Z Axis - Sliding Parallel Table

Posted by Mogal

|

Z Axis - Sliding Parallel Table March 07, 2017 05:03PM |

Registered: 11 years ago Posts: 250 |

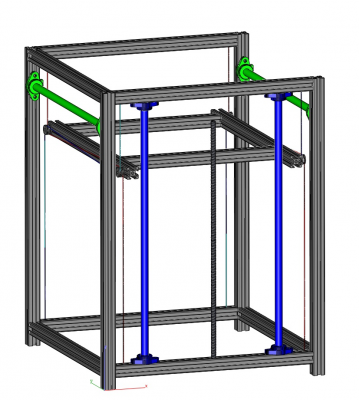

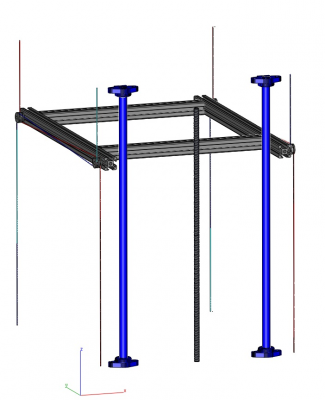

I don't know why did didn't think of this earlier. I've already implemented this on my CNC machine.

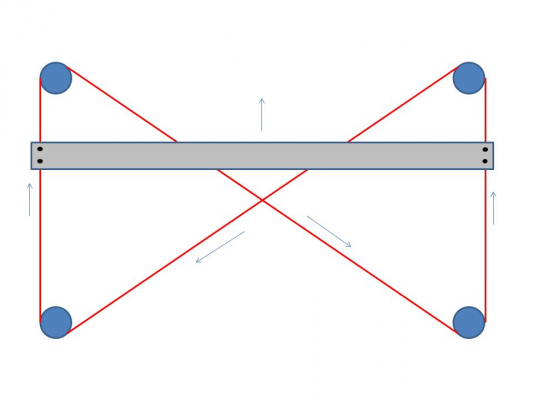

Now its time to put it to use on the 3D Printer! I'm still designing it, but have the basis down.

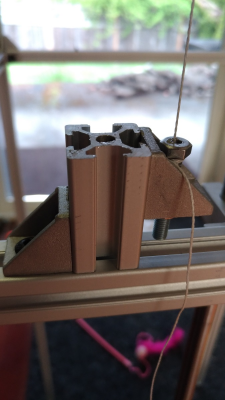

I have V groove bearings and some 80lb spectra line I'm going to use.

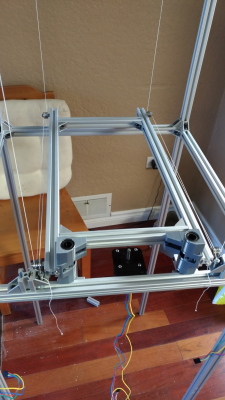

I'm building a new CoreXY, based off the Hypercube 3D printer by Tech2C.

Hypercube 3D - youtube channel

I'm still waiting on parts, and needed a baseline of what size its going to be and how its going to go together.

(Going to shoot for a 300mm3 build volume) This is what I have come up with so far...

(Sorry for the poor CAD works... still learning!)

Let me know what you think...

Some background on the parallel slide / moving knot

CNCZONE

CNCZone - Make your gantry rock solid

Instructables

Building a parallel straightedge drafting table

You Tube Videos

Cable Drive

Proper setup of a Drafting table

Sliding parallel straight edge

Edited 1 time(s). Last edit at 03/07/2017 05:10PM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Now its time to put it to use on the 3D Printer! I'm still designing it, but have the basis down.

I have V groove bearings and some 80lb spectra line I'm going to use.

I'm building a new CoreXY, based off the Hypercube 3D printer by Tech2C.

Hypercube 3D - youtube channel

I'm still waiting on parts, and needed a baseline of what size its going to be and how its going to go together.

(Going to shoot for a 300mm3 build volume) This is what I have come up with so far...

(Sorry for the poor CAD works... still learning!)

Let me know what you think...

Some background on the parallel slide / moving knot

CNCZONE

CNCZone - Make your gantry rock solid

Instructables

Building a parallel straightedge drafting table

You Tube Videos

Cable Drive

Proper setup of a Drafting table

Sliding parallel straight edge

Edited 1 time(s). Last edit at 03/07/2017 05:10PM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Z Axis - Sliding Parallel Table March 07, 2017 06:23PM |

Registered: 11 years ago Posts: 5,780 |

Are you intending to lift the bed using the one screw, and having the cable arrangement keep the whole thing level as it moves? It will be interesting to see if it works. I'd be concerned that the cables will stretch and/or the frame will flex, allowing the whole thing to tilt. The more tension you put on the cables, the greater the load on the motor (I think). All the tension in the cables is going to be applied to the frame- I hope you have something bigger than 20 mm square t-slot.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Z Axis - Sliding Parallel Table March 07, 2017 06:58PM |

Registered: 11 years ago Posts: 250 |

I will be building the standard cantilevered design, and using the cables to add that extra support.

There wont be a whole lot of tension on the cables(spectra line) and with the locations at the corners, I wouldn't think there would be any deflection at all.

I think realistically, there would only be a couple of pounds tension on the strings.

The Tantillus utilizes 65lb spectra line, and it had good success with it.

As you can see, there is a history with the implementation of the parallel slide, and I think it will turn out to be a great counter action to the cantilever.

But that's my thoughts... it's working great on my CNC (425oz-in stepper pushing a 60lb gantry)

If someone wants to run with the idea, please do, as I will still be a few weeks(month) to get all the parts in for the build.

Chris

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

There wont be a whole lot of tension on the cables(spectra line) and with the locations at the corners, I wouldn't think there would be any deflection at all.

I think realistically, there would only be a couple of pounds tension on the strings.

The Tantillus utilizes 65lb spectra line, and it had good success with it.

As you can see, there is a history with the implementation of the parallel slide, and I think it will turn out to be a great counter action to the cantilever.

But that's my thoughts... it's working great on my CNC (425oz-in stepper pushing a 60lb gantry)

If someone wants to run with the idea, please do, as I will still be a few weeks(month) to get all the parts in for the build.

Chris

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Z Axis - Sliding Parallel Table April 21, 2017 03:53AM |

Registered: 7 years ago Posts: 7 |

|

Re: Z Axis - Sliding Parallel Table April 21, 2017 01:29PM |

Registered: 11 years ago Posts: 250 |

Project is in limbo, as half my eBay order hasn't shown up yet...

Got a few disputes open, and other parts ordered.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Got a few disputes open, and other parts ordered.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Z Axis - Sliding Parallel Table April 22, 2017 09:19AM |

Registered: 7 years ago Posts: 7 |

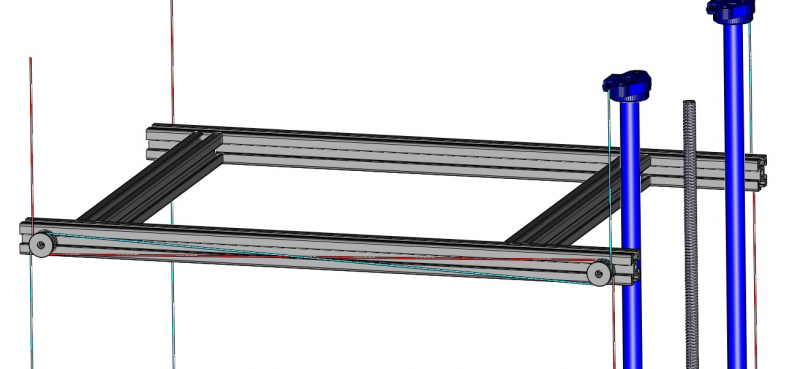

I was thinking: if you decide to use this sliding support, you also must have your frame about the same size as your intended printbed otherwise you can not have the cords vertically aligned. Or am I far off here?

Or would it be feasible to add 2 extra horizontal extrusion parts on the top and bottom of the frame to be able to mount the sliding mechanism?

BTW, It would be more clear if you turn sketch1.jpg 90 degrees. (or did I misinterpret the picture?)

Edited 3 time(s). Last edit at 04/22/2017 09:36AM by robb_nl.

Or would it be feasible to add 2 extra horizontal extrusion parts on the top and bottom of the frame to be able to mount the sliding mechanism?

BTW, It would be more clear if you turn sketch1.jpg 90 degrees. (or did I misinterpret the picture?)

Edited 3 time(s). Last edit at 04/22/2017 09:36AM by robb_nl.

|

Re: Z Axis - Sliding Parallel Table April 22, 2017 11:34AM |

Registered: 11 years ago Posts: 250 |

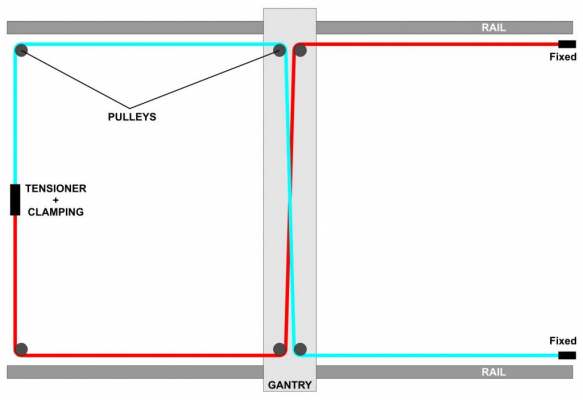

Yes, everything must be parallel, just like the XY belts.

Yes, the table extrusions will need to be all long as the frame to incorporate the bearings for the cables.

Or, as you've pointed out, add upper and lower extrusions for cable anchor points.

The bed size can be whatever size you want within the confines of the frame.

Once I get a chance I will get some better drawings posted.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Yes, the table extrusions will need to be all long as the frame to incorporate the bearings for the cables.

Or, as you've pointed out, add upper and lower extrusions for cable anchor points.

The bed size can be whatever size you want within the confines of the frame.

Once I get a chance I will get some better drawings posted.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Z Axis - Sliding Parallel Table April 22, 2017 12:16PM |

Registered: 7 years ago Posts: 7 |

|

Re: Z Axis - Sliding Parallel Table May 14, 2017 12:46PM |

Registered: 11 years ago Posts: 250 |

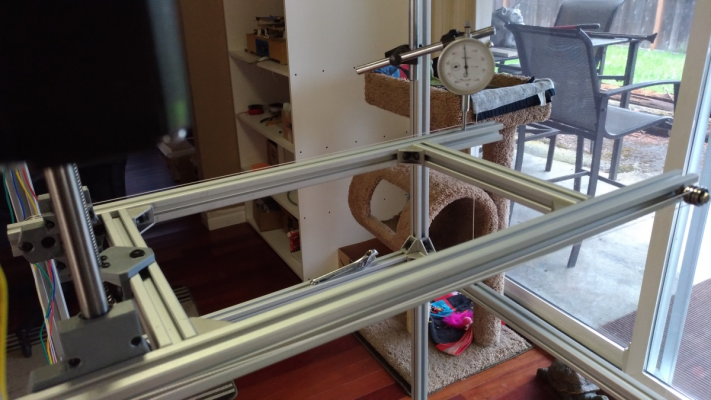

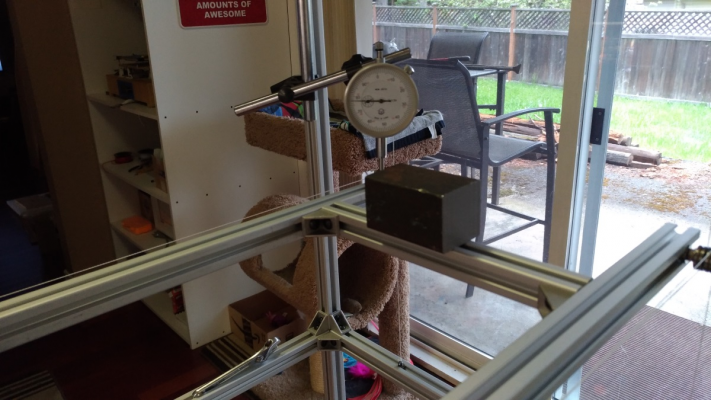

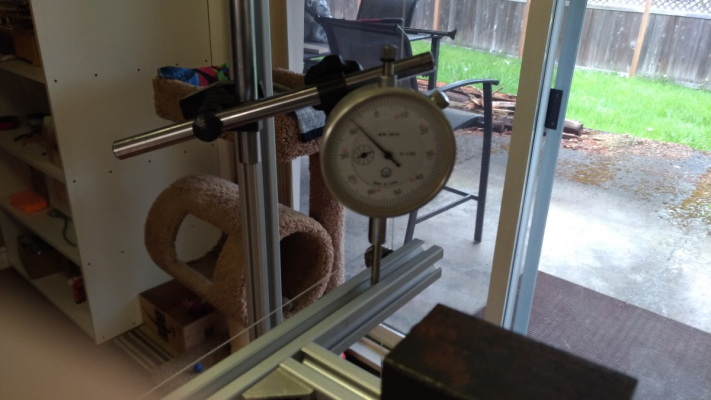

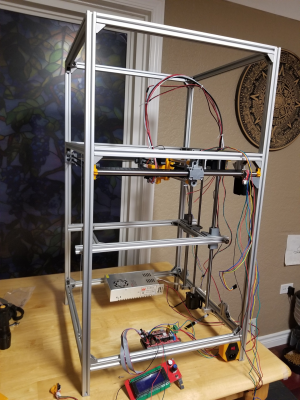

Well, I got some parts and pieces, but still not everything

I was however able to get the Sliding knot hooked up.

Not a complete success, but still pretty good.

The deflection ultimately got reduced from 23 thou to 8. Not too bad considering

I used a 745gram weight. If your print is that big... LOL

There is no noticeable 'Extra tension' in the Z Lift from the Sliding Knot (as the forces balance)

There is also a small amount of leveling you can do with this (lifting the front of the bed)

and a little bit of tilt (left and right)

I'll be playing and tweaking with the tension of the string to try and clear out even more deflection.

Any questions, ask, as I have a little time as I wait for more parts...

P.S. Don't mind the construction zone outside... Old patio is coming out.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

I was however able to get the Sliding knot hooked up.

Not a complete success, but still pretty good.

The deflection ultimately got reduced from 23 thou to 8. Not too bad considering

I used a 745gram weight. If your print is that big... LOL

There is no noticeable 'Extra tension' in the Z Lift from the Sliding Knot (as the forces balance)

There is also a small amount of leveling you can do with this (lifting the front of the bed)

and a little bit of tilt (left and right)

I'll be playing and tweaking with the tension of the string to try and clear out even more deflection.

Any questions, ask, as I have a little time as I wait for more parts...

P.S. Don't mind the construction zone outside... Old patio is coming out.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Z Axis - Sliding Parallel Table May 14, 2017 01:45PM |

Registered: 11 years ago Posts: 250 |

I guess I should also point out that the bed extrusions are 500mm.

If your putting together a smaller 200mm bed, the deflection would be much less.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

If your putting together a smaller 200mm bed, the deflection would be much less.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Z Axis - Sliding Parallel Table May 20, 2017 12:04PM |

Registered: 11 years ago Posts: 250 |

Here's a small video of the sliding table.

Demonstrates how everything is balanced on the Spectra Lines, with no rails used.

3D Printer Slidding Table Video

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Demonstrates how everything is balanced on the Spectra Lines, with no rails used.

3D Printer Slidding Table Video

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Z Axis - Sliding Parallel Table May 20, 2017 12:47PM |

Registered: 11 years ago Posts: 5,780 |

It looks like you have it cantilevered the long direction instead of the short direction. Why would you do that?

Slicers usually put prints at the center of the bed. I suggest testing it that way- you'll probably get more realistic (and smaller) deflection numbers.

Is there going to be any difference in the deflection when the bed is near the top of the machine and when it's near the bottom?

Does humidity and temperature have any effect on the stretchiness of the cord? If the machine is heated to print ABS and the cord lengthens, the bed may tilt a bit even before it is loaded.

Edited 1 time(s). Last edit at 05/20/2017 12:48PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Slicers usually put prints at the center of the bed. I suggest testing it that way- you'll probably get more realistic (and smaller) deflection numbers.

Is there going to be any difference in the deflection when the bed is near the top of the machine and when it's near the bottom?

Does humidity and temperature have any effect on the stretchiness of the cord? If the machine is heated to print ABS and the cord lengthens, the bed may tilt a bit even before it is loaded.

Edited 1 time(s). Last edit at 05/20/2017 12:48PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Z Axis - Sliding Parallel Table May 20, 2017 02:34PM |

Registered: 11 years ago Posts: 250 |

Yes the framework looks cantilevered the long way, but it'll be a square bed...

The 2020 bed frame is 500mm x 240mm.

The frame is currently 500mm x 500mm with an undetermined Z height so far.

I have a 300mm x 300mm mirror for the bed to start with.

I don't have all those answers yet, but I hope to when I'm done. It's a work in progress. Thanks for the questions, as I will look into them as the build progresses.

I would think there wouldn't be any more twisting or bending then any other Z method when dealing with temperature changes.

Edited 2 time(s). Last edit at 05/20/2017 10:00PM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

The 2020 bed frame is 500mm x 240mm.

The frame is currently 500mm x 500mm with an undetermined Z height so far.

I have a 300mm x 300mm mirror for the bed to start with.

I don't have all those answers yet, but I hope to when I'm done. It's a work in progress. Thanks for the questions, as I will look into them as the build progresses.

I would think there wouldn't be any more twisting or bending then any other Z method when dealing with temperature changes.

Edited 2 time(s). Last edit at 05/20/2017 10:00PM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Z Axis - Sliding Parallel Table December 10, 2018 10:00PM |

Registered: 11 years ago Posts: 250 |

UPDATE!! LOL one day I'll finish this thing!

Couple small videos to show:

Part one shows some z travel with the z rails removed. You can see the effects of the lead screw wobble.

Part two is with the Z rails installed and the system buttery smooth.

[youtu.be]

[youtu.be]

Edited 2 time(s). Last edit at 12/10/2018 10:18PM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Couple small videos to show:

Part one shows some z travel with the z rails removed. You can see the effects of the lead screw wobble.

Part two is with the Z rails installed and the system buttery smooth.

[youtu.be]

[youtu.be]

Edited 2 time(s). Last edit at 12/10/2018 10:18PM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Z Axis - Sliding Parallel Table December 12, 2018 12:18PM |

Registered: 6 years ago Posts: 134 |

|

Re: Z Axis - Sliding Parallel Table December 12, 2018 01:29PM |

Registered: 11 years ago Posts: 250 |

LOL nope, never considered that! but interesting concept.

Not too sure that it would be steady enough without the rods.

I would still use the Z rails, but doubling up on the cables would sure make everything super steady.

I have enough parts and pieces to implement it, if I get some time I may try it out.

I'm reconfiguring the build platform so...

(Still need to get the firmware properly configured and having issues) <-- newb stuff.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Not too sure that it would be steady enough without the rods.

I would still use the Z rails, but doubling up on the cables would sure make everything super steady.

I have enough parts and pieces to implement it, if I get some time I may try it out.

I'm reconfiguring the build platform so...

(Still need to get the firmware properly configured and having issues) <-- newb stuff.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Z Axis - Sliding Parallel Table December 12, 2018 02:07PM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Z Axis - Sliding Parallel Table December 12, 2018 03:59PM |

Registered: 5 years ago Posts: 61 |

|

Re: Z Axis - Sliding Parallel Table December 12, 2018 06:05PM |

Registered: 11 years ago Posts: 250 |

Thanks MKSA! good link. Similar but I'm still using the threaded rod for the movement, not the strings.

Yes, Ed3D once I get the printer running properly (Get the firmware going) I'll definitely be getting a dial on it.

I also want to reconfigure the bed frame, but need more 2020 for that.

If you scroll up, I had done a few preliminary tests, it reduced the deflection by about 2/3rds.

(From 0.6mm to 0.2mm at the end of the bed (farthest point from the rails using a 750g weight)

So that's a good start.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Yes, Ed3D once I get the printer running properly (Get the firmware going) I'll definitely be getting a dial on it.

I also want to reconfigure the bed frame, but need more 2020 for that.

If you scroll up, I had done a few preliminary tests, it reduced the deflection by about 2/3rds.

(From 0.6mm to 0.2mm at the end of the bed (farthest point from the rails using a 750g weight)

So that's a good start.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Z Axis - Sliding Parallel Table December 13, 2018 01:18PM |

Registered: 5 years ago Posts: 61 |

That's a pretty big reduction for sure but is that better than you would get with a second screw?

Although the deflection is interesting I'm more interested in the repeatability of the whole system, e.g. will that bed return to the same place when you move it. Try zeroing a dial on the bed then dropping the bed 10mm and raising it back 10 mm - does the dial zero out again? I fear the biggest issue you will face is lag in the system where the front of the bed isn't moved in complete synchronisation as the back.

Although the deflection is interesting I'm more interested in the repeatability of the whole system, e.g. will that bed return to the same place when you move it. Try zeroing a dial on the bed then dropping the bed 10mm and raising it back 10 mm - does the dial zero out again? I fear the biggest issue you will face is lag in the system where the front of the bed isn't moved in complete synchronisation as the back.

|

Re: Z Axis - Sliding Parallel Table December 13, 2018 03:28PM |

Registered: 11 years ago Posts: 250 |

Stronger then a second screw? Nope, but super simple to implement and still makes for a sturdier build plate.

I don't think lag is possible as its mechanically locked. (as the vid with no rails shows)

One side moves up, the other side has no choice but to move down and visa versa.

String tension may adjust with temperature, but even so, it would be minimal.

The aluminum frame would be a bigger concern over temperature changes.

I'll be using auto bed levelling when I get it figured out as well.

Once I get everything up and running, I'll make some repeatability tests and post results.

My cable routing is different, but produces the same results.

Edited 2 time(s). Last edit at 12/13/2018 03:40PM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

I don't think lag is possible as its mechanically locked. (as the vid with no rails shows)

One side moves up, the other side has no choice but to move down and visa versa.

String tension may adjust with temperature, but even so, it would be minimal.

The aluminum frame would be a bigger concern over temperature changes.

I'll be using auto bed levelling when I get it figured out as well.

Once I get everything up and running, I'll make some repeatability tests and post results.

My cable routing is different, but produces the same results.

Edited 2 time(s). Last edit at 12/13/2018 03:40PM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Z Axis - Sliding Parallel Table December 13, 2018 07:19PM |

Registered: 11 years ago Posts: 250 |

Well, I'll be down until I get a new ramps board.

One of them little sticky heatsinks fell of and shorted out one of the drivers, not only that, the moment

it shorted, I got the 'disconnect' sound from windows. I changed out the driver, and the board boots up,

everything moves, but one of the limit switches logic is backwards, so I need to reflash it.

I cant get it talking to the computer anymore... USB port in the computer is still good.

Thoughts on a new RAMPS with a RE-ARM? or stick with the mega 2560?

It claims to run MARLIN 2.0 (or smoothieware)

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

One of them little sticky heatsinks fell of and shorted out one of the drivers, not only that, the moment

it shorted, I got the 'disconnect' sound from windows. I changed out the driver, and the board boots up,

everything moves, but one of the limit switches logic is backwards, so I need to reflash it.

I cant get it talking to the computer anymore... USB port in the computer is still good.

Thoughts on a new RAMPS with a RE-ARM? or stick with the mega 2560?

It claims to run MARLIN 2.0 (or smoothieware)

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Z Axis - Sliding Parallel Table December 13, 2018 07:59PM |

Registered: 11 years ago Posts: 250 |

Being as I still have motor movement, but no comms, I can still do this:

A quick vid of the repeatability

There is 0.0015" (0.0381mm) backlash. Not an issue when printing though...

Edited 2 time(s). Last edit at 12/13/2018 08:01PM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

A quick vid of the repeatability

There is 0.0015" (0.0381mm) backlash. Not an issue when printing though...

Edited 2 time(s). Last edit at 12/13/2018 08:01PM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Z Axis - Sliding Parallel Table December 13, 2018 10:05PM |

Registered: 11 years ago Posts: 5,780 |

That seems like a pretty big error compared to typical layer thickness. How is it not an issue when printing? Maybe if the Z axis only goes in one direction, but most people use Z lift on retract so the bed is constantly moving up and down.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Z Axis - Sliding Parallel Table December 13, 2018 11:01PM |

Registered: 11 years ago Posts: 250 |

Not understanding the exaggeration of the error here?

Remember, this is a corexy. The bed moving down (for the Z lift) then back up would clear that 0.0381mm backlash.

I guess it could be an issue with other machines depending on configs?

Even so, printing at a 0.3mm layer height, the 0.0381mm of backlash is an error of only 0.01% - (I can't get a circle to print inside of that accuracy!)

And really, that would only be see on the very first layer.

- The machine moves up to home, then down to first layer height. After that its all down, no backlash (not using Z Lift)

Am I missing something?

Whats a typical layer height today?

What kind of tolerances should one expect out of a FFF Printer?

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Remember, this is a corexy. The bed moving down (for the Z lift) then back up would clear that 0.0381mm backlash.

I guess it could be an issue with other machines depending on configs?

Even so, printing at a 0.3mm layer height, the 0.0381mm of backlash is an error of only 0.01% - (I can't get a circle to print inside of that accuracy!)

And really, that would only be see on the very first layer.

- The machine moves up to home, then down to first layer height. After that its all down, no backlash (not using Z Lift)

Am I missing something?

Whats a typical layer height today?

What kind of tolerances should one expect out of a FFF Printer?

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Z Axis - Sliding Parallel Table December 14, 2018 01:58AM |

Registered: 6 years ago Posts: 1,007 |

Quote

Mogal

Stronger then a second screw? Nope, but super simple to implement and still makes for a sturdier build plate.

....

No, it is not simpler. It looks simpler but in fact to make it properly and above all adjust it and that it stays that way, is far from simpler.

This system is known, has been used but for a 3D printer bed ? I am pretty sure someone has tried it already (thought about it too, dismissed it right away). If yes, it looks like didn't achieved any fame.

May be we should look in this forum and Thingiverse, among the dead, stillborn, never finished projects.

Everything is easy in CAD, great animations too, even a quick prototype. Too bad reality is such a bitch.

Edited 5 time(s). Last edit at 12/14/2018 07:01AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Z Axis - Sliding Parallel Table December 14, 2018 07:13AM |

Registered: 11 years ago Posts: 5,780 |

Your math is off a little. With a 300 um layer thickness, that 38 um of backlash represents about 12.7% of the layer height. With more typical 200 um layers (when using a 400 um nozzle), the error goes to 19%. With 100 um layers, a common "high quality" print mode, the error is 38%. It's difficult to imagine exactly what the print would look like based on the numbers. I suspect the outer surface of the print will look rough, but that's just a guess, and it may be entirely acceptable, at least at some layer heights.

When the error is positive- the bed is further from the nozzle than it should be, printed line widths will get thinner. If the error is negative the line widths will get wider, so it will look like over and/or under extrusion in some areas. However, there may already be so much error from other causes that this error is masked or "buried in the noise".

A good test would be to print a few different and uniquely shaped parts at the same time, scattered around the bed, with Z lift on retract turned off, and then print the same batch of parts with Z lift on retract turned on.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

When the error is positive- the bed is further from the nozzle than it should be, printed line widths will get thinner. If the error is negative the line widths will get wider, so it will look like over and/or under extrusion in some areas. However, there may already be so much error from other causes that this error is masked or "buried in the noise".

A good test would be to print a few different and uniquely shaped parts at the same time, scattered around the bed, with Z lift on retract turned off, and then print the same batch of parts with Z lift on retract turned on.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Z Axis - Sliding Parallel Table December 14, 2018 07:20AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Z Axis - Sliding Parallel Table December 14, 2018 10:06AM |

Registered: 11 years ago Posts: 250 |

ah... shoulda expected responses like this...

Not trying to revolutionize the 3d printer world. Just thought I'd try and get a sturdier cantilevered print bed. And from what I've seen, I'm achieving that.

To me, the backlash will be cleared / negligible during each movement.

My little wooden MDF Mendel90 has produced great accurate prints for years now, with almost no maintenance/adjustments.

And I'm sure its backlash is WAY worse then this machine.

So (again) In the real world, what accuracy and repeatability can one expect from a home built FFF 3D printer?

Edited 1 time(s). Last edit at 12/14/2018 10:06AM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Not trying to revolutionize the 3d printer world. Just thought I'd try and get a sturdier cantilevered print bed. And from what I've seen, I'm achieving that.

To me, the backlash will be cleared / negligible during each movement.

My little wooden MDF Mendel90 has produced great accurate prints for years now, with almost no maintenance/adjustments.

And I'm sure its backlash is WAY worse then this machine.

So (again) In the real world, what accuracy and repeatability can one expect from a home built FFF 3D printer?

Edited 1 time(s). Last edit at 12/14/2018 10:06AM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Z Axis - Sliding Parallel Table December 14, 2018 10:19AM |

Registered: 11 years ago Posts: 5,780 |

It isn't something easily modeled, so I think it's worth trying. I'll be interested to see prints from it. It may well be better than just cantilevering, and it's certainly less costly than adding another screw to support the bed. Reducing the backlash, if needed, might be a simple matter of using heavier cord that will stretch less (if that is what causes the backlash).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.