZ axis steps/mm in corexy setup March 02, 2017 02:14PM |

Registered: 7 years ago Posts: 26 |

-------------------------------------

In my first post i worte sometinhg worng. I corrected it now:

Also, i'm thinking in the Z axiswith pulley/belt system with two ball screws (on which side of the print bed) conected with a belt to the motor, as seen in the image below. For a 1.8º (200 per revolution) motor, 1/6 microsteps, M8 (1.25 mm per rotation) screw and GT2 2mm belt, what's the optimum steps/mm, gear ratio and pulleys thooth of the three pulleys used? Why? I realised (wrong or not) that in the Z axis we need more steps/mm for a better resolution, is that correct?

This is a bottom view

So my goal of Z axis setup is: Z axis with two ball screws (on which side of the print bed) conected with a belt to the motor.

I found this post and i will read it later with more attention: [www.duet3d.com]

-------------------------------------

With a common 20 tooth pulley and 2 mm pitch belt, 1 motor rev= 40 mm of linear displacement.

How do you calculate that?

Since 1 rev requires 3200 usteps (pulses), the controller will have to be able to deliver 5 rev/sec x 3200 pulses/rev = 16,000 pulses per sec. So, you can see that the controller is almost never going to be the limiting factor in the speed.

But this is for one motor only, right? I intend to use four motors, so the processor will not handle. 4x16000 = 64000 pps (Marlin = 40000). I misunderstood something? Going crazy right now! LOL!

So in theory, we loses torque (for more microsteps compared to less) if we only consider a move of one microstep to another. But in practice we move more than that so we dont´t lose torque, right? If you then send either one 1/16 microstep or 16 1/256 microsteps, the current in the coils will be exactly the same.

sine of the lag angle

???

God help!

In my first post i worte sometinhg worng. I corrected it now:

Also, i'm thinking in the Z axis

This is a bottom view

So my goal of Z axis setup is: Z axis with two ball screws (on which side of the print bed) conected with a belt to the motor.

I found this post and i will read it later with more attention: [www.duet3d.com]

-------------------------------------

Quote

the_digital_dentist

All you have to worry about is how many pulses per second the processor/firmware can handle. Each pulse represents one microstep. Marlin/Arduino/RAMPS (MAR) maxs out at 40,000 pps. Smoothieware defaults to 100,000 pps (though I think it can be tweaked upward a little).

The linear speed of the extruder carriage (or Y or Z axis) translates to revs per sec of the motor. revs per sec of the motor translates to usteps per sec which equals pps from the controller.

Almost everyone uses 200 step/rev motors with 16:1 ustepping. That requires 3200 usteps (pulses) per rev. With a common 20 tooth pulley and 2 mm pitch belt, 1 motor rev= 40 mm of linear displacement. You want to print at 200 mm/sec, the motor has to spin at 200 mm/sec / 40 mm/rev = 5 rev/sec. Since 1 rev requires 3200 usteps (pulses), the controller will have to be able to deliver 5 rev/sec x 3200 pulses/rev = 16,000 pulses per sec. So, you can see that the controller is almost never going to be the limiting factor in the speed.

The situation changes if you want to use some of the better drivers that can use finer ustepping- some as high as 256 usteps/step. In that case, the 200 step/rev motor will need 200 steps/rev X 256 pulses/step = 51200 pulses per rev. MAR can only produce 40,000 pps, so you'll be able to go 40,000 pps / 51,200 pprev = 0.78125 revs per sec. If one rev moves 40 mm, that means top print speed will be 0.78125 revs/sec x 40 mm = 31.25 mm/sec.

Smoothie can go faster- 100,000 pps / 51,200 pprev = 1.95 revs/sec which translates to 1.95 revs/sec x 40 mm/rev = 78.125 mm/sec.

Higher microstepping gives up a little torque but reduces vibration - i.e. motors run very quietly.

With a common 20 tooth pulley and 2 mm pitch belt, 1 motor rev= 40 mm of linear displacement.

How do you calculate that?

Since 1 rev requires 3200 usteps (pulses), the controller will have to be able to deliver 5 rev/sec x 3200 pulses/rev = 16,000 pulses per sec. So, you can see that the controller is almost never going to be the limiting factor in the speed.

But this is for one motor only, right? I intend to use four motors, so the processor will not handle. 4x16000 = 64000 pps (Marlin = 40000). I misunderstood something? Going crazy right now! LOL!

Quote

dc42

Quote

the_digital_dentist

Higher microstepping gives up a little torque but reduces vibration - i.e. motors run very quietly.

It's a myth that higher microstepping loses torque. The torque for a given lag angle is exactly the same whatever microstepping you use, with the exception that when going from full steps to half steps you lose about 30% of torque if you keep the current the same.Think of it this way: suppose you energise the motor and then clamp the shaft in its current position. If you then send either one 1/16 microstep or 16 1/256 microsteps, the current in the coils will be exactly the same.

What confuses people is that there are tables on the web that show how the torque per additional microstep of lag angle drops with increasing microstepping. That's hardly surprising, because the torque produced by a motor is approximately proportional to the sine of the lag angle - that's the difference between the actual position of the motor shaft and the equilibrium position.

Increasing microstepping from 16x to 256x does make them much quieter, to the extent that the motor noise is typically drowned by the fan noise.

So in theory, we loses torque (for more microsteps compared to less) if we only consider a move of one microstep to another. But in practice we move more than that so we dont´t lose torque, right? If you then send either one 1/16 microstep or 16 1/256 microsteps, the current in the coils will be exactly the same.

sine of the lag angle

???

God help!

|

Re: Optimum XYZ axis steps/mm in corexy setup March 02, 2017 05:03PM |

Registered: 9 years ago Posts: 31 |

Quote

renatortb

But this is for one motor only, right? I intend to use four motors, so the processor will not handle. 4x16000 = 64000 pps (Marlin = 40000). I misunderstood something? Going crazy right now! LOL!

No, look at the following.

Quote

o_lampe

40.000 ppm is for all steppers, but it doesn't make a difference for the CPU if it is one stepper or 8 steppers, because the step pulses are all sent simultaneously by an 8bit register.

-os3dp

|

Re: Optimum XYZ axis steps/mm in corexy setup March 02, 2017 08:23PM |

Registered: 7 years ago Posts: 26 |

Quote

os3dp

Quote

renatortb

But this is for one motor only, right? I intend to use four motors, so the processor will not handle. 4x16000 = 64000 pps (Marlin = 40000). I misunderstood something? Going crazy right now! LOL!

No, look at the following.

Quote

o_lampe

40.000 ppm is for all steppers, but it doesn't make a difference for the CPU if it is one stepper or 8 steppers, because the step pulses are all sent simultaneously by an 8bit register.

-os3dp

So, if i understood correctly, i need to calculate the pps of each motor to know if (each) it will be under 40.000 pps of the board/firmware. Is this correct?

Edit:

With a common 20 tooth pulley and 2 mm pitch belt, 1 motor rev= 40 mm of linear displacement.

How do you calculate that?

I figured this out. My bad.

20 tooth x 2mm pitch belt = 40 mm of linear displacement.

PS: after i understand this correctly, i will make a tutorial of this. I think that it is the basics for building a 3D printer...

Edited 2 time(s). Last edit at 03/02/2017 08:27PM by renatortb.

|

Re: Optimum XYZ axis steps/mm in corexy setup March 03, 2017 01:10AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Optimum XYZ axis steps/mm in corexy setup March 03, 2017 04:21AM |

Registered: 10 years ago Posts: 14,672 |

Quote

o_lampe

40.000 ppm is for all steppers, but it doesn't make a difference for the CPU if it is one stepper or 8 steppers, because the step pulses are all sent simultaneously by an 8bit register.

That's not necessarily true. There are two aspects to generating step pulses: working out which motors need step pulses and doing the associated housekeeping, and generating the pulses. You can generate all the pulses in parallel, but you can't work out which motors need pulses in parallel on an ordinary microcontroller. So on most firmwares, the maximum step pulse generation rate is likely to reduce with the number of motors moving simultaneously. This might not apply to Smoothieware because it has a fixed 100kHz step interrupt frequency, and it might be able to do the calculations for 3 motors in 10us and therefore maintain 100k steps/sec.

I took the trouble to measure the maximum step rate that RepRapFirmware can generate with both 1 motor and 3 motoras moving simultaneously. RepRapFirmware does generate all the step pulses concurrently, but the maximum rate per motor still drops from around 360k steps/second with one motor moving to 180k steps/sec with 3 motors moving. Other firmwares may show a smaller or larger drop, it depends on what algorithm they use to time the step pulses.

Edited 2 time(s). Last edit at 03/03/2017 04:38AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Optimum XYZ axis steps/mm in corexy setup March 03, 2017 08:12AM |

Registered: 7 years ago Posts: 26 |

Quote

dc42

Quote

the_digital_dentist

Higher microstepping gives up a little torque but reduces vibration - i.e. motors run very quietly.

It's a myth that higher microstepping loses torque. The torque for a given lag angle is exactly the same whatever microstepping you use, with the exception that when going from full steps to half steps you lose about 30% of torque if you keep the current the same.Think of it this way: suppose you energise the motor and then clamp the shaft in its current position. If you then send either one 1/16 microstep or 16 1/256 microsteps, the current in the coils will be exactly the same.

What confuses people is that there are tables on the web that show how the torque per additional microstep of lag angle drops with increasing microstepping. That's hardly surprising, because the torque produced by a motor is approximately proportional to the sine of the lag angle - that's the difference between the actual position of the motor shaft and the equilibrium position.

Increasing microstepping from 16x to 256x does make them much quieter, to the extent that the motor noise is typically drowned by the fan noise.

What about that? [www.micromo.com]

|

Re: Optimum XYZ axis steps/mm in corexy setup March 03, 2017 01:24PM |

Registered: 10 years ago Posts: 14,672 |

Quote

renatortb

Quote

dc42

Quote

the_digital_dentist

Higher microstepping gives up a little torque but reduces vibration - i.e. motors run very quietly.

It's a myth that higher microstepping loses torque. The torque for a given lag angle is exactly the same whatever microstepping you use, with the exception that when going from full steps to half steps you lose about 30% of torque if you keep the current the same.Think of it this way: suppose you energise the motor and then clamp the shaft in its current position. If you then send either one 1/16 microstep or 16 1/256 microsteps, the current in the coils will be exactly the same.

What confuses people is that there are tables on the web that show how the torque per additional microstep of lag angle drops with increasing microstepping. That's hardly surprising, because the torque produced by a motor is approximately proportional to the sine of the lag angle - that's the difference between the actual position of the motor shaft and the equilibrium position.

Increasing microstepping from 16x to 256x does make them much quieter, to the extent that the motor noise is typically drowned by the fan noise.

What about that? [www.micromo.com]

The formulae on that web page say the same as I did in my post:

Quote

The actual expression for incremental torque for a single microstep is:

1. TINC = THFS x sin (90/µPFS)

The incremental torque for N microsteps is:

2. TN = THFS x sin ((90 x N)/µPFS))

Edited 1 time(s). Last edit at 03/03/2017 01:24PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Optimum XYZ axis steps/mm in corexy setup March 04, 2017 09:24AM |

Registered: 7 years ago Posts: 26 |

Quote

dc42

Quote

renatortb

Quote

dc42

Quote

the_digital_dentist

Higher microstepping gives up a little torque but reduces vibration - i.e. motors run very quietly.

It's a myth that higher microstepping loses torque. The torque for a given lag angle is exactly the same whatever microstepping you use, with the exception that when going from full steps to half steps you lose about 30% of torque if you keep the current the same.Think of it this way: suppose you energise the motor and then clamp the shaft in its current position. If you then send either one 1/16 microstep or 16 1/256 microsteps, the current in the coils will be exactly the same.

What confuses people is that there are tables on the web that show how the torque per additional microstep of lag angle drops with increasing microstepping. That's hardly surprising, because the torque produced by a motor is approximately proportional to the sine of the lag angle - that's the difference between the actual position of the motor shaft and the equilibrium position.

Increasing microstepping from 16x to 256x does make them much quieter, to the extent that the motor noise is typically drowned by the fan noise.

What about that? [www.micromo.com]

The formulae on that web page say the same as I did in my post:

Quote

The actual expression for incremental torque for a single microstep is:

1. TINC = THFS x sin (90/µPFS)

The incremental torque for N microsteps is:

2. TN = THFS x sin ((90 x N)/µPFS))

I realised that now. Thanks!

Sorry, only registered users may post in this forum.