Help with Cantilever bed for corexy please

Posted by n9jcv

|

Help with Cantilever bed for corexy please March 17, 2017 03:09PM |

Registered: 10 years ago Posts: 211 |

I have a similar post in General, but did not get much traction there, I should have put it here I guess sorry

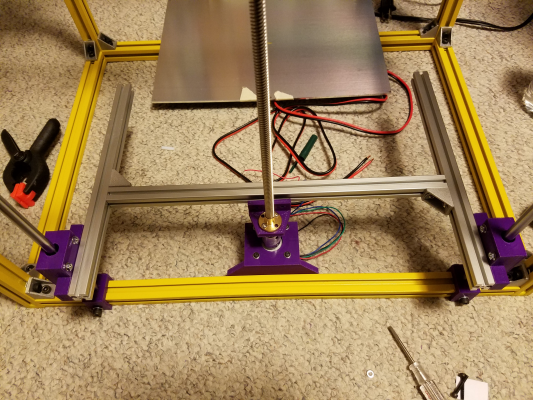

Anyway, the issue I have with a corexy I am building is this; I have a cantilever bed, 2 smooth rods and LMLUU bearings and 1 t8 lead screw, in the rear, the t8 lead screw is centered. I have the frame for the heatbed, but no heatbed attached yet. The frame will not move in the x or y direction, it is very tight that way. However, the bed can tilt sided to side, moving in the z axis. Meaning just a very slight pressure down on the left side produces the same amount of movement up on the left side. The frame seems to be balanced very well with the t8 in the center, So then when the motor moves the bed up or down, you sometimes see the bed tilt instead of both sides moving in the same direction the same amount. The bouncing seems to make it worse.

I am building a corexy similar to a fusebox and a hypercube mixed. Probably 100+ of those have been built. I can't believe I am the only person to experience this issue. I tried moving the lead screw to the front, the problem actually became worse, the bouncing was then at the rear. I am looking to see how others have solved or potentially how I can solve.

I was thinking of using a z belt instead of T8 but not sure that will fix it. I even thought perhaps just use a m5 threaded rod for Z, the tolerance may be tighter because the threads are close together and perhaps the issue would be minimized.

My frame is 2020 and it seems really strong and solid, and now I can't believe that my bouncing bed is my weak point. ARRGGGH any help would be greatly appreciated

Thank You

Anyway, the issue I have with a corexy I am building is this; I have a cantilever bed, 2 smooth rods and LMLUU bearings and 1 t8 lead screw, in the rear, the t8 lead screw is centered. I have the frame for the heatbed, but no heatbed attached yet. The frame will not move in the x or y direction, it is very tight that way. However, the bed can tilt sided to side, moving in the z axis. Meaning just a very slight pressure down on the left side produces the same amount of movement up on the left side. The frame seems to be balanced very well with the t8 in the center, So then when the motor moves the bed up or down, you sometimes see the bed tilt instead of both sides moving in the same direction the same amount. The bouncing seems to make it worse.

I am building a corexy similar to a fusebox and a hypercube mixed. Probably 100+ of those have been built. I can't believe I am the only person to experience this issue. I tried moving the lead screw to the front, the problem actually became worse, the bouncing was then at the rear. I am looking to see how others have solved or potentially how I can solve.

I was thinking of using a z belt instead of T8 but not sure that will fix it. I even thought perhaps just use a m5 threaded rod for Z, the tolerance may be tighter because the threads are close together and perhaps the issue would be minimized.

My frame is 2020 and it seems really strong and solid, and now I can't believe that my bouncing bed is my weak point. ARRGGGH any help would be greatly appreciated

Thank You

|

Re: Help with Cantilever bed for corexy please March 17, 2017 03:13PM |

Registered: 10 years ago Posts: 211 |

|

Re: Help with Cantilever bed for corexy please March 17, 2017 09:20PM |

Registered: 10 years ago Posts: 211 |

So that was not the problem, I think at this point the only solution I have is to go to 2 z steppers, one positioned by each smooth rod.

Thanks

Edited 1 time(s). Last edit at 03/18/2017 12:01AM by n9jcv.

|

Re: Help with Cantilever bed for corexy please March 18, 2017 12:16AM |

Registered: 11 years ago Posts: 5,780 |

The nut is there to provide lift, not to constrain lateral motion- that's what the bearings and guide rails are for. The tilt is caused by play in the bearings and maybe some flexibility in the bed support structure. The bearings are too short. If you go to two screws, drive them both with one motor or plan on releveling the bed very frequently. With two or more motors, autolevel will work until the bed becomes so tilted that it binds, then you'll be looking for the right way to do it again. Save yourself the trouble and do it right the first time.

Making a cantilevered bed work well is difficult. It requires a very rigid structure- both the printer's frame and the Z axis motion parts.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Making a cantilevered bed work well is difficult. It requires a very rigid structure- both the printer's frame and the Z axis motion parts.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Help with Cantilever bed for corexy please March 18, 2017 12:57AM |

Registered: 10 years ago Posts: 211 |

so have others just ignored this problem and printed with this tilting/slop? I observer the t8 nut very closely and that is the cantilever point and the nut itself rocks side to side, if that were rock solid, then there would not be this issue, but I realize play is necessary for smooth movement.

what is my best option for a stable bed, using 1 or 2 z steppers and 2 smooth rods, is there a good option? Or do I need more smooth rods. I just don't feel good about taking this to printing knowing this tilting issue is there, it is bound to cause problems.

Thanks again

what is my best option for a stable bed, using 1 or 2 z steppers and 2 smooth rods, is there a good option? Or do I need more smooth rods. I just don't feel good about taking this to printing knowing this tilting issue is there, it is bound to cause problems.

Thanks again

|

Re: Help with Cantilever bed for corexy please March 18, 2017 01:27AM |

Registered: 11 years ago Posts: 5,780 |

It can't tilt unless the bearings are allowing it. Plastic bearing mounts don't help. You need longer bearings and they need to be coupled to each other very solidly. Of course it pivots on the nut. The nut is in the middle.

Once you solve that problem, you can start trying to fix the bouncing edge.

Two motors driving one axis is an option, but it's never a good option. Multiple screws (2 or 3) driven by a single motor is probably the best way to go. Two guide rails will fully constrain the lateral motion and three screws will constrain the vertical motion.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Once you solve that problem, you can start trying to fix the bouncing edge.

Two motors driving one axis is an option, but it's never a good option. Multiple screws (2 or 3) driven by a single motor is probably the best way to go. Two guide rails will fully constrain the lateral motion and three screws will constrain the vertical motion.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Help with Cantilever bed for corexy please March 18, 2017 03:58AM |

Registered: 8 years ago Posts: 5,232 |

My gut feeling tells me that placing the T8 screw in the middle is the worst place. The bed can tip over any time. Did you try to put it slightly off side or add some weight on one side of the bed?

Not too much, you want to keep the screw and nut from binding.

I'm dealing with a similar problem, although I'm using two ball screws and linear rails. I tried to place the screws at different places, but had no luck so far.

Think, I'll order a third screw and some pulleys/ close belt.

Not too much, you want to keep the screw and nut from binding.

I'm dealing with a similar problem, although I'm using two ball screws and linear rails. I tried to place the screws at different places, but had no luck so far.

Think, I'll order a third screw and some pulleys/ close belt.

|

Re: Help with Cantilever bed for corexy please March 18, 2017 10:23AM |

Registered: 11 years ago Posts: 5,780 |

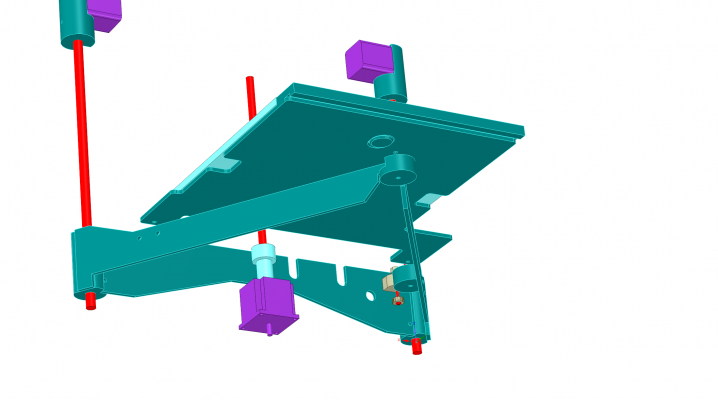

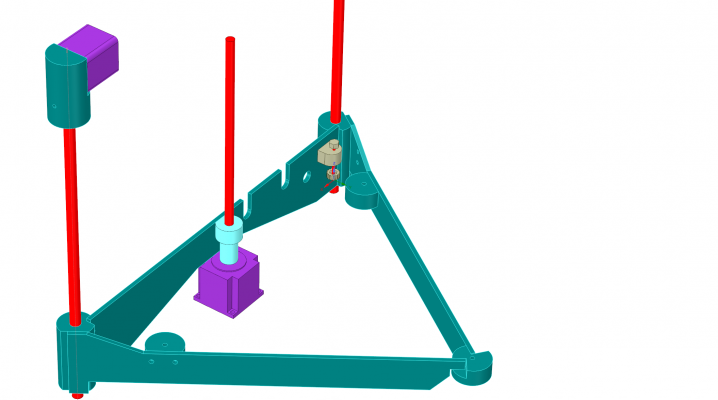

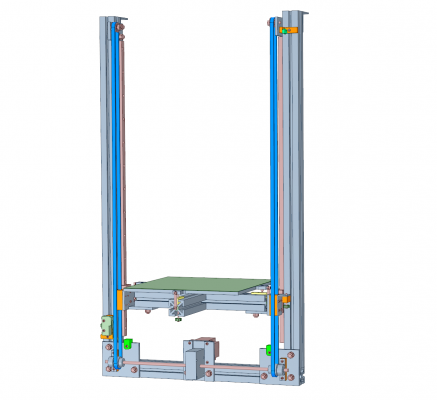

I have a CubeX Duo printer with a cantilevered bed. Here's how they made it relatively stable:

You can see details a little better in the model I made:

The arms coming forward are 5 mm thick aluminum. The original back plate was 8 mm thick acrylic which I replaced with 5mm thick aluminum. The bearings are 80 mm long and inside aluminum mounts. The vertical rails are 12mm in diameter and 460 mm apart. It looks like they designed it to have more weight on one side than the other in case it tilts. Or it may be that way for mechanical clearance or other reasons.

This bed maintains level and zero quite well, but the free end tends to bounce if you try to print fast. I'd say this printer is good for high quality prints up to about 40 mm/sec, but I typically run it at 30.

Edited 2 time(s). Last edit at 03/18/2017 10:38AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You can see details a little better in the model I made:

The arms coming forward are 5 mm thick aluminum. The original back plate was 8 mm thick acrylic which I replaced with 5mm thick aluminum. The bearings are 80 mm long and inside aluminum mounts. The vertical rails are 12mm in diameter and 460 mm apart. It looks like they designed it to have more weight on one side than the other in case it tilts. Or it may be that way for mechanical clearance or other reasons.

This bed maintains level and zero quite well, but the free end tends to bounce if you try to print fast. I'd say this printer is good for high quality prints up to about 40 mm/sec, but I typically run it at 30.

Edited 2 time(s). Last edit at 03/18/2017 10:38AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Help with Cantilever bed for corexy please March 18, 2017 11:36PM |

Registered: 10 years ago Posts: 211 |

So I have been looking and thinking and stumbled on this

[forums.reprap.org]

Seems like a good solution, easy and does not require a lot of extra parts or over engineering. What are your thoughts on that? Seems like I would not have to worry about bouncing. And comments at thingiverse suggest there is not any issue with slop or wobble, like the tilting bed issue I experienced.

[forums.reprap.org]

Seems like a good solution, easy and does not require a lot of extra parts or over engineering. What are your thoughts on that? Seems like I would not have to worry about bouncing. And comments at thingiverse suggest there is not any issue with slop or wobble, like the tilting bed issue I experienced.

|

Re: Help with Cantilever bed for corexy please March 19, 2017 01:31AM |

Registered: 11 years ago Posts: 5,780 |

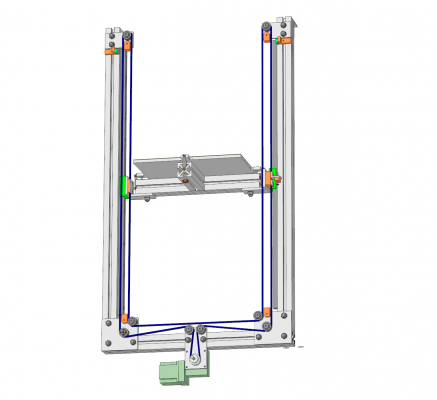

Counterweights can help reduce the torque required to move the bed and help relieve the power-off bed drop problem. I tried a long serpentine belt (the diagram posted in the thread is incorrect- the right side belt clamp is in the wrong place) and decided that I didn't like the asymmetry. The bed effectively hangs from the parts of the belt that are under tension. The end point is the motor. If you follow the belt from each clamp back to the motor, you'll see one side is a much longer path than the other. The longer path will tend to stretch more under load than the shorter path, causing the bed to tilt slightly. This mostly happens when the print gets heavy, so may not be very realistic, but it's worth considering.

This is the second versionof the Z axis in my printer, with the serpentine belt. The first design used a NEMA-23 motor directly driving the belt and moving the bed. After rebooting the controller and having the 4 kg bed and support drop 700 mm to the bottom of the Z axis, I decided to do something about it. I considered counterweights, but they can only compensate for an empty bed, and they are hard to implement in a way that looks like anything but a Rube Goldberg contraption. Put a kg or so of print on it and bed drop will still be a problem. I chose to use a 30:1 worm gear reducer- it is compact and easy to mount. There is no bed drop at all.

Follow the belt from each clamp back to the motor and you'll see the different lengths I mentioned. I ultimately settled on the design below- the worm gear reducer now drives two equal length belts, so stretch is less, and even on both belted sides of the bed.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

This is the second versionof the Z axis in my printer, with the serpentine belt. The first design used a NEMA-23 motor directly driving the belt and moving the bed. After rebooting the controller and having the 4 kg bed and support drop 700 mm to the bottom of the Z axis, I decided to do something about it. I considered counterweights, but they can only compensate for an empty bed, and they are hard to implement in a way that looks like anything but a Rube Goldberg contraption. Put a kg or so of print on it and bed drop will still be a problem. I chose to use a 30:1 worm gear reducer- it is compact and easy to mount. There is no bed drop at all.

Follow the belt from each clamp back to the motor and you'll see the different lengths I mentioned. I ultimately settled on the design below- the worm gear reducer now drives two equal length belts, so stretch is less, and even on both belted sides of the bed.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Help with Cantilever bed for corexy please March 19, 2017 02:19AM |

Registered: 10 years ago Posts: 211 |

|

SOLVED Help with Cantilever bed for corexy please April 06, 2017 01:48AM |

Registered: 10 years ago Posts: 211 |

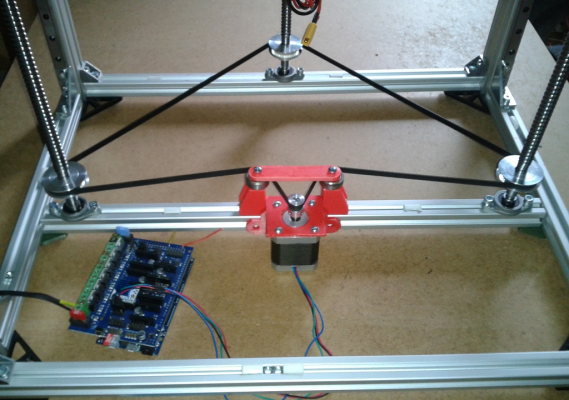

Thanks for all the help and suggestions. I went with a Z axis powered by a single motor, with 2 belts kept in sync by a 8mm rod and pulleys, and a short loop pulley to the motor. Very similar to DD's design, although less metal.

My bed is very stable and accurate and there is NO noticable bounce at all on the bed!!

Some pics of my solution.

also on thingiverse I posted all my parts for the Z axis mod of the Hypercube in case they help anyone else.

Thingiverse Z Axis Mods

My bed is very stable and accurate and there is NO noticable bounce at all on the bed!!

Some pics of my solution.

also on thingiverse I posted all my parts for the Z axis mod of the Hypercube in case they help anyone else.

Thingiverse Z Axis Mods

|

Re: Help with Cantilever bed for corexy please April 06, 2017 07:59AM |

Registered: 11 years ago Posts: 5,780 |

Just as in the other axes, it is very important that the belt segments between the end pulleys and the attachment to the bed support are parallel to the Z axis guide rails.

Are you doing anything to lessen the impact of the bed dropping when power to the Z motor is cut?

Edited 1 time(s). Last edit at 04/06/2017 08:02AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Are you doing anything to lessen the impact of the bed dropping when power to the Z motor is cut?

Edited 1 time(s). Last edit at 04/06/2017 08:02AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Help with Cantilever bed for corexy please April 06, 2017 05:33PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Help with Cantilever bed for corexy please April 06, 2017 07:28PM |

Registered: 11 years ago Posts: 5,780 |

I don't think syncing the teeth on the pulleys matters. I didn't make any effort to match them in my printer. I did make an effort to make their grub screws accessible when the bed is at the bottom of the Z axis.

In n9jcv's design, the belts will be pulling hard on the centers of the members at the top and bottom of the machine's frame. I would think that vertical supports in the frame parallel and adjacent to the belts would prevent frame flex due to the belt tension and help stiffen up the frame overall.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

In n9jcv's design, the belts will be pulling hard on the centers of the members at the top and bottom of the machine's frame. I would think that vertical supports in the frame parallel and adjacent to the belts would prevent frame flex due to the belt tension and help stiffen up the frame overall.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Help with Cantilever bed for corexy please April 06, 2017 11:34PM |

Registered: 10 years ago Posts: 211 |

In my case I don't think the belt tension is enough to flex the 2020 extrusion, but if so, I have not noticed.

As far as the bed falling, I only print when I am near the machine, that said, I could still have a power outage. I have not figured this out yet. Sometimes when I turn off the power, the motors are still engaged and the bed drifts very slowly to the bottom, as if the z motor is acting like a generator. Other times, there is no resistance. I would like it to always have resistance, but I have not figured out the secret sauce as to why it is like that sometimes. When it has resistance, all motors have resistance. Even now I checked, the machine is off. All motors have resistance.

As far as the bed falling, I only print when I am near the machine, that said, I could still have a power outage. I have not figured this out yet. Sometimes when I turn off the power, the motors are still engaged and the bed drifts very slowly to the bottom, as if the z motor is acting like a generator. Other times, there is no resistance. I would like it to always have resistance, but I have not figured out the secret sauce as to why it is like that sometimes. When it has resistance, all motors have resistance. Even now I checked, the machine is off. All motors have resistance.

|

Re: Help with Cantilever bed for corexy please April 07, 2017 04:07AM |

Registered: 8 years ago Posts: 5,232 |

I had the same resistance-effect with different drivers.

I blamed it on the reverse protection diodes in the drivers MOSFets acting as a shortcut in the coil. But they require some minimum reverse voltage to switch open, so it depends on the moment, you switch off the printer. ( just wild guessing, but with an educated background )

One could add a DPDT relais between the driver and stepper that would short the coils while power is off. The relais would switch on, when the driver enable pin is low.

Edited 1 time(s). Last edit at 04/07/2017 04:15AM by o_lampe.

I blamed it on the reverse protection diodes in the drivers MOSFets acting as a shortcut in the coil. But they require some minimum reverse voltage to switch open, so it depends on the moment, you switch off the printer. ( just wild guessing, but with an educated background )

One could add a DPDT relais between the driver and stepper that would short the coils while power is off. The relais would switch on, when the driver enable pin is low.

Edited 1 time(s). Last edit at 04/07/2017 04:15AM by o_lampe.

|

Re: Help with Cantilever bed for corexy please April 07, 2017 04:10AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Help with Cantilever bed for corexy please April 07, 2017 08:22AM |

Registered: 11 years ago Posts: 5,780 |

Shorting the motors doesn't provide much braking force- I tried that first for my Z axis. The motor has to be spinning to generate the EMF that brakes the motion. If the motor is spinning, it isn't braking much. It will slow things down a little, for a second or so, but the speed will keep increasing and the motor will start torque-slipping and the bed will resume dropping like a rock.

You can use counterweights but they will only slow, not stop, bed drop. You're counting on the weight of the bed assembly to keep the drive belts tight all the way back to the motor. If you use so much counterweight that you stop the bed drop completely, you may create backlash in the Z axis. You don't really have to stop it completely as long as the drop speed isn't too high, if you put some sort of bumper at the bottom of the Z axis so it doesn't slam directly into the frame. You're going to set up the counterweight for an empty bed, but the weight of the print will start speeding up the drop again, which shouldn't matter much until you make big, heavy prints.

I tried directly driving the Z axis without any gearing and it worked OK, but I didn't test it under load. Have you loaded the bed with any weight to see how much the motor can handle?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You can use counterweights but they will only slow, not stop, bed drop. You're counting on the weight of the bed assembly to keep the drive belts tight all the way back to the motor. If you use so much counterweight that you stop the bed drop completely, you may create backlash in the Z axis. You don't really have to stop it completely as long as the drop speed isn't too high, if you put some sort of bumper at the bottom of the Z axis so it doesn't slam directly into the frame. You're going to set up the counterweight for an empty bed, but the weight of the print will start speeding up the drop again, which shouldn't matter much until you make big, heavy prints.

I tried directly driving the Z axis without any gearing and it worked OK, but I didn't test it under load. Have you loaded the bed with any weight to see how much the motor can handle?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Help with Cantilever bed for corexy please April 07, 2017 09:58AM |

Registered: 8 years ago Posts: 5,232 |

Don't want to hijack the thread, but want to show my aproach to the same problem:

Made a 608-belt tensioner today and tested accuracy at 40mm/s.

Even with switching the stepper off in between moves, I was able to repeadedly send 0.1mm moves without loosing steps.

Made a 608-belt tensioner today and tested accuracy at 40mm/s.

Even with switching the stepper off in between moves, I was able to repeadedly send 0.1mm moves without loosing steps.

|

Re: Help with Cantilever bed for corexy please April 07, 2017 10:47AM |

Registered: 11 years ago Posts: 5,780 |

I like everything except the plastic motor and pulley mount. I might have positioned the two pulleys closer together to get a little more belt wrap around the drive pulley, but that's a quibble. With the load presented the wrap you have is probably sufficient. How do you adjust the belt tension?

Does the bed drop when Z motor power is cut?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Does the bed drop when Z motor power is cut?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Help with Cantilever bed for corexy please April 07, 2017 08:52PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Help with Cantilever bed for corexy please April 08, 2017 01:14AM |

Registered: 11 years ago Posts: 5,780 |

100 ustep/mm of bed movement is OK. Less OK is the lack of torque multiplication, but if the motor produces sufficient torque to lift the bed plus print, even that is OK. It would be interesting to see how much it can lift. I didn't load test my original Z axis when it was being directly driven, but the motor had sufficient torque to lift the bed and support structure - 3-4 kg of aluminum. Using a bigger pulley on the shaft that drives the lifting belts would multiply the torque and increase the resolution for just a couple $.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Help with Cantilever bed for corexy please April 08, 2017 02:48AM |

Registered: 8 years ago Posts: 5,232 |

Quote

the_digital_dentist

I like everything except the plastic motor and pulley mount. I might have positioned the two pulleys closer together to get a little more belt wrap around the drive pulley, but that's a quibble. With the load presented the wrap you have is probably sufficient. How do you adjust the belt tension?

Does the bed drop when Z motor power is cut?

To adjust the belt tension I have to move the extrusion and readjust the ballscrew-nuts on the bed frame.

With two ball screws and two steppers, the bed dropped a bit. But only because every move built up some tension in the bed frame.

Now with three ballscrews and one stepper, the bed moves without wobble and stays put when I switch off.

I'll redesign the tensioner to lower the toothed pulley on the motor shaft. I could bring the idlers closer together, but then it's harder to print.

|

Re: Help with Cantilever bed for corexy please April 08, 2017 08:55AM |

Registered: 11 years ago Posts: 5,780 |

Why not just add a positionable idler pulley that pushes against the belt? Then you can adjust tension without messing around with anything else.

Or redesign the motor mount so it can slide or rotate a little to tension the belt.

I suspect that the belt tension is distorting the printer frame and creating some side load on the ball screws and that's why it isn't dropping when the power is cut. It is also why you may have Z axis artifacts in prints. Have you printed with it yet?

Edited 2 time(s). Last edit at 04/08/2017 09:02AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Or redesign the motor mount so it can slide or rotate a little to tension the belt.

I suspect that the belt tension is distorting the printer frame and creating some side load on the ball screws and that's why it isn't dropping when the power is cut. It is also why you may have Z axis artifacts in prints. Have you printed with it yet?

Edited 2 time(s). Last edit at 04/08/2017 09:02AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Help with Cantilever bed for corexy please August 30, 2017 10:52AM |

Registered: 11 years ago Posts: 40 |

I know this is a bit old but for anyone looking for an idea for a fix to a cantilevered platform I designed this a while ago,

finally printing the parts to it now

[www.thingiverse.com]

finally printing the parts to it now

[www.thingiverse.com]

|

Re: Help with Cantilever bed for corexy please August 31, 2017 02:02AM |

Registered: 8 years ago Posts: 5,232 |

Quote

Blitz2190

I know this is a bit old but for anyone looking for an idea for a fix to a cantilevered platform I designed this a while ago,

finally printing the parts to it now

[www.thingiverse.com]

Don't want to jump in your parade, but IMHO the fixed length cross-beams should be replaced with adjustable ones. Just use flat aluminum stripes with long holes.

|

Re: Help with Cantilever bed for corexy please September 01, 2017 10:29AM |

Registered: 11 years ago Posts: 40 |

while they are fixed length they can be scaled up or down as needed using the same printed parts. They are only shown at that size with measurements because those are the lengths needed to work with prusa i2 hardware, which at the time was the printer I had when designed so I could reuse most of my parts. I was more so posting it to show the counter weight idea to take the strain of the bearings for the bed.

Edited 1 time(s). Last edit at 09/01/2017 10:29AM by Blitz2190.

Edited 1 time(s). Last edit at 09/01/2017 10:29AM by Blitz2190.

|

Re: Help with Cantilever bed for corexy please September 07, 2017 06:44PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Help with Cantilever bed for corexy please September 08, 2017 09:35AM |

Registered: 7 years ago Posts: 162 |

Maybe something like this could help:

[www.thingiverse.com]

Keeps most of your current system in tact but introduces the required safety / brake to avoid the bed dropping.

Keep posting, I will need to so something similar, soon...

Cheers,

Hugo

[www.thingiverse.com]

Keeps most of your current system in tact but introduces the required safety / brake to avoid the bed dropping.

Keep posting, I will need to so something similar, soon...

Cheers,

Hugo

Sorry, only registered users may post in this forum.